Patents

Literature

59results about How to "Achieve deep dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge-dewatering compound conditioning agent and application method thereof

ActiveCN102381828AAchieve deep dehydrationShorten spin timeSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPOLYMER SUBSTANCEFenton reagent

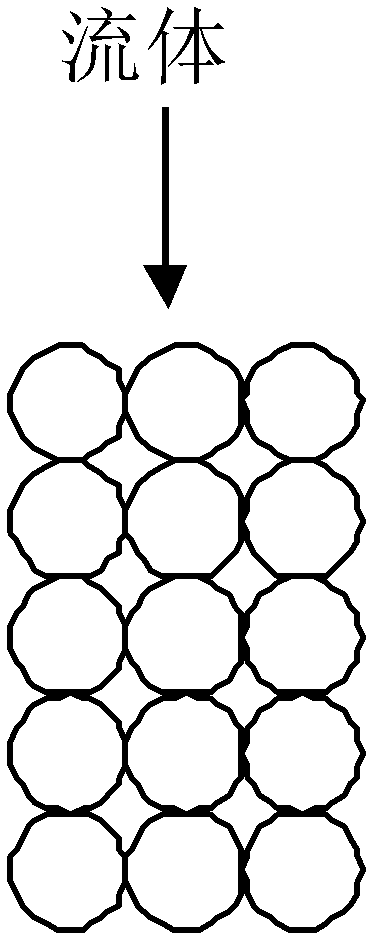

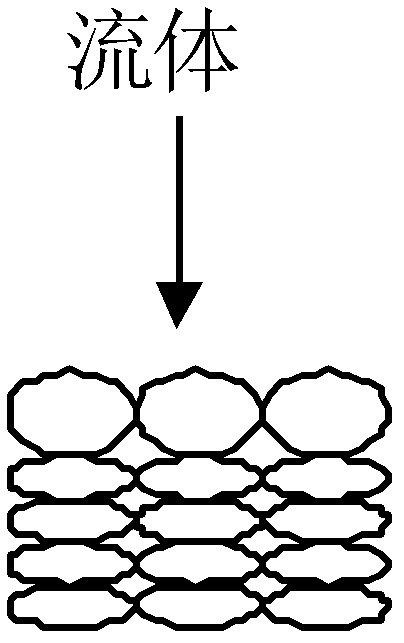

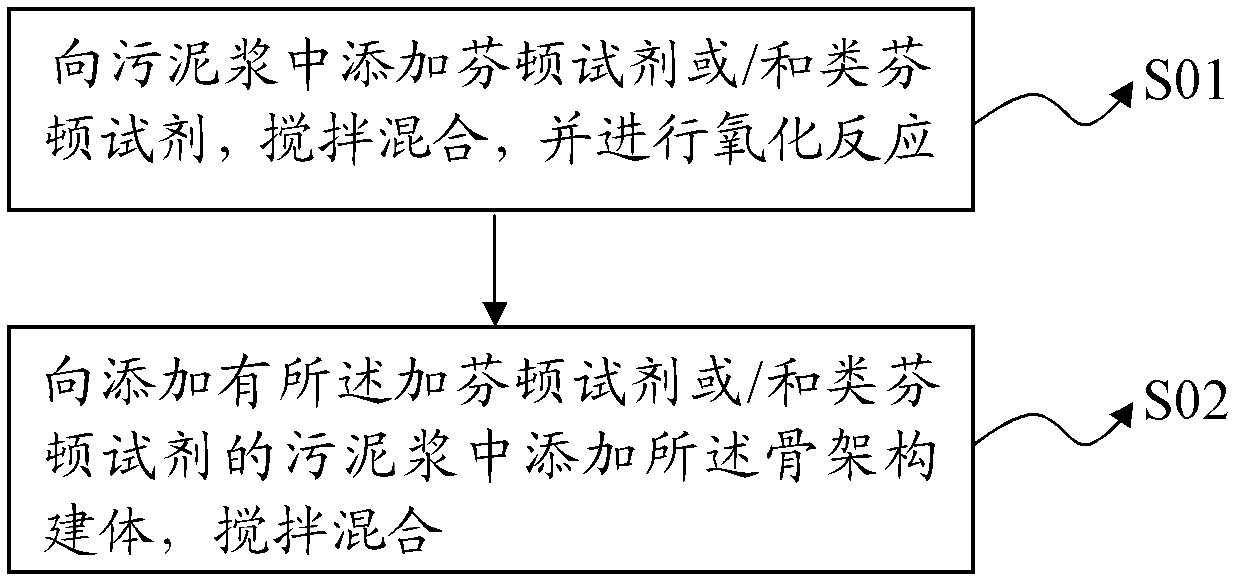

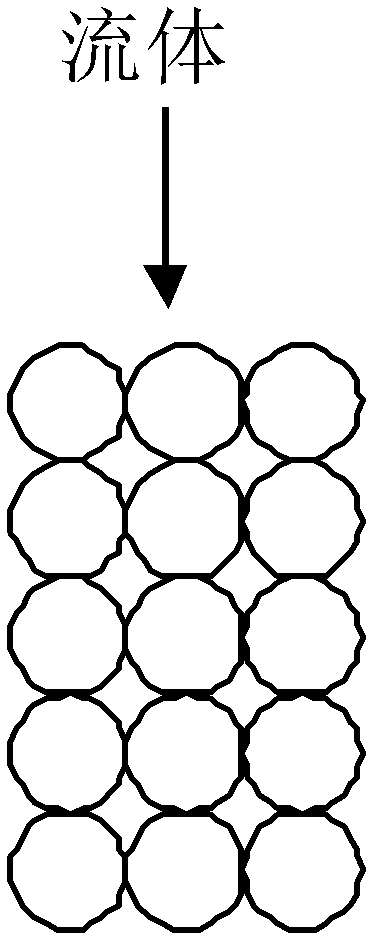

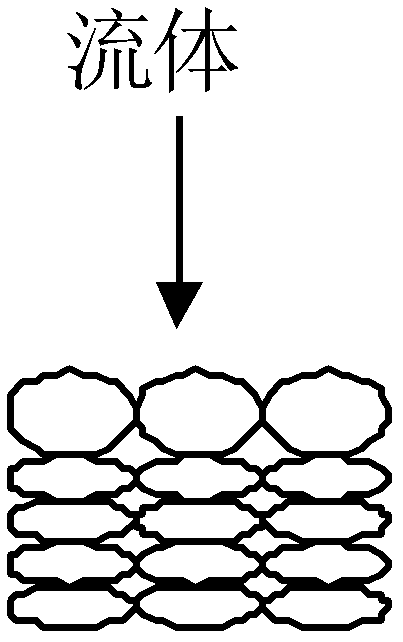

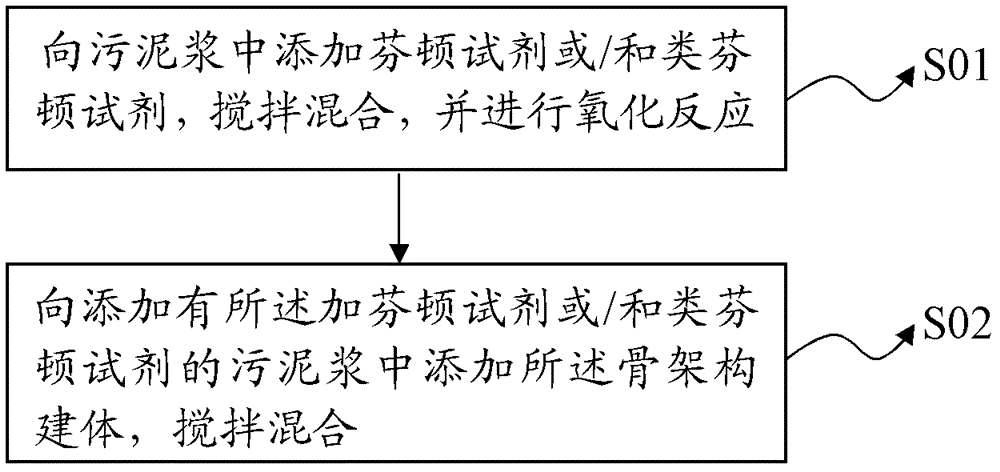

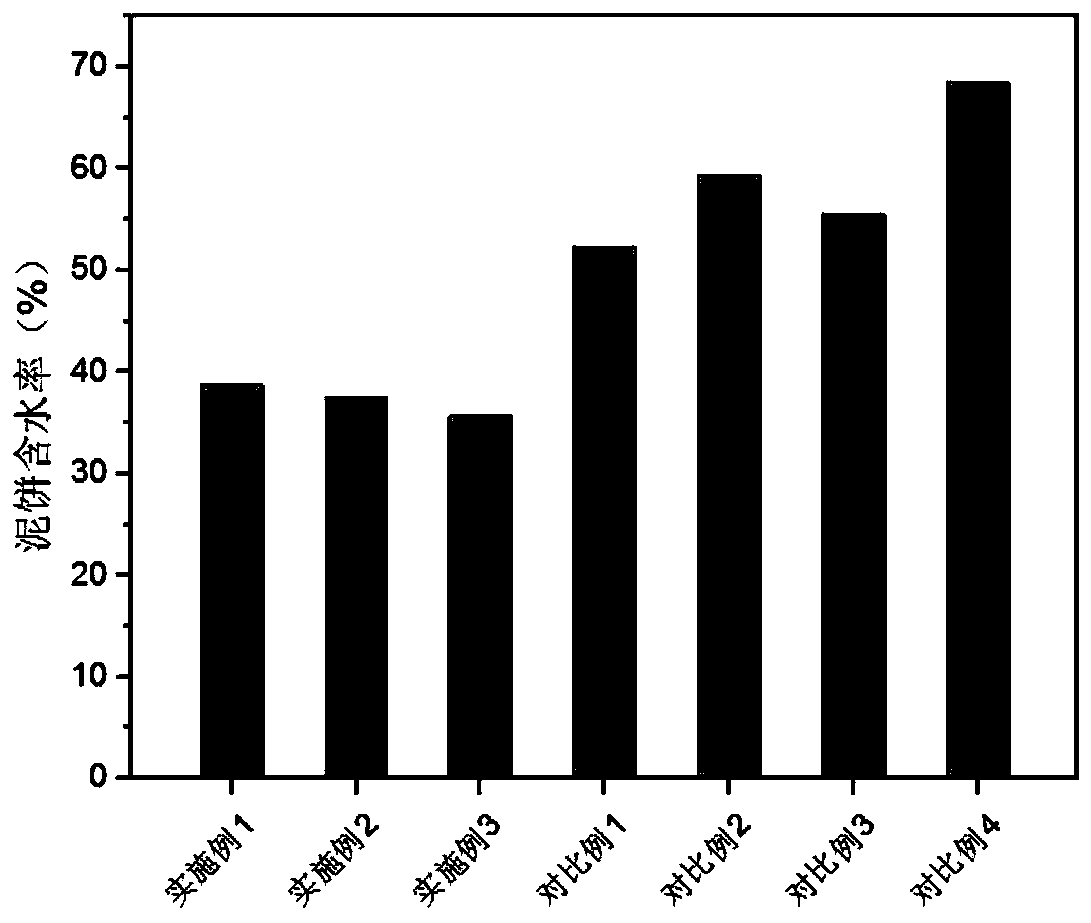

The invention provides a sludge-dewatering compound conditioning agent and an application method thereof. The sludge-dewatering compound conditioning agent comprises a Fenton reagent or / and similar Fenton reagent and a skeleton construct, and the weight ratio of the Fenton reagent or / and similar Fenton reagent and the skeleton construct is 1: (0.05-300); and the skeleton construct adopts a powder body. The application method comprises the following steps: adding the Fenton reagent or / and similar Fenton reagent into sludge slurry, and mixing for oxidation; and adding the skeleton construct into the sludge slurry with the Fenton reagent or / and similar Fenton reagent, and mixing. Due to synergy of the Fenton reagent or / and similar Fenton reagent and the powder type skeleton construct, extracellular polymeric substances in sludge can be destructed effectively, the compressibility of organic substances can be reduced, and the sludge dewatering performance of the sludge-dewatering compound conditioning agent can be improved greatly. The procedures of the application method are simple, the conditions can be controlled easily, the sludge dewatering time can be shortened, and the large-scale treatment of the sludge can be realized.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

