Patents

Literature

52results about How to "Reliably reduced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

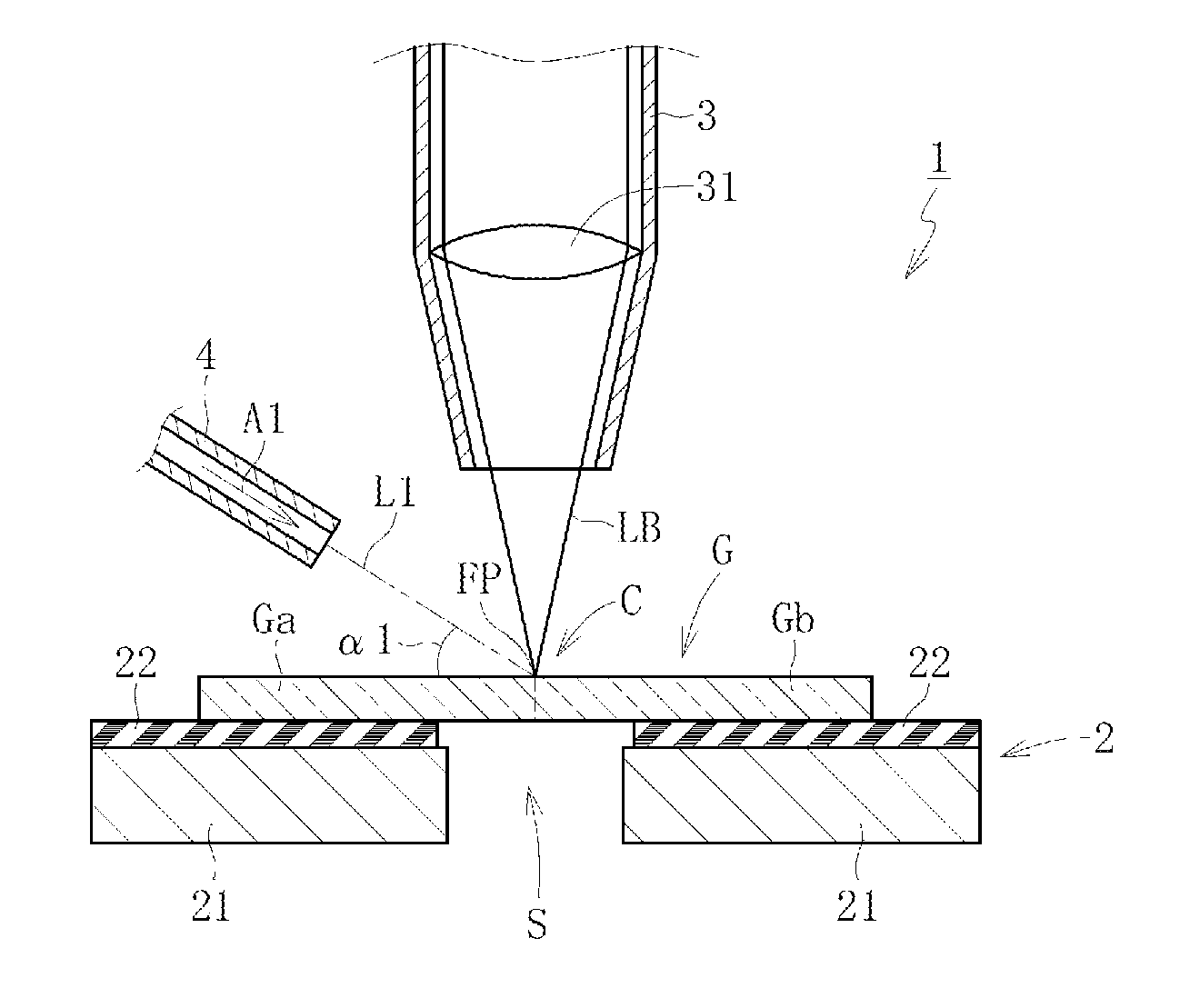

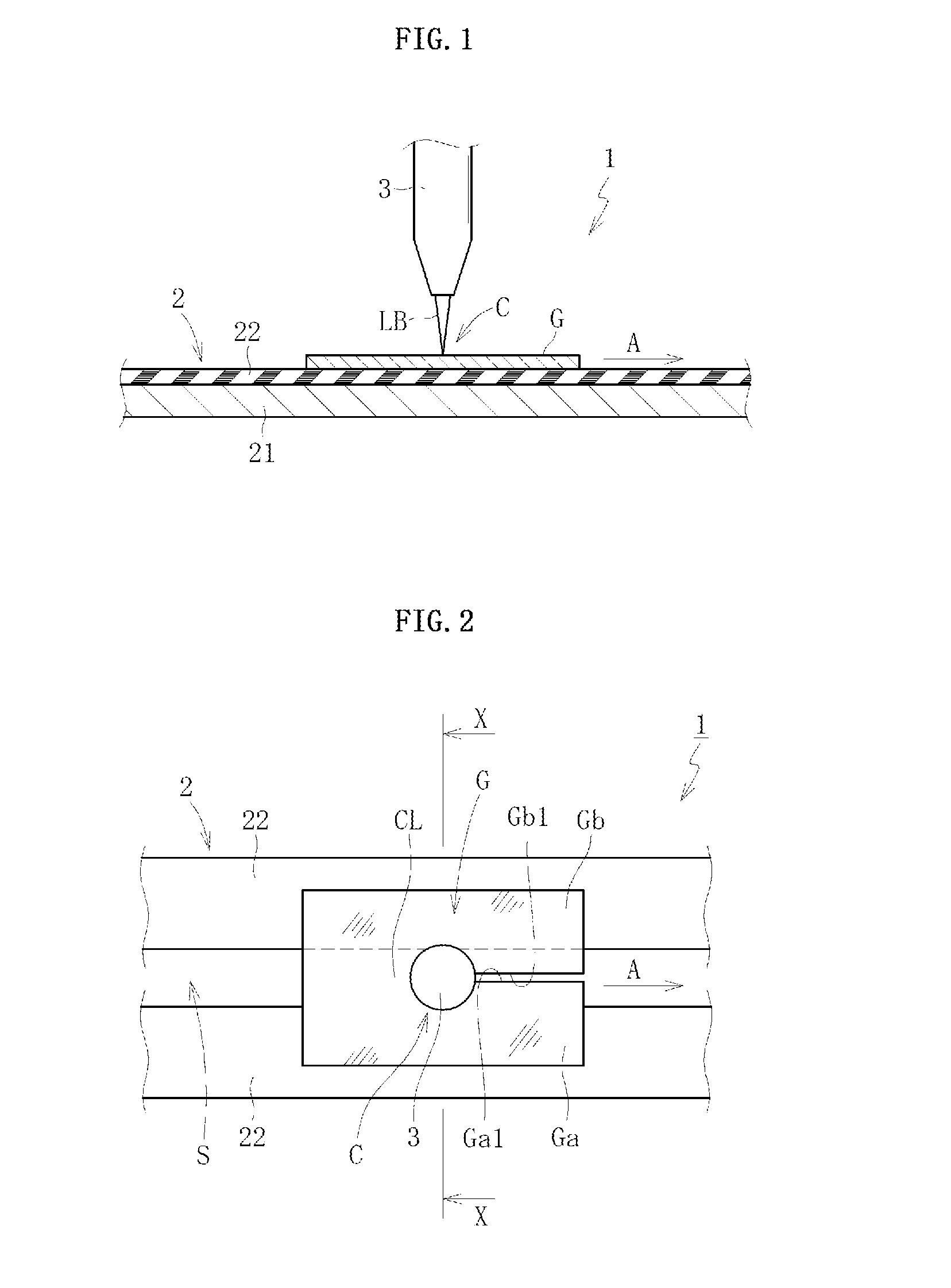

