Novel sludge drying processing device

A sludge drying and drying technology, applied in water/sludge/sewage treatment, temperature-controlled sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of incomplete dehydration of sludge and inability to direct resources The problem of chemical utilization and final disposal of sludge is difficult to achieve the level of inhibiting microbial activity and the effect of heat treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

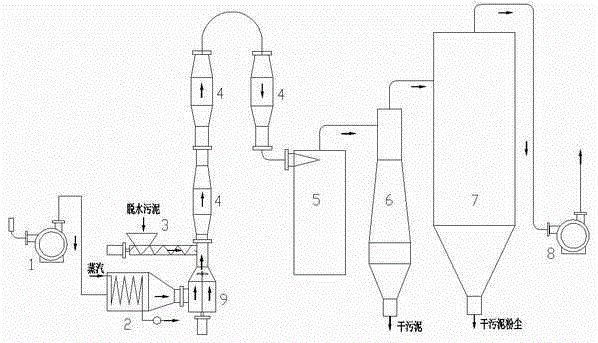

[0010] figure 1 A schematic diagram of a novel sludge drying treatment device is shown. This new type of sludge drying treatment device includes a feeder 3, which sends the sludge into the sludge drying system. The sludge drying system includes a blower 1, an air heater 2, a disperser 9, and an airflow dryer. 4. Cyclone dryer 5, cyclone separator 6, dust collector 7 and induced draft fan 8. The air blower 1 sends air into the air heater 2 heated by steam, and the hot air above 100°C enters the disperser 9 and is dehydrated with the water content of 80% entered from the feeder 3 and crushed by the disperser 9. The sludge is mixed to form a hot air sludge flow. The sludge in the air sludge flow is dried by the three-stage airflow dryer 4 in series and then enters the cyclone dryer 5 to continue drying. The dried air sludge flow enters the cyclone separator 6 Centrifuge to separate dry sludge with moisture content less than 5%. The dry sludge is discharged from the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com