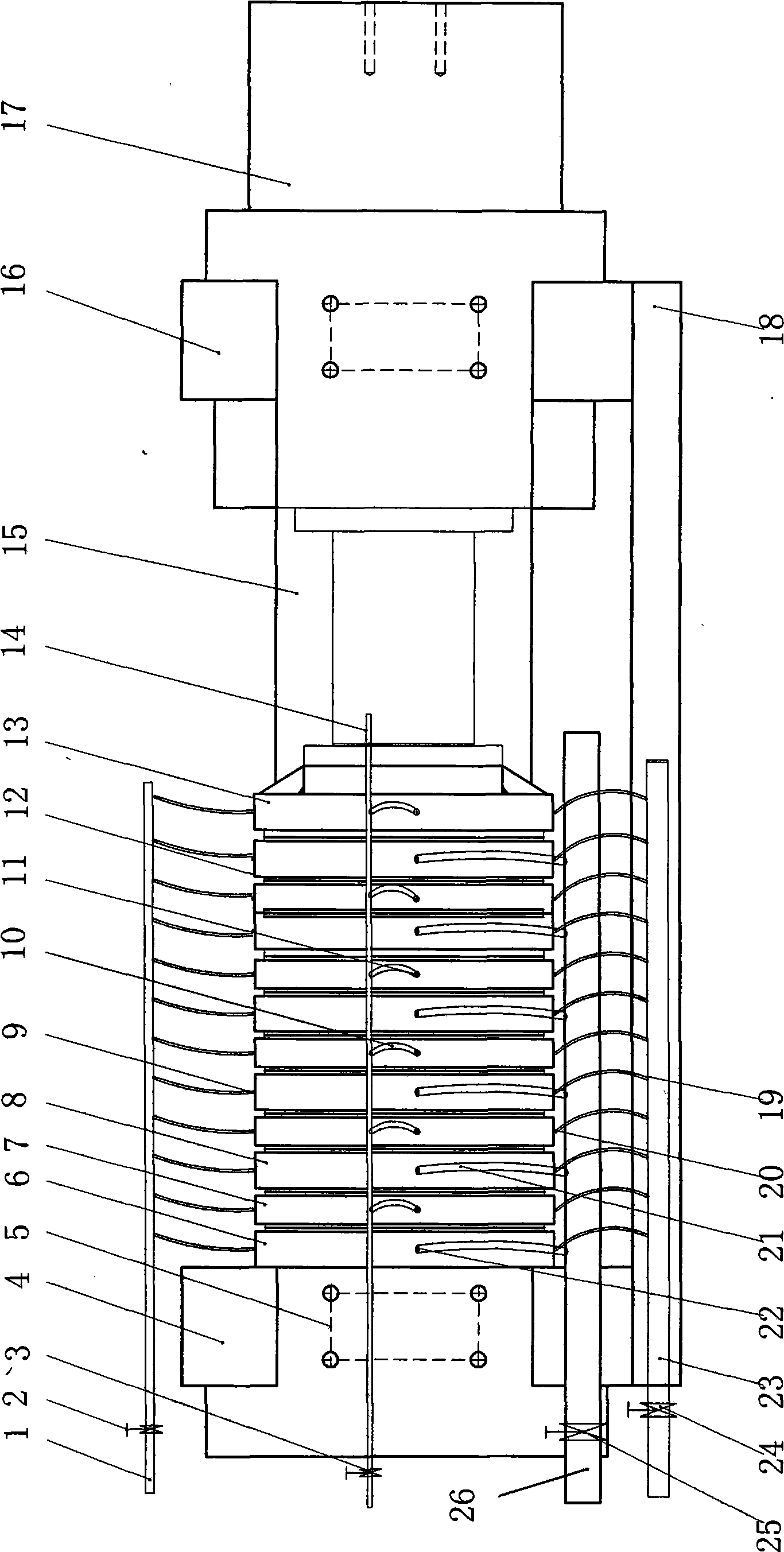

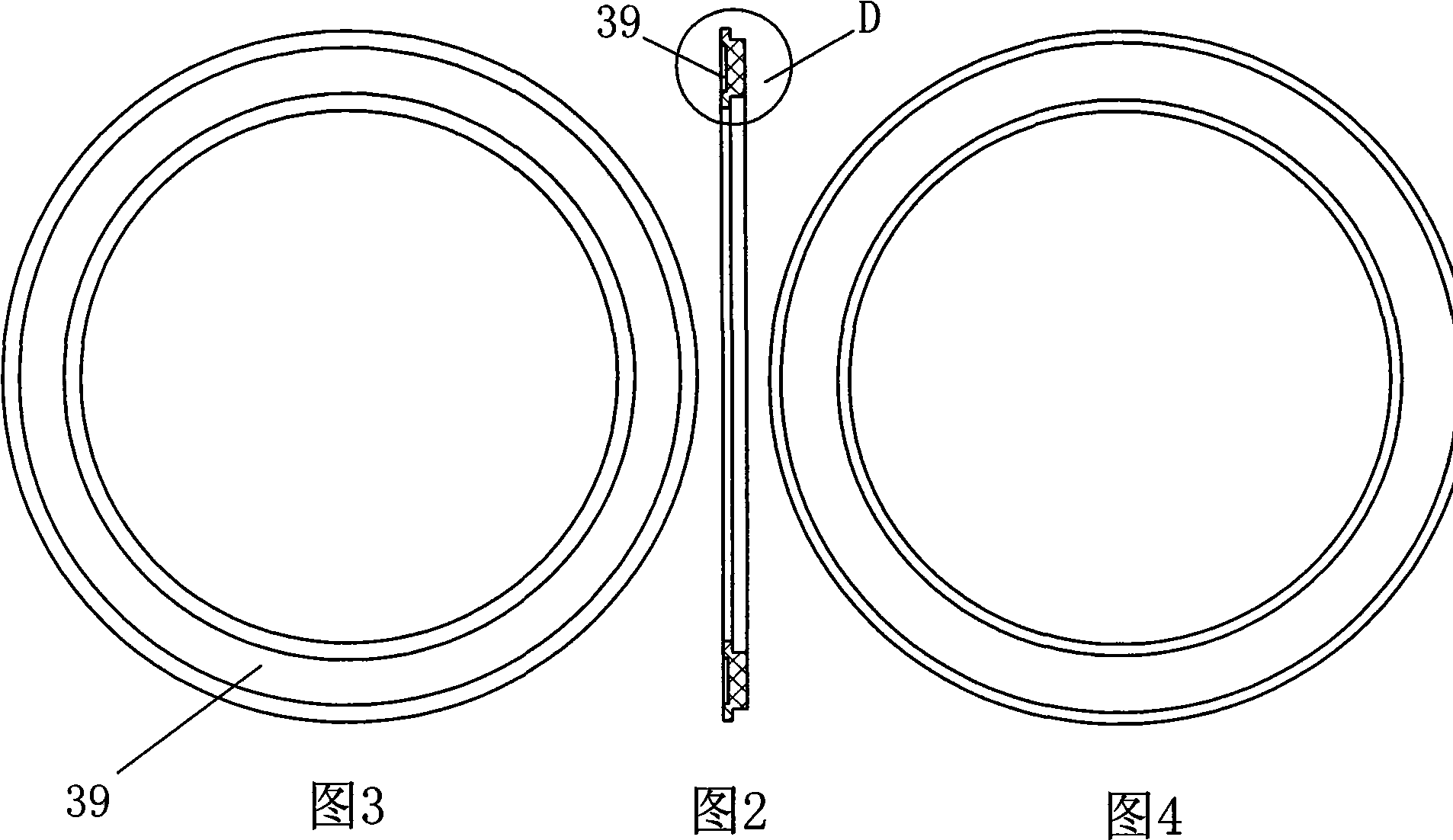

Plate-type sludge dewatering machine and dewatering method therefor

InactiveCN101544459AReasonable structureImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningElastomerHigh pressure

The invention discloses a plate-type sludge dewatering machine and a dewatering method therefore. The plate-type sludge dewatering machine adopts elastomers positioned among pressing filter plates, adjacent anti-thrust filter plates, air-inlet filter plates, feeding filter plates and thrust filter plates to form at least three hermetic pressing filter chambers variable in volume, utilizes the compression deformation and resilience of the elastomers to deep squeeze and dewater a filter cake, and adopts sealing plugs which are arranged in front of air-inlet holes of the air-inlet filter plates and the thrust filter plates and are on positions opposite to feeding holes on the feeding filter plates and the anti-thrust filter plates, wherein the feeding filter plates are adjacent and involutory to the air-inlet filter plates. After low-pressure filter dewatering is over and feeding is stopped, the sealing plugs block and seal the feeding holes so as to prevent sludge from flowing back and entering pipelines during pressing filtration. The dewatering method adopts the variable hermetic pressing filter chambers formed by the elastomers to perform pressing filtration and dewatering, and adds the operation of adopting the sealing plugs to block the feeding holes before high-pressure squeezing-dewatering operation. The invention has the advantages of high dewatering efficiency, strong adaptability, low energy consumption, low use cost and the like.

Owner:ZHEJIANG HUAZHANG TECH

Conditioner for sludge dehydration and conditioning method

ActiveCN102001814ALow costEasy accessSludge treatment by de-watering/drying/thickeningCoal gangueIron salts

The invention discloses a conditioner for sludge dehydration. Based on the dry weight of the sludge to be treated, the formula of the conditioner contains 10 to 20 percent of iron salt, 10 to 20 percent of burnt lime, 10 to 20 percent of coal gangue and 0.01 to 0.05 percent of potassium permanganate bactericide. The invention also discloses a conditioning method for the conditioner for the sludge dehydration, which comprises the following steps of: adding the potassium permanganate bactericide into the sludge to be treated at normal temperature under normal pressure, treating the sludge for at least 2 minutes with stirring, and then adding the iron salt to react for at least 2 minutes; and then adding the burnt lime to adjust the pH value to be neutral, reacting the mixture for at least 2 minutes, adding the coal gangue to react for at least 2 minutes, and finally performing pressure filtration. The invention has the advantages of low cost, wide raw material source, no toxicity, environmental friendliness, short treatment time, high sludge dehydration degree and the like.

Owner:湖南多普生环境能源有限公司

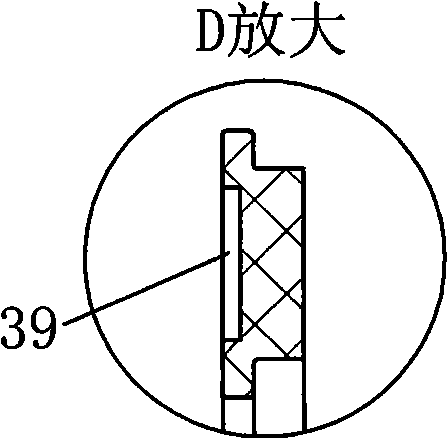

Novel sludge drying processing device

InactiveCN105399301AWith heat treatment effectLevel of inhibition of microbial activitySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFertilizerBuilding material

The invention discloses a novel sludge drying processing device, and belongs to the technical field of environmental protection equipment. The novel sludge drying processing device comprises a feeding machine, an air blower, an air heater, a diffuser, air flow dryers, a cyclone dryer, a cyclone separator, a dust remover, and an induced draft fan; air is heated by the air heater to a temperature higher than 100 DEG C, is delivered into the diffuser, and is mixed with dewatered sludge so as to obtain a hot air sludge flow, wherein water content of the dewatered sludge is controlled to be 80%, and the dewatered sludge is delivered into the diffuser via the feeding machine, and is smashed using the diffuser; sludge in the hot air sludge flow is dried using the air flow dryers and the cyclone dryer, dried air sludge flow is delivered into the cyclone separator so as to obtain dried sludge with a water content less than 5% via separation; hot air and dried sludge dust are delivered into the dust remover; and dried sludge dust is discharged via the bottom of the dust remover. The novel sludge drying processing device is used for processing sludge using a man-made heat source, deep dewatering is realized, thermal treatment effect is achieved, the activity of microorganisms in sludge are inhibited, and the obtained dried sludge can be taken as fertilizers, building materials, and the like.

Owner:大连大孤山污水处理有限公司

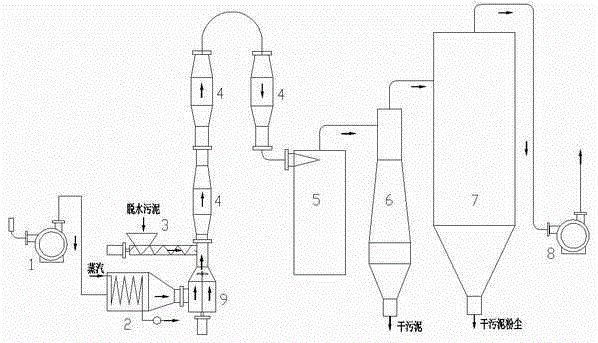

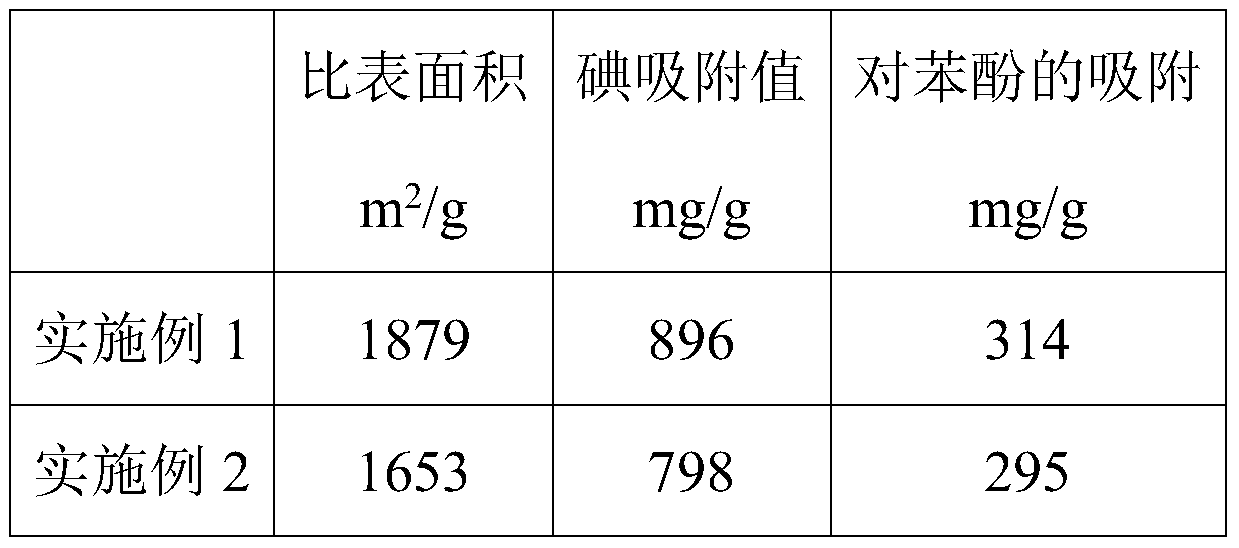

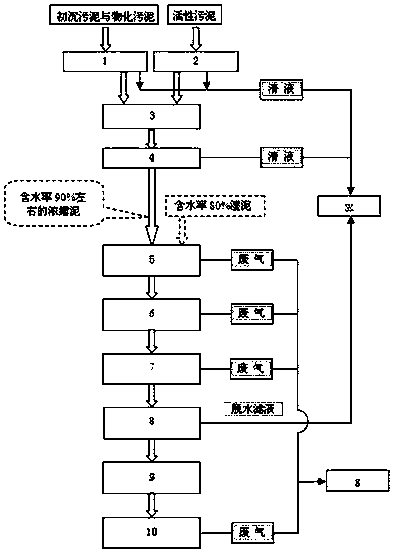

Sludge resource utilization processing system and method

InactiveCN110092557AReduce consumptionEffective destructionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisActivated carbonResource utilization

The invention belongs to the technical field of environment protection, and discloses a sludge resource utilization processing system. The sludge resource utilization processing system comprises a preliminary dehydration unit, an ultrasonic wave dehydration unit, a drying unit, a sludge pyrolysis unit, a gas liquid separation unit, a sludge activation unit, and an acid pickling unit. The method isused for resource utilization of sludge, and activation study on sludge semi-coke generated in sludge processing; activation process is adopted to prepare sludge semi-coke into sludge activated carbon which can be used in the field of sludge processing; and at the same time, the sludge activated carbon obtained through resource utilization is adopted to process sewage generated in sludge dehydration, so that a sludge and sewage processing virtuous circulation system is formed in sludge processing factories, and processing cost is reduced.

Owner:DALIAN UNIV

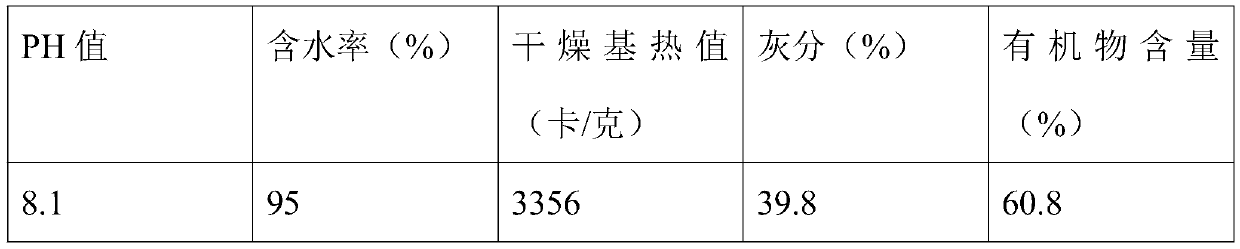

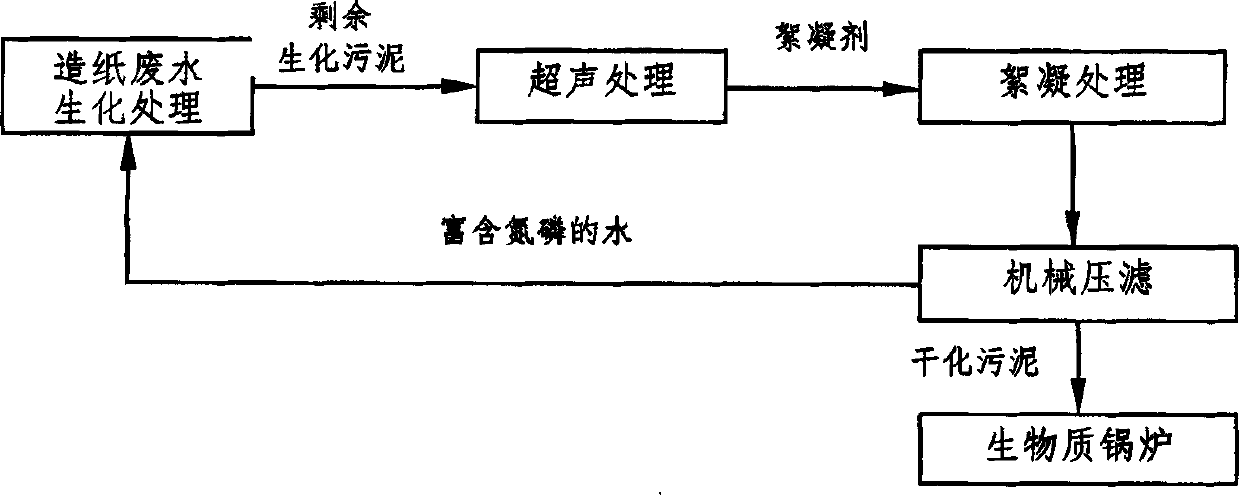

Method for extracting and recycling nitrogen and phosphorus in biochemical papermaking sludge and dehydrating sludge

ActiveCN103771681AAchieve deep dehydrationReduce doseSludge treatment by de-watering/drying/thickeningBiomass boilerChemistry

