Sludge resource utilization processing system and method

A treatment system and treatment method technology, applied in the field of environmental protection, can solve the problems of increased cost input, underutilized, less further research on semi-coke, etc., and achieve the effect of reducing treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

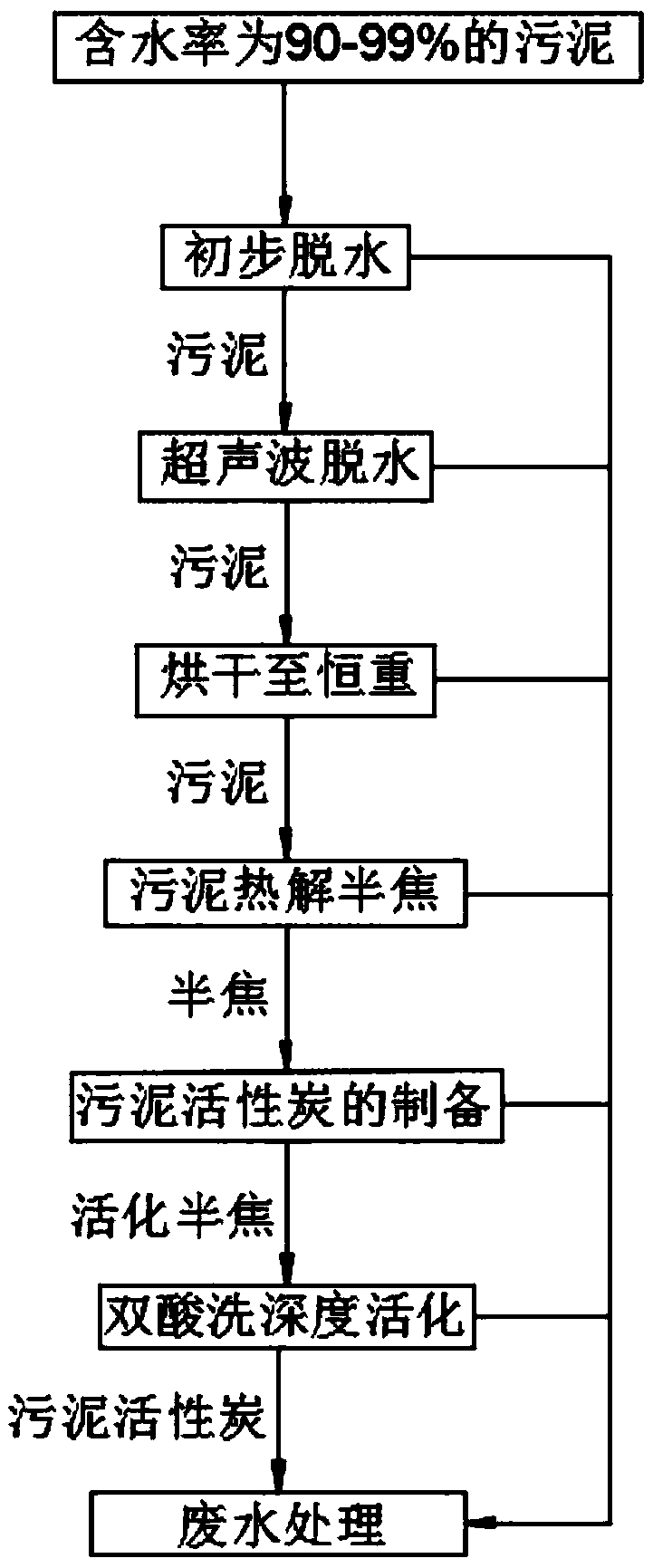

Method used

Image

Examples

Embodiment 1

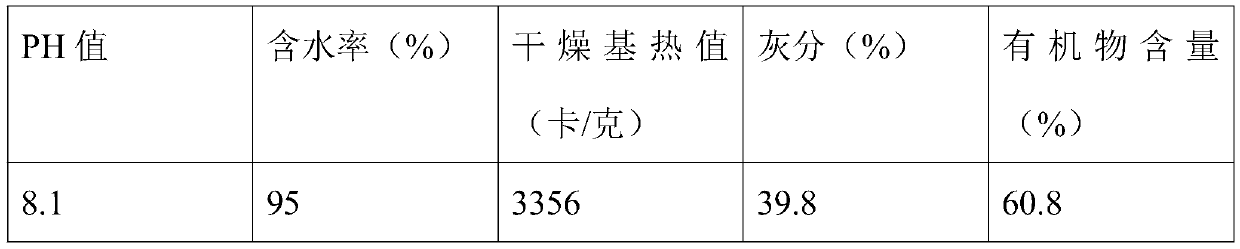

[0071] Step 1. Preliminary dehydration: first pump the sludge with a moisture content of 90%-99% into the sludge conditioning tank, and add ferric chloride while stirring, preferably in a liquid state, and the dosage is 10% of the mass of the sludge, after 25 minutes of reaction, add polymeric organic flocculant polyacrylamide (PAM) for a further 20 minutes of reaction, PAM is 5% of the total mass of the sludge, to destroy the floc structure in the sludge, conditioning The final sludge is sequentially pumped into the mixing equipment and tableting equipment, and pressed into cakes in the tableting equipment;

[0072] Step 2. Ultrasonic dehydration: send the cake-like sludge in the above step 1 to the ultrasonic treatment device through the conveyor belt. The sludge after ultrasonic treatment is further dehydrated by the dehydration equipment, and the dewatered wastewater is discharged into the sewage treatment tank. The dehydrated sewage Mud enters the later stage of resource ...

