Deep dewatering method and power generation recycling method of blue algae

A deep dewatering and energy-based technology, applied in chemical instruments and methods, dewatering/drying/concentrating sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of high moisture content and complex products, and achieve market prospects Good and energy-efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

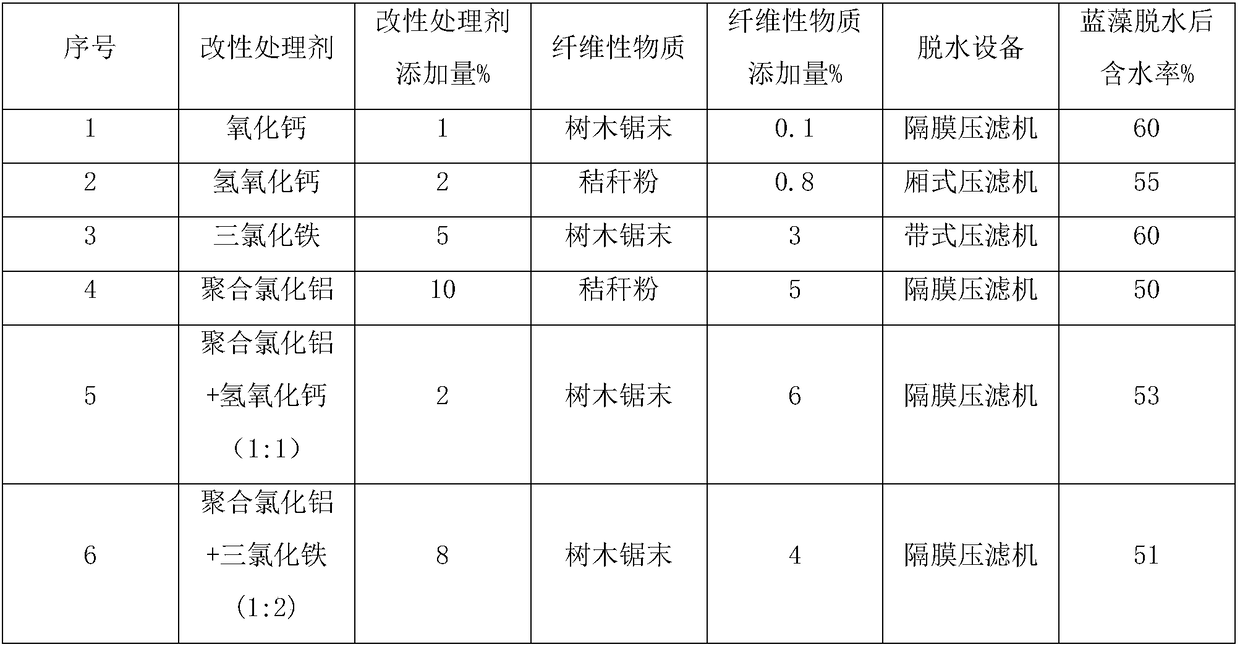

[0032] The cyanobacteria deep dehydration method of the present embodiment comprises:

[0033] The first step, modification treatment: add a modification treatment agent to the cyanobacteria pulp, and add fibrous substances; the modification treatment agent includes at least one of calcium oxide, calcium hydroxide, ferric chloride, and polyaluminum chloride; the cyanobacteria The water content of the pulp is greater than 60%, the added weight of the modified treatment agent accounts for 1-10% of the weight of the dry matter of the blue-green algae in the blue-green algae pulp, and the added weight of the fibrous substance accounts for 0.1-6% of the weight of the dry matter of the blue-green algae in the blue-green algae pulp; The active substance is plant fiber; the plant fiber is tree sawdust and / or straw powder.

[0034] The second step, dehydration treatment: the cyanobacteria pulp obtained in the first step of modification treatment is dehydrated by dehydration equipment. ...

Embodiment 2

[0040] The cyanobacteria deep dehydration method of the present embodiment comprises:

[0041] The first step, modification treatment: add a modification treatment agent to the cyanobacteria pulp, and add fibrous substances; the modification treatment agent is one of calcium oxide, calcium hydroxide, ferric chloride, polyaluminum chloride or Various; the water content of the cyanobacteria pulp is greater than 60% and less than 99.9%, the added weight of the modified treatment agent accounts for 1 to 10% of the dry matter weight of the cyanobacteria in the cyanobacteria pulp, and the added weight of the fibrous substance accounts for 1% to 10% of the dry cyanobacteria in the cyanobacteria pulp. 0.1-6% by weight of the substance; the fibrous substance is plant fiber; the plant fiber is tree sawdust and / or straw powder.

[0042] The second step, dehydration treatment: the cyanobacteria pulp obtained in the first step of modification treatment is dehydrated by dehydration equipmen...

Embodiment 3

[0046] The cyanobacteria power generation energy conversion method of the present embodiment comprises:

[0047] (1) adopt the deep dehydration method of cyanobacteria of embodiment 1 to process cyanobacteria slurry, and obtain cyanobacteria cake;

[0048] (2) adding the blue-green algae cake into the incinerated matter, and then incinerating to generate electricity; the added weight of the blue-green algae cake accounts for 10-50% of the weight of the incinerated matter.

[0049] Among them, the incineration includes coal and / or household waste. Garbage incinerators are used for incineration for power generation; when incineration for power generation, the excess air is controlled by 30-100%, and the temperature is controlled at 600°C-700°C.

[0050] In this embodiment, the deeply dehydrated cyanobacteria can be used for incineration to generate electricity, thereby realizing the energy generation of cyanobacteria.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com