Honeycomb carrier, and preparation method and application thereof

A honeycomb carrier, honeycomb technology, applied in the field of catalysis, can solve the problems of high mechanical strength and thermal shock, low thermal expansion, small size, etc., to improve moisturizing performance and lubricating performance, increase plasticity and adhesion, and reduce cracking effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

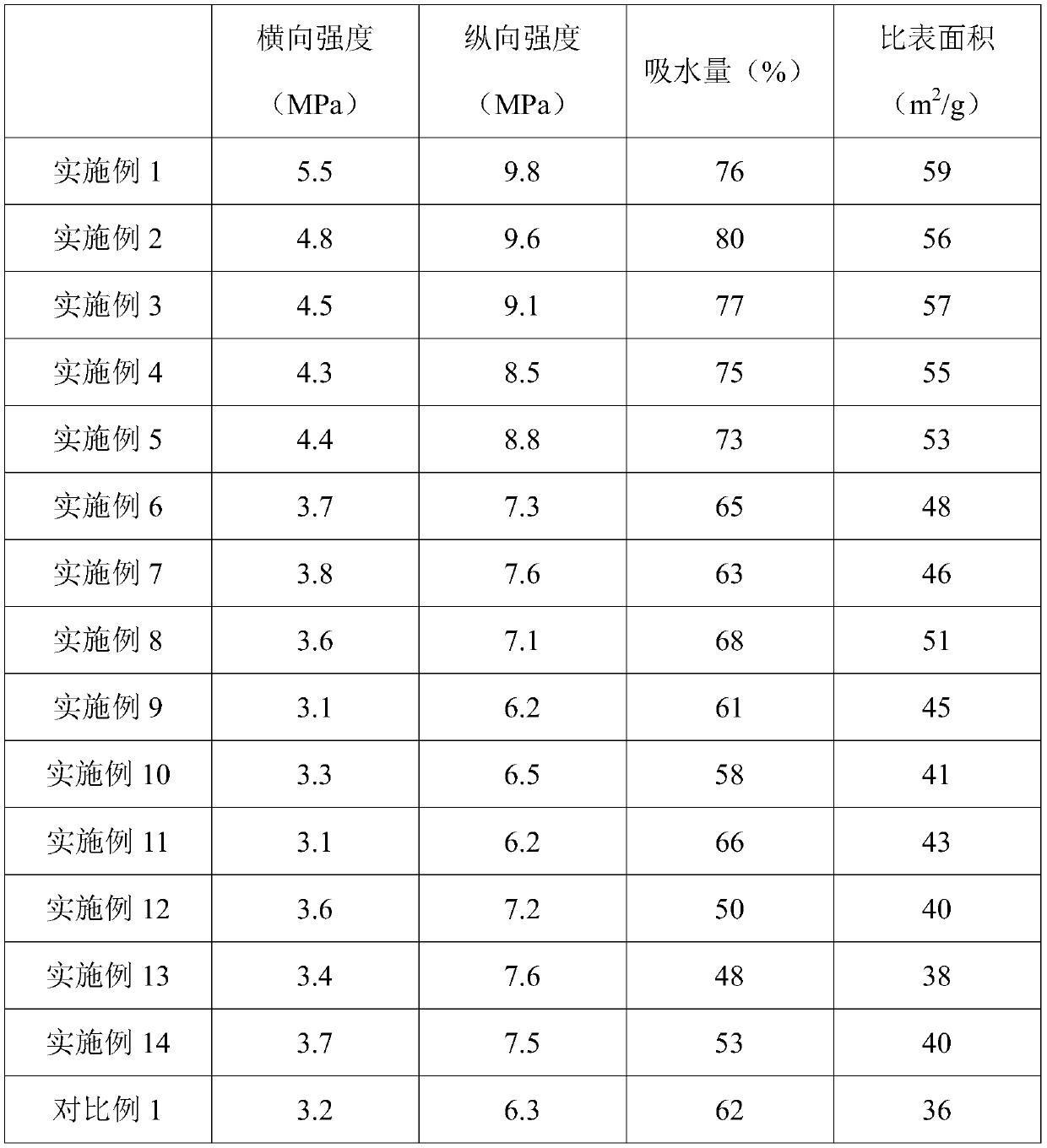

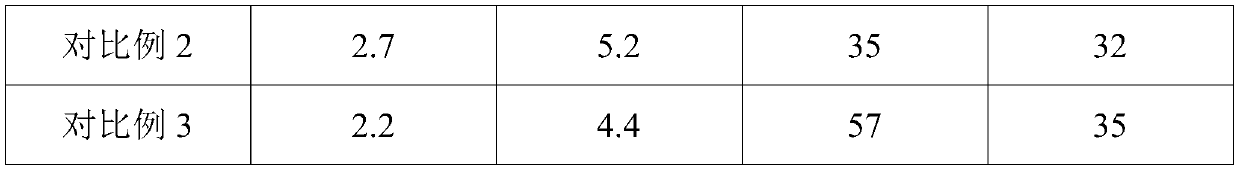

Examples

Embodiment 1

[0088] This embodiment provides a preparation method of a honeycomb carrier, the preparation method comprising the following steps:

[0089] (1) Mix the first raw material and the second raw material in the mixer to obtain mixed powder, the particle size D90 of the first raw material is 100-150 μm, and the specific surface area of each composition is 50-100 μm 2 / g;

[0090] (2) Stir the mixed water, the first organic molding additive and the mixed powder obtained in step (1) at a speed of 650r / min at 85°C for 1.5 hours; reduce the stirring speed to 200r / min and then add the second organic molding Auxiliary and structural enhancer, continue stirring at 40°C; then reverse stirring until the moisture content of the mud is 25%;

[0091] (3) The sludge obtained in the kneading step (2) is naturally cooled during the kneading process. When the temperature of the sludge is lowered to 40°C, the sludge after kneading is pre-extruded, and the screen mesh used for pre-extrusion is 80...

Embodiment 2

[0102] This embodiment provides a preparation method of a honeycomb carrier, the preparation method comprising the following steps:

