MBR (membrane bioreactor)-based system and method for oil refining wastewater biochemical treatment and membrane component cleaning method

A technology for oil refinery wastewater and biochemical treatment, applied in the field of water treatment, can solve problems such as surface damage of membrane materials, and achieve the effects of short generation period, good adaptability, and shortened treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

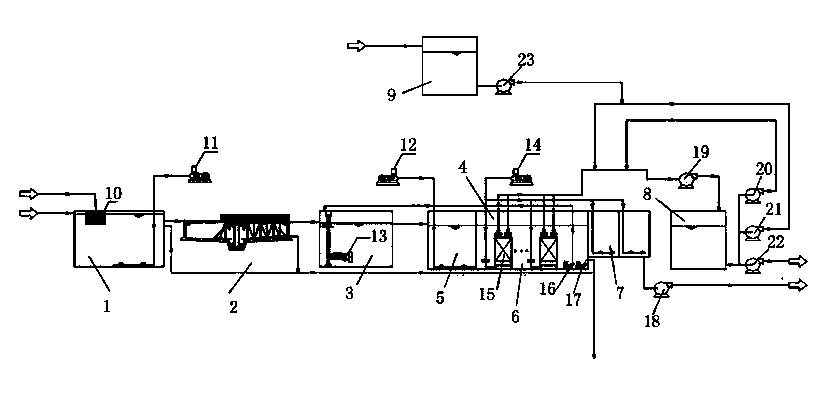

[0039] The oil refinery wastewater treated by oil separation + vortex concave air flotation + dissolved air flotation enters the aerobic aeration tank 1, and the domestic sewage also enters the aerobic aeration tank 1 after passing through the basket grid 10 to remove large particles and suspended solids. Domestic sewage can bring exogenous bacterial populations. The hydraulic retention time (HRT) of aerobic aeration tank 1 is 0.5h, the sludge age is 0.5d, and the sludge load is 3 kgBOD 5 / kgMLSS·d, the sludge can form microbial populations with short generation time, strong activity and strong adsorption capacity, and a large amount of oily substances insoluble in water are adsorbed in the sludge. Oxygen is supplied to the microorganisms through the aeration fan 11 of the aerobic tank, but the low-oxygen state (dissolved oxygen is lower than 1 mg / L) is maintained, which is beneficial to the growth of facultative microorganisms. The sludge adsorbed with oily substances is sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com