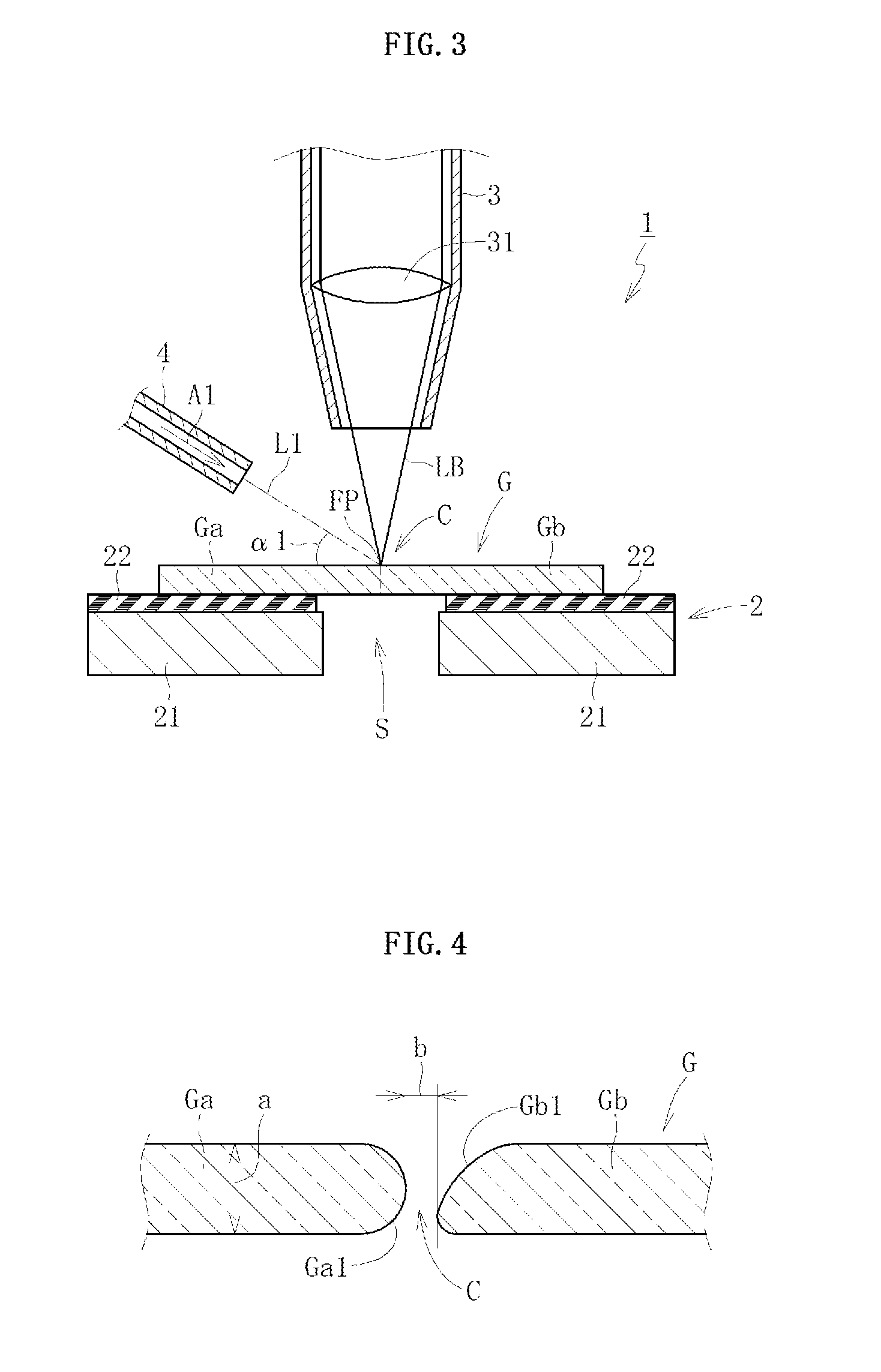

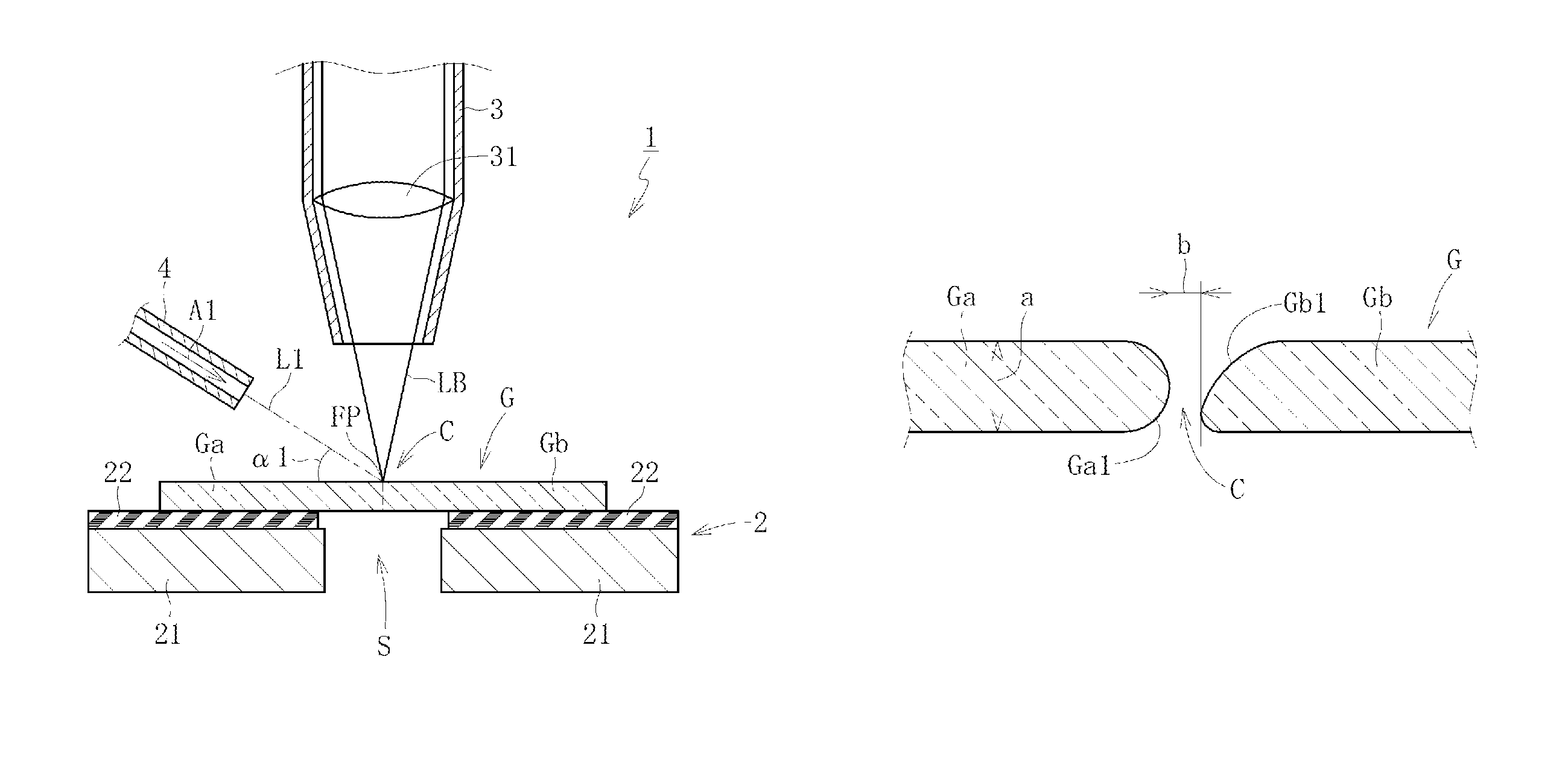

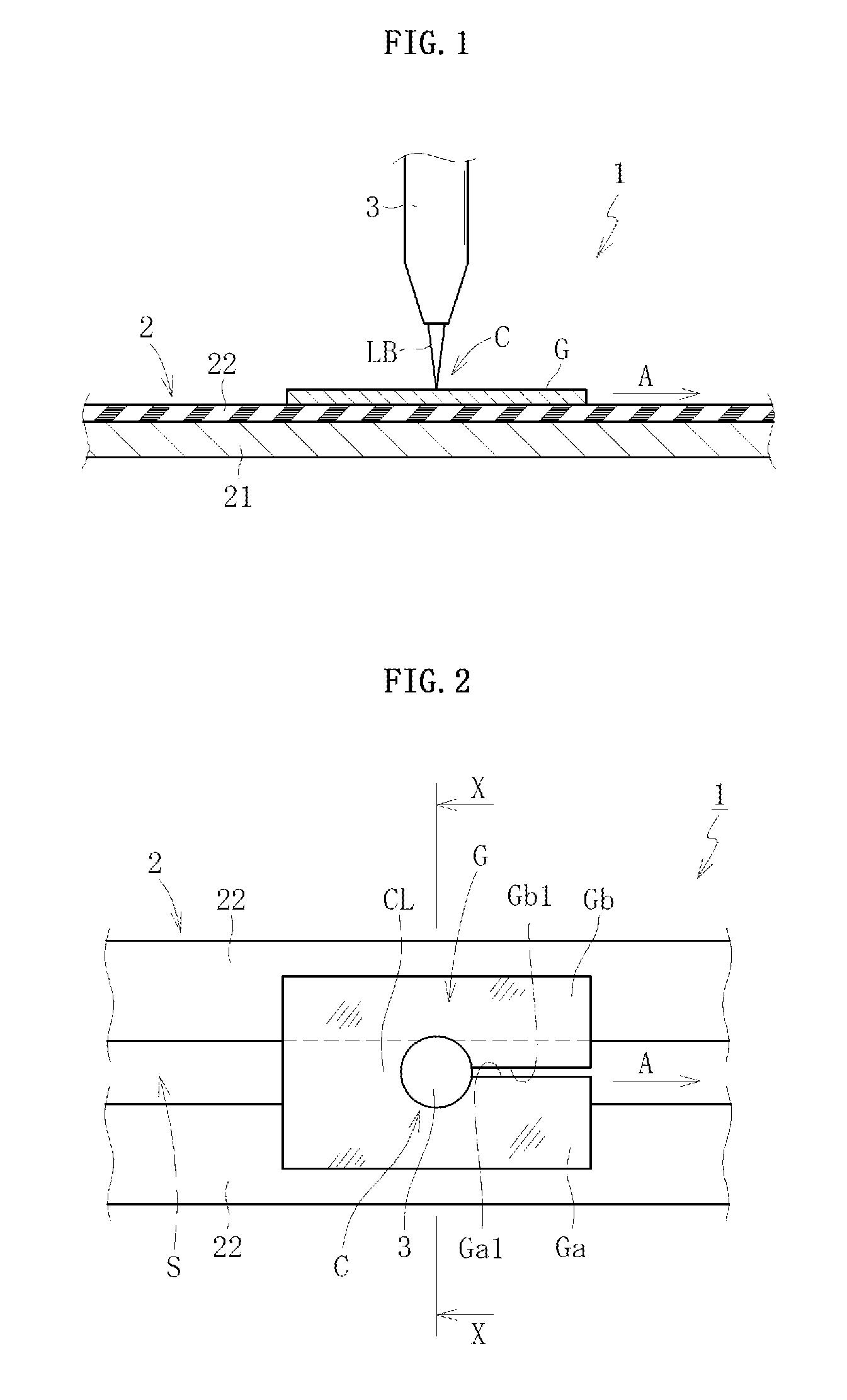

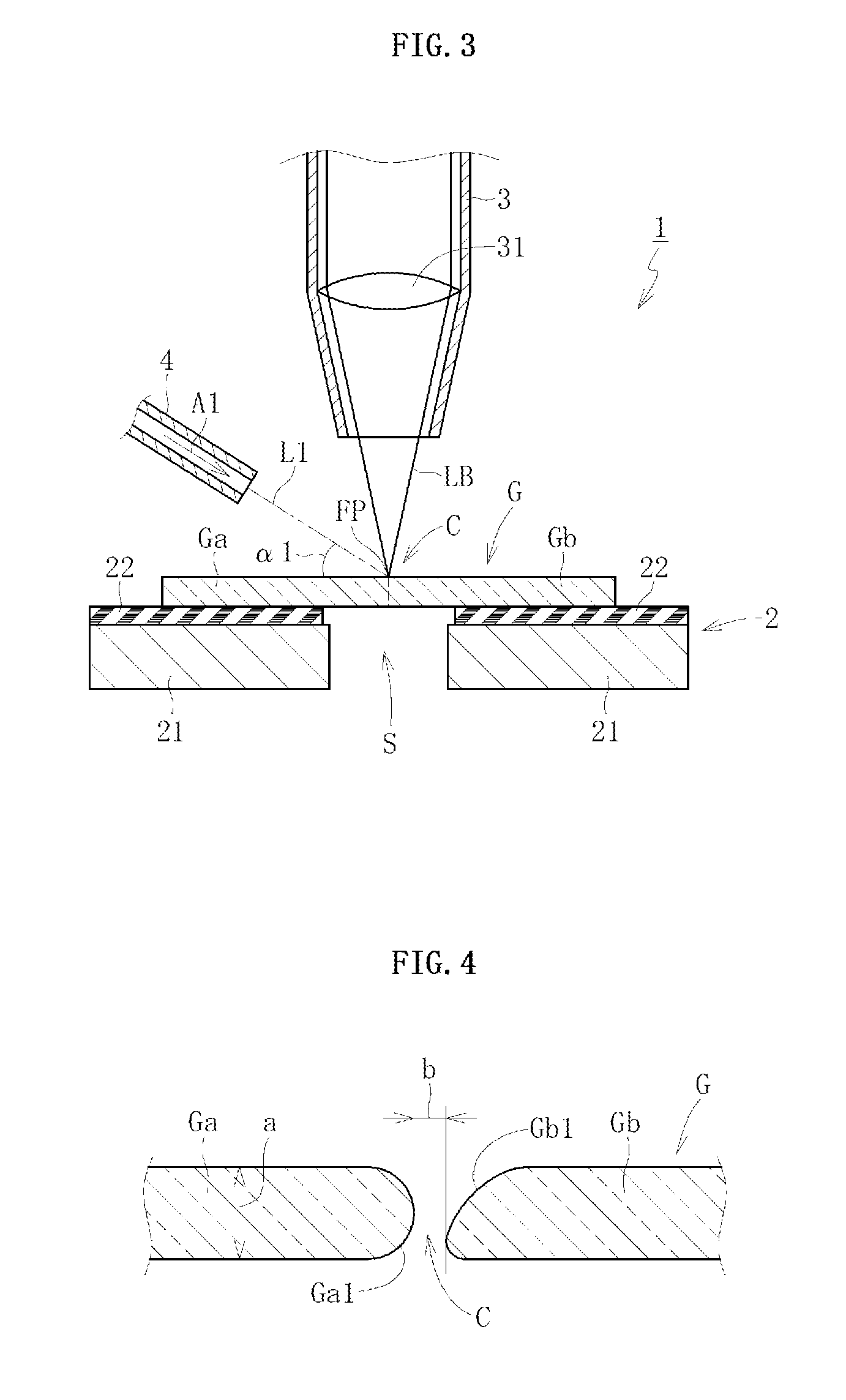

Cutting method for glass sheet and glass sheet cutting apparatus

ActiveUS20130122264A1Safe separationStrict managementGlass furnace apparatusCellulosic plastic layered productsLaser beamsGlass sheet

Provided is a cutting method for a glass sheet, comprising radiating a laser beam to a cutting portion (C) of a glass sheet (G) having a thickness of 500 μm or less to fuse the glass sheet (G), wherein a narrowest gap between fused end surfaces (Ga1 and Gb1) of the glass sheet (G), which face each other in the cutting portion (C), is managed to satisfy a relationship of 0.1≦b / a≦2, where “a” is a thickness of the glass sheet (G) and “b” is the narrowest gap.

