Sludge magnetic dewatering agent and dewatering method thereof

A dehydrating agent and magnetic technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high energy consumption, difficult to remove, difficult to operate, etc., to improve physical and mechanical properties, solve problems in treatment and disposal, and reduce dehydration time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

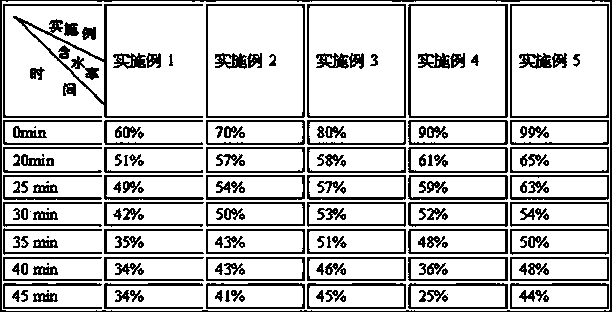

Embodiment 1

[0039] (1) Prepare 50Kg of the magnetic dehydrating agent, wherein the contents of each component of the magnetic dehydrating agent are as follows: acrylamide 4.5Kg, chitin 8.5Kg, ferric chloride 10.5Kg, sodium chloride 7.5Kg, aluminum chloride 7.5 Kg, concentrated sulfuric acid 4Kg, iron powder 7.5Kg, described concentrated sulfuric acid is placed separately, stand-by; Described acrylamide, chitin, ferric chloride, sodium chloride, aluminum chloride, iron powder are mixed by described weight After uniformity, pour into a beaker, add clear water to the beaker, the volume ratio of the added clear water to the mixture is: 1:1. The beaker is then heated in a boiling water bath until all the water has evaporated, the mixture is taken out and ground into powder;

[0040] (2) Take 1 ton of sludge to be treated with a water content of 60%, add the mixed and ground powder described in step (1) to the sludge, stir evenly, and then add the step ( 1) Concentrated sulfuric acid with the ...

Embodiment 2

[0044] (1) Prepare 60Kg of the magnetic dehydrating agent, wherein the contents of each component of the magnetic dehydrating agent are as follows: acrylamide 11.4Kg, chitin 4.2Kg, ferric chloride 8.4Kg, sodium chloride 10.2Kg, aluminum chloride 9Kg , concentrated sulfuric acid 0.6Kg, iron powder 16.2Kg, the concentrated sulfuric acid is placed separately, stand-by; The acrylamide, chitin, ferric chloride, sodium chloride, aluminum chloride, iron powder are mixed according to the stated weight After uniformity, pour into a beaker, add clear water to the beaker, the volume ratio of the added clear water to the mixture is: 1:1. The beaker is then heated in a boiling water bath until all the water has evaporated, the mixture is taken out and ground into powder;

[0045] (2) Take 1 ton of sludge to be treated with a water content of 70%, first add the mixed and ground powder described in step (1) to the sludge, stir evenly, and then add the step ( 1) Concentrated sulfuric acid wi...

Embodiment 3

[0049] (1) Prepare 80Kg of the magnetic dehydrating agent, wherein, the contents of each component of the magnetic dehydrating agent are as follows: 12Kg of acrylamide, 8Kg of chitin, 16Kg of ferric chloride, 12Kg of sodium chloride, 17.6Kg of aluminum chloride, concentrated sulfuric acid 4Kg, iron powder 10.4Kg, place the concentrated sulfuric acid separately, stand-by; Mix the acrylamide, chitin, ferric chloride, sodium chloride, aluminum chloride, iron powder according to the stated weight and then pour into A beaker, adding clear water to the beaker, the volume ratio of the added clear water to the mixture is: 1:1. The beaker is then heated in a boiling water bath until all the water has evaporated, the mixture is taken out and ground into powder;

[0050] (2) Take 1 ton of sludge to be treated with a water content of 80%, add the mixed and ground powder described in step (1) to the sludge, stir evenly, and then add the step ( 1) Concentrated sulfuric acid with the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com