Plate-type sludge dewatering machine and dewatering method therefor

A sludge dewatering machine and plate-type technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of uneven filter cake thickness, harsh working environment, and broken filter cloth, so as to ensure the service life and facilitate filtration. Cake thickness, the effect of adjusting filter cake thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below by way of examples.

[0049] Embodiment of the plate type sludge dehydrator of the present invention:

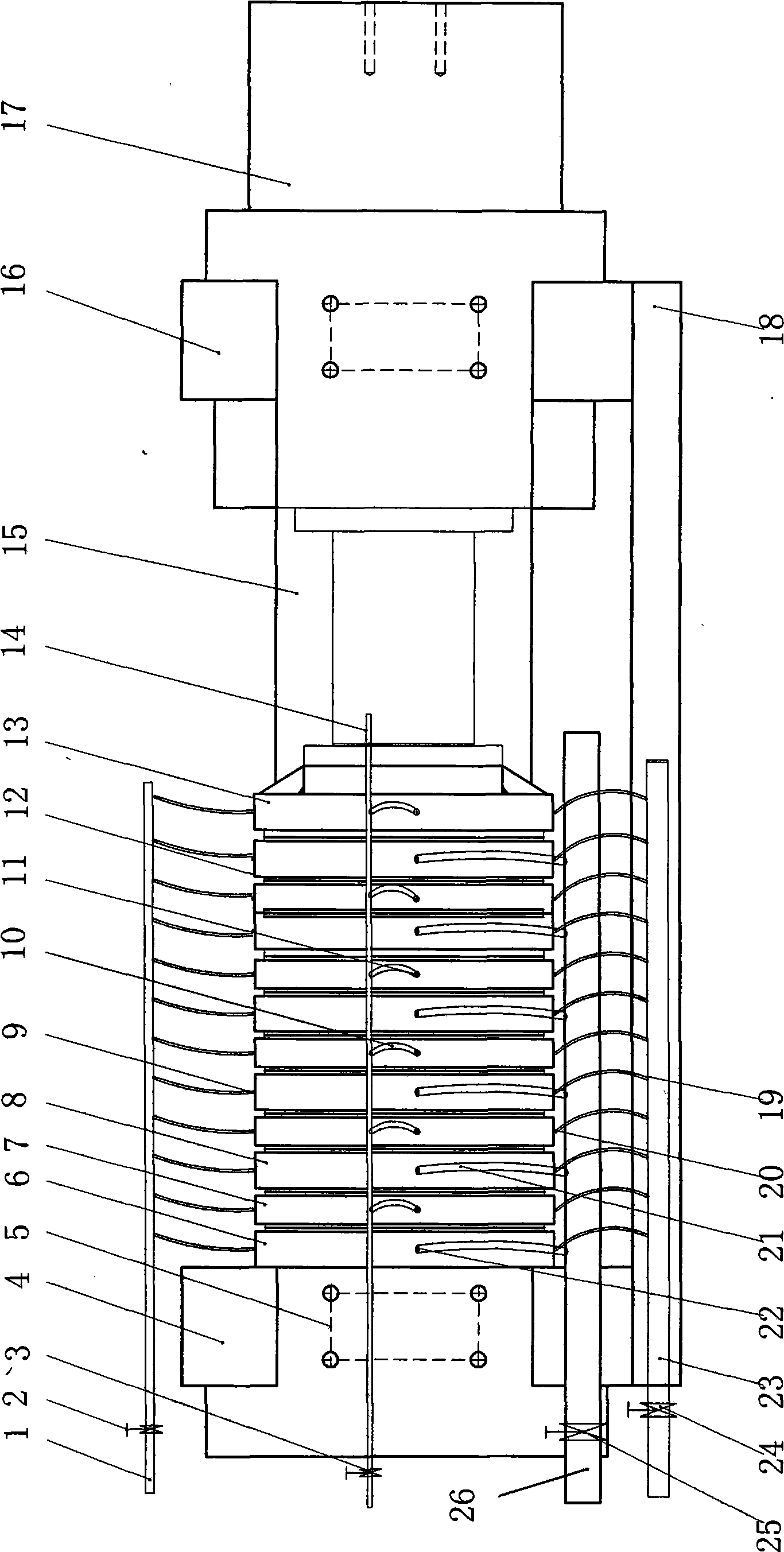

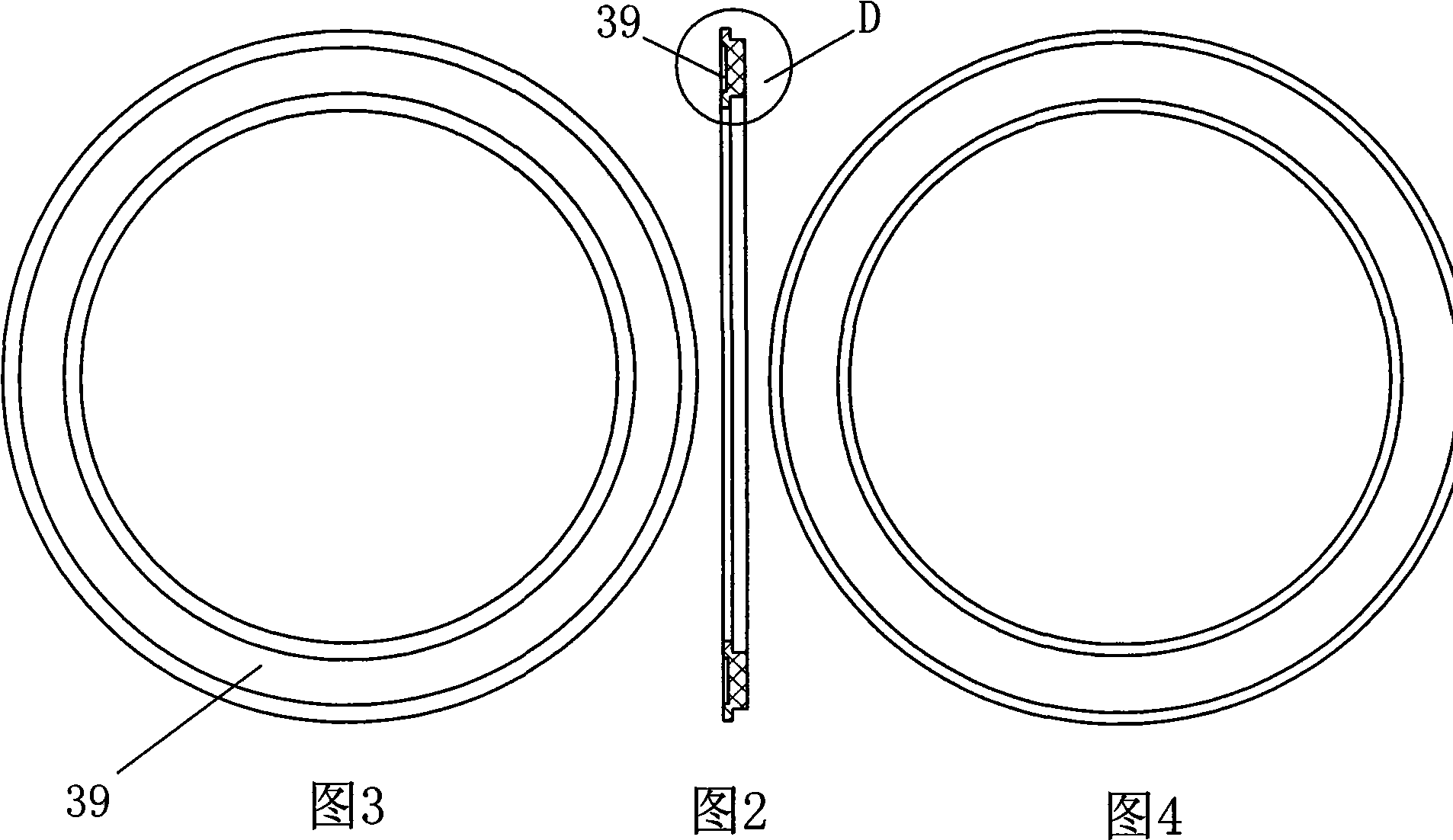

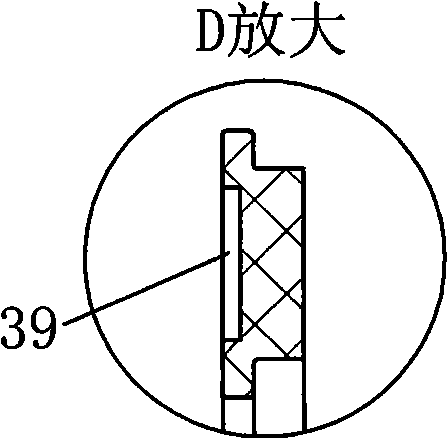

[0050] see figure 1 , the plate sludge dewatering machine includes a frame, a filter press plate, an elastic body 12, a sealing plug 29, a liner net 39, a filter cloth 38, a hydraulic pressure device, auxiliary equipment and a programmable logic controller PLC. The plates constitute a number of pressure filter chambers for pressure filtration and dehydration of sludge.

[0051] The frame is used to fix and support the filter press plate, and the pressurized oil cylinder 17 of the hydraulic pressure device is installed, such as figure 1 As shown, the frame is mainly composed of the front box body 4, the main beam plate 15, the rear box body 16 and the base 18. The frame of the plate sludge dewatering machine should be able to bear the axial tensile force of more than 600t without deformation, stable and firm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com