Deep dewatering method for sludge

A deep dehydration and sludge technology, which is applied in the field of agricultural and forestry waste recycling, can solve the problems of high water content of mud cake, low dehydration performance, high heavy metal content, etc., achieve low heavy metal leaching content, improve permeability, and low operating cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

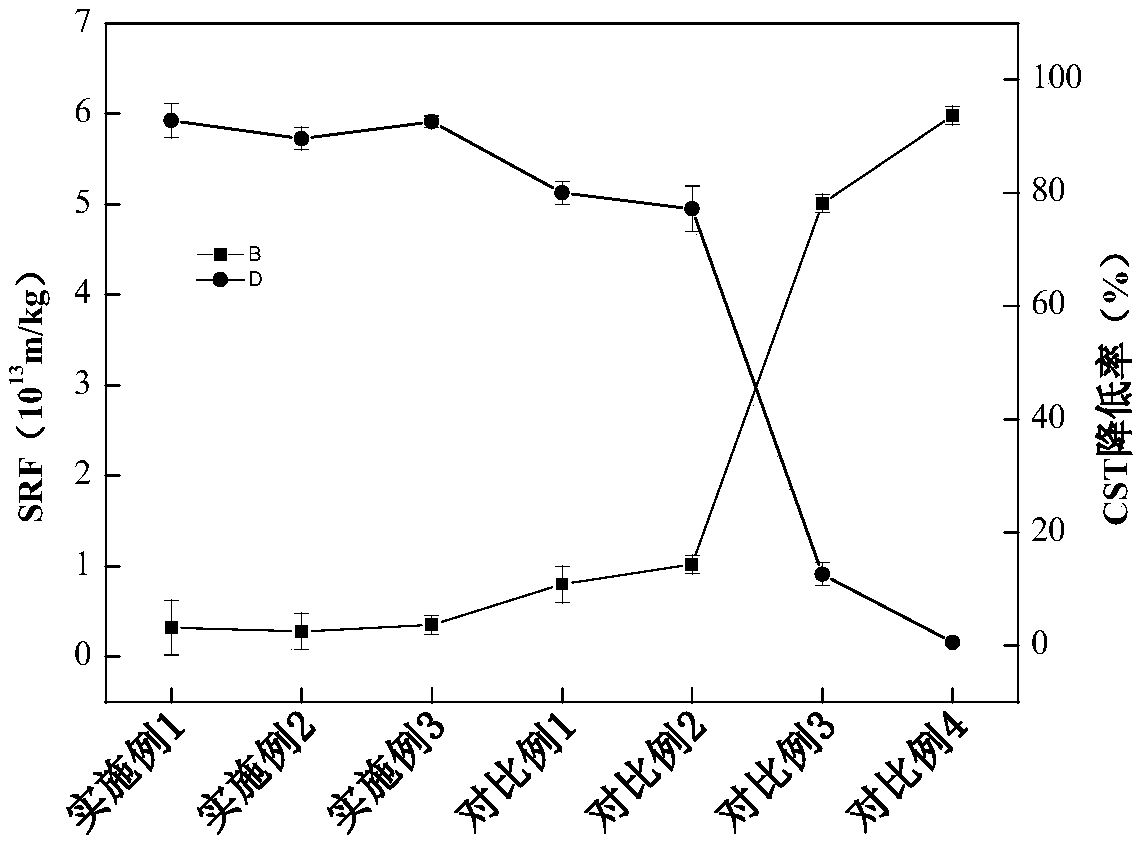

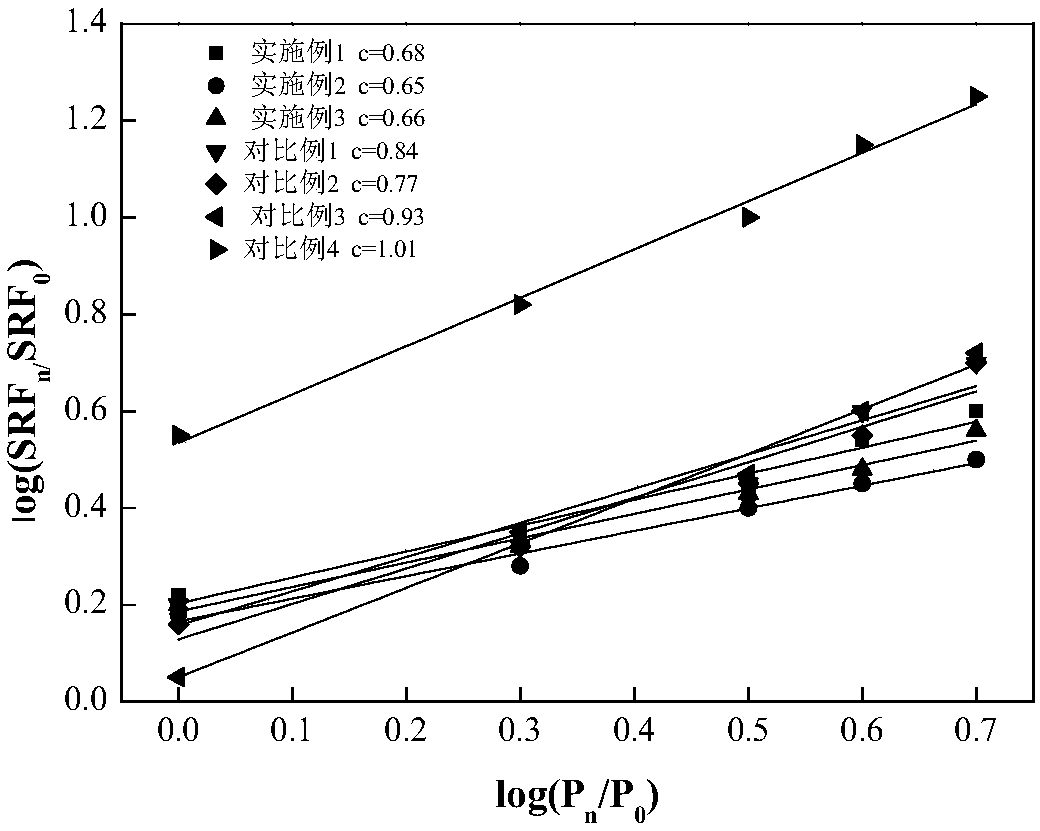

Embodiment 1

[0031] A sludge deep dewatering technology of the present invention, the raw materials are as follows: sludge, ferrous sulfate, sodium persulfate, rice husk and water. Its conditioning steps are as follows:

[0032] (1) put the dried rice husk into a ball mill and grind for 10 minutes at a speed of 3500r / min, and dry to obtain rice husk powder;

[0033] (2) passing the rice husk powder through a square hole sieve to obtain rice husk powder with a particle size of 0.075-0.15mm;

[0034] (3) Under 25 ℃, add the sodium persulfate of 15.2wt% sludge dry weight, stir 5min, then add the Fe of 4.6wt% sludge dry weight 2+ , control the solid-liquid ratio 1:10, stir for 10 minutes;

[0035] (4) Add rice husk powder with 33.3wt% sludge dry weight, and stir for 10min at 25°C;

[0036] (5) The sludge enters the plate and frame filter press for 0.5h to obtain a mud cake.

