Aerobic membrane bioreactor and process

A membrane bioreactor and process technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of large quantity and other problems, so as to achieve the effect of remarkable and efficient operation effect, small equipment footprint and simple process design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

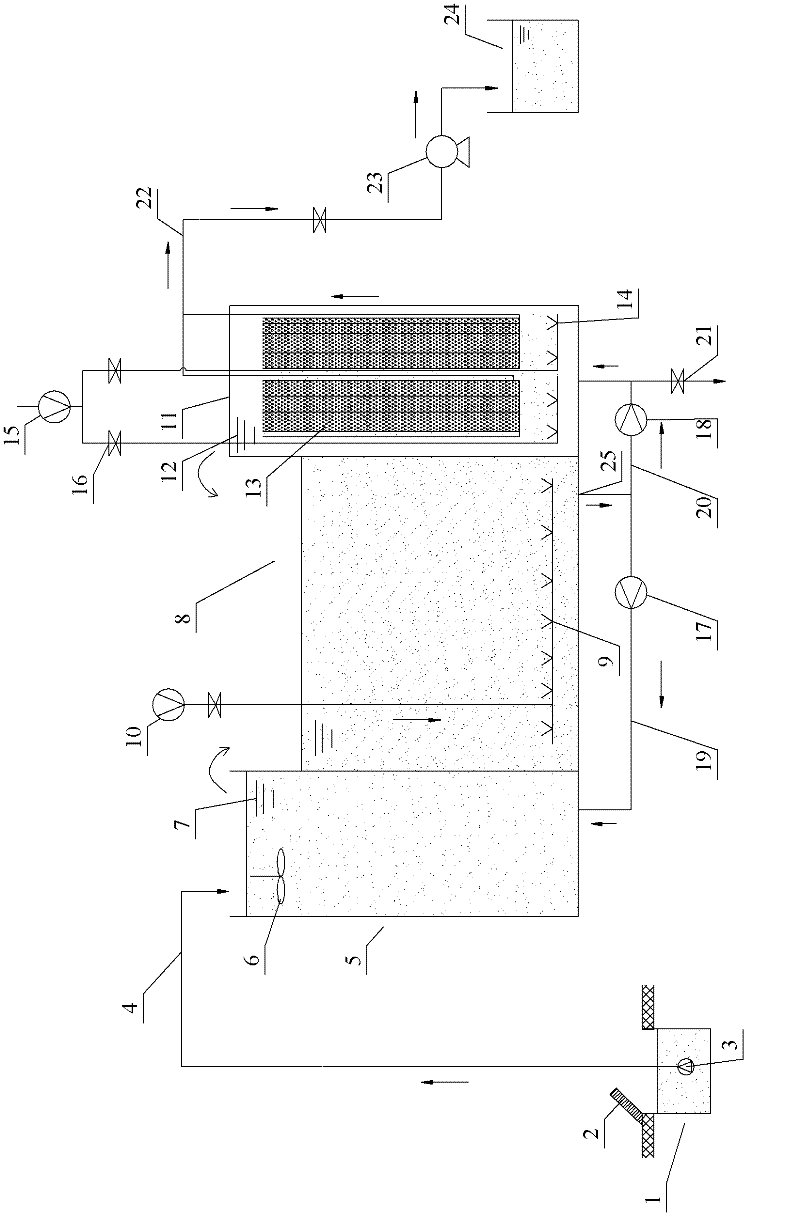

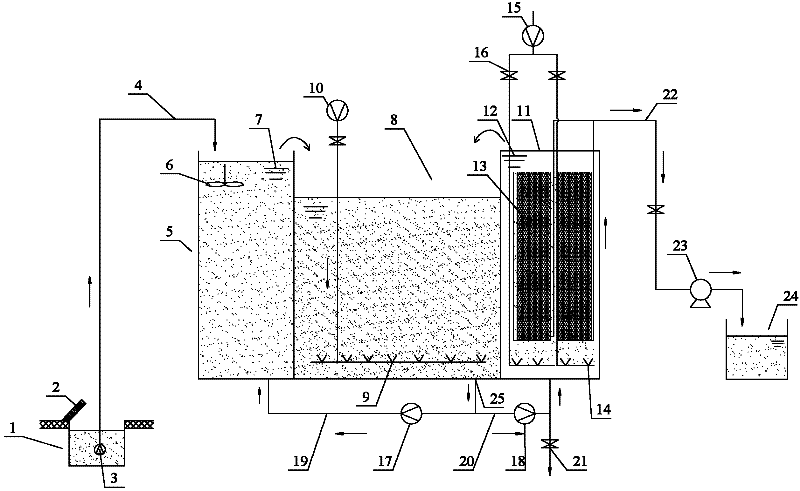

[0029] see figure 1 , is the aerobic membrane bioreactor involved in the present invention. It includes water collecting well 1, anoxic pool 5, aerobic pool 8, membrane pool 11 and clear water pool 24 which are set separately. The water collection well 1 is arranged under the ground surface, and a fine grid 2 is arranged on the ground surface, and the size of the grid 2 is not more than 1mm. A lift pump 3 is arranged in the water collection well 1, and the sewage can be extracted and transported through the water inlet pipe 4, and the water inlet pipe 4 above the upper opening of the anoxic pool 5. An agitator 6 is set in the anoxic pool 5 . The aerobic pool 8 is located between the anoxic pool 5 and the membrane pool 11 . The liquid levels of the anoxic pool 5 and the membrane pool 11 are all higher than the liquid level of the aerobic pool 8, and the side of the anoxic pool 5 near the aerobic pool 8 is provided with a first upper overflow port 7, and the membrane pool 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com