Anaerobic-anoxic/aerobic-parallel reinforced dephosphorization and denitrification technique

An anoxic, aerobic, and denitrification technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water pollutants, etc., can solve the problem of increasing power costs, anaerobic tank volume, and denitrification of return sludge Time increase, increase the volume of the anoxic tank, etc., to achieve the effect of reducing volume, reducing power consumption, and increasing sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

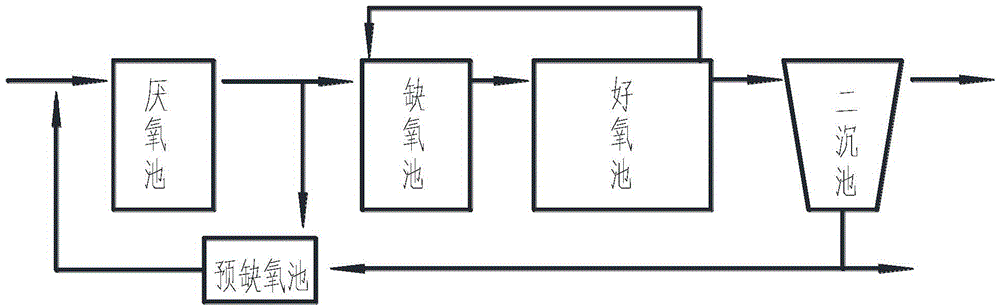

[0017] Such as figure 1 As shown, the anaerobic concurrent anoxic and aerobic enhanced phosphorus and nitrogen removal process of the present invention utilizes anaerobic tanks, pre-anoxic tanks, anoxic tanks, aerobic tanks, and secondary sedimentation tanks to introduce raw water into anaerobic tanks. After being treated by the anaerobic tank, it enters the anoxic tank, and after being treated by the anoxic tank, it enters the aerobic tank. Part of the water treated by the aerobic tank flows back to the anoxic tank, and part of it enters the secondary sedimentation tank for precipitation. The supernatant in the settling tank is discharged, part of the sedimentation sludge is discharged, and part of it is returned to the pre-anoxic tank for treatment, and part of the water treated in the anaerobic tank is diverted into the pre-anoxic tank and the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com