The invention relates to a method for extracting and recycling nitrogen and phosphorus in biochemical papermaking sludge and dehydrating the sludge, belonging to the field of pulping and papermaking environment friendliness. The method is adopted for overcoming the current situations that papermaking wastewater is rich in carbon source and lack of nitrogen and phosphorus, microorganisms in biochemical sludge are rich in nitrogen and phosphorus, part of the biochemical sludge is finally used as residual sludge to be discharged out of a water treatment system, and the dehydration is difficult. The method comprises the steps of ultrasonic crushing, flocculation and mechanical filter pressing is adopted. Firstly, microorganisms are crushed under the ultrasonic action so that substances in the microorganism are released, then, solid-liquid separation is realized under the actions of flocculation and machines, the liquid is recycled to a papermaking wastewater treatment process, the weight of the recycled N and P in treating every ton of biochemical sludge can be respectively up to over 0.45kg and over 0.1kg, and the nitrogen and phosphorus which are added for biochemically treating the papermaking wastewater can be effectively reduced; and meanwhile, the dryness of the sludge can be up to over 50%, the heat value of the sludge can be up to over 6MJ / kg, and the sludge can be directly burned in a biomass boiler. By using the method, the biochemical papermaking sludge can be comprehensively utilized.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

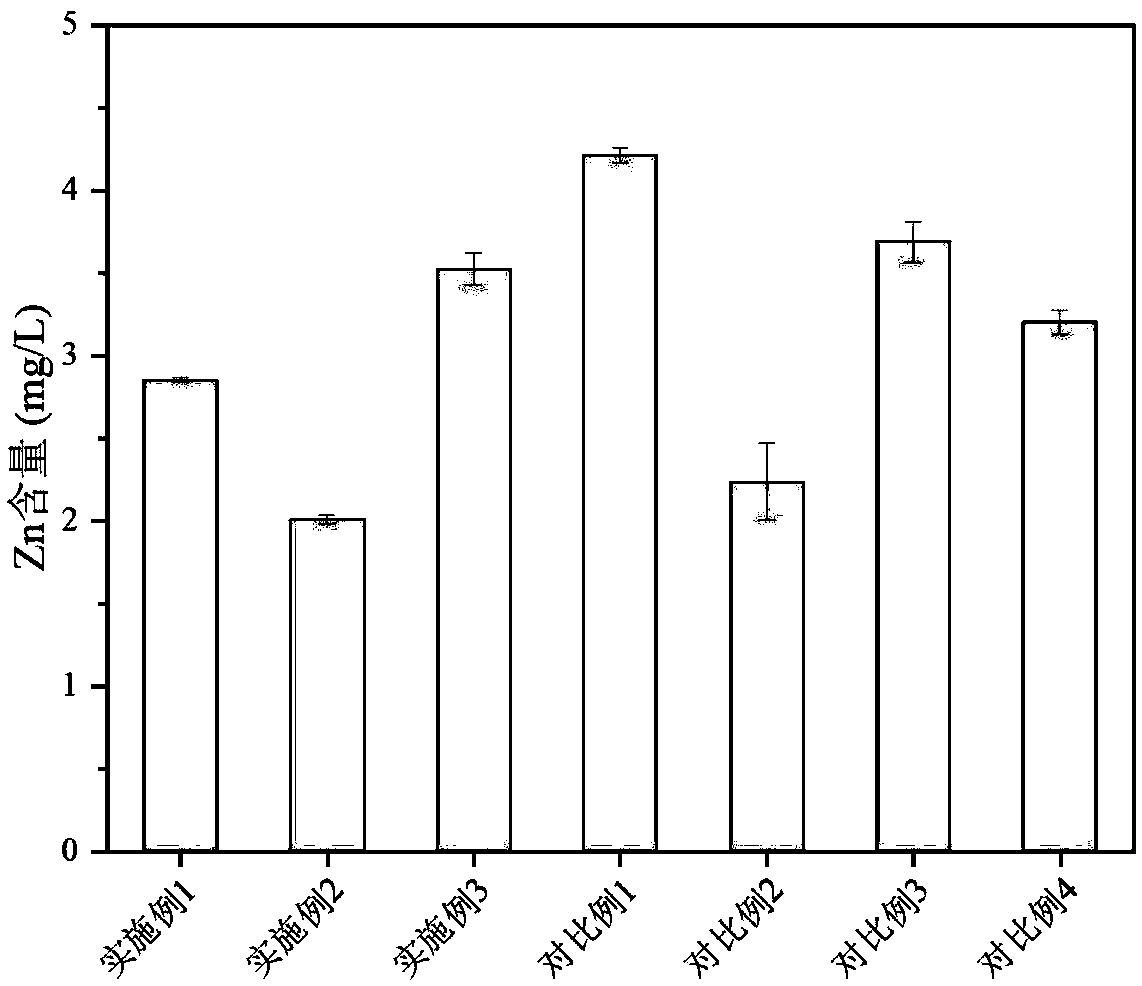

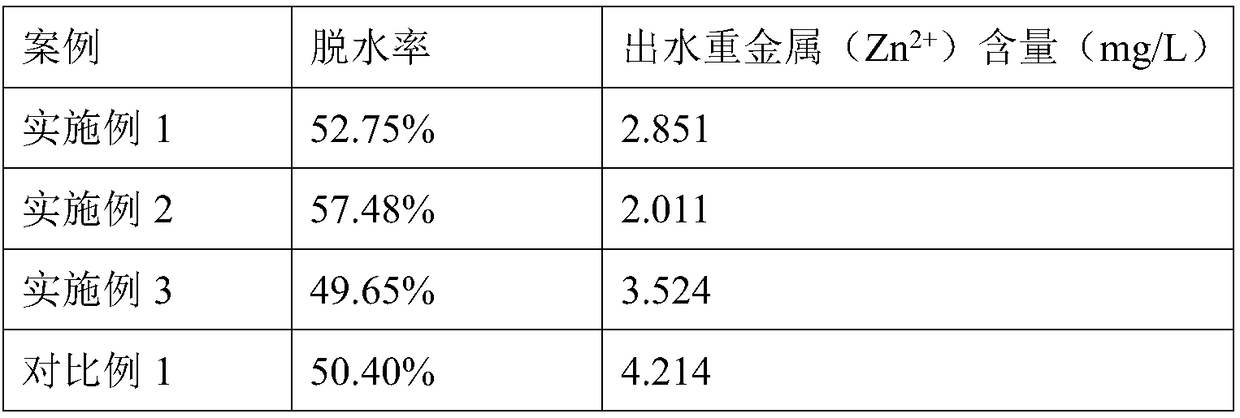

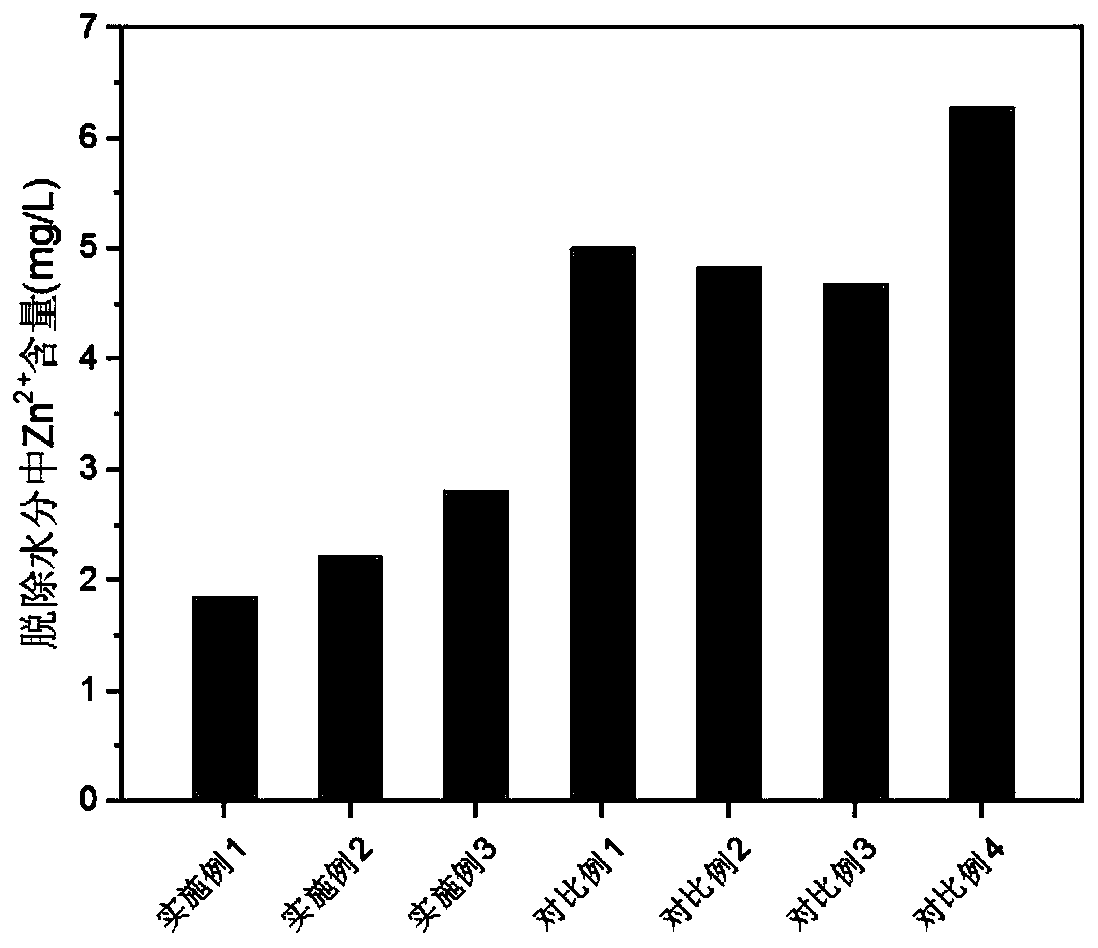

Sludge dewatering method

ActiveCN109368985AHigh degree of dehydrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningReaction systemToxic industrial waste

The invention belongs to the technical field of sludge treatment, and particularly discloses a sludge dewatering method. The method comprises the following steps: performing pre-reaction on sludge anda conditioner M; adding a flocculating agent to the pre-reaction system, and performing hydrothermal reaction under the sealed condition; finally, performing solid-liquid separation to recover waterin the pre-reaction system to obtain dry sludge. The conditioner M comprises industrial waste residues and an activator. According to the method, the content of heavy metals in water removed from thesludge is lower, and harmless treatment and reduction of the sludge are achieved.

Owner:肇庆市珈旺环境技术研究院

Deep dewatering method for sludge

InactiveCN109608021AGood compressibilityImprove dehydration effectSludge treatment by de-watering/drying/thickeningSludgeSulfate

