Two-stage double-flow autotrophic denitrification biofilter

An autotrophic denitrification and biological filter technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of weak shock load resistance, bacterial loss, low biomass, etc., and achieve good shock load resistance, Solve the effect of packing blockage and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

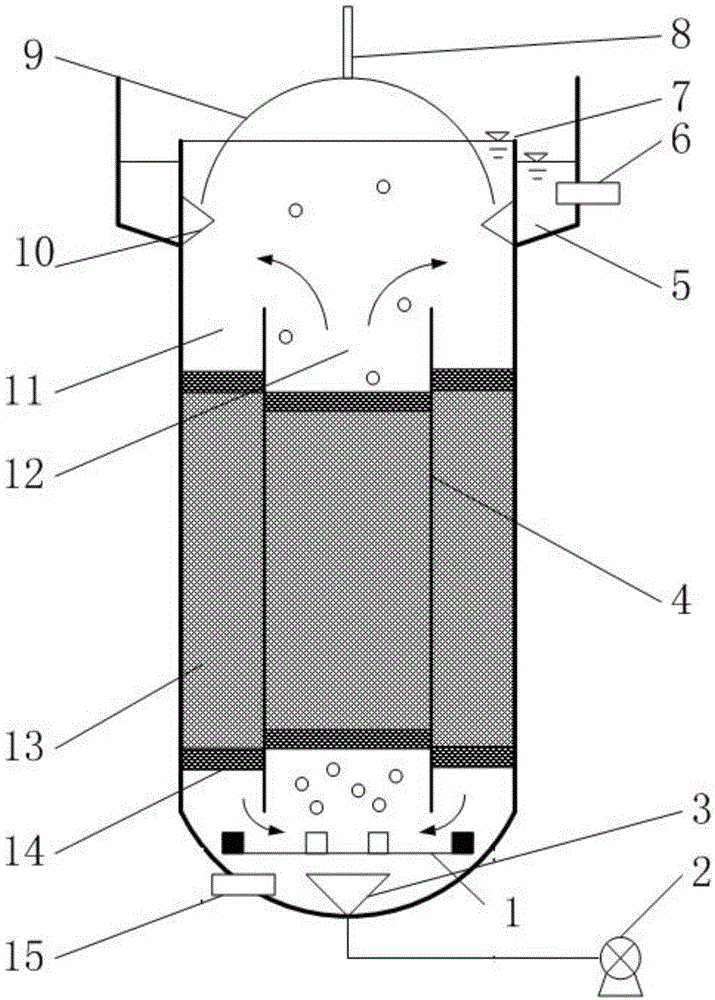

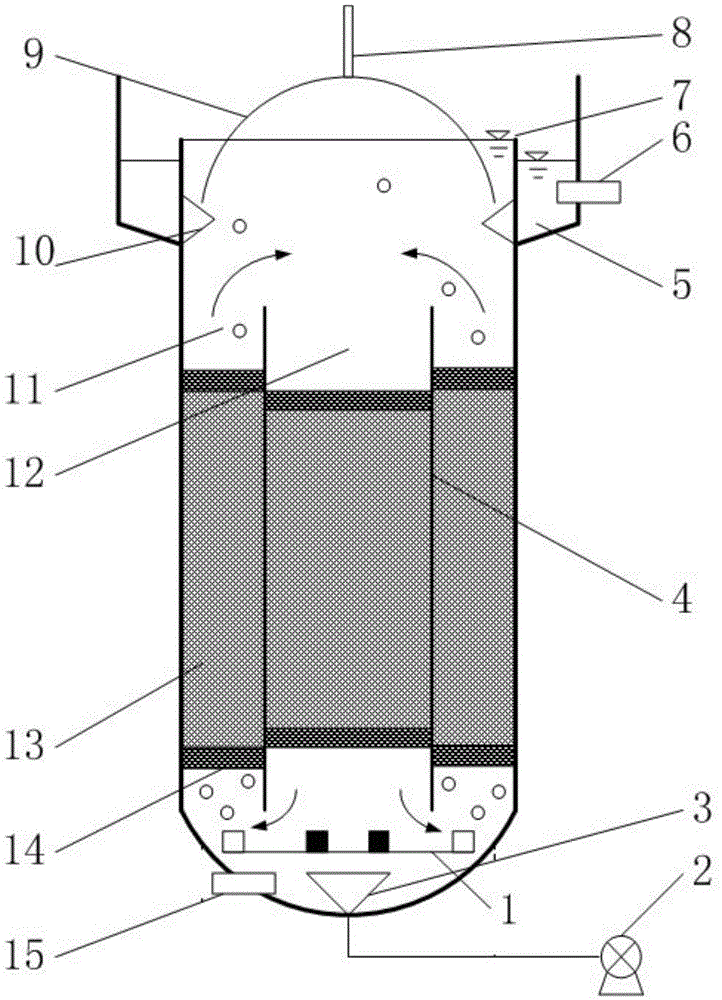

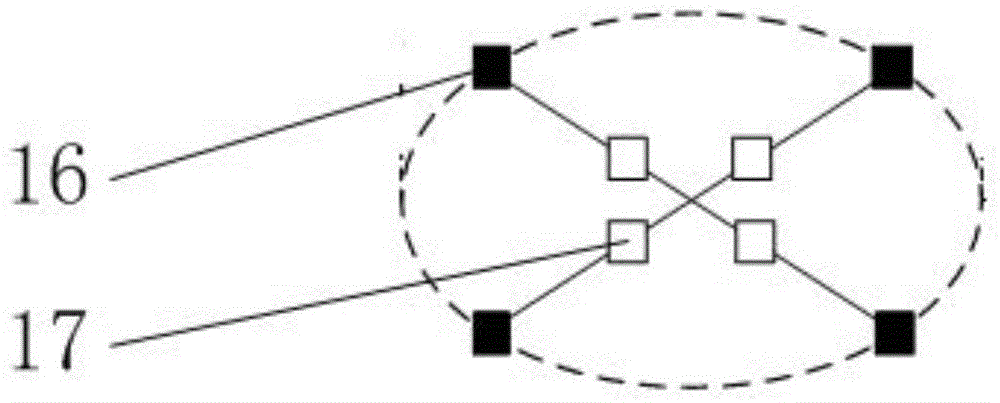

[0020] Example 1 A two-stage double-flow autotrophic denitrification biological filter according to the present invention includes a reactor body, a sleeve and a packing inside the reactor, and the reactor body is provided with a backflow water distribution system from bottom to top unit, sludge discharge unit, autotrophic denitrification unit, three-phase separation unit, water outlet and exhaust unit, the return water distribution unit includes an aeration pan 1, a conical water distributor 3, and the aeration pan 1 is The set aeration head is divided into an outer aeration head 16 and a central aeration head 17, wherein the outer aeration head 16 is arranged directly below the outer filter tank 11, and the central aeration head 17 is arranged directly below the inner filter tank 12. The conical water distributor 3 is fixed at the bottom of the reactor body below the aeration pan 1, and the water inlet of the conical water distributor 3 is connected to the water outlet of the...

Embodiment 2

[0029] Embodiment 2 utilizes the device of embodiment 1, carries out reaction: a kind of two-stage two-flow type autotrophic denitrification biofilter of the present invention can be made with PVC board or steel plate, and its mode of operation one ( figure 1 ) is as follows: Nitrogen-containing wastewater is introduced into the reactor by the water inlet pump 2 through the conical water distributor 3, aerated through the central aeration head 17, and the wastewater enters the inner filter tank 12 from the lower part, and part of the NH 4 + The nitrous acid bacteria attached to the surface of filler 13 are converted into NO 2 - , NO 2 - and NH again 4 + The anaerobic ammonium oxidation bacteria in the inner layer of the filler is converted into nitrogen, and the generated nitrogen and remaining air enter the three-phase separation zone, and the gas rises continuously and is collected by the hemispherical gas collection hood 9 and discharged from the exhaust port 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com