Deep dehydration method for blue-green algae

A technology of deep dehydration and cyanobacteria, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of reduction and resource utilization, environmental pollution, easy Problems such as rancidity and deterioration, to achieve the effect of reduction and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

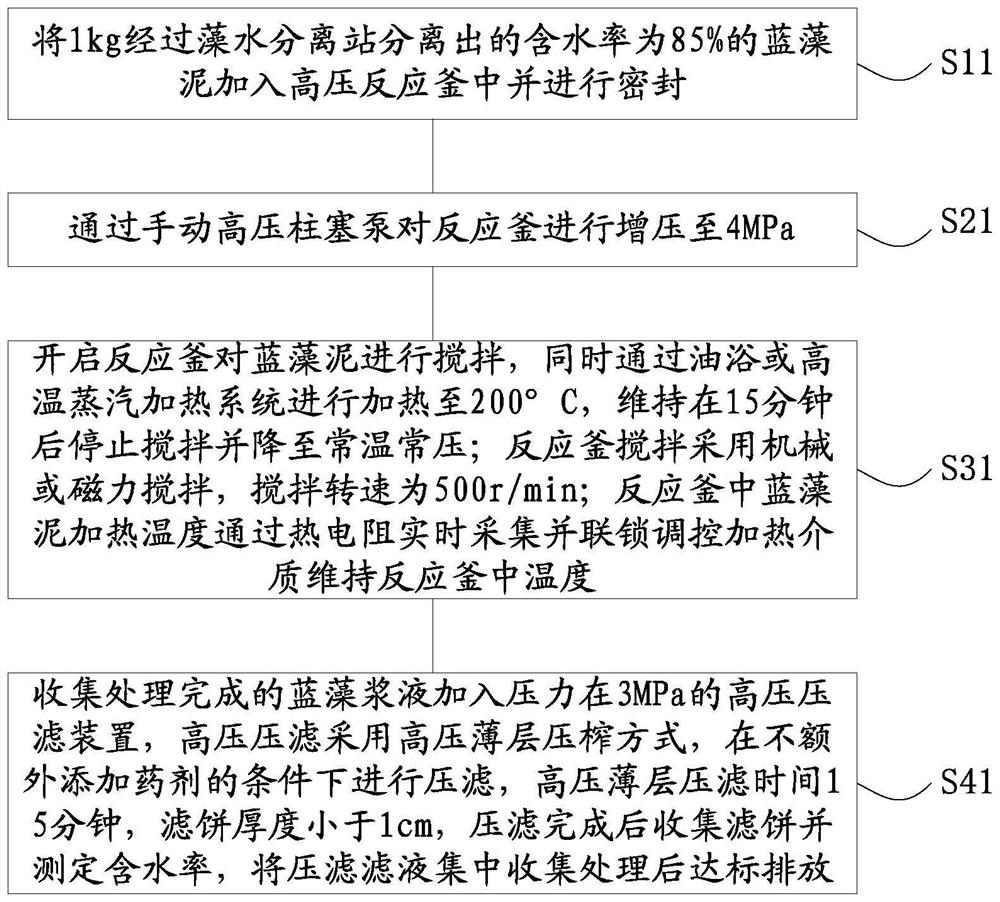

[0030] Such as figure 1 Shown, a kind of cyanobacteria depth dehydration method comprises steps,

[0031] S11, adding 1 kg of cyanobacteria mud with a moisture content of 85% separated by the algal water separation station into the high-pressure reactor and sealing it;

[0032] S21, the reactor is pressurized to 4MPa by a manual high-pressure plunger pump;

[0033] S31. Open the reaction kettle to stir the cyanobacteria mud, and at the same time, heat it to 200°C through an oil bath or high-temperature steam heating system, stop stirring after maintaining it for 15 minutes and lower it to normal temperature and pressure; the reaction kettle is stirred by mechanical or magnetic stirring, stirring The rotation speed is 500r / min; the heating temperature of the blue-green algae mud in the reaction kettle is collected in real time through the thermal resistance and interlocked to regulate the heating medium to maintain the temperature in the reaction kettle.

