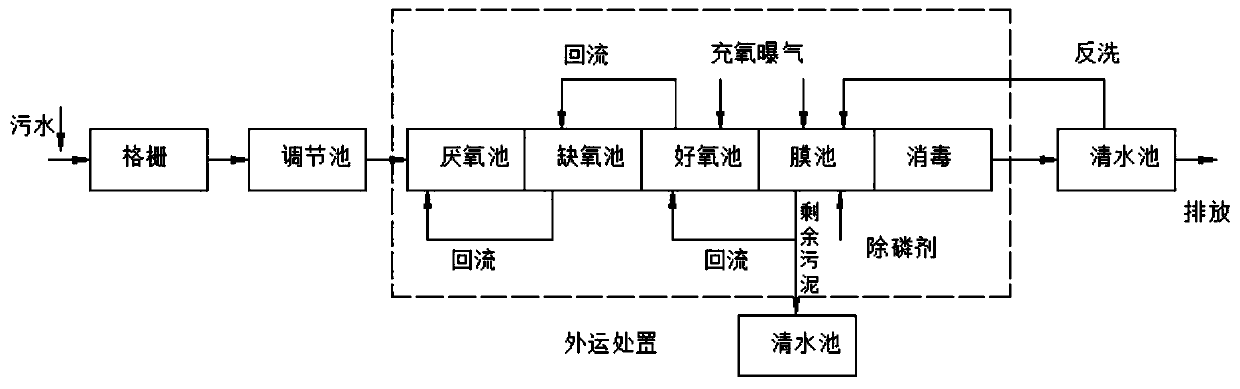

Enhanced type efficient nitrogen and phosphorus-removing sewage treatment system and treatment technology

A sewage treatment system, denitrification and phosphorus removal technology, applied in water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc. and low stable operation ability, to achieve the effects of hydraulic retention time, improved solid-liquid separation efficiency, and increased dosage of phosphorus removal agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0063] Sewage source: municipal sewage

[0064] Processing scale: 2 groups of 1000m 3 / d in parallel

[0065] Water standard: Quasi-IV

[0066] Processing technology: EUCT-MBR

[0067] (1) Return unit: the membrane system unit returns to the front end of the aerobic pool of the biochemical treatment unit, with a large return ratio of 400%; the effluent from the aerobic pool of the biochemical treatment unit returns to the inlet of the anoxic pool, Mix with the effluent from the anaerobic tank of the biochemical treatment unit, and enter the anoxic tank together, with a reflux ratio of 200%; return the effluent from the anoxic tank of the biochemical treatment unit to the inlet of the anaerobic tank, mix with the pretreated effluent, and enter the anaerobic tank together Oxygen pool, the reflux ratio is 200%;

