Device and method for producing biogas by distillers' grain fermentation

A distiller's grains and biogas technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problem of affecting the removal effect of insoluble organic matter, easy blockage of riser and return pipe, and stable granular sludge To achieve the effect of enhancing the mud-water separation effect, reducing the amount of sludge discharged, and good methane production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

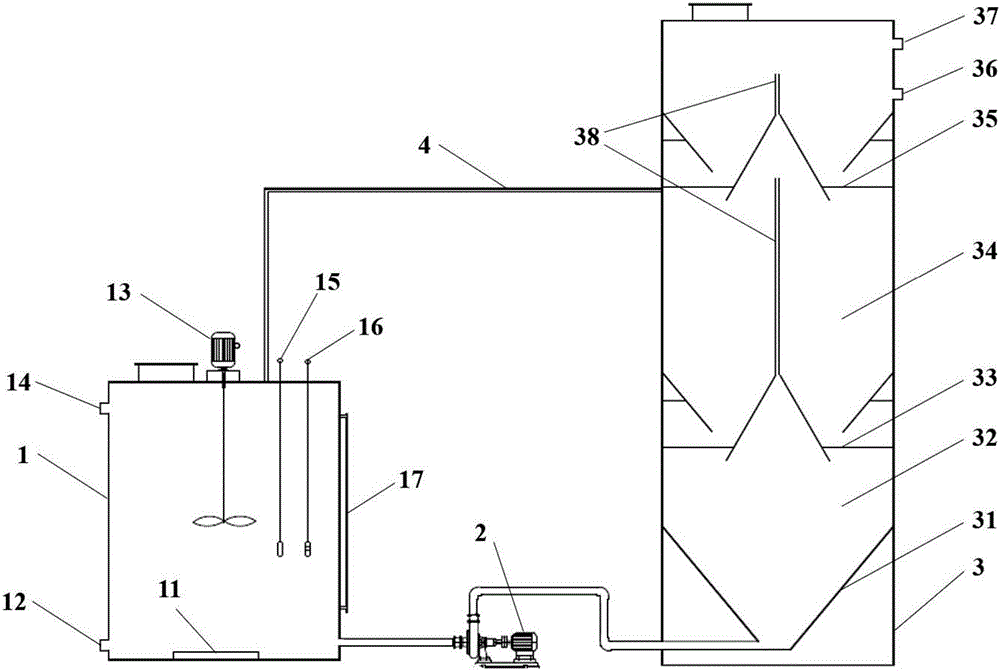

[0028] The present invention will be further explained and illustrated below in conjunction with specific embodiments and accompanying drawings.

[0029] Depend on figure 1 It can be seen that a device for biogas production by fermenting distiller's grains, which includes a mixing tank 1, a circulation pump 2 and a reaction tank 3 connected in sequence through pipelines, and also includes a part of the sludge in the second reaction chamber 34 of the reaction tank 3 The distiller's grain wastewater returns to the return pipe 4 of the mixing tank 1; the reaction tank 3 is provided with a water distributor 31, a first reaction chamber 32, a first-stage three-phase separator 33, and a second reaction chamber 34 in sequence from bottom to top , second stage three-phase separator 35, guide pipe 38, drain port 36 and exhaust port 37; described mixing tank 1 body is provided with heating device 11, emptying port 12, agitator 13 and Feed port 14.

[0030] Preferably, the mixing tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com