A kind of sludge deep dehydration composite conditioner and its application

A deep dehydration and conditioning agent technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of blocked water filtration channels, low mechanical dehydration efficiency, easy compression deformation, etc., to improve compressibility and solve organic matter. Compressibility problem, effect of improving effective action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of sludge deep dehydration composite conditioner, comprising the ferrous sulfate and potassium persulfate that mass ratio is 0.7, surfactant is cetyl trimethyl ammonium chloride, and skeleton construct is bentonite (fineness is 200 orders Sieve residue is less than 15%).

[0027] The application method of the sludge dehydration composite conditioner is as follows:

[0028] Take the remaining sludge from a certain urban sewage treatment plant, the water content is 97.0%, the sludge concentration is 34.5g / L, and the above chemicals are added to the sludge. The adding steps are as follows:

[0029] Add cetyltrimethylammonium chloride solution (concentration is 20%) in the surplus sludge of moisture content 97.0%, the dosage of cetyltrimethylammonium chloride is sludge dry basis 0.5%; and stir for 5 minutes, so that the surfactant is fully mixed with the sludge;

[0030] Dosing FeSO to sludge containing surfactant 4 (40% concentration), FeSO 4 The dosage is 2.5% ...

Embodiment 2

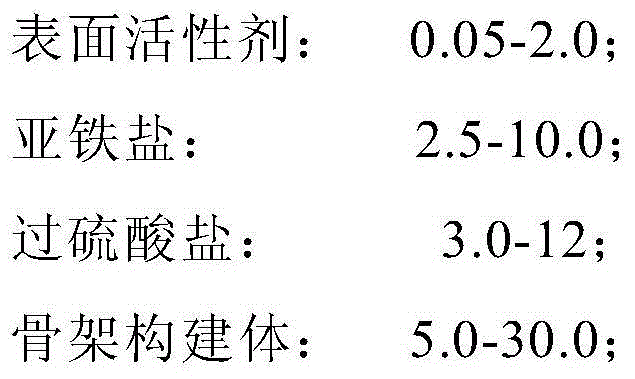

[0036] A composite conditioner for sludge deep dehydration, the conditioner is composed of the following components by weight:

[0037] Surfactant: cetyltrimethylammonium bromide 1;

[0038] Ferrous salt: FeSO 4 2.5;

[0039] Persulfate: K 2 S 2 o 8 3.0;

[0040] Skeleton construct: powdered diatomite (fineness is less than 15% on 200 mesh sieve) 5.0;

[0041] An application of a composite conditioner for deep dehydration of sludge. The composite conditioner for deep dewatering of sludge is used for deep dehydration of sludge, comprising the following steps:

[0042] (1) Add a surfactant to the sludge to be treated (digested sludge) with a water content of 96.5%, stir and mix evenly, wherein the dosage of the surfactant is 1% of the dry weight of the sludge;

[0043] (2) Continue to add ferrous salt and persulfate, stir and mix, and oxidation reaction occurs, wherein the dosage of ferrous salt is 2.5% of the dry weight of sludge, and the dosage of persulfate is 2% of th...

Embodiment 3

[0047] A composite conditioner for sludge deep dehydration, the conditioner is composed of the following components by weight:

[0048] Surfactant: alkyl glycoside 0.05;

[0049] Ferrous salt: FeCl 2 3.35;

[0050] Persulfate: (NH 4 ) 2 S 2 o 8 6;

[0051]Skeleton construct: powdered bentonite (fineness is less than 15% on 200 mesh sieve) 15.0;

[0052] An application of a composite conditioner for deep dehydration of sludge. The composite conditioner for deep dewatering of sludge is used for deep dehydration of sludge, comprising the following steps:

[0053] (1) Add a surfactant to the sludge to be treated with a water content of 97.5%, stir and mix evenly, wherein the dosage of the surfactant is 0.05% of the dry weight of the sludge;

[0054] (2) Continue to add ferrous salt and persulfate, stir and mix, and oxidation reaction occurs, wherein the dosage of ferrous salt is 3.35% of the dry weight of sludge, and the dosage of persulfate is 3.35% of the dry weight of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com