Coking wastewater optimizing treatment process and device

A technology for coking wastewater and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of good effluent effect, high load and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

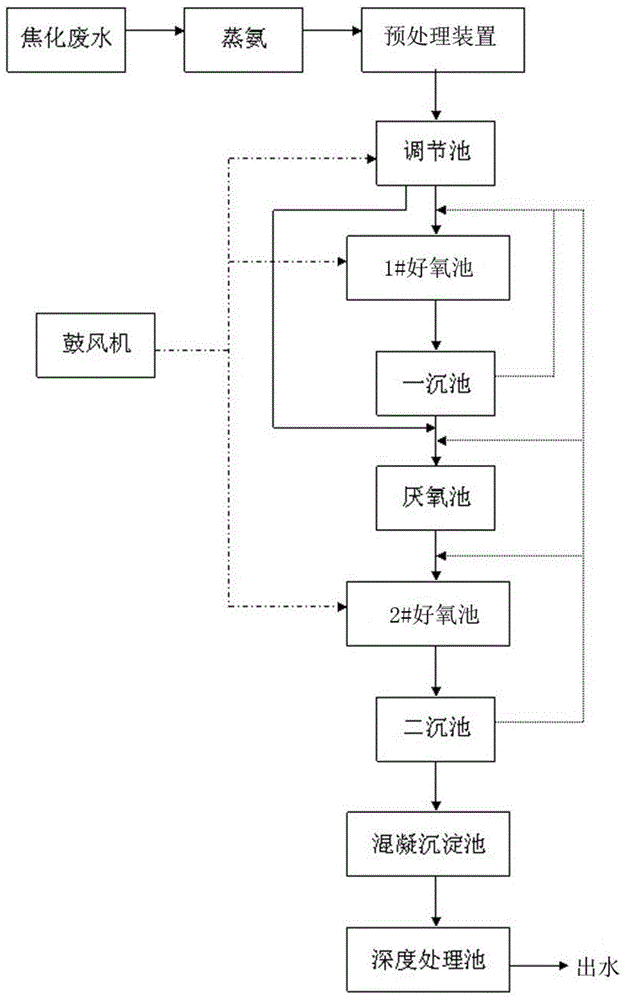

[0022] See figure 1 , is a process roadmap of the present invention, and a kind of coking wastewater optimization treatment process of the present invention comprises the following steps:

[0023] 1) Coking wastewater from coking, gas purification, and chemical product refining processes. After ammonia distillation, the ammonia nitrogen is reduced to 200-500mg / L; first stay in the grease trap for 1.5 to 2 hours to remove the light oil and heavy oil in the coking wastewater, and then reduce the ammonia nitrogen in the coking wastewater through air flotation treatment. The water quality of coking wastewater after air flotation treatment is: COD<4000mg / L, ammonia nitrogen<300mg / L, oil<30mg / L, SS<10mg / L, phenol<100mg / L, cyanide<20mg / L;

[0024] 2) Put the coking wastewater treated by oil separation and air flotation into the regulating tank and mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com