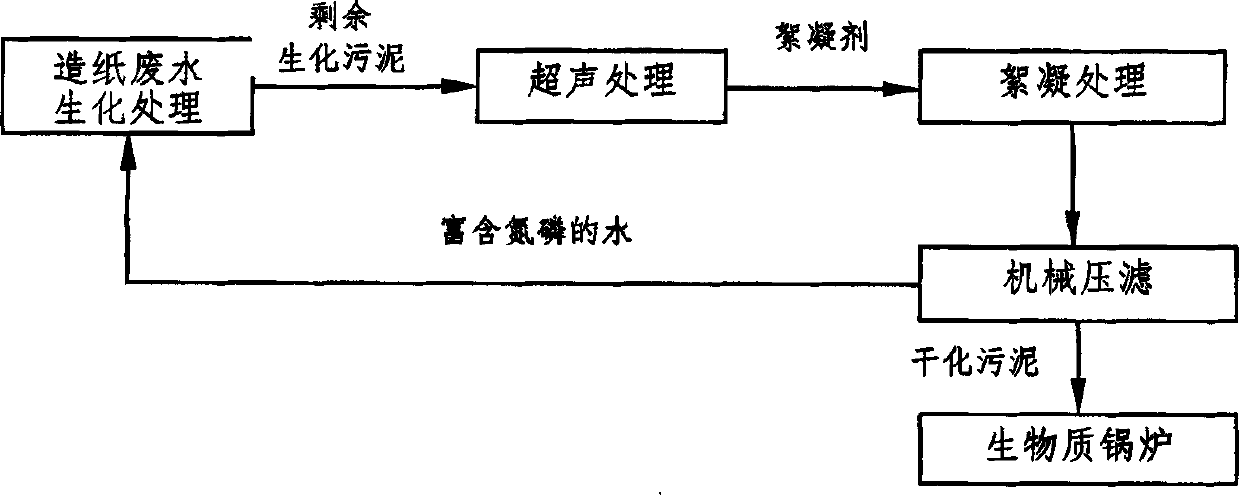

Method for extracting and recycling nitrogen and phosphorus in biochemical papermaking sludge and dehydrating sludge

A technology for biochemical sludge and sludge dewatering, which is applied in the direction of dewatering/drying/concentrating sludge treatment, and can solve the problems of difficult sludge deep dewatering, nitrogen and phosphorus release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The sludge is taken from a large comprehensive pulp and paper factory in Shandong with an area of 80,000 m 3 / d Secondary sedimentation tank of wastewater treatment project, from which nitrogen and phosphorus are extracted and reused and deep dehydration is realized through the following steps:

[0019] (1) Pretreatment of papermaking wastewater biochemical sludge

[0020] Take 150ml of papermaking wastewater to treat biochemical sludge, put the power of the ultrasonic transducer head at 400w, and the ultrasonic frequency at 20kHz, and insert it into the sludge for 10s to treat the biochemical sludge under the mechanical effect and cavitation effect of ultrasonic waves. Breakdown of microorganisms in mud. The intracellular substances and water are released, and part of the intracellular water is converted into adsorbed water.

[0021] (2) Flocculation treatment

[0022] The sludge mixture obtained through step (1), under the condition that the stirring speed is 300...

Embodiment 2

[0026] The sludge is taken from a small paper mill in Hebei that uses waste cardboard as raw material to produce packaging paper with an area of 30,000 m 3 / d Secondary sedimentation tank of wastewater treatment project, from which nitrogen and phosphorus are extracted and reused and deep dehydration is realized through the following steps:

[0027] (1) Pretreatment of papermaking wastewater biochemical sludge

[0028] Take 150ml of papermaking wastewater to treat biochemical sludge, put the power of the ultrasonic transducer head at 500w, and the ultrasonic frequency at 25kHz, and insert it into the sludge for 12s to treat the biochemical sludge under the mechanical effect and cavitation effect of ultrasonic waves. Breakdown of microorganisms in mud. The intracellular substances and water are released, and part of the intracellular water is converted into adsorbed water.

[0029] (2) Flocculation treatment

[0030] The sludge mixture obtained through step (1), under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com