[0034] S41. The cya...

Embodiment 2

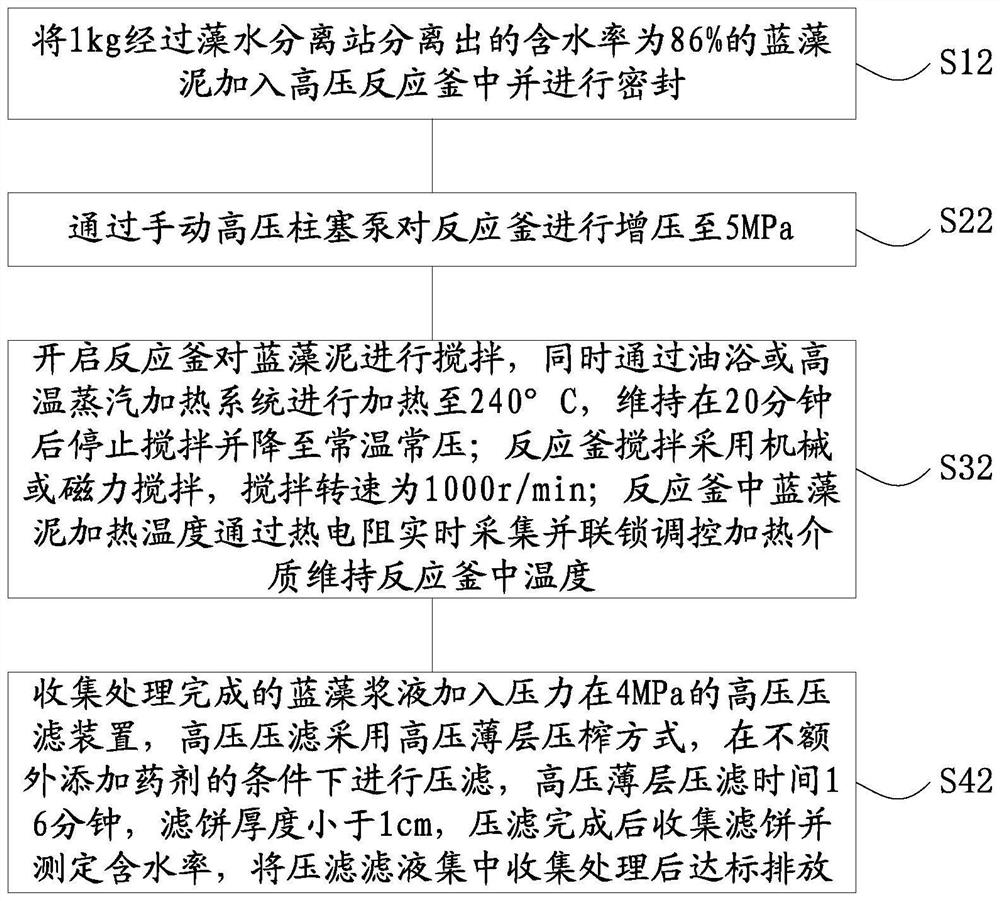

[0036] Such as figure 2 Shown, a kind of cyanobacteria depth dehydration method comprises steps,

[0037] S12, adding 1 kg of blue-green algae mud with a moisture content of 86% separated by the algae-water separation station into the autoclave and sealing it;

[0038] S22, the reactor is pressurized to 5MPa by a manual high-pressure plunger pump;

[0039] S32. Turn on the reactor to stir the cyanobacteria mud, and at the same time, heat it to 240°C through an oil bath or high-temperature steam heating system, stop stirring after maintaining it for 20 minutes and lower it to normal temperature and pressure; the reactor is stirred by mechanical or magnetic stirring, stirring The rotation speed is 1000r / min; the heating temperature of the cyanobacteria mud in the reactor is collected in real time through the thermal resistance and interlocked to regulate the heating medium to maintain the temperature in the reactor.

