Parallel A2O-MBR denitrifying phosphorus removal method

A nitrification, polyphosphorus and denitrification, parallel technology is applied in the field of activated sludge process sewage biological treatment process, which can solve the problems of reduced impact load capacity, consumption, and high nitrate concentration, and achieves good dynamism, increased control, and reduced land occupation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

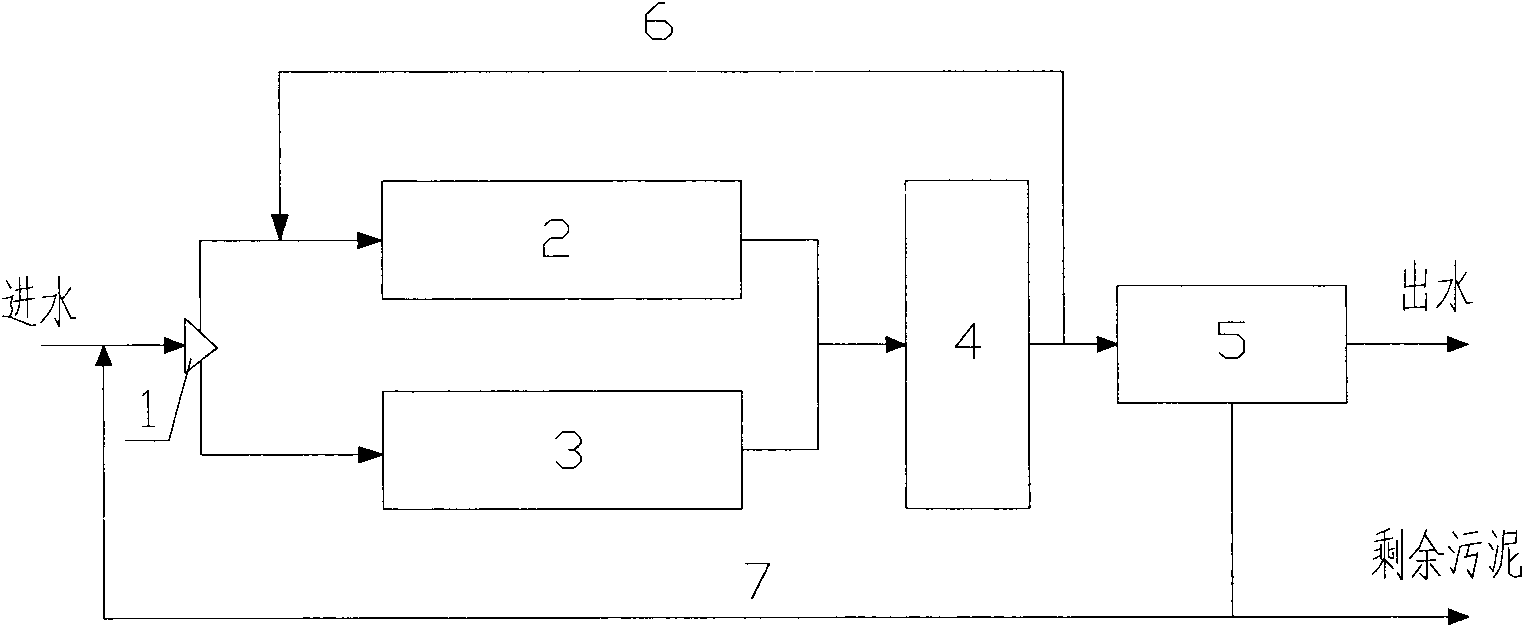

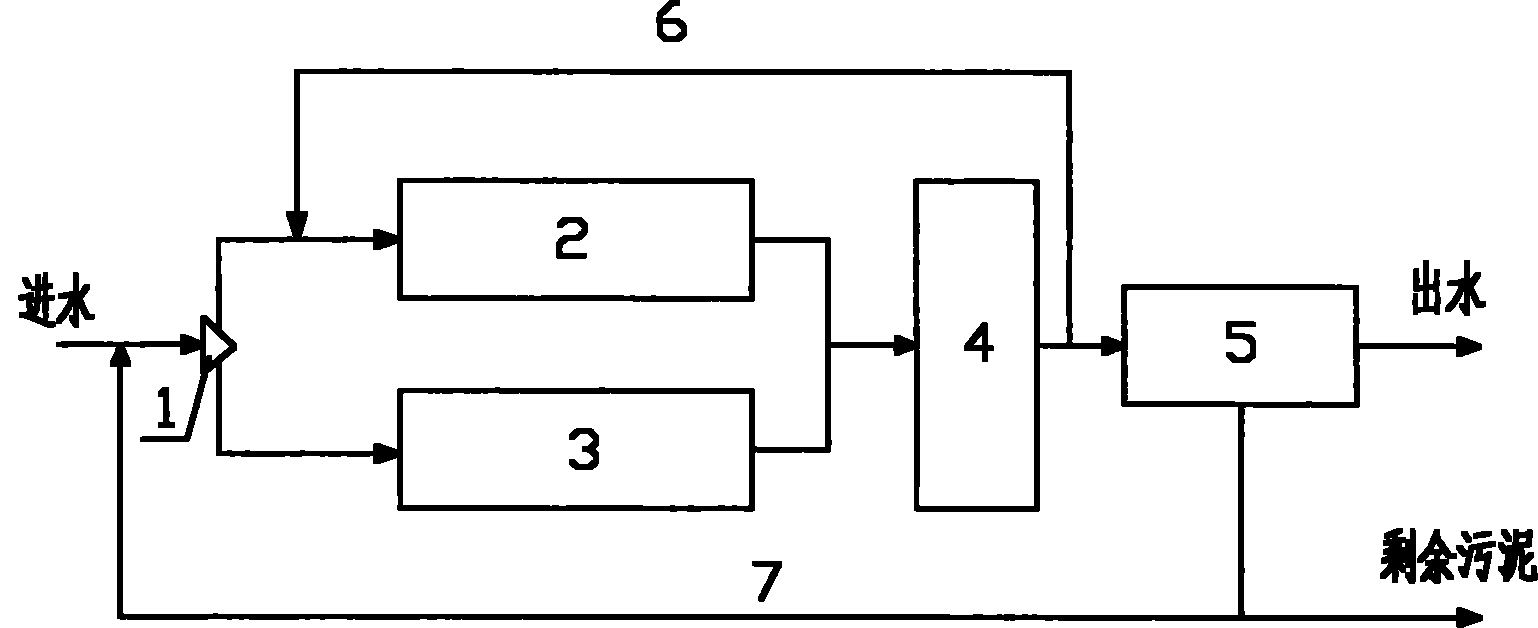

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0018] The present invention is composed of water distribution inlet, anaerobic pool, aerobic pool, anoxic pool, mixed liquid return system, sludge return system and MBR pool. The anaerobic pool and aerobic pool are connected in parallel, and then enter the anoxic pool together. , and finally through the membrane water. The sewage first passes through the water distribution well to distribute water for the anaerobic pool and the aerobic pool. The water distribution well adopts the overflow weir type, and the weir plate is adjustable, so as to adjust the influent flow of the anaerobic pool and the aerobic pool; the sewage entering the anaerobic pool and the return flow The sludge is mixed to provide carbon source for the phosphorus-accumulating bacteria in the anaerobic tank for anaerobic phosphorus release; another part of the sewage enters the aerobic zone, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com