Owner:NIPPON ELECTRIC GLASS CO LTD

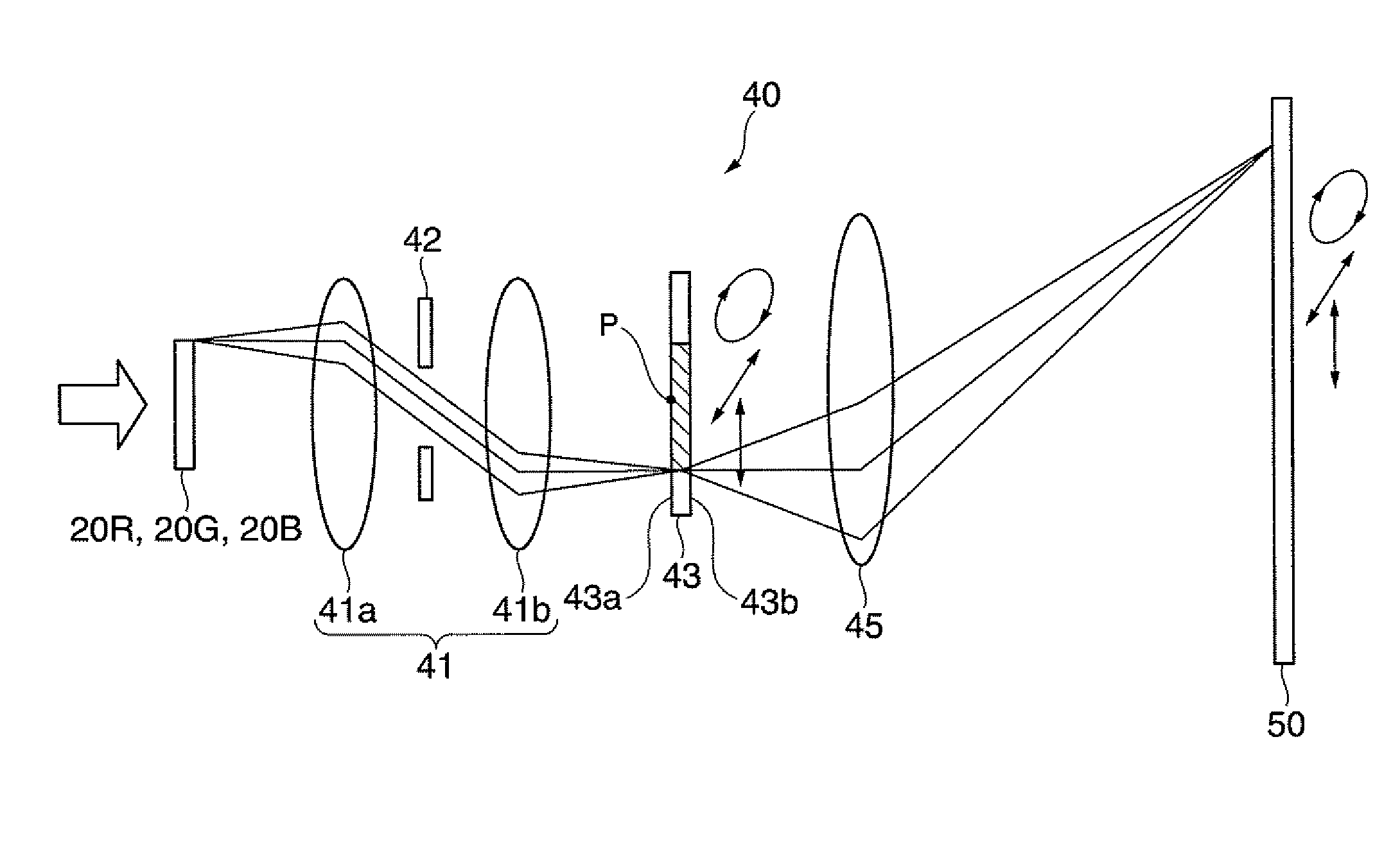

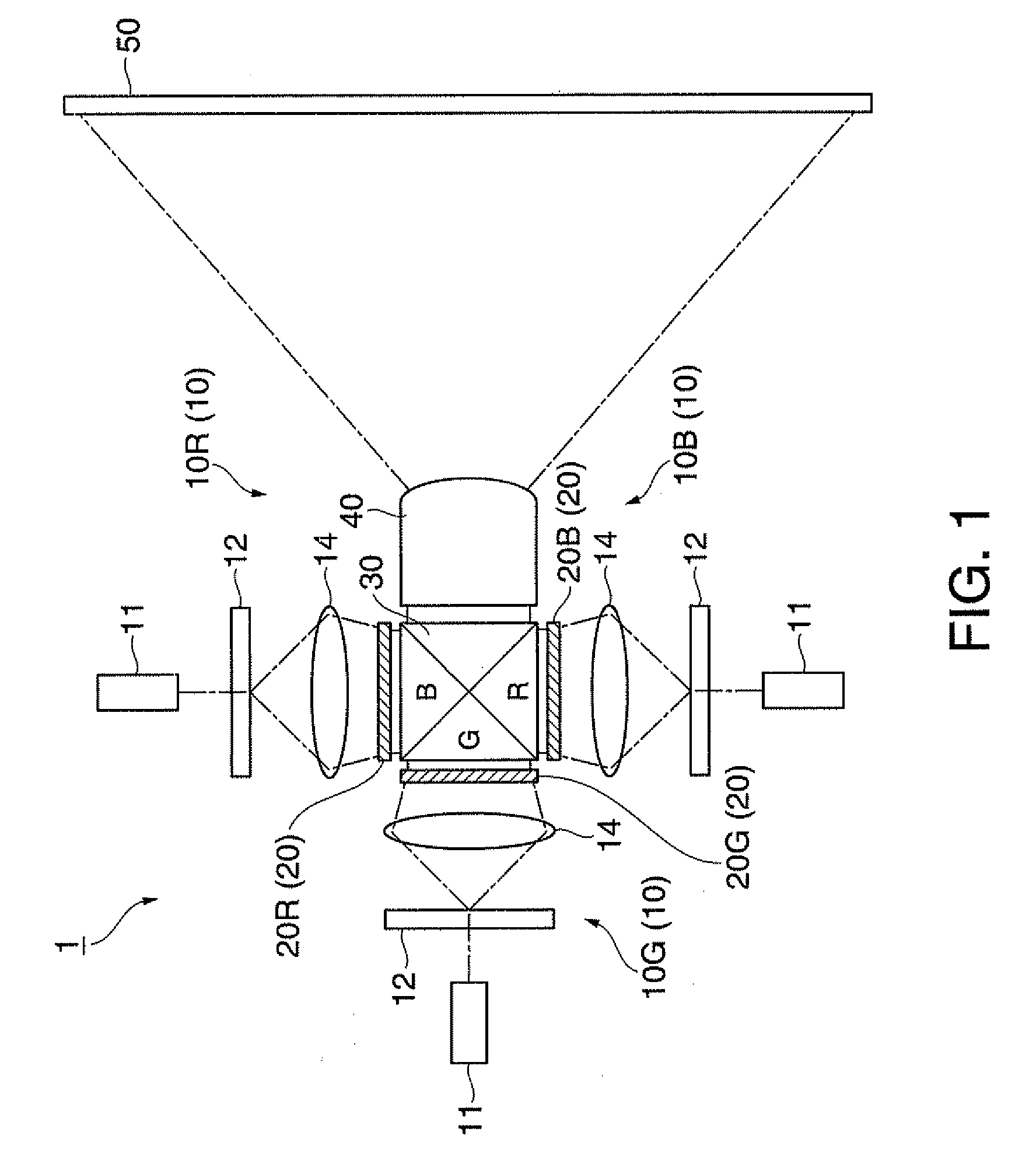

