Sludge dewatering method

A technology for sludge dehydration and sludge, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as high heavy metal content, secondary pollution, low degree of sludge dehydration, etc. Achieve low operating cost, improve dehydration degree, and avoid heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

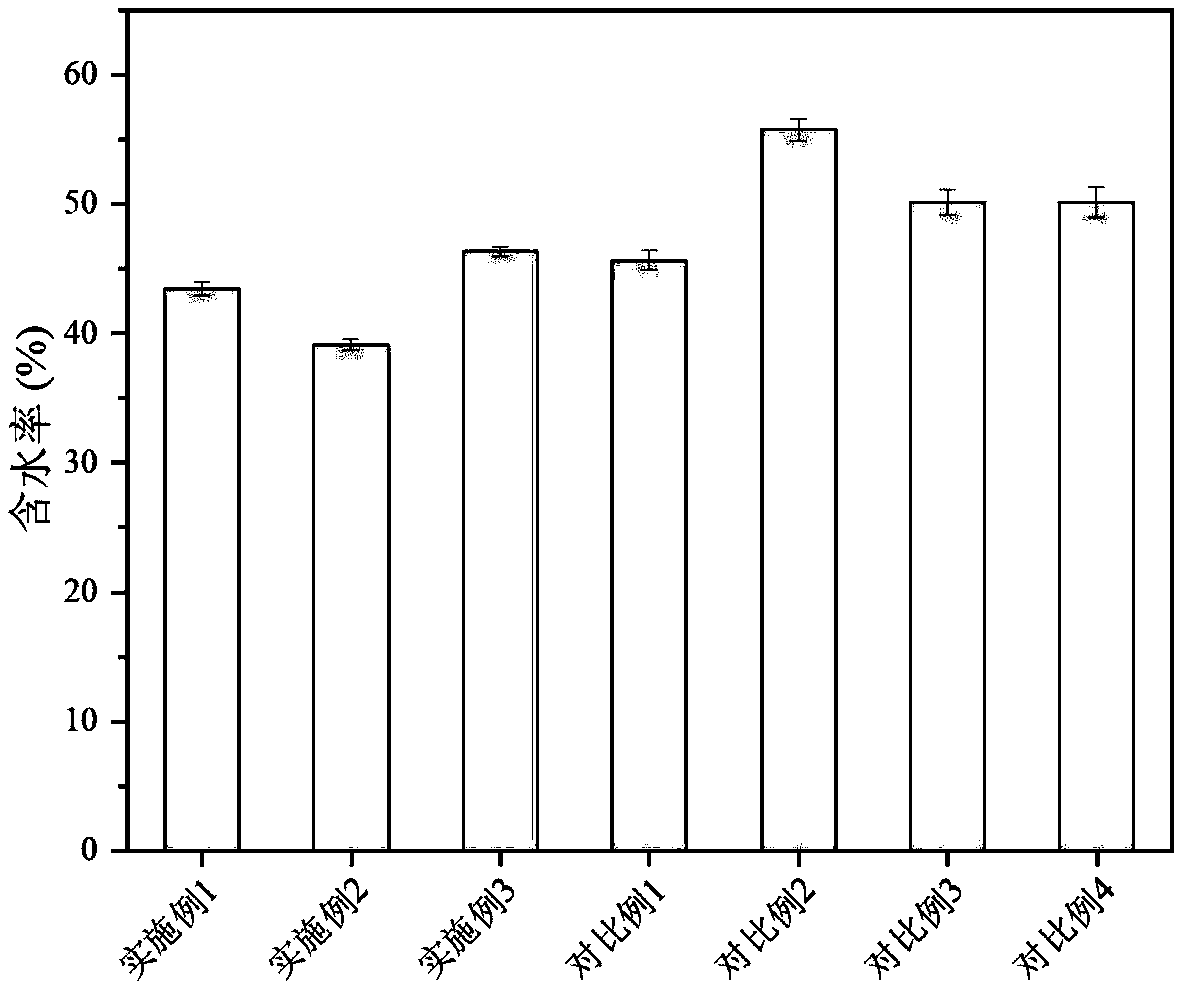

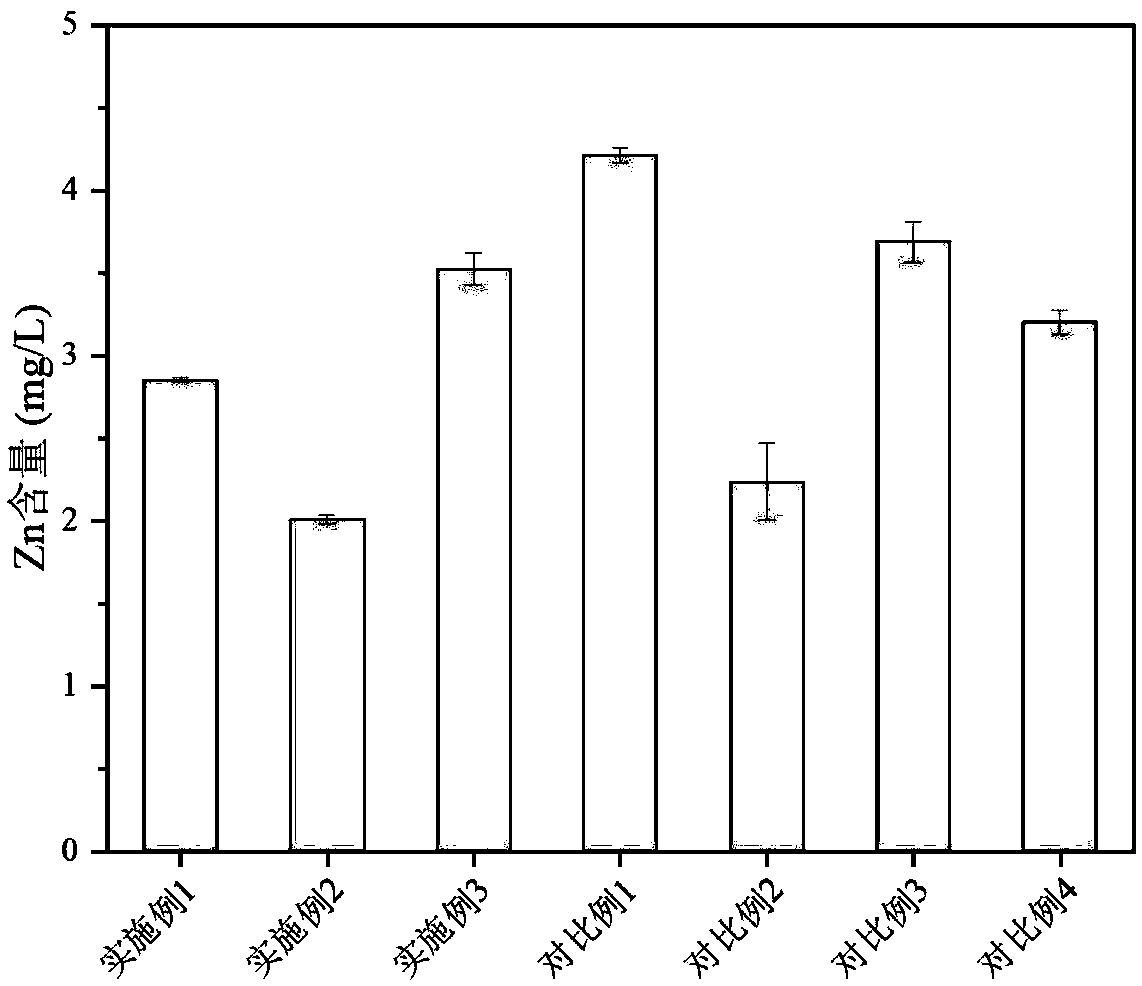

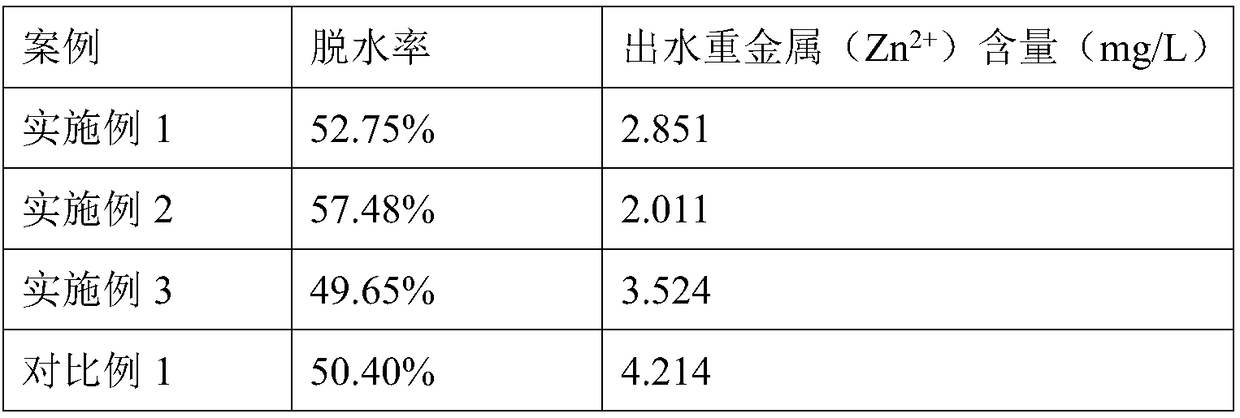

[0042] A mild hydrothermal modified dehydration method for sludge of the present invention, the raw materials are: municipal sludge, conditioning agent M and modifying agent FeCl 3 . Specific steps are as follows:

[0043] (1) Transport the raw sludge (with a water content of 92wt.%) from Wuhan Sanjintan Sewage Treatment Plant to the conditioning kettle, and add conditioning agent M (wherein the mass ratio of industrial waste residue is 1:12:4 Phosphorus slag, slag and boiling slag, the activator is Na with a mass ratio of 8:1:4:7 2 CO 3 , NaOH, KAl(SO 4 ) 2 12H 2 O and CaSO 4 ; The mass ratio of industrial waste residue and activator is 85:10), the addition of conditioner M is 8wt.% of the amount of sludge, and reacted for 1h under stirring conditions;

