Composite technology for coking wastewater treatment

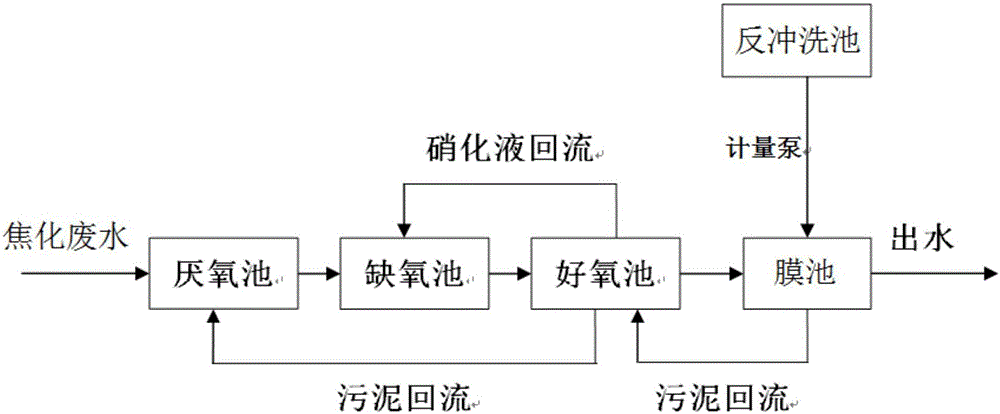

A technology of coking wastewater and composite process, which is applied in multi-stage water treatment, anaerobic digestion treatment, biological water/sewage treatment, etc. It can solve the problem that effluent COD and ammonia nitrogen are difficult to meet the standards, the concentration of activated sludge is low, and the impact load is poor. problems, to achieve the effect of saving infrastructure costs, small footprint, and improving impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

