Excess sludge deep dehydration conditioner

A deep dehydration and sludge dehydration technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of large dosage of sludge conditioner, corrosion of incineration equipment, lower calorific value, etc., and achieve resource utilization , the effect of wide source of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The test sludge was taken from Huilian Thermal Power Plant, the moisture content of the raw sludge was 84.67%, and the moisture content of the sludge was adjusted to 95% before the test. Add 30% rice husk + 0.3% PAM, 30% rice husk + 0.3% PAM + 5% FeCl of sludge dry solids 3 , 30% lime + 0.3% PAM + 5% FeCl 3 , PAM as a 0.1% solution, FeCl 3 as a 33% solution. After stirring and conditioning, press with a plate and frame filter press, wherein the feeding pressure is 0.5-0.8Mpa, the time is 25-30min, and the pressing pressure is 1.8Mpa, and the time is 40min. Adopt rice husk powder after passing through 30 mesh sieves. The main test indicators are sludge moisture content, organic matter content and calorific value, and the results are shown in Table 1.

[0036] Table 1 Results of dehydration experiment of rice husk powder

[0037]

[0038] It can be seen from Table 1 that adding 30% rice husk + 0.3% PAM and 30% rice husk + 0.3% PAM + 5% FeCl 3 After conditioning, ...

Embodiment 2

[0041] The present invention compares the effects of rice husk powder and lime on the dry basis calorific value of sludge. It was found that with the increase of CaO dosage, the sludge wall was broken under the action of high temperature and high pH, a large amount of organic matter was transferred to the liquid phase, and its calorific value decreased accordingly. When the dosage was 60%, It is only 1600kJ / kg, a decrease of 36%, indicating that although the use of CaO can reduce the water content, it is not suitable to use CaO for dehydration. However, when rice husk powder is added, the calorific value of sludge gradually increases. On the one hand, because rice husk powder is organic matter, adding it will increase the calorific value; on the other hand, it is because rice husk powder only acts as a skeleton structure , will not destroy the microbial cell structure of the sludge, making it easy to incinerate.

[0042]In addition, the impact of rice husk and lime on the u...

Embodiment 3

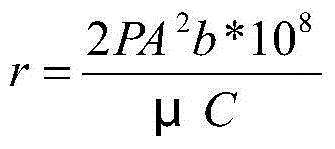

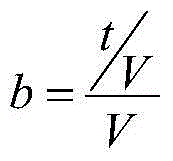

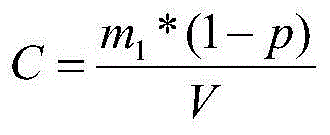

[0044] Get sludge (water content 95%) in conditioning cup, add the rice husk (crossing 60 mesh sieves) that the quality is 20% of sludge dry solids, conditioning cup is placed on the blender, first quick stirring (300r / min) for 5 min, then stir slowly (50r / min) for 20 min. After the conditioned sludge was evenly stirred with a glass rod, it was subjected to suction filtration, and various parameters of the sludge were measured after suction filtration. Each group of experiments was repeated twice to reduce errors. The results show that the sludge specific resistance is 2.9x10 13 m / kg, the moisture content of the filter cake is 82.3%, the organic matter content is 67.2%, and the calorific value is 2686kJ / kg. Under the same conditions, compared with the sludge conditioned by adding sawdust, the sludge conditioned by adding rice husk powder, the sludge specific resistance and filter cake water content decreased by 3.3% and 2.5% respectively, and the organic matter content and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com