Sludge dewatering flocculating agent and dewatering method thereof

A sludge dehydration and flocculant technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of long dehydration cycle, low dehydration rate, large dosage, etc., and achieve low price, cost saving and operation cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

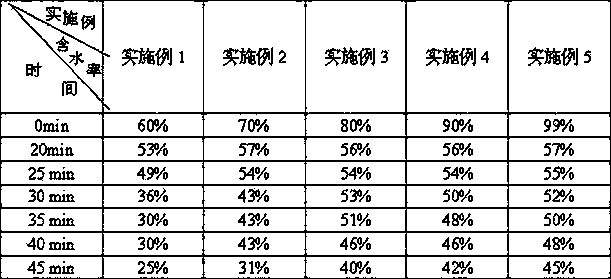

Embodiment 1

[0033] (1) Prepare 50Kg of the sludge dewatering flocculant, wherein the contents of each component of the flocculant are as follows: 2.5Kg of alumina, 9Kg of chitin, 12.5Kg of silica, 12Kg of acrylamide, 7.5Kg of sodium chloride, Concentrated sulfuric acid 6.5Kg, the alumina, chitin, silicon dioxide, acrylamide, sodium chloride are mixed uniformly according to the weight and then ground into powder, stand-by, the concentrated sulfuric acid is placed separately, stand-by;

[0034] (2) Take 1 ton of sludge to be treated with a moisture content of 60%, add the ground powder described in step (1) to the sludge, stir evenly, and then add the sludge in step (1) to the sludge The concentrated sulfuric acid of described weight, continue to stir evenly, obtain the sludge that conditioning is good;

[0035] (3) Let the conditioned sludge in step (2) stand for 25 to 45 minutes. After standing, the sludge and water will separate, and the sludge will settle at the bottom, and the clearer ...

Embodiment 2

[0037](1) Prepare 80Kg of the sludge dewatering flocculant, wherein the contents of each component of the flocculant are as follows: 21.6Kg of alumina, 3.2Kg of chitin, 20Kg of silica, 19.2Kg of acrylamide, and 14.4Kg of sodium chloride , 1.6Kg of concentrated sulfuric acid, mix the alumina, chitin, silicon dioxide, acrylamide, and sodium chloride uniformly according to the weight and grind them into powder for use, place the concentrated sulfuric acid separately for use ;

[0038] (2) Take 1 ton of sludge to be treated with a water content of 70%, add the ground powder described in step (1) to the sludge, stir evenly, and then add the sludge in step (1) to the sludge The concentrated sulfuric acid of described weight, continue to stir evenly, obtain the sludge that conditioning is good;

[0039] (3) Let the conditioned sludge in step (2) stand for 25 to 45 minutes. After standing, the sludge and water will separate, and the sludge will settle at the bottom, and the clearer w...

Embodiment 3

[0041] (1) Prepare 100Kg of the sludge dewatering flocculant, wherein the contents of each component of the flocculant are as follows: 25Kg of alumina, 18Kg of chitin, 13Kg of silicon dioxide, 24Kg of acrylamide, 10Kg of sodium chloride, and 10Kg of concentrated sulfuric acid , mixing the alumina, chitin, silicon dioxide, acrylamide, and sodium chloride uniformly according to the weight and then grinding them into powder for use, placing the concentrated sulfuric acid separately for use;

[0042] (2) Take 1 ton of sludge to be treated with a water content of 80%, add the ground powder described in step (1) to the sludge, stir evenly, and then add the sludge in step (1) to the sludge The concentrated sulfuric acid of described weight, continue to stir evenly, obtain the sludge that conditioning is good;

[0043] (3) Let the conditioned sludge in step (2) stand for 25 to 45 minutes. After standing, the sludge and water will separate, and the sludge will settle at the bottom, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com