[0040] S42. The cyanobacteria slurry that has been collect...

Embodiment 3

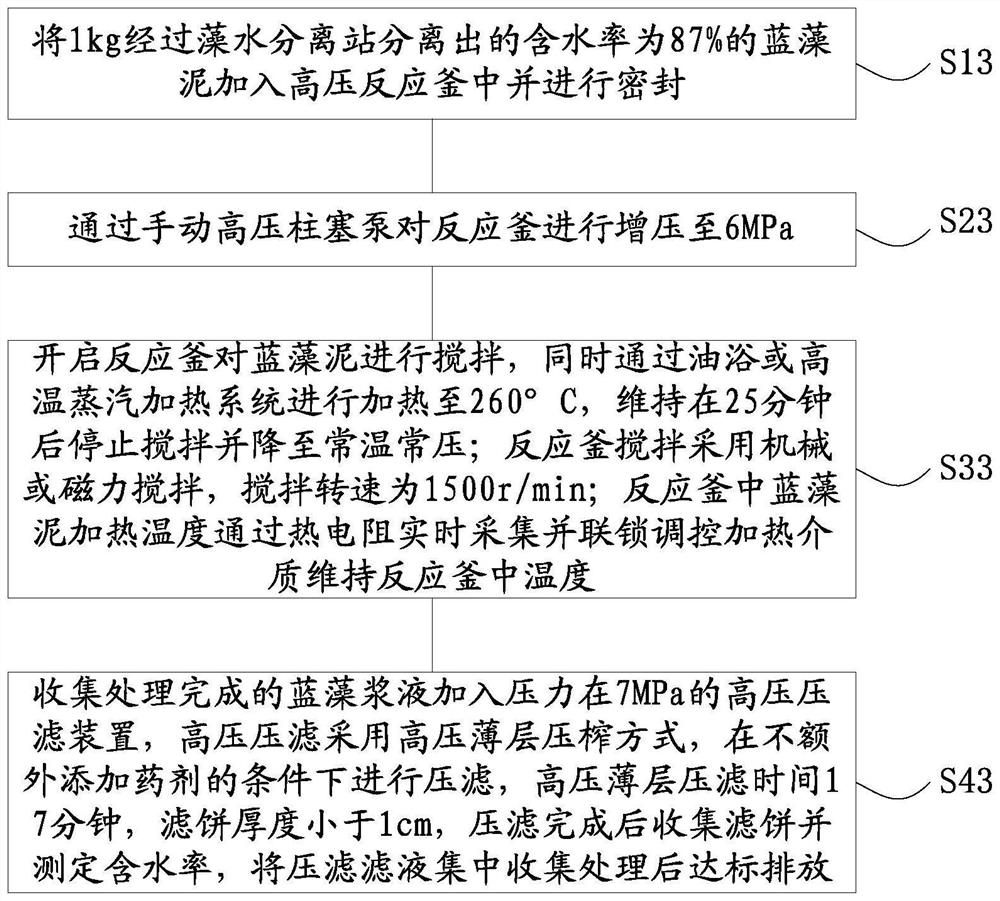

[0042] Such as image 3 Shown, a kind of cyanobacteria depth dehydration method comprises steps,

[0043] S13, adding 1 kg of blue-green algae mud with a water content of 87% separated by the algae-water separation station into the high-pressure reactor and sealing it;

[0044] S23, the reactor is pressurized to 6MPa by a manual high-pressure plunger pump;

[0045] S33. Turn on the reactor to stir the cyanobacteria mud, and at the same time, heat it to 260°C through an oil bath or a high-temperature steam heating system, stop stirring after 25 minutes and lower it to normal temperature and pressure; the reactor is stirred by mechanical or magnetic stirring, stirring The rotation speed is 1500r / min; the heating temperature of the cyanobacteria mud in the reactor is collected in real time through the thermal resistance and interlocked to regulate the heating medium to maintain the temperature in the reactor.

[0046]S43. The cyanobacteria slurry that has been collected and pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com