Lossless drying method for natural gas and circulation reaction gas in production of chloromethane with methane method

A technology of cyclic reaction and drying method, which is applied in separation methods, chemical instruments and methods, gas fuels, etc., and can solve problems such as no treatment plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

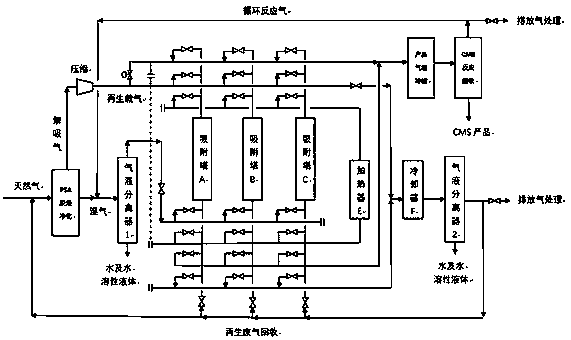

[0043] Such as figure 1 As shown, a non-destructive drying method for natural gas and circulating reaction gas in the methane process for producing chloromethane comprises the following steps:

[0044] (1) Gas-liquid separator 1, which comes from the dehydrogenated natural gas required for the methane chlorination reaction and the circulating reaction gas formed by the methane chlorination reaction, with a temperature of 20~40°C and a pressure of 0.8~1.0MPa, Enter the gas-liquid separator 1, a small amount of water and water-soluble liquid flow out from the bottom, and the gas flows out from the top as raw material gas, hereinafter referred to as "moisture", its water content is 500~700ppm, water-soluble organic volatiles are about 200ppm, and nitrogen gas is 2.4 %(v), methane 97.6%(v), and the rest are trace amounts of carbon monoxide, carbon dioxide, oxygen, argon, helium, etc., with a flow rate of 6,560Nm3 / h, entering the subsequent process, that is, the adsorption step;

...

Embodiment 2

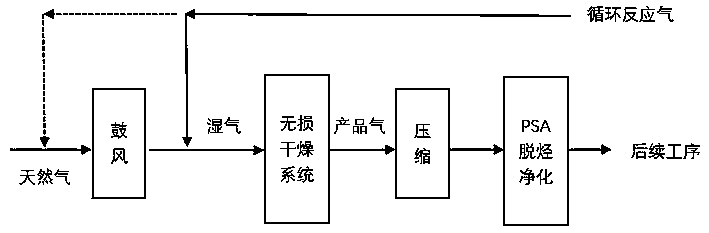

[0050] Based on Example 1, such as figure 2 As shown, the raw material gas directly comes from the natural gas required for the methane chlorination reaction, that is, the natural gas without dehydrogenation purification treatment, and the circulating reaction gas formed by the methane chlorination reaction, the pressure is less than 0.3MPa, no need to pressurize , directly transported by blower into the non-destructive drying system of the front-end natural gas and circulating reaction gas for circulation operation, the adsorption operation temperature of each adsorption tower in the system is 20~30°C, the adsorption operation pressure is less than 0.3MPa, and the thermal regeneration operation temperature The temperature is 200~220℃, the operating pressure is less than 0.3MPa, the cold regeneration operating temperature is 20~30℃, and the operating pressure is less than 0.3MPa; the dry gas flowing out of the non-destructive drying system has a water content of less than or e...

Embodiment 3

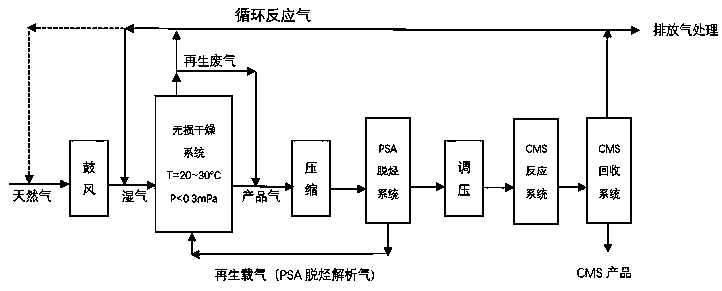

[0052] Based on Examples 1 and 2, such as image 3 As shown, the hot regeneration carrier gas (hot blowing gas) comes from the desorption gas of the natural gas PSA dehydrocarbon purification treatment after the non-destructive drying system, that is, the desorption gas of this process is heated to 200~220 by the heater E °C, it is used as the thermal regeneration carrier gas to perform thermal regeneration on the adsorption tower A after the adsorption step is completed. The regeneration waste gas is cooled to 20~30 °C by the cooler F and enters the gas-liquid separator 2 for gas-liquid separation. Water and water-soluble liquid The cooled gas flowing out from the top is returned to the subsequent natural gas to continue dehydrogenation purification treatment and methane recovery; after the thermal regeneration of the adsorption tower A is completed, the dry gas, that is, the product gas, is used as the cold regeneration carrier gas. The bottom of the adsorption tower A in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com