[0044](2) The sludge treated by the conditioning tank is pumped to the hydrothermal modification conditioning tank, and the modified conditioning agent FeCl is added 3 , the addition amount is 4wt.% of the sludge amou...

Embodiment 2

[0049] A mild hydrothermal modified dehydration method for sludge of the present invention, the raw materials are: municipal sludge, conditioning agent M and modifying agent FeCl 3 . Specific steps are as follows:

[0050] (1) Transport the raw sludge (with a water content of 92wt.%) from Wuhan Sanjintan Sewage Treatment Plant to the conditioning kettle, and add conditioning agent M (wherein the mass ratio of industrial waste residue is 1:12:4 Phosphorus slag, slag and boiling slag; the activator is Na with a mass ratio of 8:1:4:7 2 CO 3 , NaOH, KAl(SO 4 ) 2 12H 2 O and CaSO 4 ; The mass ratio of industrial waste slag and activator is 85:10), the addition of conditioner M is 15wt.% of the amount of sludge, and reacted for 1.5h under stirring conditions;

[0051] (2) The sludge treated by the conditioning tank is pumped to the hydrothermal modification conditioning tank, and the modified conditioning agent FeCl is added 3 , the amount added is 4wt.% of the amount of slu...

Embodiment 3

[0056] A mild hydrothermal modified dehydration method for sludge of the present invention, the raw materials are: municipal sludge, conditioning agent M and modifying agent FeCl 3 . Specific steps are as follows:

[0057] (1) Transport the raw sludge (with a water content of 92wt.%) from Wuhan Sanjintan Sewage Treatment Plant to the conditioning kettle, and add conditioning agent M (wherein the mass ratio of industrial waste residue is 1:12:4 Phosphorus slag, slag and boiling slag; the activator is Na with a mass ratio of 8:1:4:7 2 CO 3 , NaOH, KAl(SO 4 ) 2 12H 2 O and CaSO 4 ; The mass ratio of industrial waste slag and activator is 85:10), the addition of conditioner M is 2wt.% of the amount of sludge, and reacted for 1h under stirring conditions;

[0058] (2) The sludge treated by the conditioning tank is pumped to the hydrothermal modification conditioning tank, and the modified conditioning agent FeCl is added 3 , the addition amount is 2wt.% of the sludge amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com