Sewage treatment process for recovering N-methyl pyrrolidone

A methyl pyrrolidone and sewage treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of inability to meet discharge requirements, high concentration, complex components, etc. , to achieve the effects of reduced energy consumption, high mud age and short hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

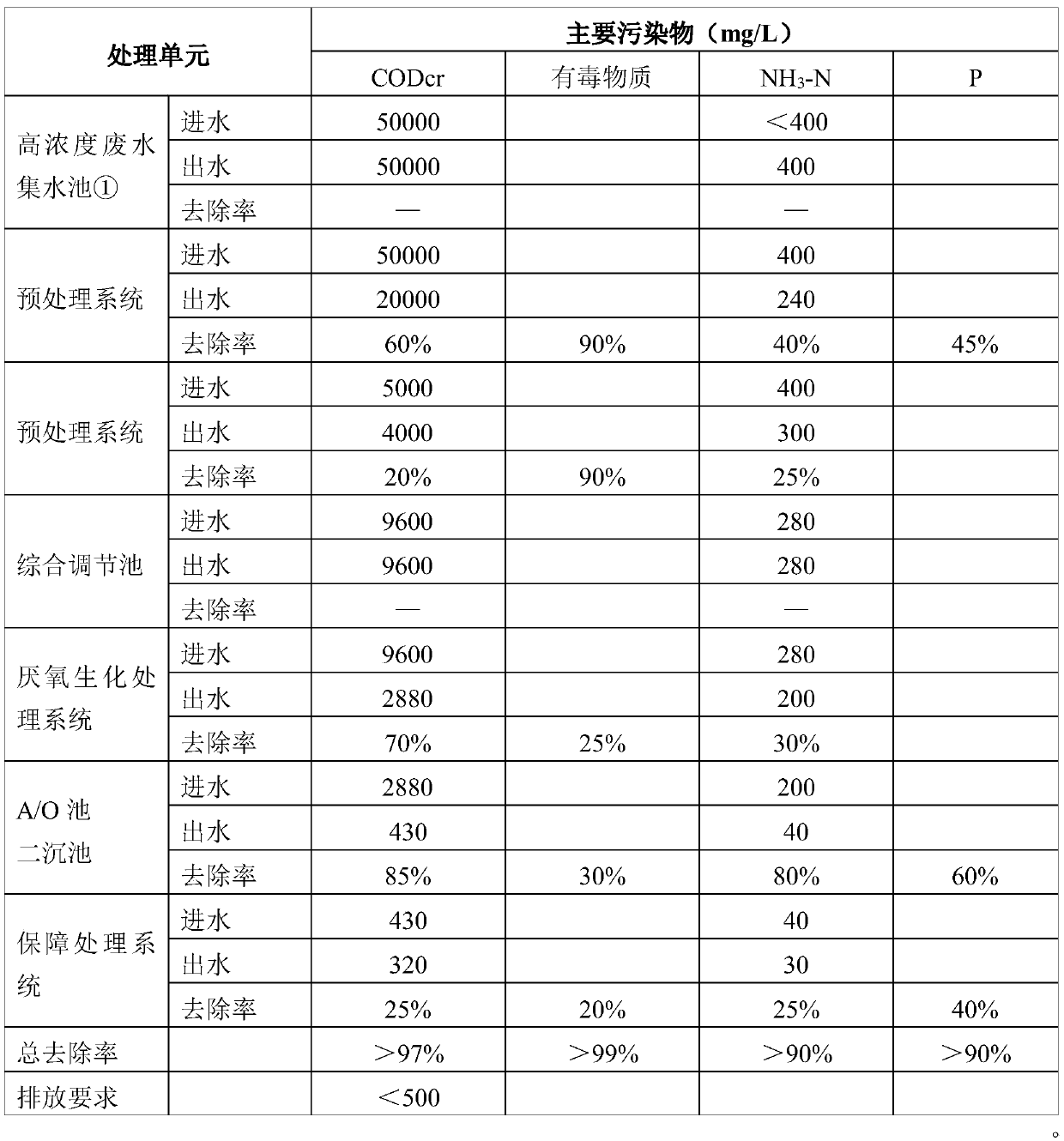

[0082] The sewage treatment process of N-methylpyrrolidone recovery is characterized in that the process comprises the following steps:

[0083] Step (1) high-concentration wastewater pretreatment; now the high-concentration wastewater is pretreated, and the pretreatment includes catalytic cracking, high-voltage pulse electrolysis and coagulation precipitation in turn; obtain pretreatment wastewater;

[0084] Step (2) biochemical treatment; the pretreated wastewater in step (1) is sequentially mixed and homogenized, anaerobic reaction, hydrolytic acidification and contact oxidation; biochemically treated water is obtained;

[0085] Step (3) guarantee treatment; the biochemically treated water in step (2) is subjected to precipitation reaction, multimedia filtration and activated carbon filtration in sequence to complete the recovery.

[0086] Further, the catalytic cracking in step (1) adopts "Fenton's reagent method"; Fe in Fenton's reagent 2+ As a homogeneous catalyst, whil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com