Embodiment 2

[0079] Ultrasonic dehydration: the ultrasonic frequency of the ultrasonic treatment device is 80kHz, the ultrasonic sound energy density is controlled at 0.5w / g, and the processing time of the ultrasonic device is 15 minutes;

[0080] Sludge pyrolysis semi-coke: first, heat the pyrolysis furnace reactor to the set temperature, and set the final pyrolysis temperature to 600°C. When the pyrolysis furnace reaches the set temperature, the sludge treated in step 3 is fed through a screw, and the residence time of the sludge in the pyrolysis furnace is 50 minutes respectively to obtain pyrolysis gas and sludge pyrolysis carbon;

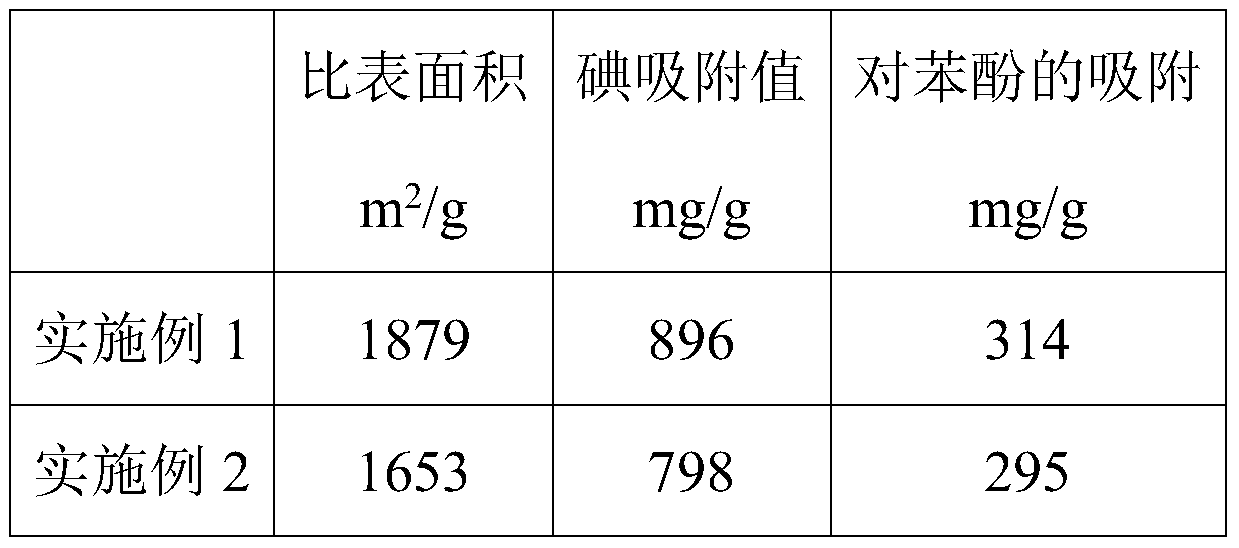

[0081] The sludge concentration after the step 4 treatment is 10mol / L ZnCl 2 Impregnate according to the mass ratio of 2:1, filter after impregnating for 15 hours, put the filtered sludge semi-coke into an oven at 105°C, dry to constant weight, and then perform anaerobic activation in a high-temperature reaction kettle, the activation temperature is respect...

Embodiment 3

[0085] Preliminary dehydration: first pump the sludge with a moisture content of 90%-99% into the sludge conditioning tank, and add quicklime while stirring, and the adding method can be solid or liquid;

[0086] Ultrasonic dehydration: the ultrasonic frequency of the ultrasonic treatment device is 20KHz, the ultrasonic sound energy density is controlled at 1.0w / g, and the processing time of the ultrasonic device is 20 minutes;

[0087] Sludge pyrolysis semi-coke: first, heat the pyrolysis furnace reactor to the set temperature, and set the final pyrolysis temperature to 400°C. When the pyrolysis furnace reaches the set temperature, the sludge treated in step 3 is fed through a screw, and the residence time of the sludge in the pyrolysis furnace is 1 hour respectively to obtain pyrolysis gas and sludge pyrolysis carbon;

[0088] The sludge concentration after described step 4 treatment is the ZnCl of 4mol / L 2 Impregnate according to the mass ratio of 2:1, filter after impregn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com