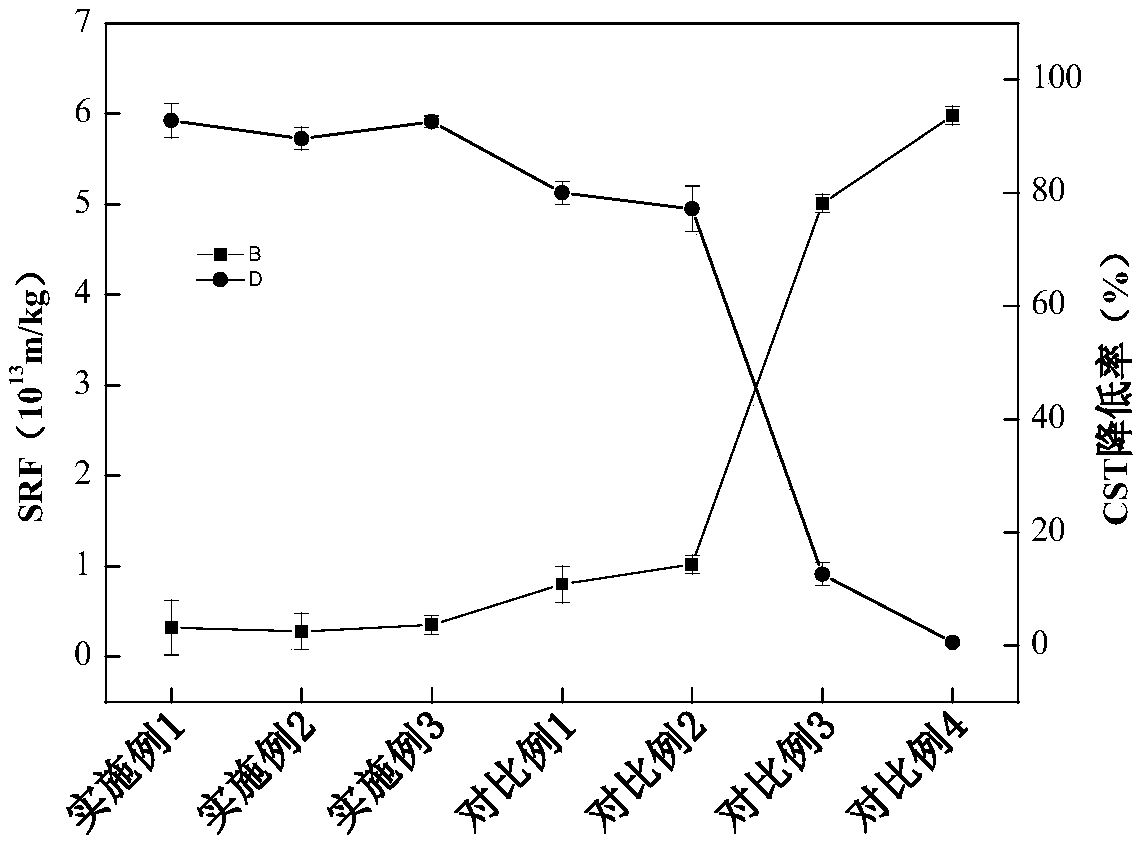

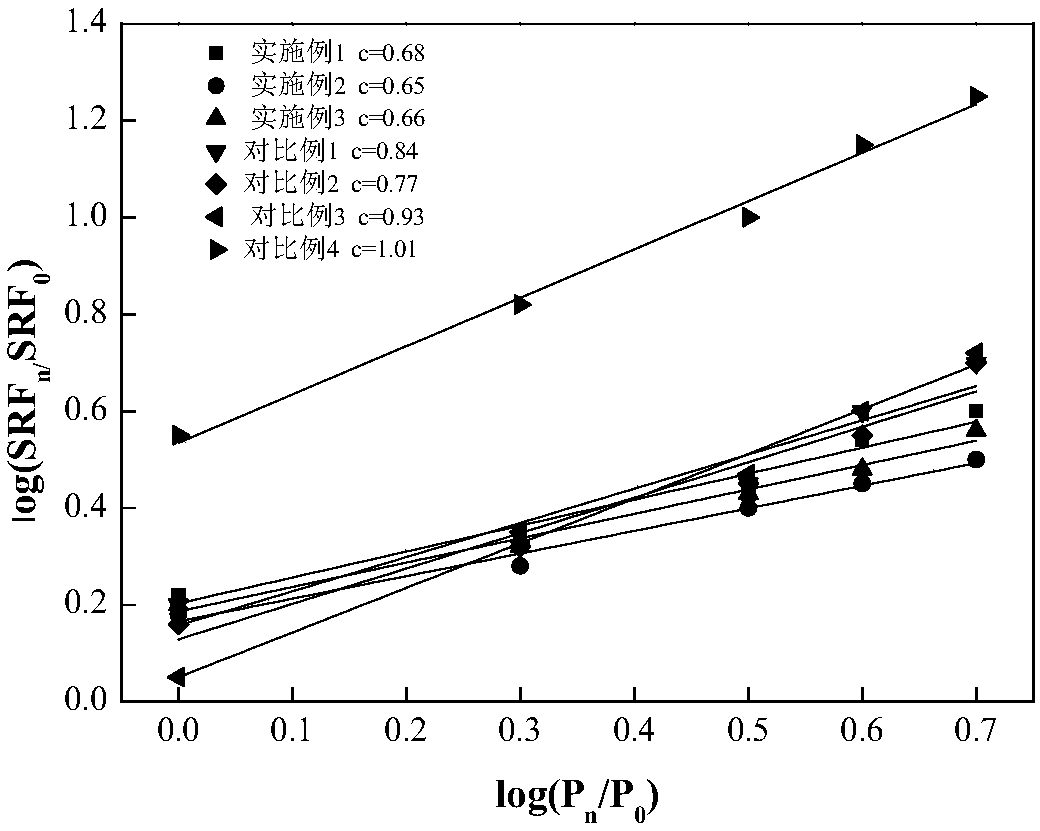

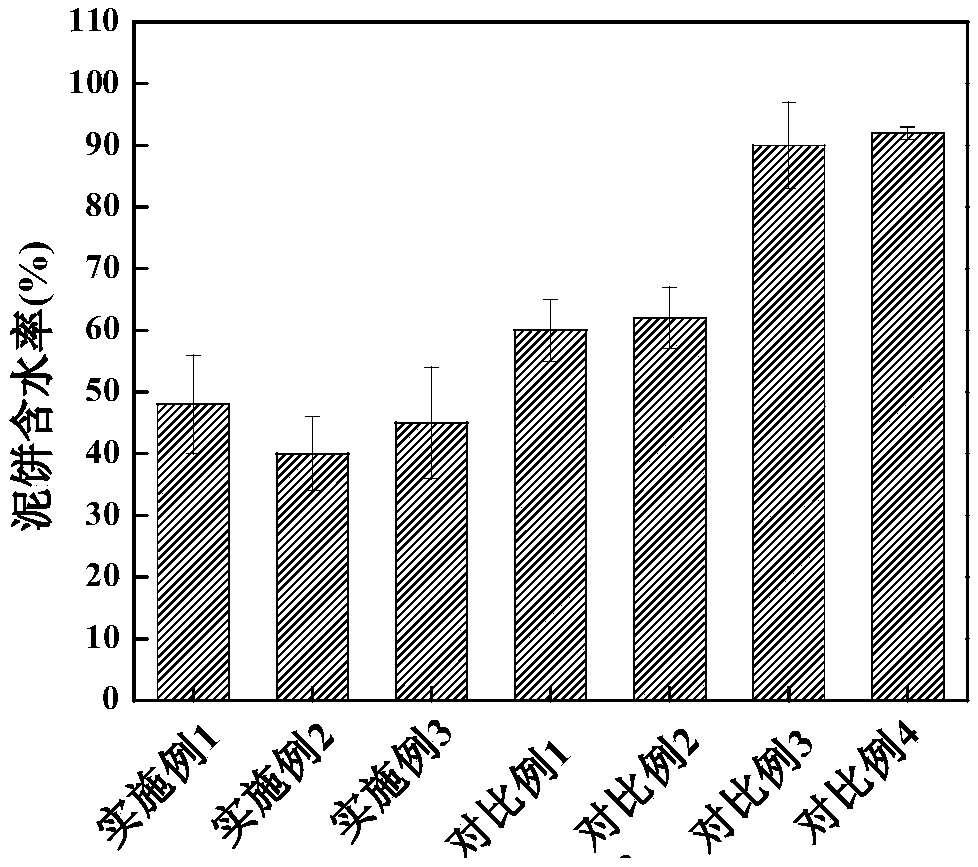

The invention discloses a deep dewatering method for sludge. Persulfate, soluble bivalent iron salt and biomass are successively added to the sludge, and a mud cake is obtained by pressure filtrationafter full reaction. The sludge is compounded and conditioned by activated persulfate oxidation and the biomass as a skeleton structure to enhance the strength of sludge flocs, improve the compressibility of the sludge, significantly improve the dewatering performance of the sludge and simultaneously stabilize and deactivate heavy metals in the sludge.

Owner:肇庆市珈旺环境技术研究院

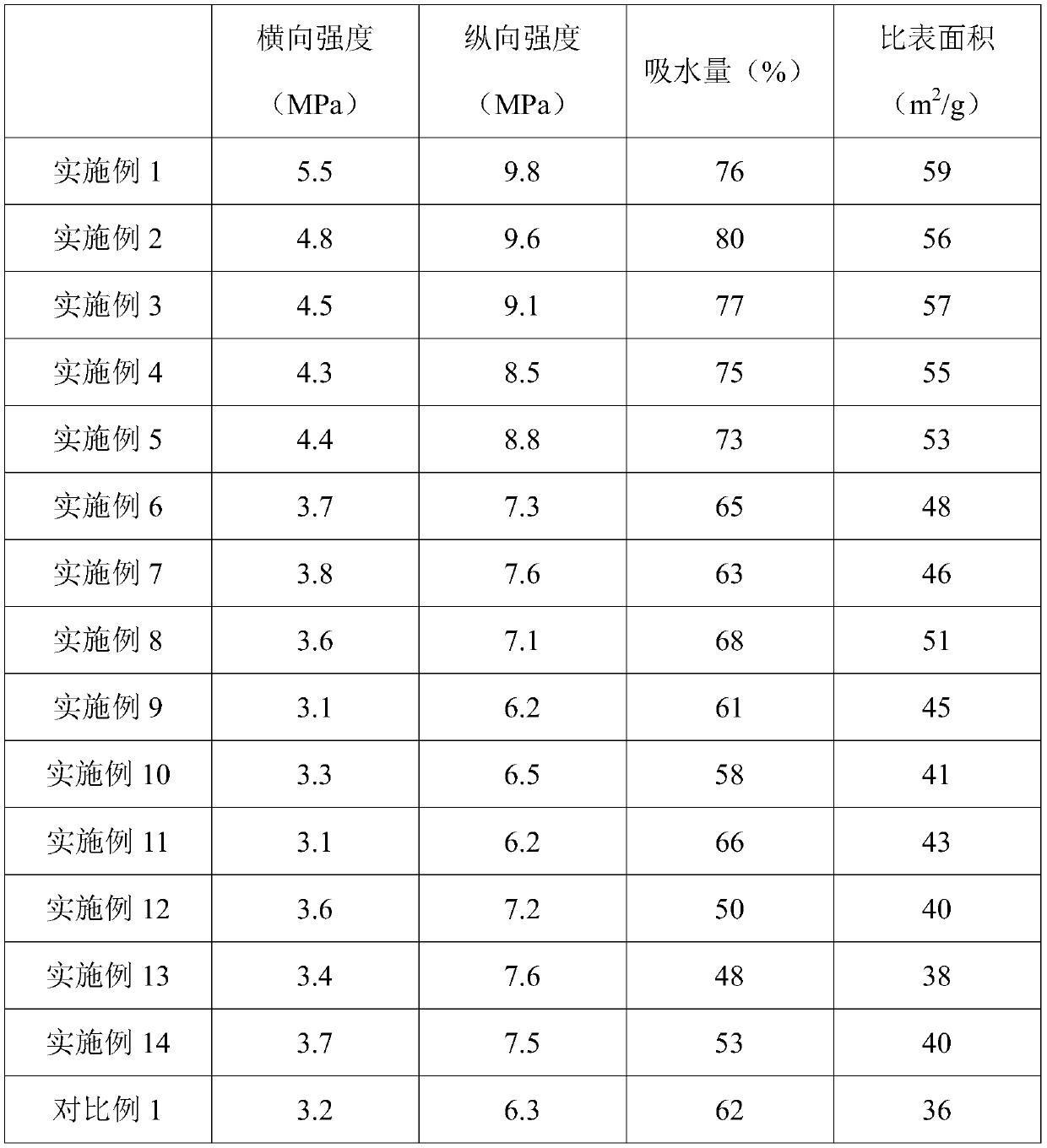

Honeycomb carrier, and preparation method and application thereof

ActiveCN111036187ALarge specific surface areaIncrease surface areaCatalyst carriersCatalyst activation/preparationHoneycombOrganic chemistry

The invention provides a honeycomb carrier, and a preparation method and an application thereof. The preparation method comprises the following steps: mixing a first raw material and a second raw material to obtain a mixed powder; mixing water, a first organic forming aid and the mixed powder under a stirring condition, reducing the stirring speed, and then sequentially adding a second organic forming aid and a structure enhancer to obtain pug; kneading the pug, and then carrying out pre-extrusion on the kneaded pug; aging the pre-extruded pug, and then extruding the aged pug in vacuum to obtain a honeycomb green body; drying the honeycomb green body until the moisture content is less than 10%, and then drying until the moisture content is less than 3% to obtain a dried green body; and roasting and drying the green body to obtain the honeycomb carrier. The prepared honeycomb carrier is large in porosity and high in adsorption capacity, can load many catalytic active components, and hasa high catalytic effect in the same space.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Excess sludge deep dehydration conditioner

InactiveCN104926075AGood effectReduce usageSludge treatment by de-watering/drying/thickeningResource utilizationEngineering

The invention discloses an excess sludge deep dehydration conditioner, and belongs to the technical field of sludge treatment. Rice hull powder is adopted as the sludge dehydration conditioner, so that the defects that at present, FeCl3 and CaO can corrode incineration facilities, and incineration is influenced along with the reduction of organic matters are overcome; compared with a manner that chemical conditioners or wood chips are used, the effect of rice hull powder is better, the raw materials source is wide, the price is low, and the problem of how to realize waste resource utilization of rice hull powder in the prior art can also be solved.

Owner:JIANGNAN UNIV

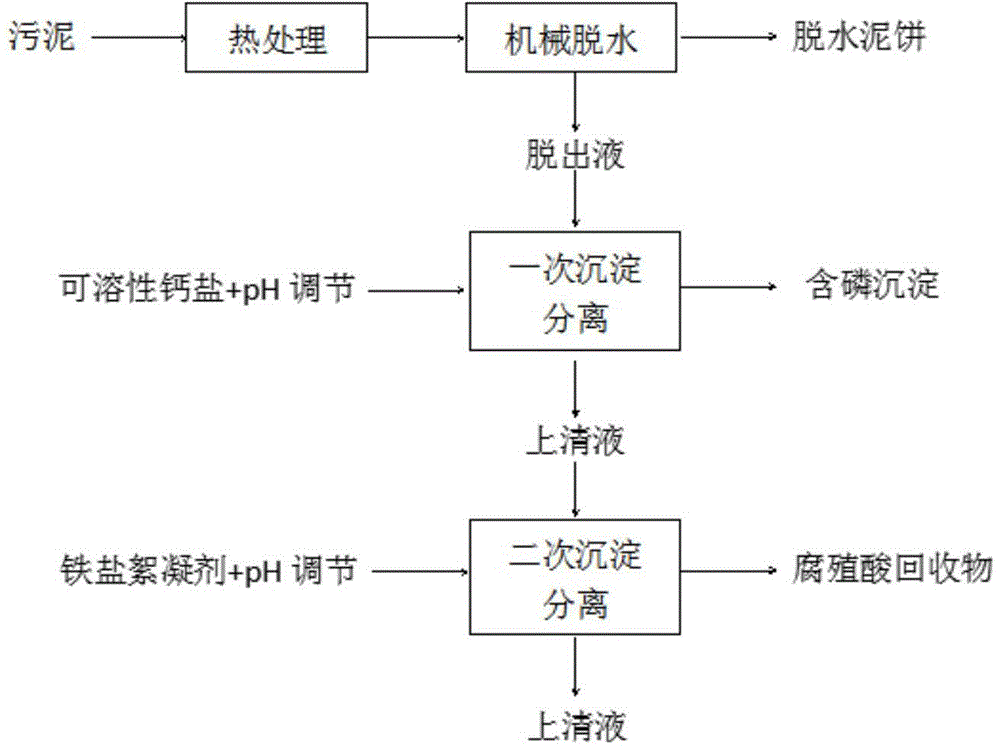

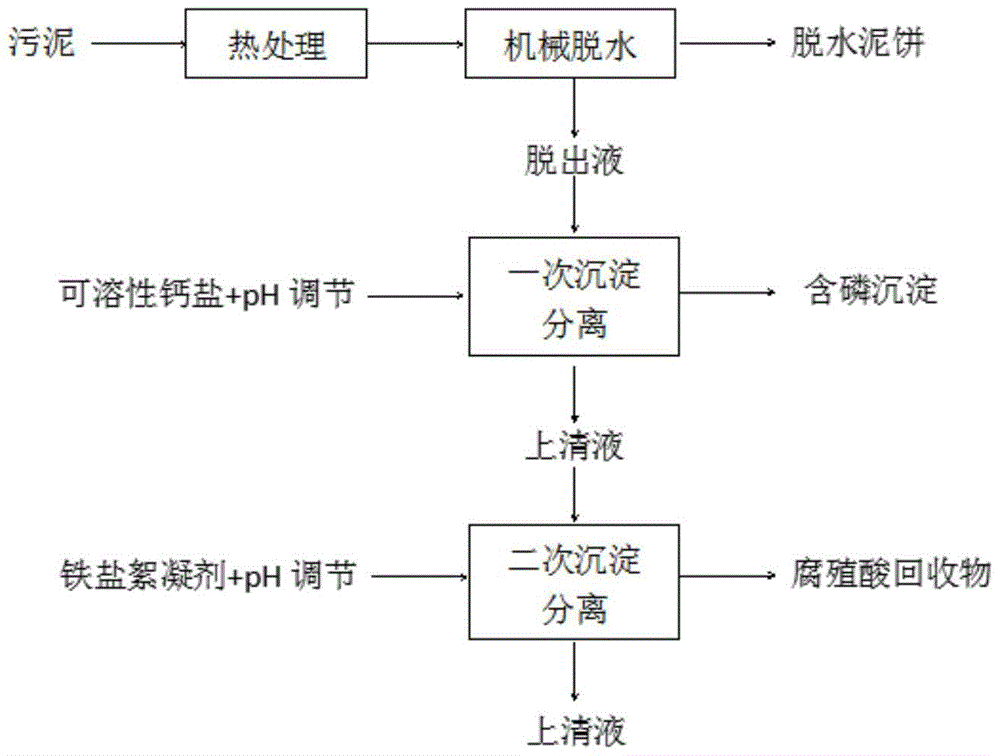

Method for recovering humic acid from sludge

ActiveCN104478190AAchieve deep dehydrationEasy to handleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPre treatmentThermal treatment

A disclosed method for recovering humic acid from sludge comprises the following steps: cracking pre-treatment, namely, performing heat treatment on sludge, and dewatering to obtain a dewatered liquid; performing first precipitation processing, namely, pouring a soluble calcium salt into the dewatered liquid, controlling the pH value to be 8-10, separating precipitate and obtaining the supernatant; and performing second precipitation processing, namely, pouring a ferric salt flocculating agent into the above supernatant, controlling the pH value to be 3-7, and separating the precipitate as a humic acid recovery substance. The method is high in humic acid recovery rate, the recovery product is high in humic acid content, and the method is simple in operation and low in cost, and also the dewatering performance of sludge is obviously improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

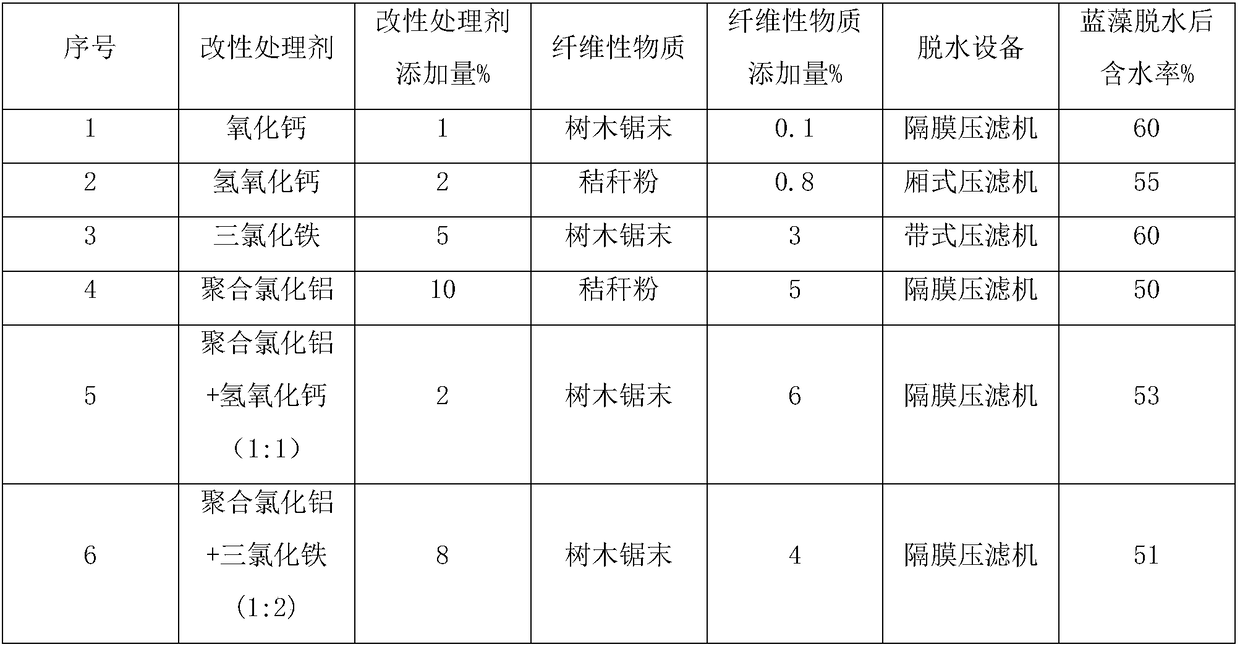

Deep dewatering method and power generation recycling method of blue algae

PendingCN109336360AAchieve deep dehydrationRealize power generation energySludge treatment by de-watering/drying/thickeningSlurryBiology

The invention relates to a deep dewatering method and a power generation recycling method of blue algae. The deep dewatering method of the blue algae comprises the steps of modification treatment anddewatering treatment, wherein the modification treatment is to add a modification treatment agent and a fibrous substance into blue alga slurry. The power generation recycling method of the blue algaecomprises the steps of adding a blue alga cake obtained by deep dewatering into an incineration substance for incineration power generation. Blue alga cells are modified by the modification treatmentagent and the fibrous substance; then, a water content of the blue algae can be reduced to be less than 60% only by dewatering through dewatering equipment; the method can achieve the deep dewateringof the blue algae through a simple process, is simple, convenient and easy to use and has good market prospects. In addition, the blue alga cake obtained by the dewatering is added into the incineration substance for incineration power generation, so that the power generation recycling of the blue algae is achieved.

