Oil-sludge-water heat treatment separation and recovery system and method

A technology of separation recovery and hydrothermal treatment, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as increased load, difficulty in oil and gas recovery, etc., and achieve small footprint and oil-water separation Good effect, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

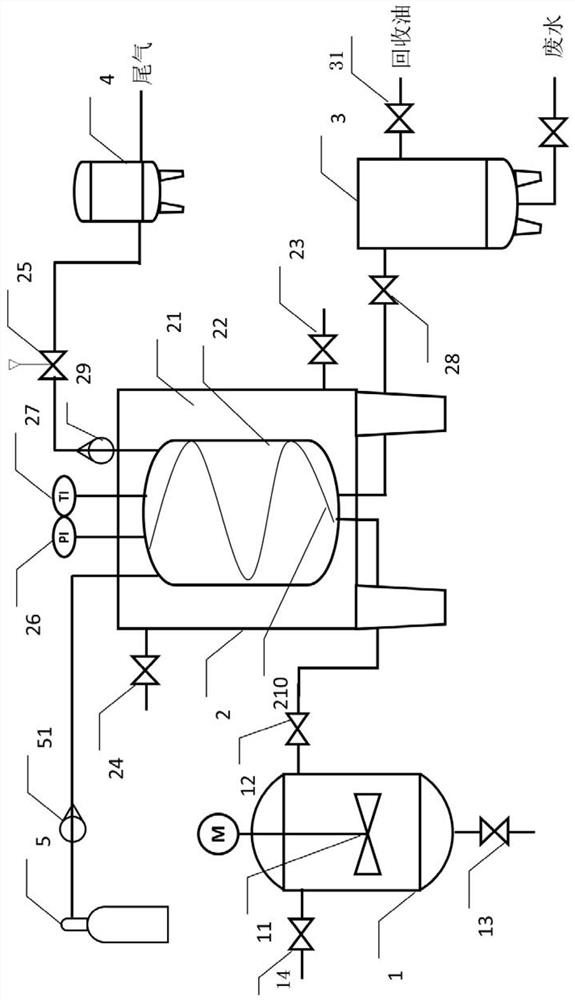

[0049] This embodiment provides a sludge hydrothermal treatment separation and recovery system, the specific structure is as follows figure 1 Shown:

[0050] The system includes: hydrothermal reactor 1, flash condensation tank 2, oil-water separator 3, adsorption tank 4, nitrogen cylinder 5;

[0051] The hydrothermal reactor 1 is a device capable of realizing a hydrothermal reaction. The hydrothermal reactor 1 is provided with a material inlet, a discharge port, and a gas outlet, wherein the discharge port of the hydrothermal reactor 1 is located at the bottom of the hydrothermal reactor and connected to There is a discharge valve 13, and the gas outlet of the hydrothermal reactor 1 is located at the upper part of the hydrothermal reactor; the material inlet of the hydrothermal reactor 1 is located at the upper part of the hydrothermal reactor 1 and is connected with a valve 14; the hydrothermal reactor 1 is provided with Magnetic stirrer 11;

[0052] The flash condensation ...

Embodiment 2

[0056] This embodiment provides a method for separating and recovering oil sludge hydrothermal treatment in fracturing flowback fluid using the oil sludge hydrothermal treatment separation and recovery system provided in Example 1, specifically as follows:

[0057] 1) 500 g of scum oil sludge (moisture content 80-85%) of a certain oil production plant in Xinjiang Oilfield is injected into the hydrothermal reactor 1 from the material inlet of the hydrothermal reactor 1, while stirring (the magnetic stirrer 11 is running) Heating to make the above-mentioned scum and oil sludge undergo a hydrothermal reaction at 120-180°C and 0.2-1.0Mpa for 20-50min, wherein the heating is electric heating, and the stirring speed is 100-300r / min;

[0058] 2) Stop heating the hydrothermal reactor 1, keep the magnetic stirrer 11 to continue running, close the exhaust valve 25 at the top of the flash condensation tank 2 and the drain valve 28 at the bottom, and open the exhaust valve cooling water in...

Embodiment 3

[0064] This embodiment provides a method for separating and recovering oil sludge hydrothermal treatment in fracturing flowback fluid using the oil sludge hydrothermal treatment separation and recovery system provided in Example 1, specifically as follows:

[0065] 1) 500 g of scum oil sludge (moisture content 75-80%) of a certain oil production plant in Xinjiang Oilfield is injected into the hydrothermal reactor 1 from the material inlet of the hydrothermal reactor 1, and 0.45- 1.45MPa, 148-197°C saturated water vapor and stirring the scum and sludge (magnetic stirrer 11 operation) makes the scum and sludge undergo hydrothermal reaction, the hydrothermal reaction time is 10-40min, the stirring speed 100-300r / min;

[0066] 2) Stop heating the hydrothermal reactor 1, keep the magnetic stirrer 11 to continue running, close the exhaust valve 25 at the top of the flash condensation tank 2 and the drain valve 28 at the bottom, and open the exhaust valve cooling water inlet valve 23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com