Mechanical internal circulation jet-flow anaerobic reactor and wastewater treatment method thereof

An anaerobic reactor and internal circulation technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the limitation of application range, unsatisfactory wastewater treatment effect, and difficult to grasp the parameters of internal circulation system and other problems, to achieve the effect of high concentration of anti-biotoxic substances, prolonging the sludge age, and strong resistance to water quality impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

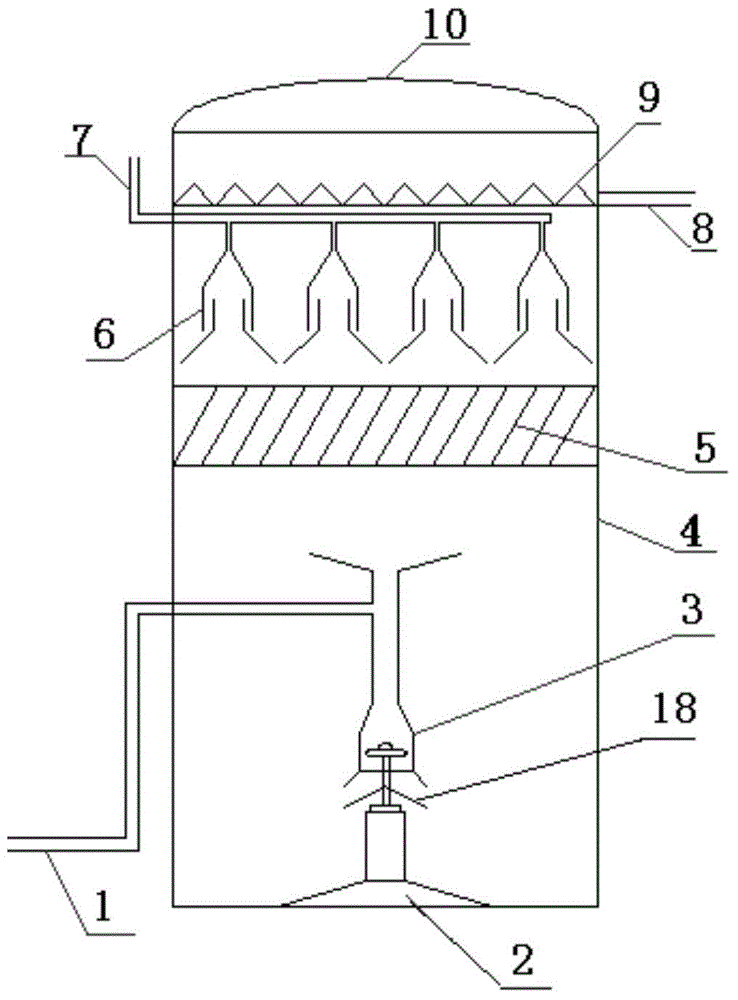

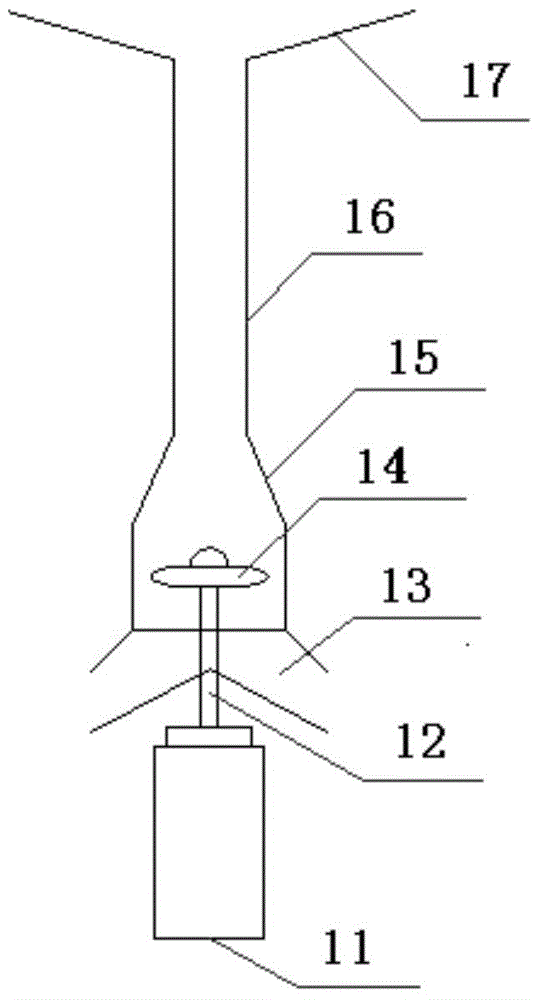

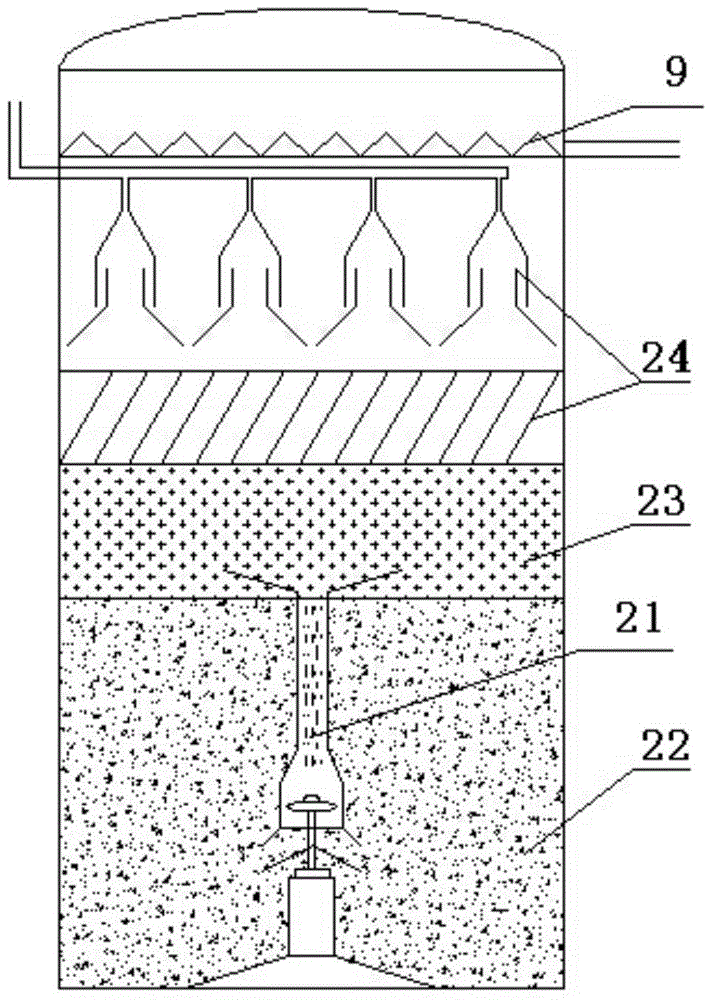

[0056] Such as figure 1 As shown, a mechanical internal circulation jet anaerobic reactor of the present embodiment includes a reactor tank 4, a multiphase separator and an outlet weir 9, and also includes an internal circulation jet 3; the reactor tank 4 It is a cylindrical structure with a height of 12 meters. It adopts a steel structure or a steel concrete structure. The inner wall is treated with anticorrosion. It is equipped with a water inlet pipe 1, a fixed platform 2, an air guide pipe 7, an outlet pipe 8 and a reactor top cover 10; The multi-phase separator comprises two-phase separator 5 and three-phase separator 6; as figure 2 As shown, the internal circulation jet 3 is composed of upper and lower parts, the upper part includes jet opening 13, diffuser opening 15, guide tube 16 and steady flow opening 17; the lower part includes motor 11, rotating shaft 12 and High-speed blades 14, wherein: the jet port 13 and the steady flow port 17 are in the shape of a bell-sha...

Embodiment 2