Owner:JIANGSU ACAD OF AGRI SCI

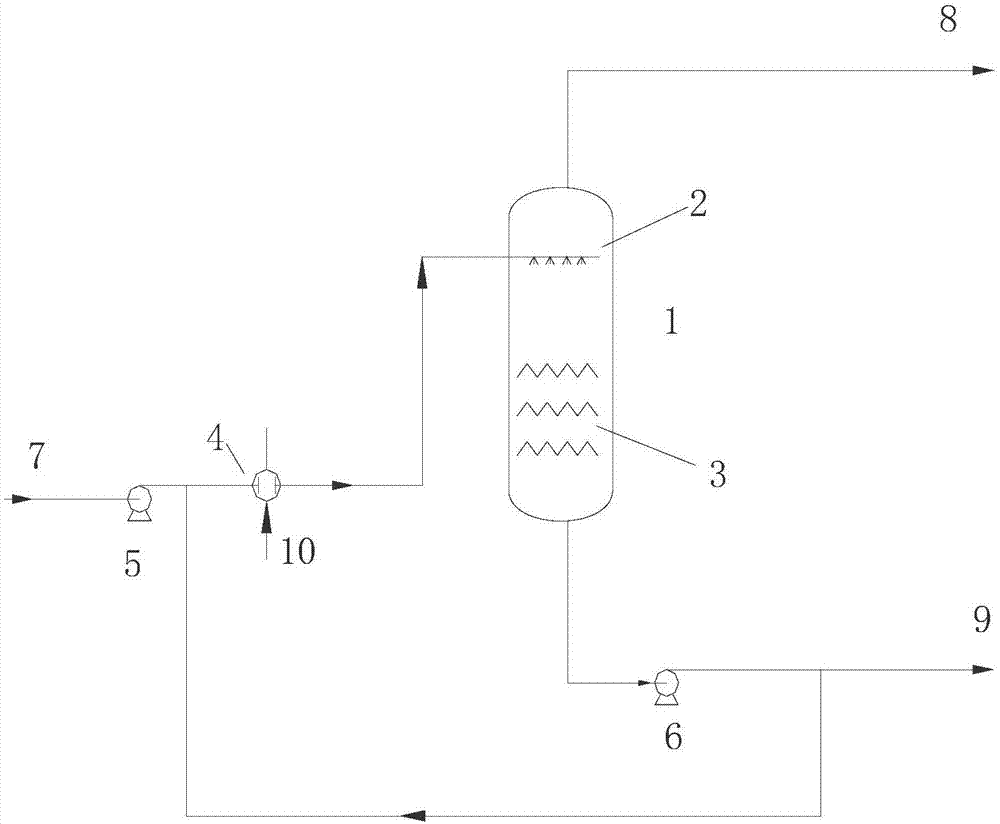

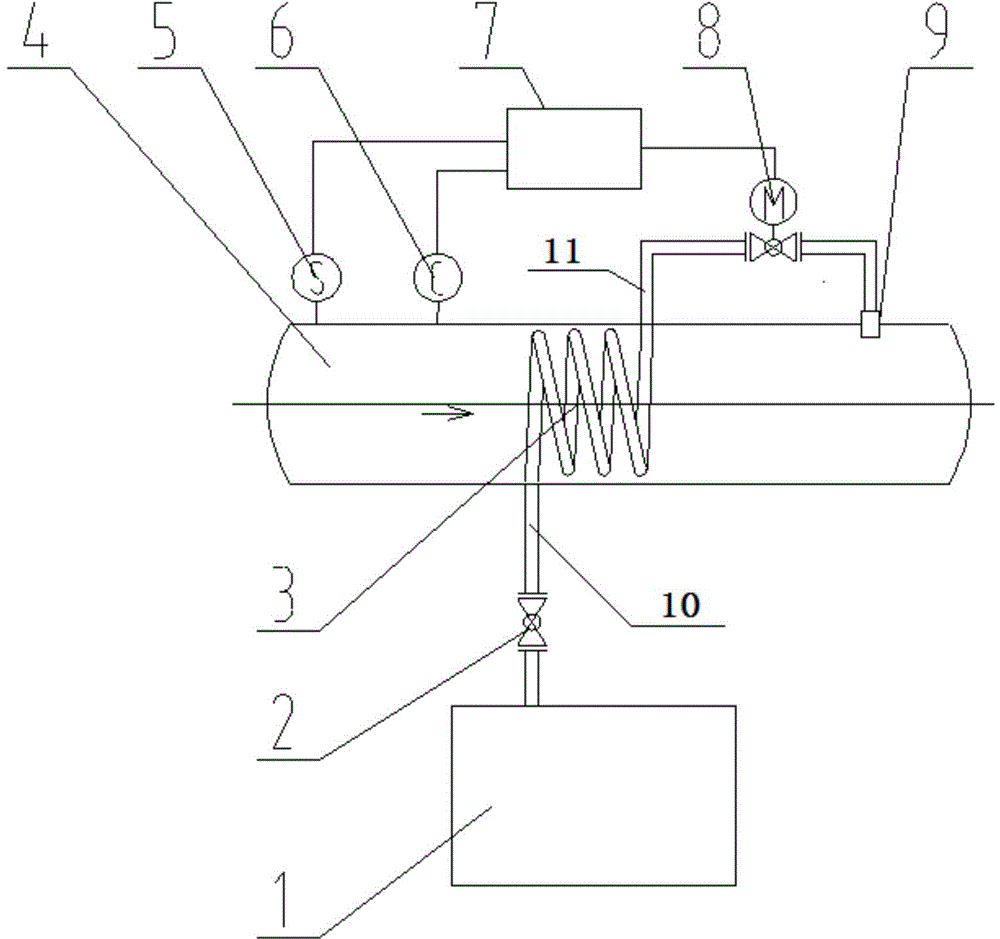

Energy-saving sump oil dehydration device and treatment method thereof

ActiveCN107880930AAchieve deep dehydrationLess waterTreatment with plural serial refining stagesEvaporationOil water

The invention provides an energy-saving sump oil dehydration device and a treatment method thereof. The energy-saving sump oil dehydration device comprises a sump oil dehydration tower, a sump oil atomizer, a Venturi rod layer, a circulating heater, a pump for sump oil to be dehydrated and a circulating sump oil pump. A circulating heating and atomizing technologies are used; low-temperature afterheat of an oil refining device is fully utilized; heated sump oil is atomized into fine fogdrop, so that the oil-water boundary tension is reduced; the oil-water evaporation area is increased; the deep dehydration of the sump oil is realized. The energy-saving sump oil dehydration device has the advantages that the flow process is simple; the operation is simple and convenient; the energy consumption is low; the dehydration effect is good; the applicability is wide. The energy-saving sump oil dehydration device can be used for light sump oil dehydration, can also be used for heavy sump oil dehydration and is particularly applicable to deep dehydration of seriously emulsified sump oil; the water content in the sump oil can be lowered to 2 percent or less; the requirement of sump oil refining on the water content is met.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD +1

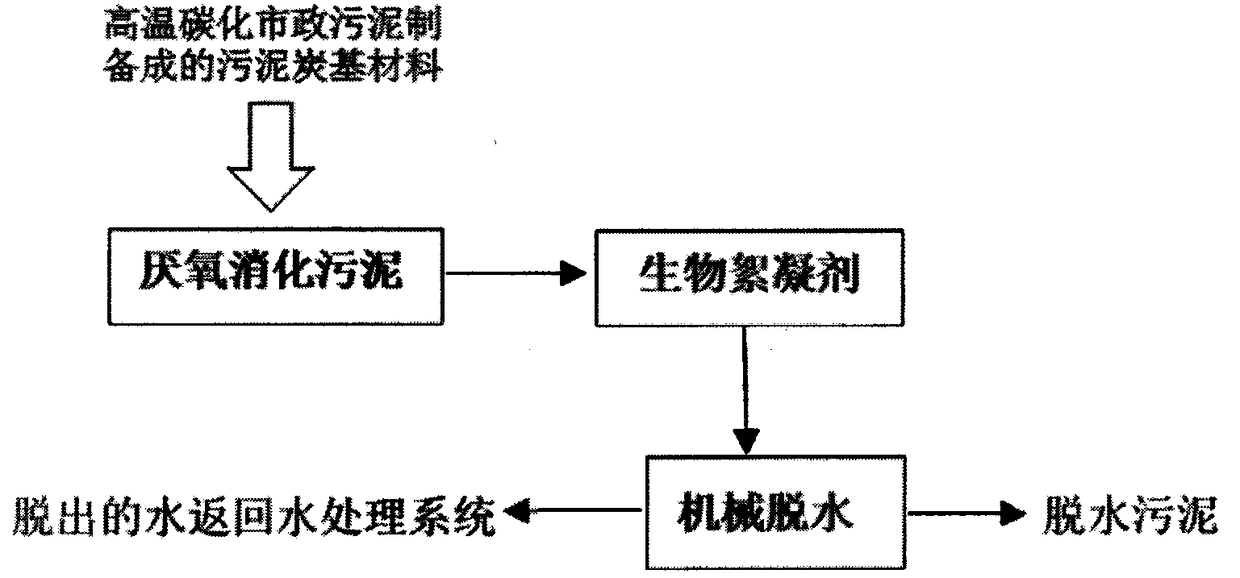

Anaerobic digestion sludge dewatering method

InactiveCN108358429AAchieve deep dehydrationImprove weight reduction effectSludge treatment by de-watering/drying/thickeningActivated carbonHigh concentration

The invention discloses an anaerobic digestion sludge dewatering method. By adopting the anaerobic digestion sludge dewatering method, secondary utilization can be performed on sludge, the sludge is prepared into a sludge activated carbon material firstly, sludge activated carbon and a biological flocculant are adopted for combined conditioning, and deep dewatering of the sludge or anaerobic digestion sludge is realized; by taking the sludge activated carbon as a skeleton structure substance, the floc structure strength of the sludge is strengthened through the hydrophobic interaction, viscousmacromolecular organic matters including humic acid and proteins and the like in a liquid phase of the anaerobic digestion sludge are removed synchronously, the filter performance of the sludge is improved, an organic load of subsequent reflux biochemical treatment is lowered; and then by further utilizing the biological flocculant for coagulation, sludge-water separation is promoted, and efficient deep dewatering of the anaerobic digestion sludge is realized. The dewatering method provided by the invention is an environment-friendly conditioning method and can improve the filtering and dewatering efficacy of the anaerobic digestion sludge specially aiming to the characteristics of small particles, high concentration of a dissolved microbial metabolite, poor filter performance and the like of the anaerobic digestion sludge.

Owner:北京环球中科水务科技股份有限公司

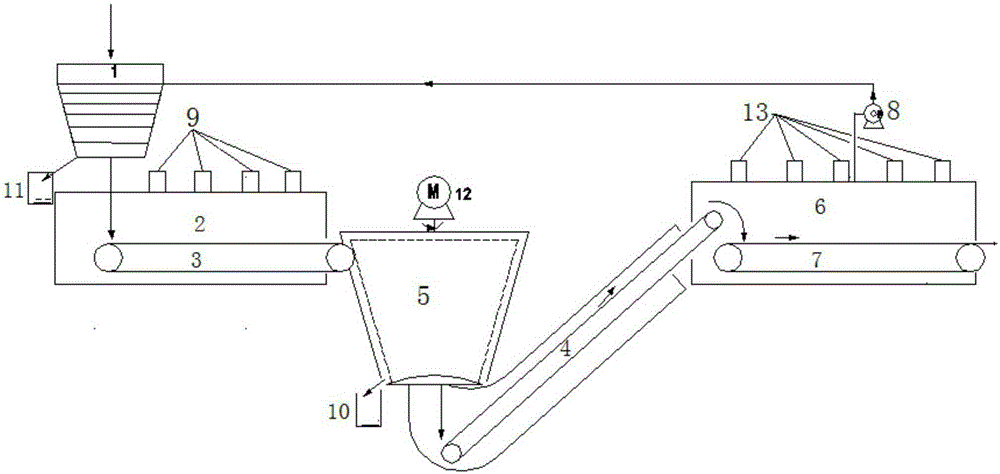

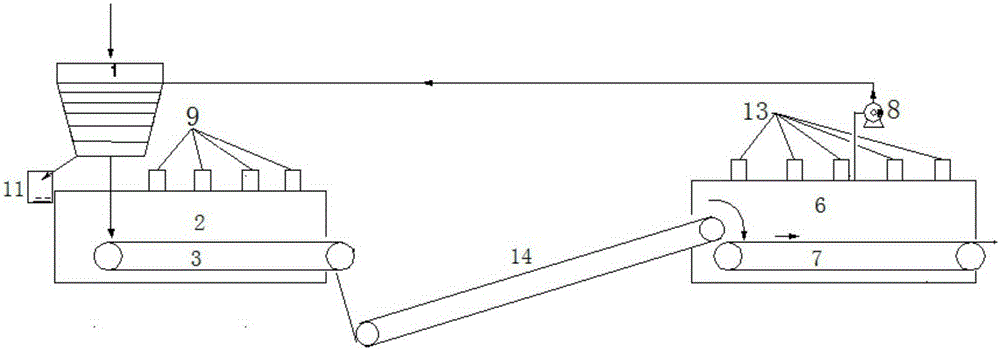

Segmented water removing and drying system for high-humidity coal and application method for segmented water removing and drying system

ActiveCN105157399AAvoid energy consumptionImprove economyDrying using combination processesDrying solid materials with heatCoalMicrowave

The invention discloses a segmented water removing and drying system for high-humidity coal and an application method for the segmented water removing and drying system. The system comprises a discharging mechanism. A first microwave drying mechanism is arranged below the discharging mechanism and internally provided with a first conveying mechanism. A solid-liquid separation mechanism is arranged at the tail end of the first conveying mechanism. A second conveying mechanism is arranged at an outlet of the solid-liquid separation mechanism. A second microwave drying mechanism is arranged at the tail end of the second conveying mechanism. The segmented water removing and drying system has the beneficial effects that a microwave heating manner and a non-heating manner are combined with the water removing and drying technology, a heat water removing manner and a non-heat water removing manner are organically combined, water in coal is removed in the form of a liquid state on the basis of low-rank coal microwave drying, and energy consumption of a microwave drying system is greatly reduced; raw coal is heated through the reutilization of residual heat and waste heat generated by the drying system, and the economical efficiency of the whole drying system is improved; and after deep drying is carried out, utilization of later finished coal is more flexible and safer, and the processing cost is reduced.