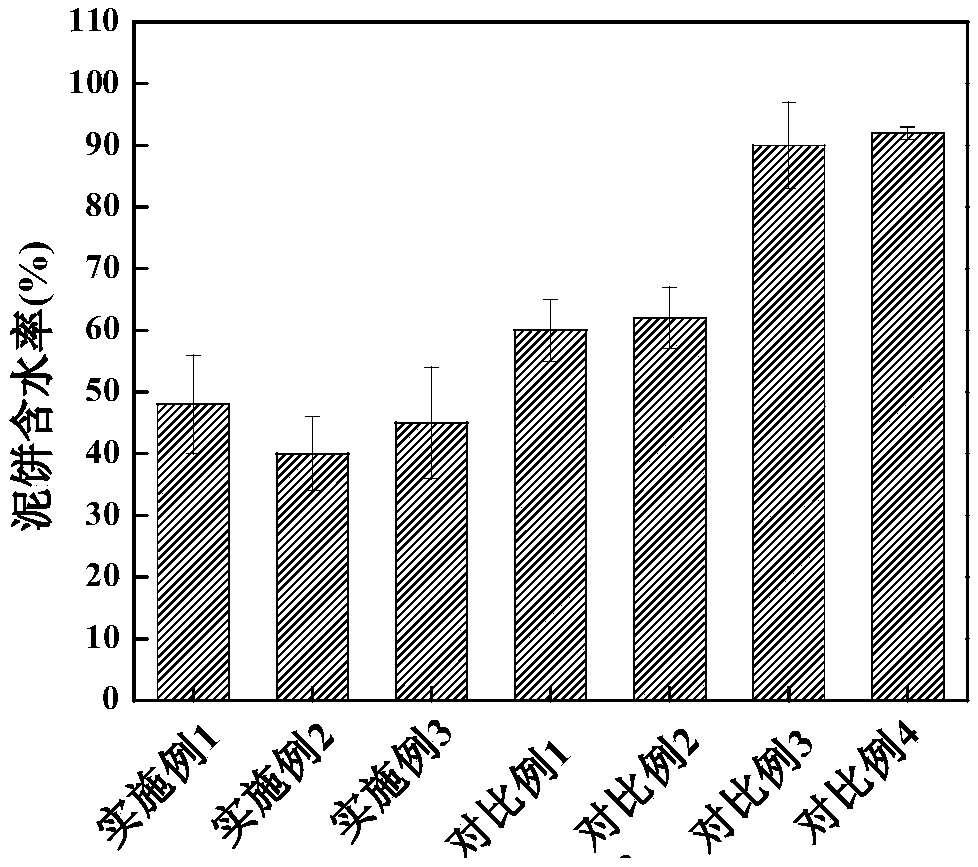

[0037] After testing, the moisture content of the mud cake was 48%.

Embodiment 2

[0039] A sludge deep dewatering technology of the present invention, the raw materials are as follows: sludge, ferrous sulfate, potassium persulfate (SPS), rice husk and water. Its conditioning steps are as follows:

[0040](1) put the dried rice husk into a ball mill and grind for 10 minutes at a speed of 3500r / min, and dry to obtain rice husk powder;

[0041] (2) passing the rice husk powder through a square hole sieve to obtain rice husk powder with a particle size of 0.075-0.15mm;

[0042] (3) Under 52 ℃, add the potassium persulfate of 15.2wt% sludge dry weight, stir 5min, then add the Fe of 4.6wt% sludge dry weight 2+ , control the solid-liquid ratio 1:10, stir for 10 minutes;

[0043] (4) Add rice husk powder with 33.3wt% sludge dry weight, and stir for 10min at 52°C;

[0044] (5) The sludge enters the plate and frame filter press for 0.5h to obtain a mud cake.

[0045] After testing, the moisture content of the mud cake was 42%.

Embodiment 3

[0047] The sludge deep dewatering technology of the present invention comprises the following raw materials: sludge, ferrous sulfate, potassium persulfate, rice husk and water. Its conditioning steps are as follows:

[0048] (1) put the dried rice husk into a ball mill and grind for 10 minutes at a speed of 3500r / min, and dry to obtain rice husk powder;

[0049] (2) passing the rice husk powder through a square hole sieve to obtain rice husk powder with a particle size of 0.075-0.15 mm;

[0050] (3) Under 80 ℃, add the potassium persulfate of 15.2wt% sludge dry weight, stir 5min, then add the Fe of 4.6wt% sludge dry weight 2+ , control the solid-liquid ratio 1:10, stir for 10 minutes;

[0051] (4) Add rice husk powder with 33.3wt% sludge dry weight, and stir for 10min at 80°C;

[0052] (5) The sludge enters the plate and frame filter press for 0.5h to obtain a mud cake.

[0053] After testing, the moisture content of the mud cake was 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com