Energy-saving sump oil dehydration device and treatment method thereof

The technology of a dehydration device and a treatment method is applied in the treatment of hydrocarbon oil, the treatment of only multi-stage series refining process, the petroleum industry, etc. Evaporation area, improving economic efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

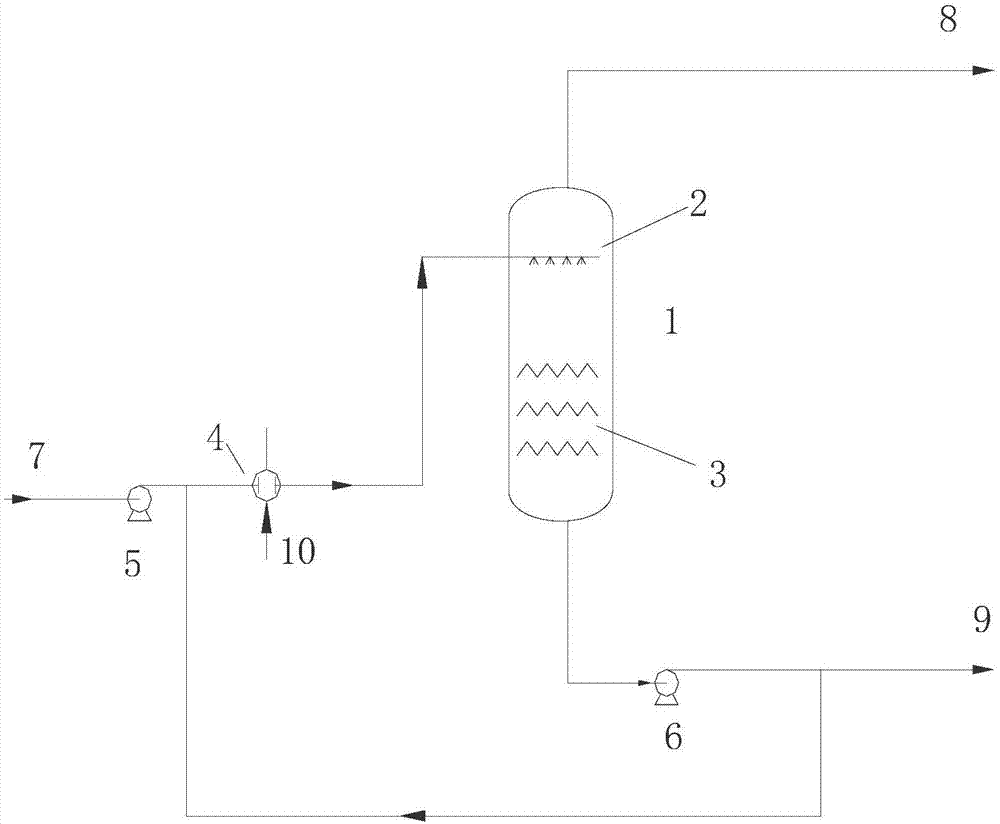

[0035] This embodiment provides an energy-saving waste oil dehydration device, such as figure 1As shown, the device includes a sewage oil dehydration tower 1, a sewage oil atomizer 2, a Venturi rod layer 3, a circulation heater 4, a sewage oil pump to be dehydrated 5 and a sewage oil circulation pump 6; wherein, the sewage oil pump to be dehydrated The inlet of 5 is connected to the sewage oil to be dehydrated 7 through a pipeline, the outlet of the sewage oil pump 5 to be dehydrated is connected to the cold flow inlet of the circulation heater 4, and the cold flow outlet of the circulation heater 4 is connected to the sewage oil dehydration tower 1, the heat flow inlet and outlet of the circulation heater 4 are connected with the heat source 10 of the circulation heater, the gas phase outlet of the waste oil dehydration tower 1 is connected with the oil gas pipeline 8 at the top of the fractionation tower, and the waste oil dehydration tower The liquid phase outlet of 1 is co...

Embodiment 2

[0041] This embodiment provides an energy-saving waste oil dehydration device. The device and its connection refer to Embodiment 1, the only difference is that the heat source 10 of the circulation heater is coked diesel oil in the refinery.

Embodiment 3

[0043] This embodiment provides a treatment method of an energy-saving waste oil dehydration device. The method is carried out using the device in Example 1. The specific treatment method includes the following steps:

[0044] (a) The waste oil to be dehydrated with a water content of 20% enters the waste oil atomizer 2 built into the waste oil dehydration tower 1 after being heated by the circulating heater 4 for atomization treatment, and the circulating heater 4 heats The temperature of the heat source 10 is 160°C;

[0045] (b) dehydrating the atomized waste oil obtained in step (a), the operating pressure is 0.1MPa, the operating temperature is 150°C, the obtained tower top product is subjected to fractionation treatment, and part of the obtained tower bottom waste oil is subjected to waste oil refining treatment , and another part returns to step (a) to mix with the waste oil to be dehydrated, and then enters the circulation heater 4 for heating.

[0046] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com