Integrated sewage treatment equipment with multi-biomembrane

A sewage treatment equipment, biofilm technology, applied in water/sludge/sewage treatment, chemical instruments and methods, aerobic and anaerobic process treatment, etc., can solve the problems of complex process flow, high cost, complicated operation, etc. , to achieve the effect of high processing efficiency, convenient management and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

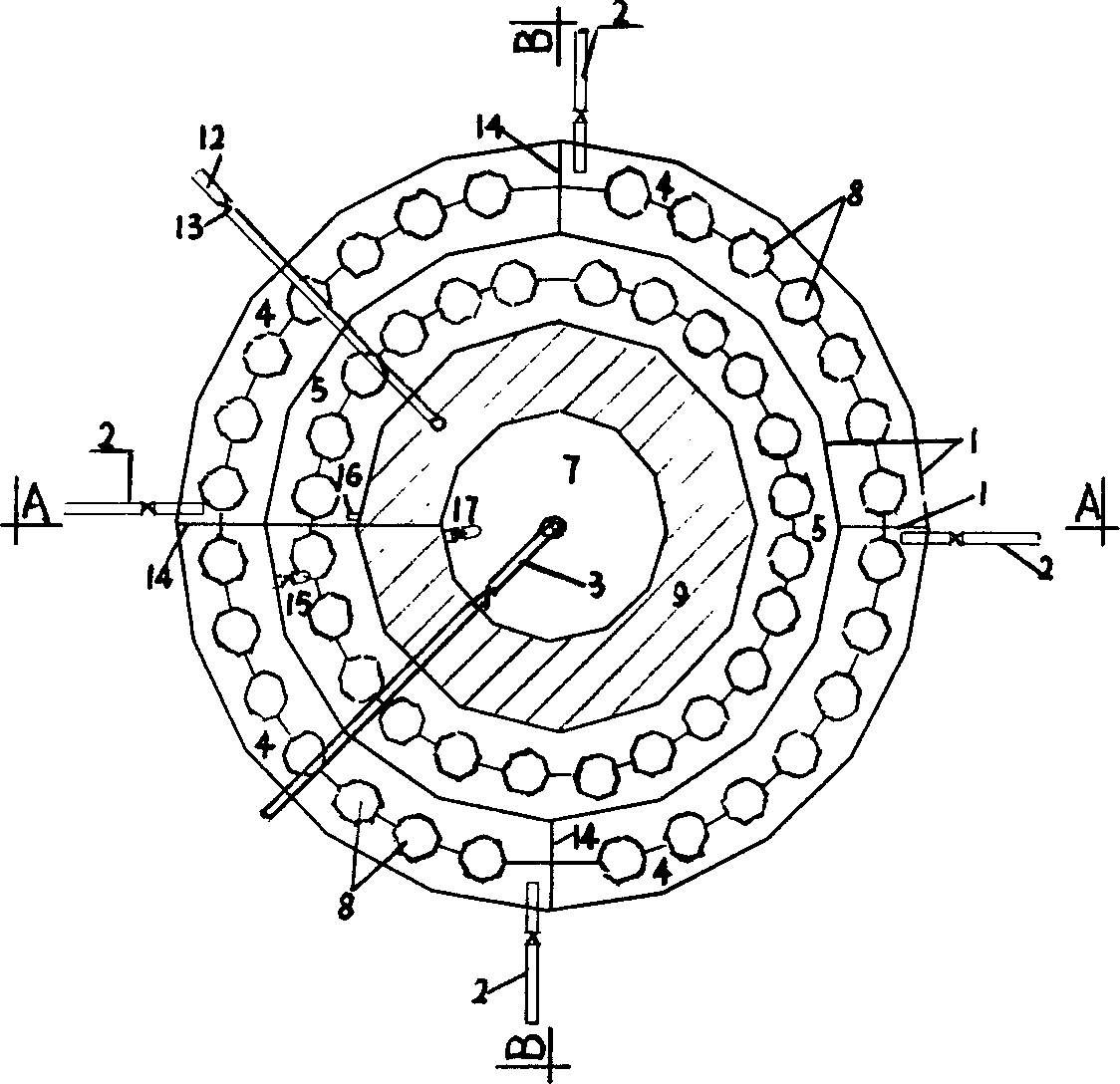

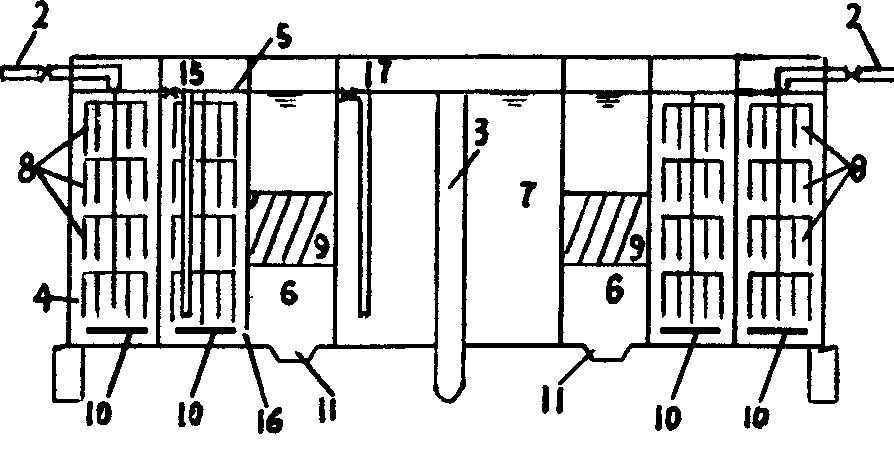

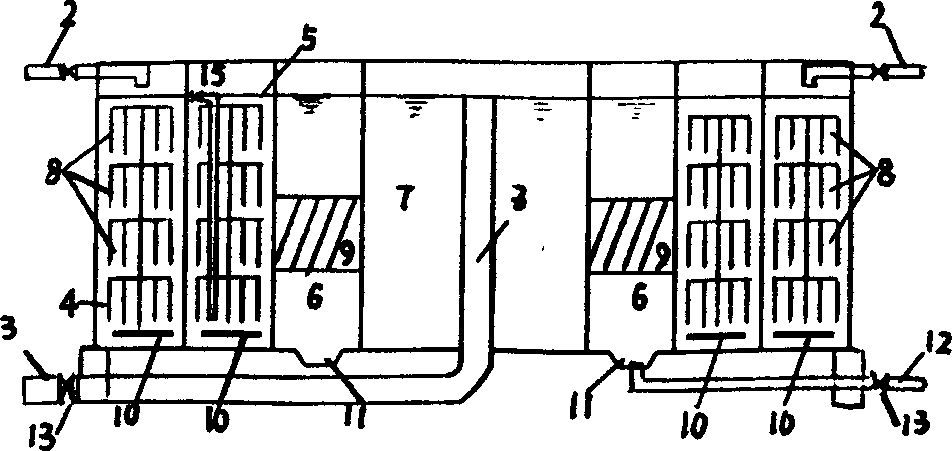

[0019] see figure 1 , 2 with image 3 , The integrated treatment equipment includes a pool body 1, a water inlet pipe 2 and a drain pipe 3, etc. The pool body 1 adopts a circular pool body, which is composed of four concentric circles, and divides the pool body into four functional areas: the outer ring 4 is divided into different reaction areas by a partition 14, and a semi-soft composite packing 8 is arranged inside, each The aerobic and anoxic alternate operation in the reaction zone, each reaction zone is connected with the water inlet pipe 2, water supply in points, and set to the water outlet pipe 15 in the middle ring. The middle ring 5 is an aerobic zone with a semi-soft composite packing 8 and a water outlet 16 to the inner ring. An underwater aeration device 10 is arranged at the bottom of the outer ring 4 and the middle ring 5 . The inner ring is the sedimentation area 6, which is equipped with inclined plates 9 (the length of the inclined plates is 0.5m, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com