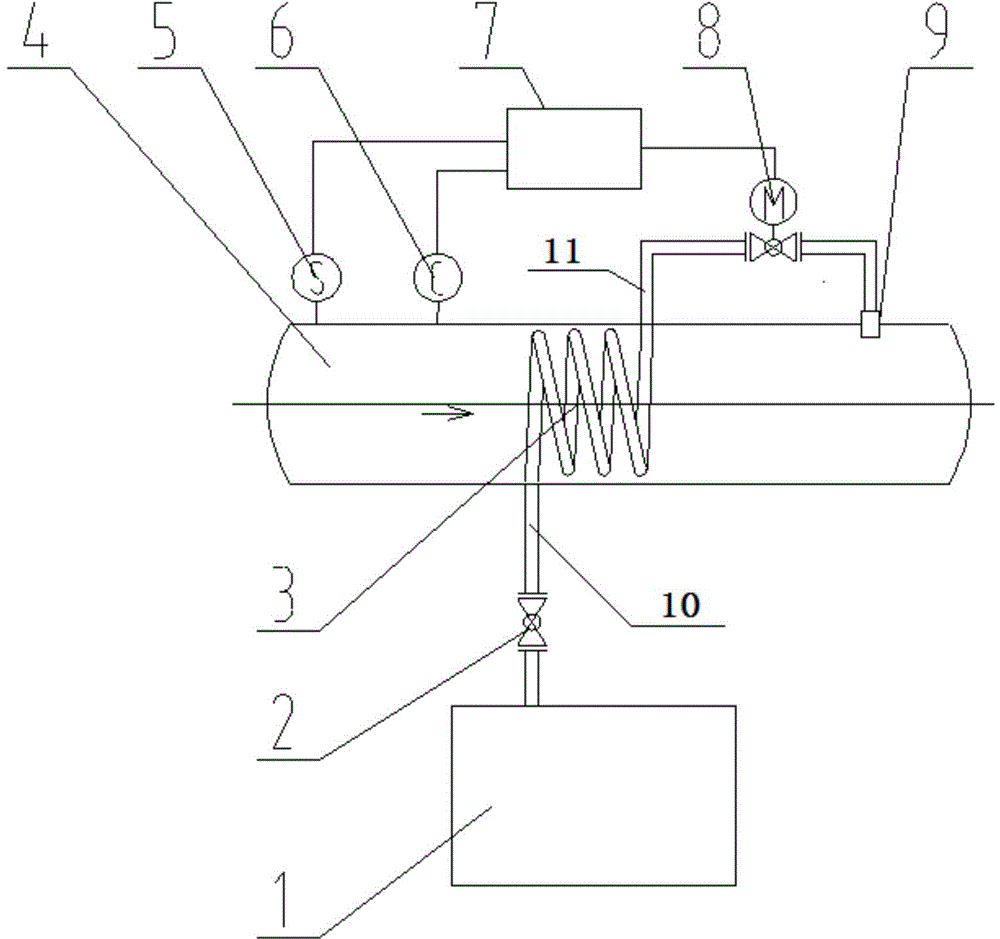

Device and method for mixing LNG fuel into methane electric generator set

A generator set and gas technology, applied in the direction of mechanical equipment, engine components, combustion engines, etc., can solve the problems of energy waste and inability to realize gas utilization, so as to improve heat exchange efficiency, improve utilization space and utilization rate, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take the mixing amount as 100m 3 / min, taking the gas concentration detected by the gas concentration sensor 6 as 7% as an example, the gas pure amount before adding LNG is 7m 3 / min; if LNG is added to make the gas concentration after blending reach 8.5%, the electric control valve 8 under the standard condition needs to be blended to control the pure amount of LNG to be 1.6393m 3 Spray at a speed of / min; the concentration after blending is 8.5%, and the mixing volume is 101.64m 3 / min to make the gas concentration meet the power generation requirement. The injection speed and injection time of LNG (liquefied natural gas) vary according to the concentration of low-concentration gas and the size of the nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com