Owner:SHANDONG UNIV

Thermal hydrolysis anaerobic digestion sludge dewatering method

InactiveCN109354367AAchieve deep dehydrationEasy to followWater treatment parameter controlSludge treatment by de-watering/drying/thickeningSludge cakeOxidative treatment

The invention discloses a thermal hydrolysis anaerobic digestion sludge dewatering method, which comprises the following steps: firstly, thermal hydrolysis anaerobic digestion sludge is conditioned byusing the combination of a specific inorganic coagulant and an organic flocculant, and the sludge is stirred at different frequencies and for different time periods by an agitator. Physical dewatering is carried out on the conditioned sludge, the water content of sludge cake made of dewatered sludge is reduced from 93-95% to below 60%, and the deep dewatering of the thermal hydrolysis anaerobic digestion sludge is achieved, which facilitates subsequent disposal and utilization. The method has low dosage of medicament and a simple conditioning process, the basicity degrees and PH values of thesludge before and after conditioning are consistent, dry solid is increased little, no odor is produced in the production process, and the problem that the dosage of traditional conditioning method is too large and the alkalinity consumption is high is solved. The method does not affect the subsequent resource-based disposal of mud cakes and anaerobic ammonia oxidation treatment of the filtrate.

Owner:北京尚水清源水处理技术有限公司

River sludge treatment method and device

InactiveCN109368953AImprove dehydration effectAchieve deep dehydrationSludge treatmentSpecific water treatment objectivesSludgeCompression device

The invention provides a river sludge treatment method which comprises the following steps: digging sludge from the bottom of a river, and collecting the sludge in a sludge storage pool; conveying thesludge into a feeding hopper above a reaction tank, enabling the sludge to slowly flow into the reaction tank via the feeding hopper, impacting the sludge by water ejected from a high-pressure jet apparatus below the feeding hopper in the reaction tank, crushing the sludge by high-pressure water, enabling the sludge to impact on inner walls of the reaction tank, enabling the sludge to flow into the bottom of the reaction tank along the inner walls of the reaction tank, standing, layering, and discharging the upper layer into a circulating water tank; and discharging the lower sludge onto a filter plate of a mechanical dewatering plant, and dehydrating the sludge under the effects of vacuum and a compression device so as to be dried. The treatment process is simple and reliable, the equipment is easy and convenient to manufacture, the operation is simple, secondary pollution is avoided, the energy consumption is low, low-cost cleaning can be performed to remove moisture in the sludge,and aims of river sludge reduction and harmlessness can be achieved.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

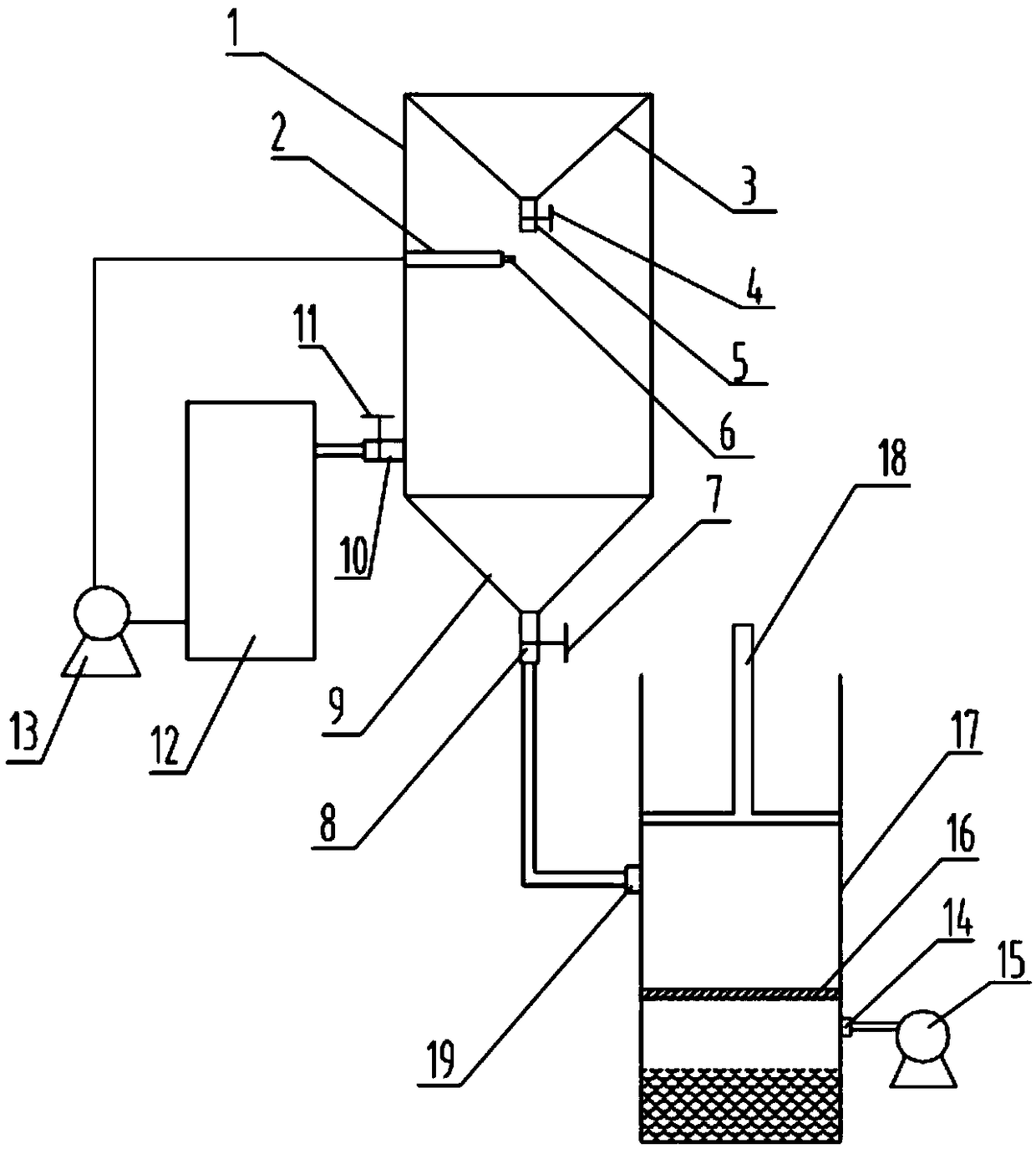

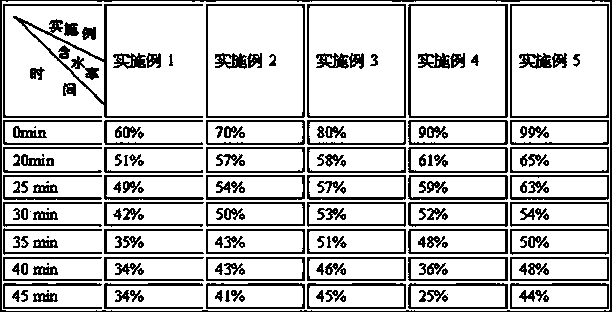

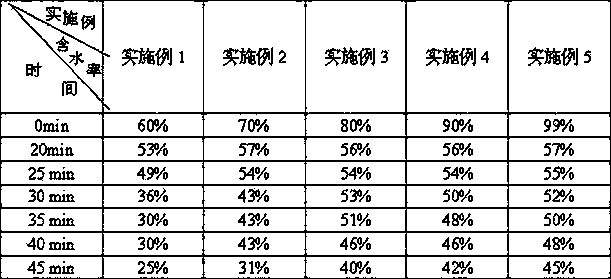

Sludge magnetic dewatering agent and dewatering method thereof

InactiveCN104016567AWide variety of sourcesLow priceSludge treatment by de-watering/drying/thickeningIron powderChitin formation

The invention relates to a sludge magnetic dewatering agent and a dewatering method thereof. The magnetic dewatering agent is composed of the following compositions in percent by weight: 9-19% of acrylamide, 7-17% of chitin, 14-21% of ferric chloride, 10-17% of sodium chloride, 15-22% of aluminum chloride, 1-8% of concentrated sulfuric acid and 15-32% of iron powder. The dewatering agent is wide in raw material source and low in price. Dewatering is performed by employing a magnetic dewatering machine and utilizing the magnetic dewatering agent, the sludge dewatering time is reduced, and also deep dewatering for sludge is realized, 1 ton of sludge with the water content of 60%-99% can be dewatered to have the water content of 25-45% in 45 min, subsequent processing of sludge is substantially facilitated, requirements on subsequent second ploughing and greening are satisfied, and the processing and disposing problems of a large amount of stacked sludge are solved. By employing the magnetic dewatering machine, economy, convenience and good dewatering efficiency are realized.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

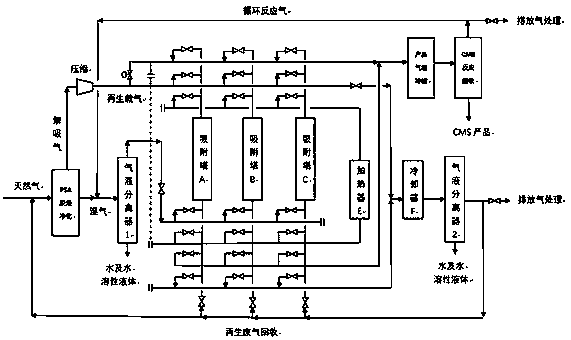

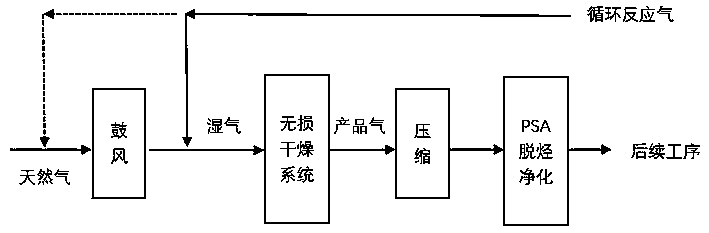

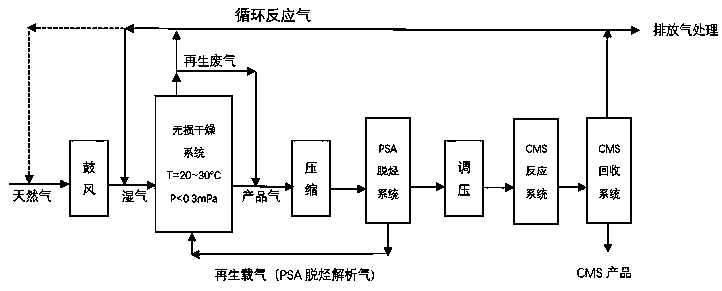

Lossless drying method for natural gas and circulation reaction gas in production of chloromethane with methane method

ActiveCN110237659AAchieve deep dehydrationReduce energy consumptionGas treatmentGaseous fuelsVapor–liquid separatorDesorption

The invention discloses a lossless drying method for a natural gas and a circulation reaction gas in production of chloromethane with a methane method. The lossless drying method comprise the following main steps: feeding a wet gas formed by a raw material natural gas and a circulation reaction gas needed in production of chloromethane (CMS) with a methane method through a gas-liquid separator 1, carrying out adsorption, heating and thermal regeneration and cooling and cold regeneration, and feeding the wet gas through a gas-liquid separator 2. Under conditions that the adsorption operation temperature is 10-60 DEG C, the adsorption operation pressure is 0.3-1.5MPa, the operation temperature of thermal regeneration is 120-220 DEG C, and the operation pressure is 0.3-1.5MPa, moisture in the wet gas is removed to be smaller than 10ppm, both a thermal regeneration carrier gas and a cold regeneration carrier gas are desorption gases generated in dealkylation purification treatment of the raw material natural gas used in production of the CMS with the methane method, the effective component methane in the wet gas is not lost, and a thermal regeneration waste gas and a cold regeneration waste gas are fed back to a dealkylation purification treatment procedure of the raw material natural gas or / and fed back to a drying system for circulation.

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

Sludge dewatering flocculating agent and dewatering method thereof

InactiveCN104016566AWide variety of sourcesLow priceSludge treatment by de-watering/drying/thickeningWater contentChemistry

The invention relates to a sludge dewatering flocculating agent and a dewatering method thereof. The sludge dewatering flocculating agent is composed of the following compositions in percent by weight: 5-27% of aluminium oxide, 4-18% of chitin, 13-25% of silicon dioxide, 10-24% of acrylamide, 6-18% of sodium chloride and 2-13% of concentrated sulfuric acid. The flocculating agent is wide in raw material source and low in price. The invention also provides the deep dewatering method of the efficient flocculating agent. By utilizing the sludge dewatering flocculating agent and the dewatering method thereof for processing sludge, the sludge dewatering time is reduced, and also deep dewatering of sludge is realized. 1 ton of sludge with the water content of 60%-99% can be dewatered to have the water content of 25-45% in 45 min, subsequent processing of sludge is substantially facilitated, requirements on subsequent second ploughing and greening are satisfied, and the processing and disposing problems of a large amount of stacked sludge are solved. Additionally, the method does not using press filtration or centrifugation equipment, so that the operation cost for dewatering processing of sludge is substantially reduced.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Rapid sludge dewatering system and dewatering method

