Sludge dewatering method and dewaterer

A sludge dehydrator and sludge dehydration technology, which are applied in sludge treatment, dehydration/drying/concentrated sludge treatment, etc., to achieve the effect of good dehydration effect, simple structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

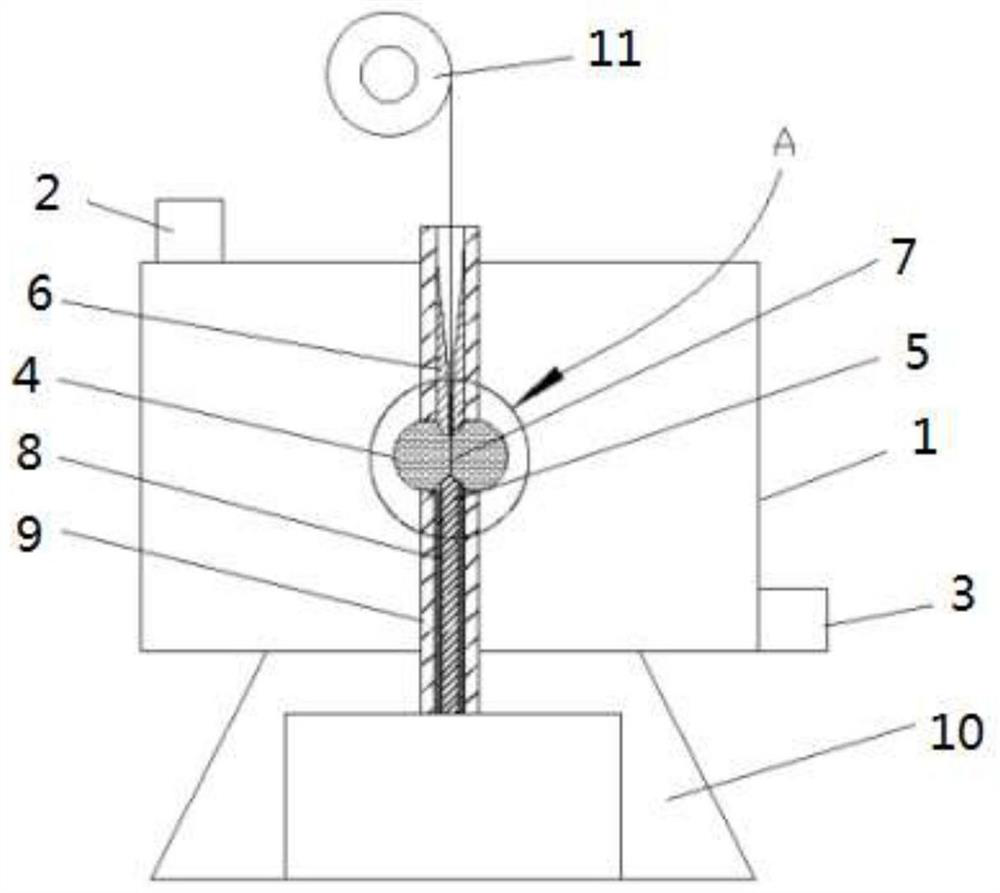

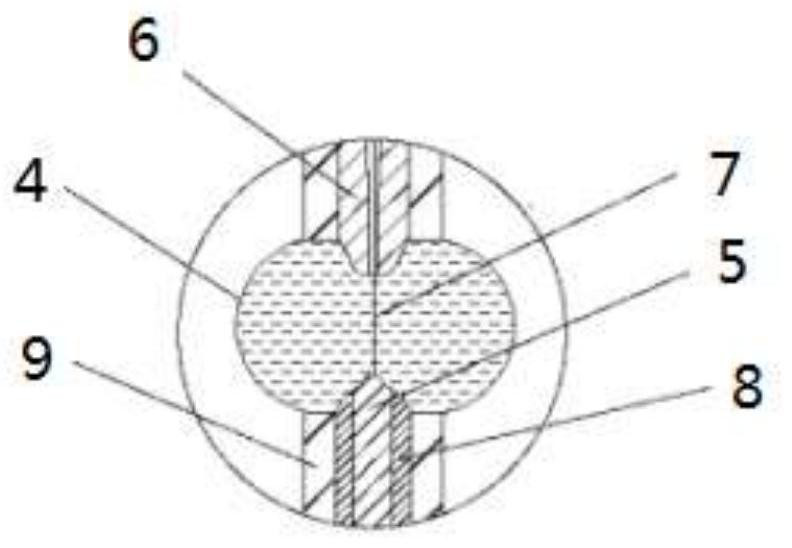

[0031] A sludge dehydrator, see figure 1 and figure 2 , including a sludge chamber 1, a pulse power drive source 10, and an energy converter. The energy converter includes a casing 9 and a high-voltage electrode 5 and a ground electrode 6 that are oppositely arranged in the casing 9. A metal The wire 7, the high voltage electrode 5 are supported on the casing 9 through the high voltage insulator 8, the ground electrode 6 is connected to the casing 9 through the ground electrode support seat, the casing 9 is located at the gap between the high voltage electrode 5 and the ground electrode 6, and the gap is used as a shock wave output window and passed through The holster 4 is sealed, and the holster 4 is filled with pure water to form a water bag; the lower end and the upper end of the shell 9 protrude from the sludge chamber 1 respectively. The upper end of the sludge chamber 1 is provided with a wire storage tray 11. The upper end of the metal wire 7 passes through the groun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com