River sludge treatment method and device

A treatment method and river sludge technology, applied in the field of environmental engineering, can solve the problems of high operating cost, secondary pollution of the atmosphere, difficult treatment, etc., and achieve the effects of simple and reliable treatment process, improved vacuum filter drying, and improved dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

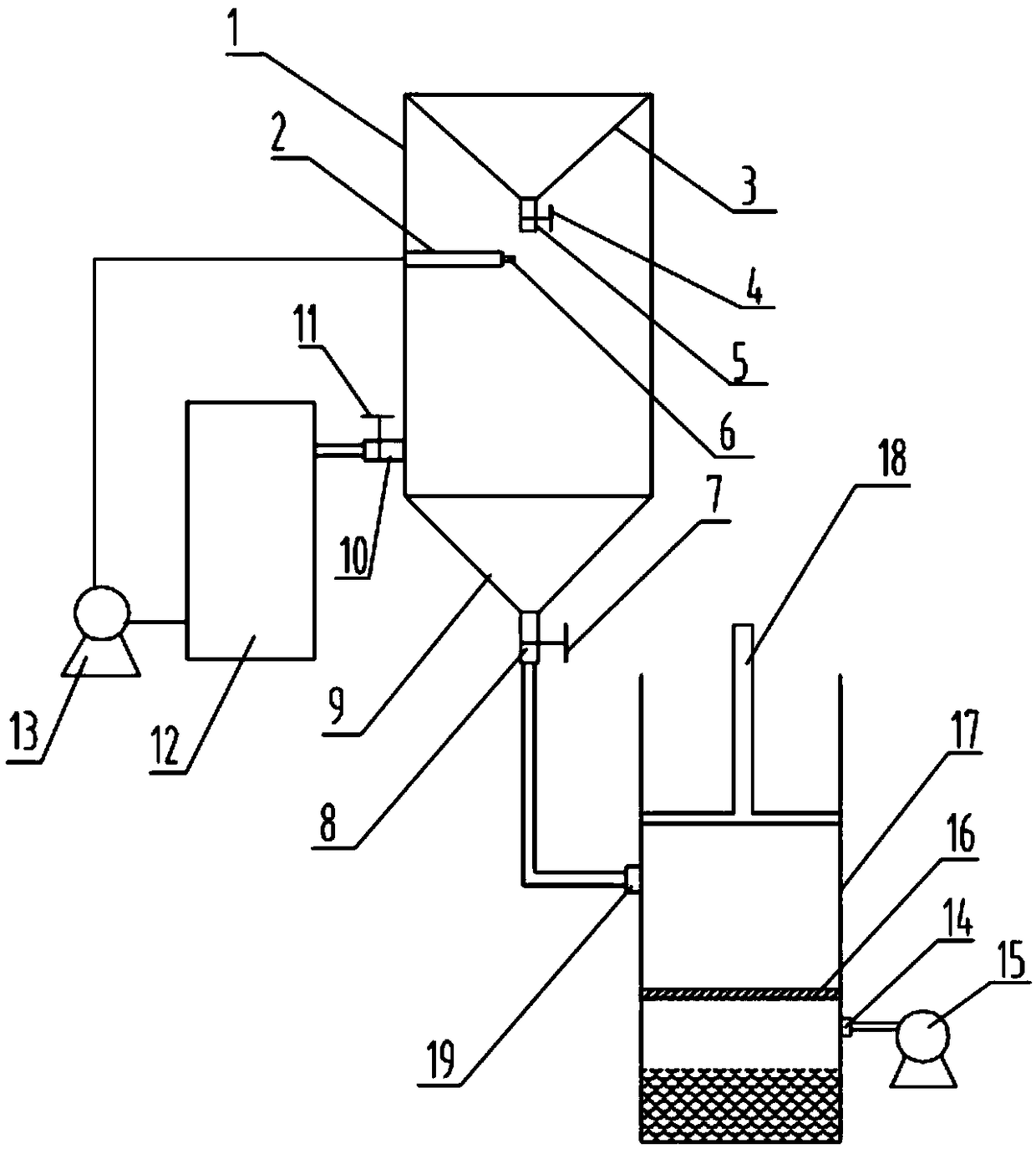

[0025] A set of devices is connected, comprising a reaction tank (1), a mechanical dehydration device (17), a vacuum pump (15), the top and the bottom of the reaction tank (1) are respectively provided with an inlet hopper (3) and an outlet hopper (9), A feed inlet (5) with a feed valve (4) is provided below the feed hopper (3), and a feed outlet (8) with a discharge valve (7) is provided below the discharge hopper (9). ), a high-pressure injection device (2) with a high-pressure spray nozzle (6) is provided below the feed inlet (5) inside the reaction tank (1), and the reaction tank (1) side discharge hopper (9) above A liquid outlet (10) with a valve (11) is provided, and the liquid outlet (10) is connected to the circulating water tank (12) and the water pump (13) in sequence through pipelines, and the water pump (13) is connected to the high-pressure injection device (2) link to each other; described mechanical dehydrator (17) middle position is provided with filter plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com