System for treating printing and dyeing wastewater with activated coke adopted and process thereof

A printing and dyeing wastewater and treatment process technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low treatment efficiency, increase residence time, improve biochemical Sexuality, prolonging the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

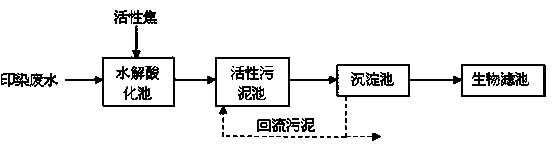

[0041] The system for treating printing and dyeing wastewater using activated coke described in this example is as follows: figure 1 shown, including

[0042] The hydrolytic acidification device, activated sludge tank, sedimentation tank and biological filter are connected in sequence; activated coke with a particle size range of 0.05~0.5mm is added in the hydrolysis acidification device, and the hydrolysis acidification device comes out containing The effluent of the activated coke enters the activated sludge tank again; in this embodiment, a return pipeline is arranged between the sedimentation tank and the activated sludge tank, and the sludge deposited in the sedimentation tank flows back to the activated sludge tank through the return pipeline. The activated sludge tank.

[0043] The biological filter described in this embodiment adopts the commonly used biological aerated filter in the prior art, and the spherical ceramsite with a particle diameter of 5-8mm is selected ...

Embodiment 2

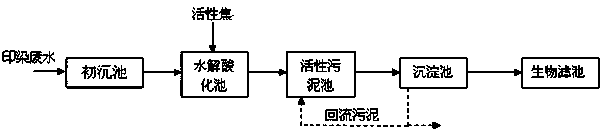

[0050] The system for treating printing and dyeing wastewater using activated coke described in this example is as follows: figure 2 shown, including

[0051] The primary settling tank, hydrolytic acidification device, activated sludge tank, sedimentation tank and biological filter are connected in sequence; activated coke with a particle size range of 0.1~1mm is added in the hydrolysis acidification device, and the hydrolysis acidification device The effluent containing activated coke enters the activated sludge tank again; there is a return pipeline between the sedimentation tank and the activated sludge tank, and the sludge settled in the sedimentation tank flows back to the activated sludge tank through the return pipeline. Activated sludge pool.

[0052] The biological filter in this embodiment adopts the biological aerated filter, and the biological filter uses activated coke with a particle size of 1.0-8.0mm as the filter material, and the filter material layer height...

Embodiment 3

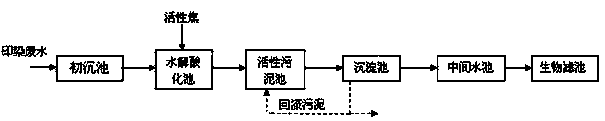

[0059] The system for treating printing and dyeing wastewater using activated coke described in this example is as follows: figure 2 shown, including:

[0060] The primary settling tank, hydrolytic acidification device, activated sludge tank, sedimentation tank and biological filter are connected in sequence; activated coke with a particle size range of 0.1~1mm is added in the hydrolysis acidification device, and the hydrolysis acidification device The effluent containing activated coke enters the activated sludge tank again; there is a return pipeline between the sedimentation tank and the activated sludge tank, and the sludge settled in the sedimentation tank flows back to the activated sludge tank through the return pipeline. Activated sludge pool.

[0061] The biofilter described in this embodiment adopts a biological aerated filter, and the biofilter uses activated coke with a particle size of 1.0-8.0 mm as the filter material, and the filter material layer height is 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com