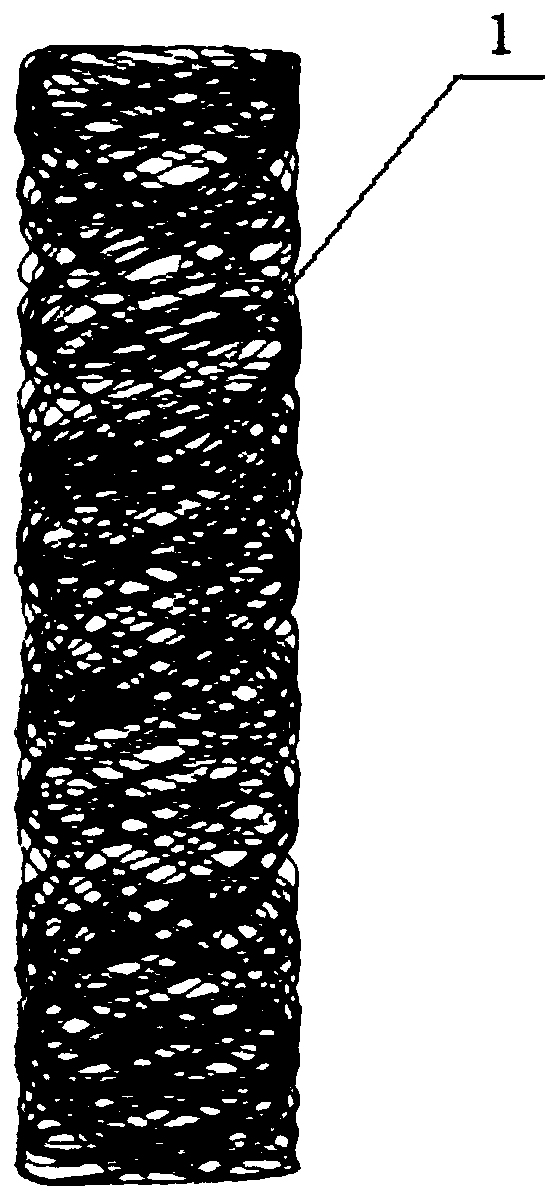

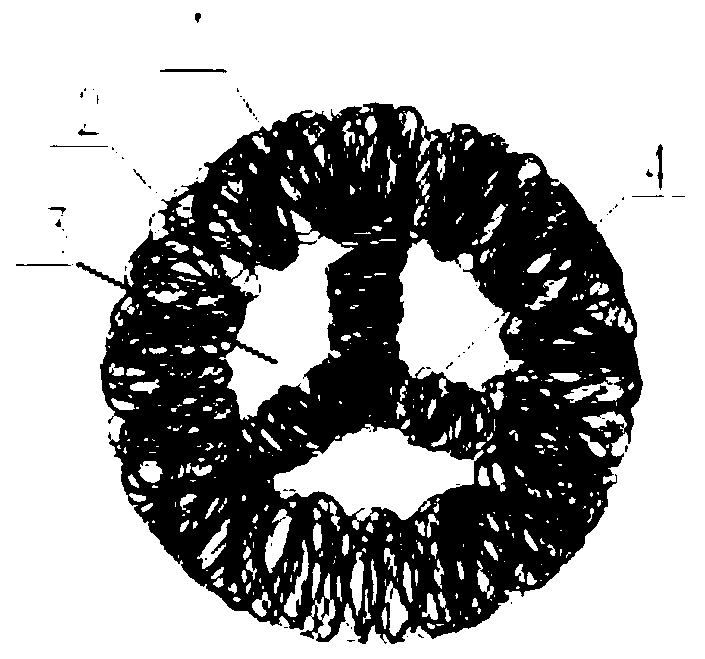

[0068] (2) Packing unit: the packing is arranged in the anoxic pool and the aerobic pool of the biochemical treatment unit; the packing type is three-dimensional sus...

example 2

[0073] Sewage source: domestic sewage

[0074] Processing scale: 500m 3 / d

[0075] Outlet standard: Class V

[0076] Processing technology: EUCT-MBR

[0077] (1) Return unit: the membrane system unit returns to the front end of the aerobic pool of the biochemical treatment unit, with a reflux ratio of 350%; the effluent from the aerobic pool of the biochemical treatment unit returns to the inlet of the anoxic pool, and The effluent from the anaerobic tank is mixed and enters the anoxic tank together, and the reflux ratio is 150%; the effluent from the anoxic tank of the biochemical treatment unit is returned to the water inlet of the anaerobic tank, mixed with the pretreated effluent, and enters the anaerobic pool together, and the reflux ratio is 150%. is 150%;

[0078] (2) Packing unit: the packing is arranged in the anoxic pool and the aerobic pool of the biochemical treatment unit; the packing type is three-dimensional suspension packing; the packing density is 70%; ...

example 3

[0083] Sewage source: domestic sewage

[0084] Processing scale: 2 groups of 200m 3 / d in parallel

[0085] Water outlet standard: Class A

[0086] Processing technology: EUCT-MBR

[0087] (1) Return unit: the membrane system unit returns to the front end of the aerobic pool of the biochemical treatment unit, and the reflux ratio is 300%; The effluent from the anaerobic tank is mixed and enters the anoxic tank together, and the reflux ratio is 100%; the effluent from the anoxic tank of the biochemical treatment unit is returned to the water inlet of the anaerobic tank, mixed with the pretreated effluent, and enters the anaerobic pool together, and the reflux ratio is 100%. is 100%;

[0088] (2) packing unit: the packing is arranged in the aerobic pool of the biochemical treatment unit; the packing type is elastic packing; the packing density is 60%;

[0089] (3) Biochemical treatment unit: the treatment process is EUCT-MBR; the quality of inflow and outflow water is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com