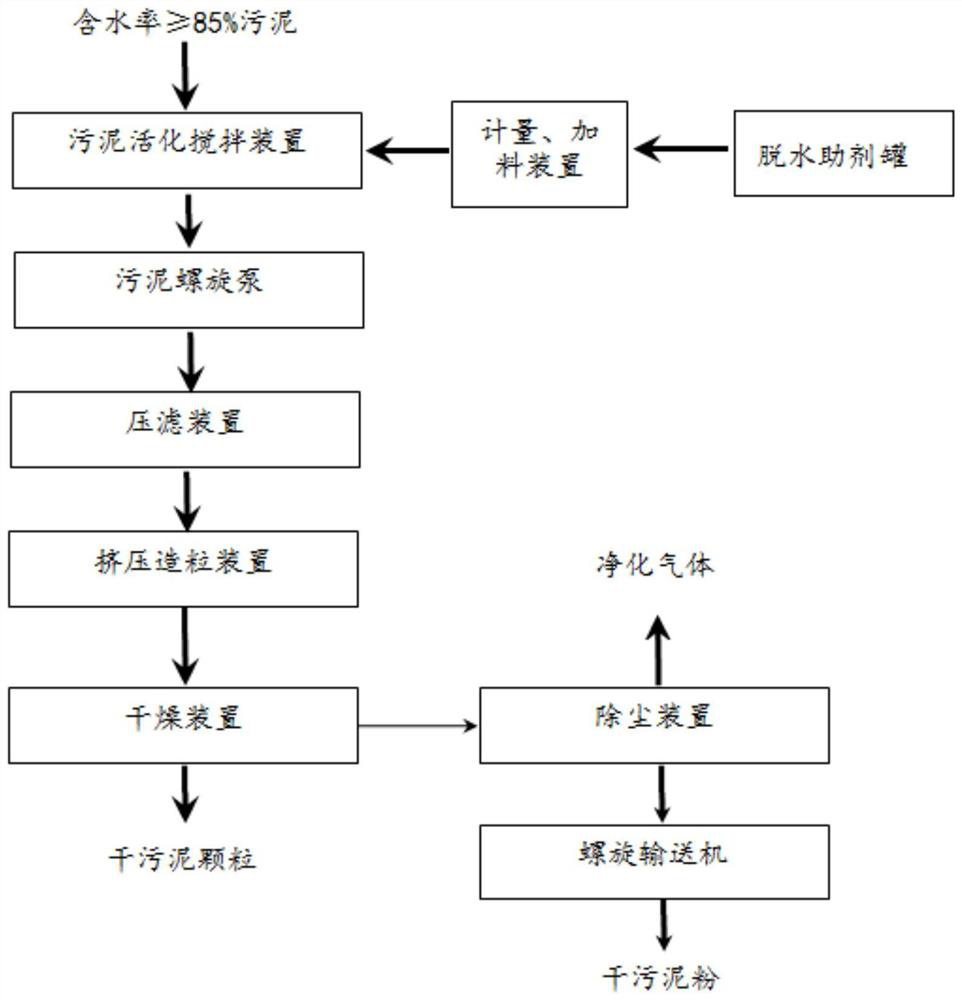

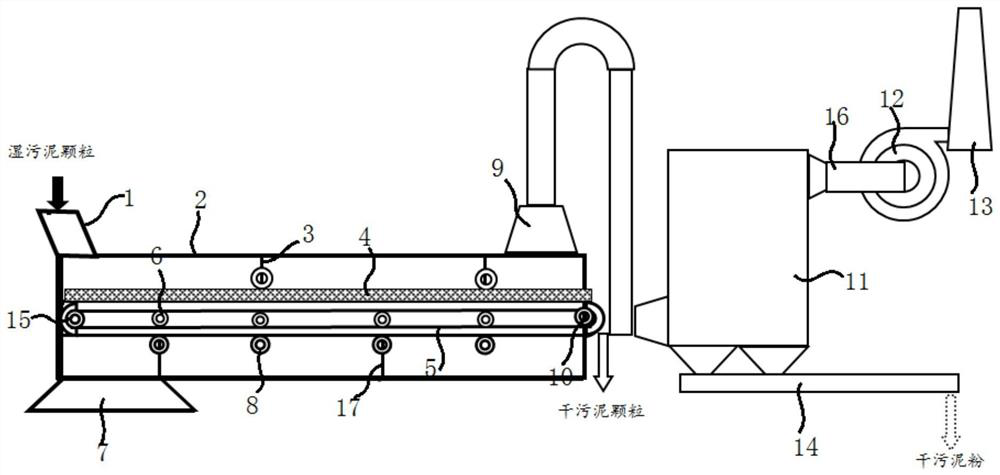

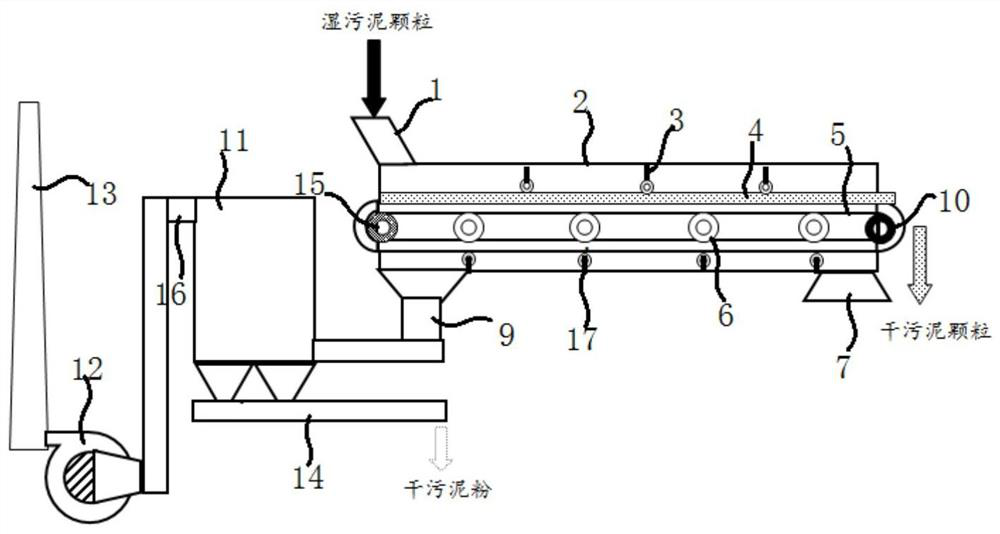

PendingCN112159074ADehydration fastEfficient dehydrationSludge treatment by de-watering/drying/thickeningGranulation by material expressionProcess engineeringFilter press

The invention discloses a rapid sludge dewatering system and a dewatering method, and belongs to the technical field of sludge dewatering. The sludge rapid dehydration system comprises a dehydration auxiliary agent tank, a sludge activation stirring device, a filter pressing device, an extrusion granulation device and a drying device, the drying device comprises a machine shell, and the interior of the machine shell is divided into an upper space and a lower space through a breathable conveying belt horizontally distributed in the length direction of the machine shell; wherein the upper spaceis divided into a plurality of air entraining channels through an upper partition baffle, the lower space is divided into a plurality of air entraining channels through a lower partition baffle, and air enters through an air inlet in one end of the machine shell and then sequentially and alternately enters the lower air entraining channels and the upper air entraining channels. By the adoption ofthe scheme, sludge can be dewatered rapidly and efficiently, deep dewatering of the sludge is achieved, the application process is easy to operate, and energy consumption is low.

Owner:安徽省融工博大环保技术材料研究院有限公司

A method for recovering humic acid from sludge

ActiveCN104478190BAchieve deep dehydrationEasy to handleSludge treatment by de-watering/drying/thickeningOrganic chemistryPre treatmentNuclear chemistry

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

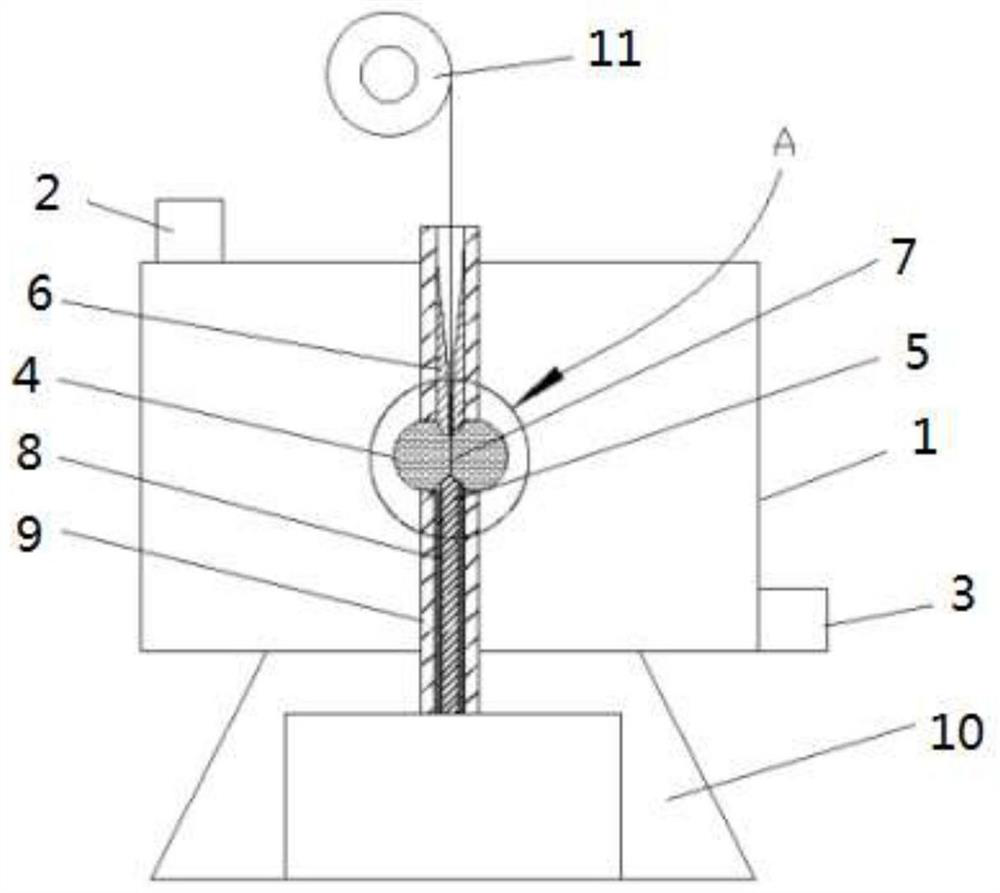

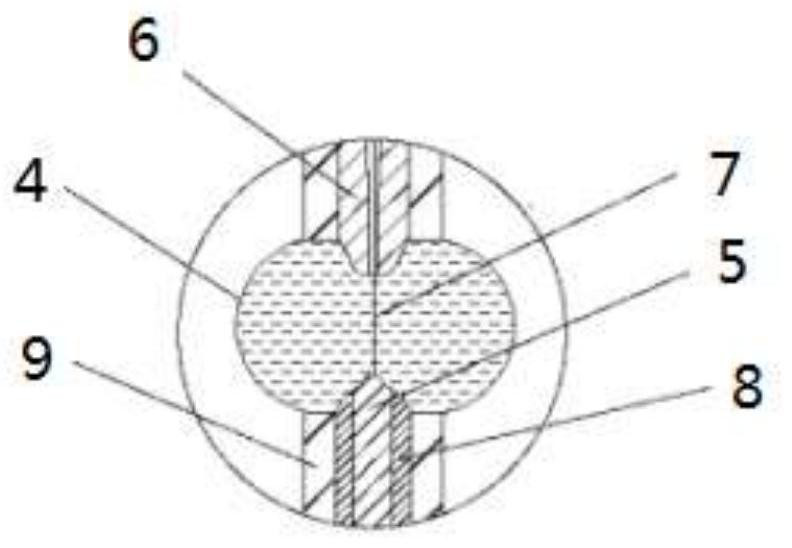

Device and method for mixing LNG fuel into methane electric generator set

ActiveCN104912696AAchieve blendingTake advantage ofInternal combustion piston enginesFuel supply apparatusFree stateProcess engineering

The invention relates to a device for mixing LNG fuel into a methane electric generator set. The device comprises a main methane conveying pipe, an LNG storage tank, a heat exchanger and an LNG gasification device. The heat exchanger is arranged inside the main methane conveying pipe. The heat exchanger is provided with an LNG inlet and an LNG outlet. The LNG inlet is communicated with the LNG storage tank through a first pipeline. The LNG outlet is communicated with the LNG gasification device through a second pipeline. The LNG gasification device is arranged on the main methane conveying pipe. The LNG fuel mixing can be achieved. When the methane concentration is fluctuated around 8%, the existing methane electric generator set can be fully utilized, and the utilization ratio of the device is improved. When the methane concentration is lower than 8%, the methane can be fully utilized, and the utilization space and the utilization ratio of the fuel are improved. Meanwhile, deep separating can be carried out on water which is in a free state and inside methane gas by the heat exchanger, and the electric generating efficiency of the electric generator set is favorable to be improved.

Owner:北京扬德环保能源科技股份有限公司

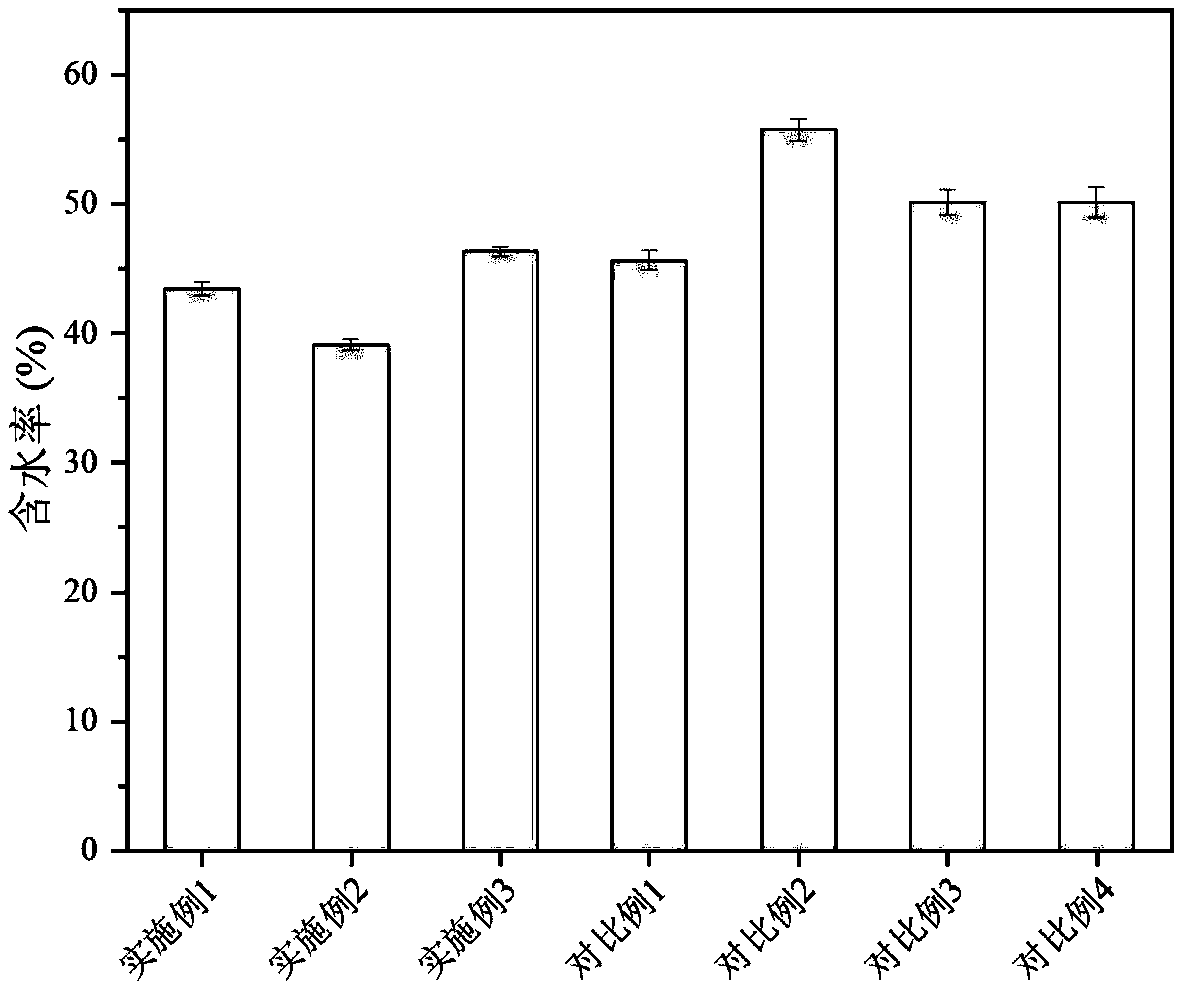

Sludge concentration and deep dehydration agent and method for sludge concentration and deep dehydration

ActiveCN105800909BAchieve deep dehydrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeEnergy consumption

The invention provides sludge concentration and deep-dehydration reagents and a sludge concentration and deep-dehydration method thereof. The sludge concentration reagent contains a concentration reagent A, a concentration reagent B and a concentration reagent C, and the sludge deep-dehydration reagent contains a conversion and regulation reagent, a stabilized regulation reagent and a modified regulation reagent. The sludge concentration and deep-dehydration method comprises the following steps that (A) sludge is transported and concentrated; (B) sludge undergoes transportation and tubular reaction; (C) concentration and dehydration of the concentrated sludge is performed; (D) transportation and stirring of the concentrated sludge is performed; (E) sludge transportation and regulation reaction are performed; (F) the regulated sludge undergoes transportation and filter-pressing dehydration; (G) finally, dry dehydrated sludge is transported to a dry sludge warehouse. The sludge concentration and deep-dehydration reagents at least have the advantages that the moisture in sludge is further removed under normal-temperature low-pressure conditions, the moisture content of the dry dehydrated sludge is 40-46%, the operation costs are low, the energy consumption is low, and investments are saved.