[0072]A kind of mechanical internal circulation jet flow anaerobic reactor of this embodiment, the basic structure is the same as embodiment 1, the difference is: the inclination angle of the PVC plate in the two-phase separator 5 is 60 °, and the two-phase separator 5 The area below the surface accounts for 75% of the total volume of the entire reactor tank body 4; the overall height of the internal circulation jet 3 is 40% of the total height of the reactor tank body 4; Down 60°, the height of the jet port 13 is 1.5 meters, and the diameter of the steady flow port 17 is 75% of the diameter of the reactor tank 4;

[0073] The pH of the mixed wastewater in the production process of a papermaking enterprise: 9-10; CODcr: 13000-15000mg / L; SS: 4000-5000mg / L, which belongs to high-concentration organic wastewater that is difficult to biodegrade. The method for treating the chemical wastewater by the reactor is the same as in Example 1. After 3 weeks of circulating treatment, the C...

Embodiment 3

[0075] A mechanical internal circulation jet flow anaerobic reactor of this embodiment has the same basic structure as that of Embodiment 1, except that the inclination angle of the PVC plate in the two-phase separator 5 is 50°, and the inclination angle of the two-phase separator 5 is The area below the surface accounts for 70% of the total volume of the entire reactor tank body 4; the overall height of the internal circulation jet 3 is 40% of the total height of the reactor tank body 4; Down 50°, the height of the jet port 13 is 1 meter, and the diameter of the steady flow port 17 is 60% of the diameter of the reactor tank body 4;

[0076] The pH of a leather enterprise's production process wastewater: 6-9; CODcr = 3000mg / L; ammonia nitrogen = 200mg / L, sulfur ion = 1000mg / L, where sulfur ion is combined with hydrogen ion in wastewater to form H 2 S is a highly toxic substance, which has a strong toxic effect on the biochemical system, especially the anaerobic system. The met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com