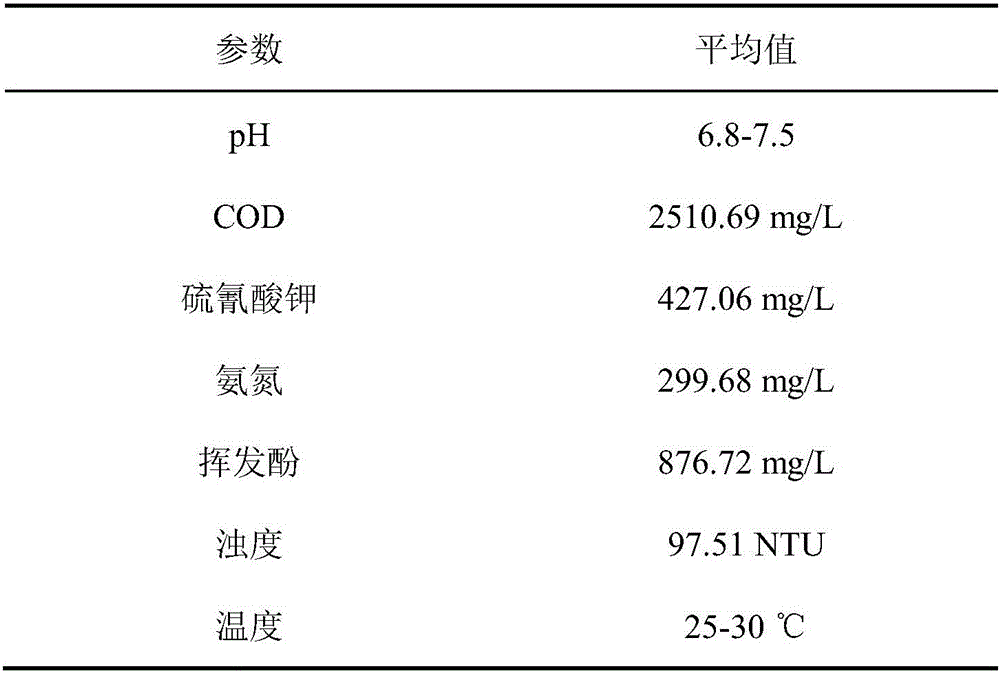

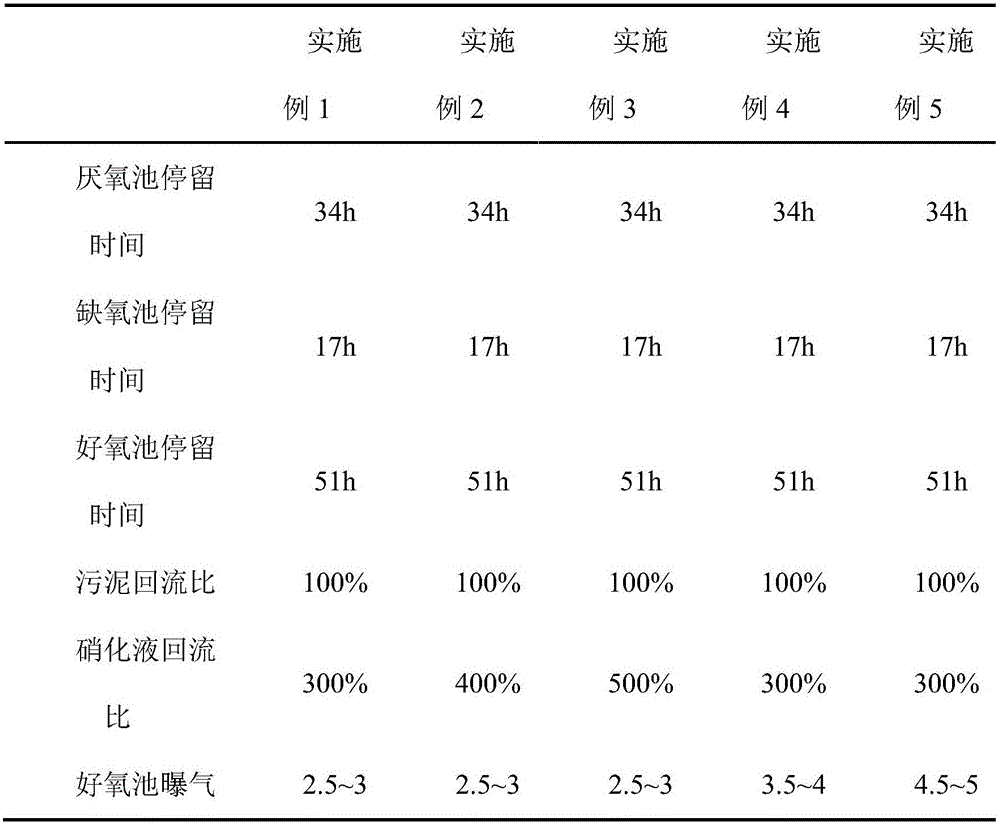

[0028] Set its operating parameters as follows: hydraulic retention time is 5 days, sludge reflux ratio is 100%, nitrifying liquid reflux ratio is 300%, and water temperature is controlled at 25-30°C. The specific steps are as follows:

[0029] (1) Coking wastewater is first pumped into the anaerobic tank by the sewage pump. In the anaerobic tank, the phosphorus accumulating bacteria release phosphorus and absorb easily degradable organic matter such as low-level fatty acids, which mainly play the role of anaerobic acidification and dilution and buffering of influent , HRT is 34h, dissolved oxygen is maintained below 0.1ppm;

[0030] (2) The coking wastewater diluted and buffered in step (1) enters the anoxic tank through overflow, and in the anoxic tank, the denitrifying bacteria convert the nitrate brought by the reflux of the nitrifying liquid into nitrogen and release it through biological denitrification into the air to achieve the purpose of denitrification, the HRT is 1...

Embodiment 2

[0036] Embodiment 2: The reflux ratio of nitrifying liquid in setting its operating parameters is adjusted from 300% to 400%, and the rest of the process parameters are the same as in Embodiment 1.

Embodiment 3

[0037] Embodiment 3: The reflux ratio of nitrification liquid in setting its operating parameters is adjusted from 400% to 500%, and the rest of the process parameters are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com