Owner:绍兴泰谱环保科技有限公司

Sludge dewatering method and dewaterer

ActiveCN111762999AAchieve deep dehydrationSolve the problem of deep dewatering of sludgeSludge treatment by de-watering/drying/thickeningSludge processingCapillary TubingSewage

The invention provides a sludge dewatering method. Electric energy is converted into shock waves to act on the deep part of the sludge through electric explosion of metal wires, so that deep dewatering of the sludge is realized, and the problem that it is difficult for the existing sludge dewatering equipment to perform deep dewatering on the sludge is solved. The invention provides a sewage dewaterer. Shock waves are generated through electric explosion of the metal wires, the energy conversion efficiency is very high, the shock waves can act on tiny particles and capillary tubes in sludge, so that deep dewatering of the sludge can be achieved. The structure is simple, the implementation is convenient, continuous discharge can be implemented by supplementing metal wires, shock waves are enabled to continuously act on the deep position of the sludge, the dewatering effect is good, and the sludge dewatering rate can be increased by 10% or above.

Owner:西安闪光能源科技有限公司

Sludge concentration dehydrating agent and preparation method thereof

The invention discloses a sludge concentration dehydrating agent and a preparation method thereof, and belonging to the technical field of sludge treatment. The preparation method comprises the following steps of: modifying crop straw and wood powder, mixing cyclodextrin and diatomite with the modified crop straw and wood powder, adding water, boiling in boiling water for 10-15 min, extracting, collecting an extracted solid product, adding humic acid and volcanic rocks, magnetically stirring for 15-20 min, adding gelatin, heating, evaporating to obtain the sludge concentration dehydrating agent. The dosage of the sludge concentration dehydrating agent is only 0.02-0.03%, the deep dehydration of sludge can be realized while the sludge dehydration time is reduced, one ton of sludge with a water content of 60-99% can be directly dehydrated within 30 minutes to the water content reaching 20-35%, and the subsequent treatment of the sludge can be greatly facilitated.

Owner:JILIN JIANZHU UNIVERSITY

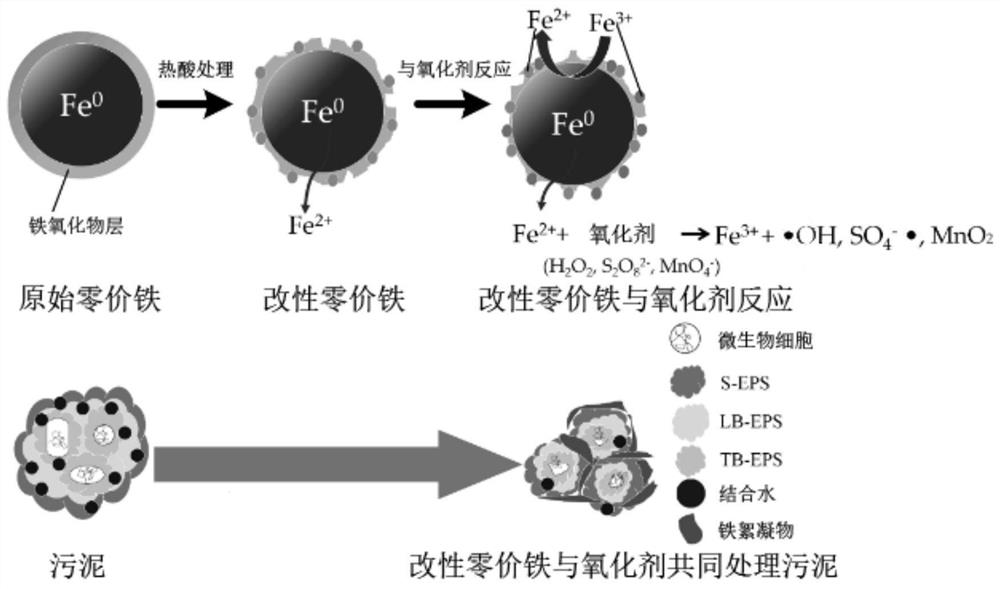

Sludge dewatering method

PendingCN113896402AImprove dehydration effectImprove dehydration efficiencySludge treatment by oxidationWater treatment compoundsZerovalent ironOxidizing agent

The invention belongs to the technical field of sludge treatment, and particularly relates to a sludge dewatering method. The original zero-valent iron and the acid solution are mixed and heated, so that the dehydration performance of the sludge can be improved, the sludge dehydration efficiency of the zero-valent iron and the oxidant can be improved, and deep dehydration of the sludge can be realized.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿

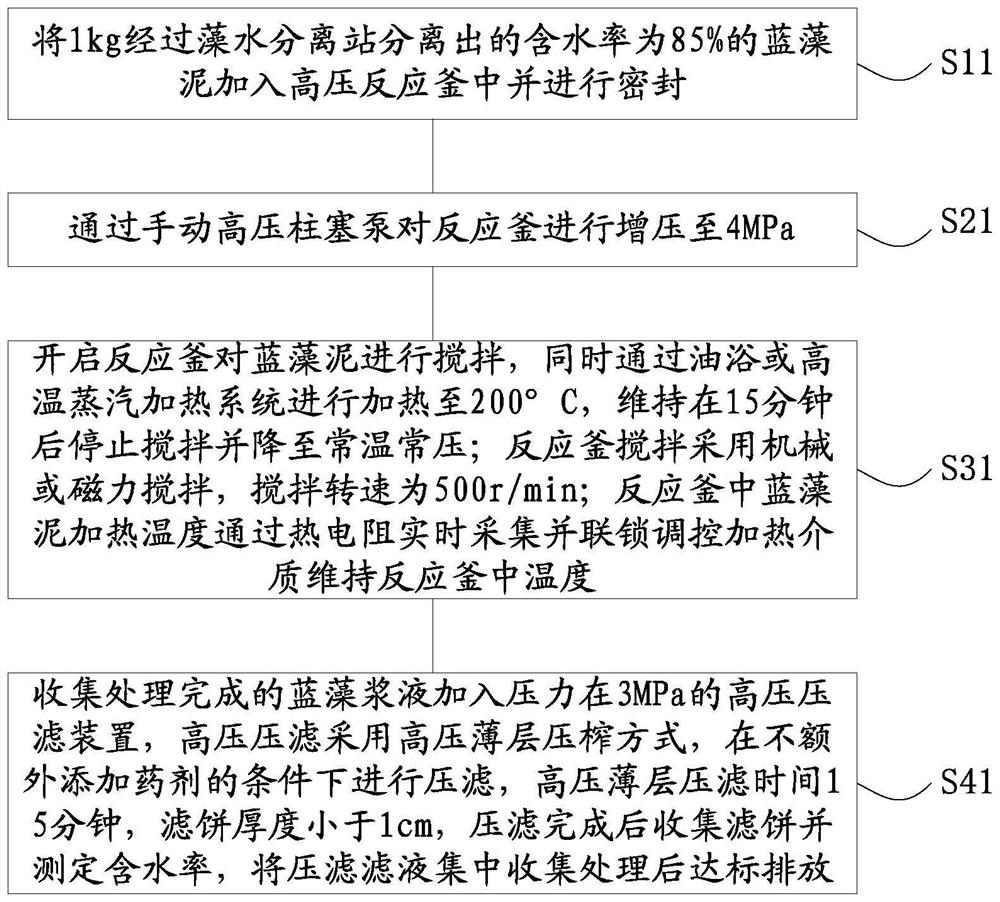

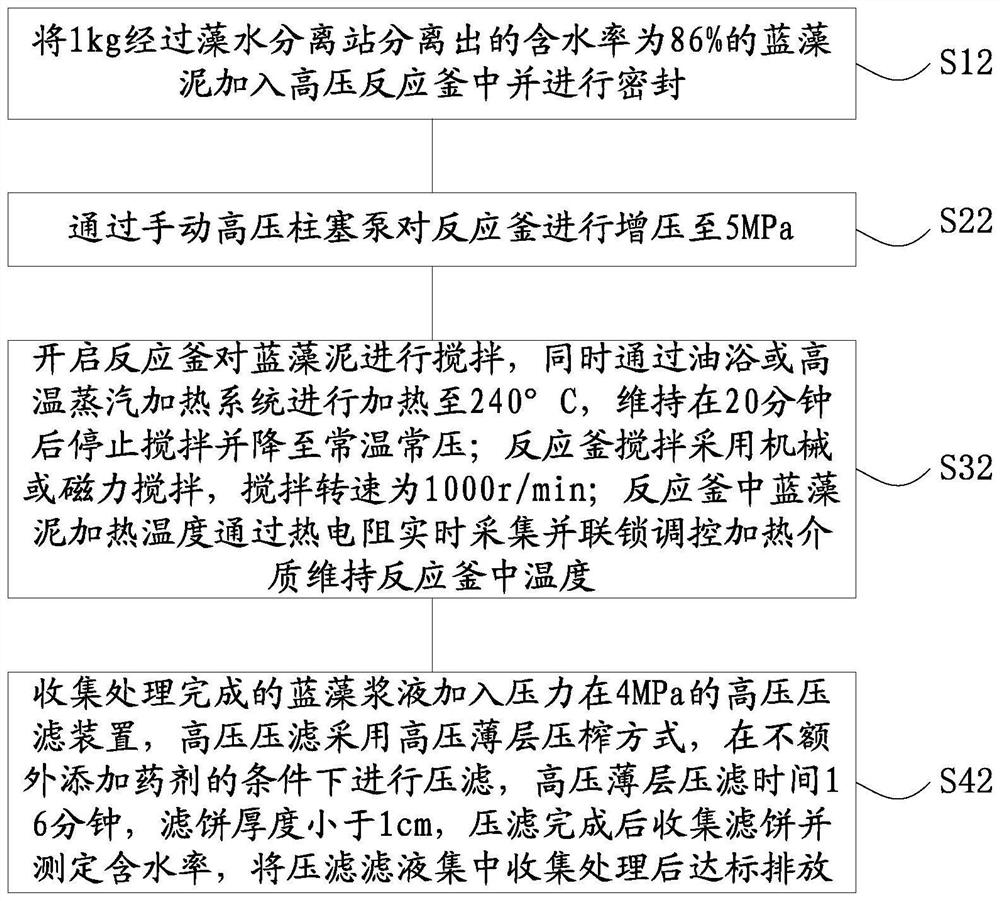

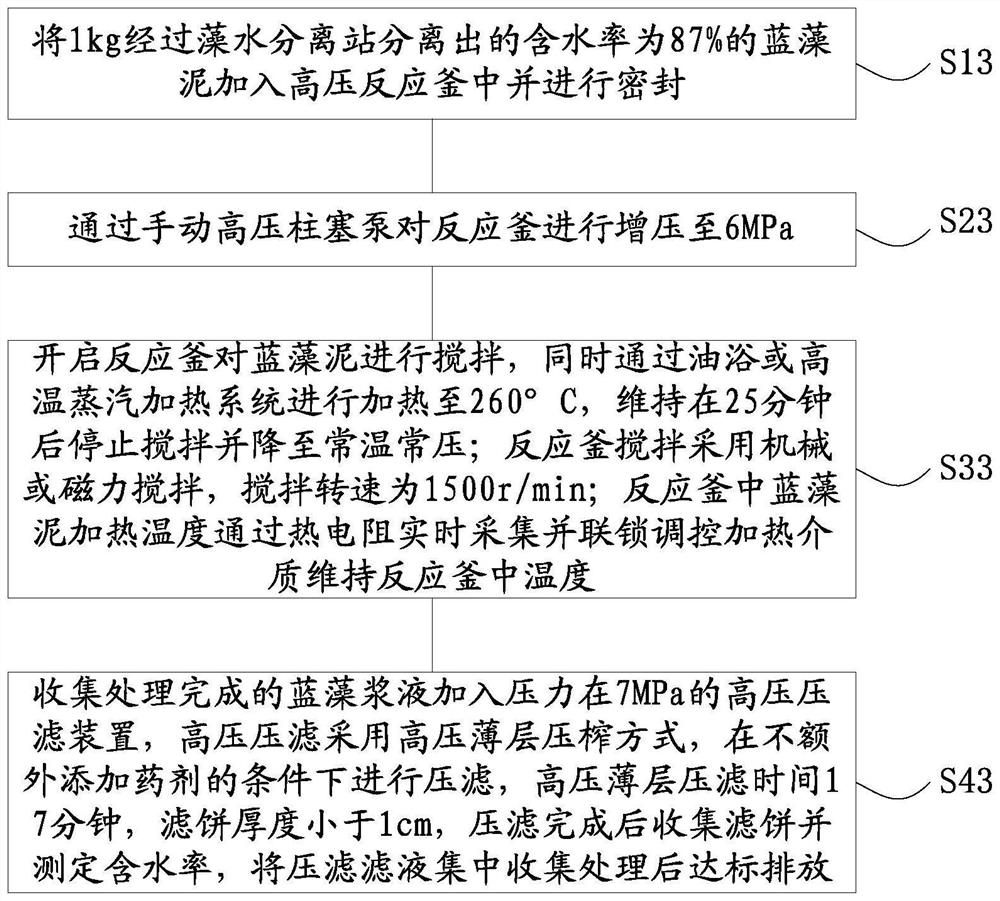

Deep dehydration method for blue-green algae

PendingCN114262140AAchieve deep dehydrationRealize resource utilizationSludge treatment by de-watering/drying/thickeningCarbon preparation/purificationEnvironmental engineeringGreen algae

The invention provides a deep dehydration method for blue-green algae, which comprises the following steps: adding blue-green algae mud separated by an algae-water separation station into a high-pressure reaction kettle, and sealing; pressurizing the reaction kettle through a manual high-pressure plunger pump; starting the reaction kettle to stir the blue-green algae mud, heating through an oil bath or a high-temperature steam heating system, maintaining for a period of preset time, stopping stirring, and cooling to normal temperature and normal pressure; and collecting the treated blue-green algae slurry, adding the collected blue-green algae slurry into a high-pressure filter pressing device, and carrying out filter pressing under the condition of not adding extra chemicals, so as to obtain a blue-green algae mud filter cake with the water content of 40-50%. The method disclosed by the invention has the beneficial effects that the problems of environmental pollution, insufficient reduction and resource utilization and the like caused by high water content, easiness in rancidity and deterioration due to long-term stacking of the blue-green algae mud separated by an algae-water separation station are solved, and the reduction and resource utilization of the blue-green algae are really realized.

Owner:华润环保发展有限公司

A kind of sludge dehydration composite conditioner and application method thereof

ActiveCN102381828BAchieve deep dehydrationShorten spin timeSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationFenton reagentSlurry

The invention provides a composite conditioner for sludge dehydration and an application method thereof. The composite conditioner for sludge dehydration comprises Fenton reagent or / and Fenton-like reagent and skeleton construct, the weight ratio of Fenton reagent or / and Fenton-like reagent to skeleton construct is 1:0.05~300; skeleton construct For powder. Its application method includes the steps of: adding Fenton reagent or / and Fenton-like reagent to the sludge slurry, stirring and mixing, and performing oxidation reaction; adding Fenton reagent or / and Fenton-like reagent to the sludge Add the backbone construct to the slurry and stir to mix. The sludge dehydration composite conditioner of the present invention can effectively destroy the extracellular polymer in the sludge through the synergistic effect of the Fenton reagent or / and the Fenton-like reagent and the skeleton structure of the powder, reduce the compressibility of the organic matter, and greatly reduce the compressibility of the organic matter. A composite conditioner for sludge dewatering that significantly improves sludge dewatering performance. The application method has simple procedures and easy control of conditions, shortens the dehydration time of sludge, and can realize large-scale treatment of sludge.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

Efficient reduction and harmlessness treatment method for sludge

InactiveCN110981157AImproves mechanical dehydration capacityImprove dehydration effectSludge treatmentDewatered sludgeToxic industrial waste

The invention discloses an efficient reduction and harmlessness treatment method for sludge, which comprises the following steps: stirring sludge and a conditioner R consisting of sludge incinerationash, industrial waste residues, an excitant and straw incineration ash to react to obtain pre-conditioned sludge; and adding a flocculating agent into the pre-conditioned sludge, carrying out hydrothermal reaction, and carrying out solid-liquid separation on a hydrothermal reaction product to obtain dry sludge. The efficient reduction and harmlessness treatment method is good in dewatering effect, the content of heavy metal in the dewatered sludge is low, harmlessness and reduction of the sludge are achieved, and secondary pollution is reduced.

Owner:肇庆市武大环境技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com