A method for recovering humic acid from sludge

A humic acid and sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increasing the difficulty and cost of ultrafiltration treatment, low content of humic acid in recovered products, High operating costs and other issues, to achieve the effect of easy disposal, low cost, and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

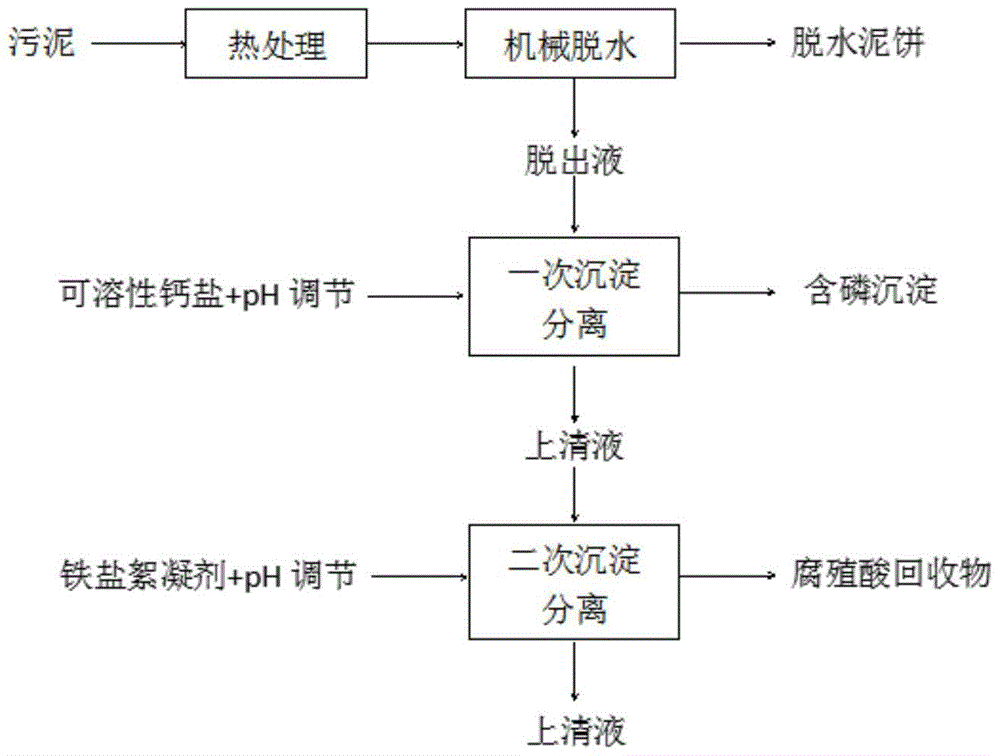

Method used

Image

Examples

example 1

[0034] The sludge produced by the sewage treatment plant (the mixed sludge of the primary sludge and the excess sludge, and the excess sludge is mainly) has a moisture content of 95% after concentration and an organic matter content of the sludge of about 50%. First, the sludge is heat-treated at a temperature of 120°C for 120 minutes, and then press-filtered and dehydrated to obtain an exudate. The humic acid content in the eductate is about 2g / L; take the eductate and add CaCl2 and Ca(OH)2, control the dosage of calcium ions to 2g / L, pH between 8 and 10, stir evenly, form insoluble matter and carry out gravity separation; after obtaining the supernatant, add FeCl3 to it to control the dosage of iron ions 2g / L, pH between 3 and 7, stirred to form flocs, and then centrifuged. About 90% of the humic acid in the supernatant was precipitated by flocculation, and the content of humic acid in the recovered product was 50%.

example 2

[0036]The digested sludge produced by the high-solids anaerobic digestion facility of the sewage treatment plant has a moisture content of 87% and an organic matter content of about 45%. First, the sludge is heat-treated at a temperature of 180°C for 10 minutes, and then press-filtered and dehydrated to obtain an exudate. The humic acid content in the eductate is about 6g / L; take the eductate, and add CaCl2 and Ca(OH)2, control the dosage of calcium ions to 4g / L, pH between 8 and 10, stir evenly, form insoluble matter and carry out gravity separation; after obtaining the supernatant, add FeCl3 to it to control the dosage of iron ions 4g / L, pH between 3 and 7, stirred to form flocs, and then centrifuged. About 70% of the humic acid in the supernatant was precipitated by flocculation, and the content of humic acid in the recovered product was 60%.

example 3

[0038] The digested sludge produced by the high-solids anaerobic digestion facility of the sewage treatment plant has a moisture content of 87% and an organic matter content of about 45%. First, the sludge is heat-treated at a temperature of 180°C for 10 minutes, and then press-filtered and dehydrated to obtain an exudate. The humic acid content in the eductate is about 6g / L; take the eductate, and add CaCl2 and Ca(OH)2, control the dosage of calcium ions to 4g / L, pH between 8 and 10, stir evenly, form insoluble matter and carry out gravity separation; after obtaining the supernatant, add FeCl3 to it to control the dosage of iron ions 3g / L, pH between 3 and 7, stirred to form flocs, and then centrifuged. About 50% of the humic acid in the supernatant was precipitated by flocculation, and the content of humic acid in the recovered product was 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com