[0103](1) Mix the first raw material and the second raw material in the mixer to obtain mixed powder, the particle size D90 of the first raw material is 120-180 μm, and the specific surface area of each composition is 80-150 μm 2 / g;

[0104] (2) Stir the mixed water, the first organic molding additive and the mixed powder obtained in step (1) at a speed of 600r / min at 90°C for 1.8 hours; reduce the stirring speed to 150r / min and then add the second organic molding Auxiliary and structural enhancer, continue stirring at 38°C; then reverse stirring until the moisture content of the mud is 22%;

[0105] (3) The sludge obtained in the kneading step (2) is naturally cooled during the kneading process. When the temperature of the sludge is lowered to 35°C, the sludge after kneading is pre-extruded, and the screen mesh used for the pre-extrusion is...

Embodiment 3

[0116] This embodiment provides a preparation method of a honeycomb carrier, the preparation method comprising the following steps:

[0117] (1) Mix the first raw material and the second raw material in the mixer to obtain mixed powder, the particle size D90 of the first raw material is 150-200 μm, and the specific surface area of each composition is 50-80 m 2 / g;

[0118] (2) Stir the mixed water, the first organic molding additive and the mixed powder obtained in step (1) at a speed of 700r / min at 80°C for 1.2 hours; reduce the stirring speed to 100r / min and then add the second organic molding Auxiliary and structural enhancer, continue stirring at 42°C; then reverse stirring until the moisture content of the mud is 28%;

[0119] (3) Kneading the mud obtained in step (2), the mud is naturally cooled during the kneading process, when the mud is cooled to 25°C, the mud after kneading is pre-extruded, and the screen mesh used for pre-extrusion is 90 mesh ;

[0120] (4) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com