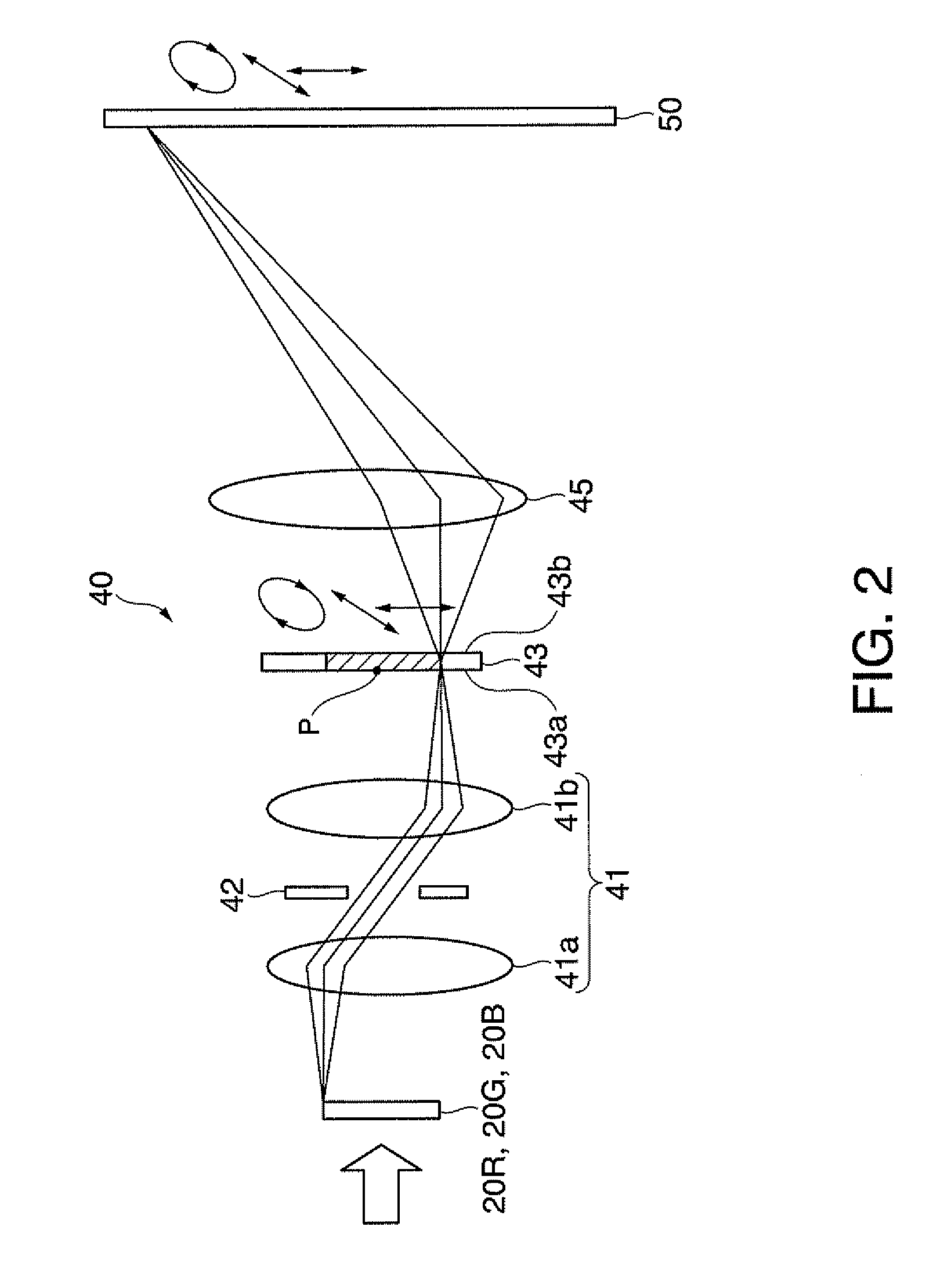

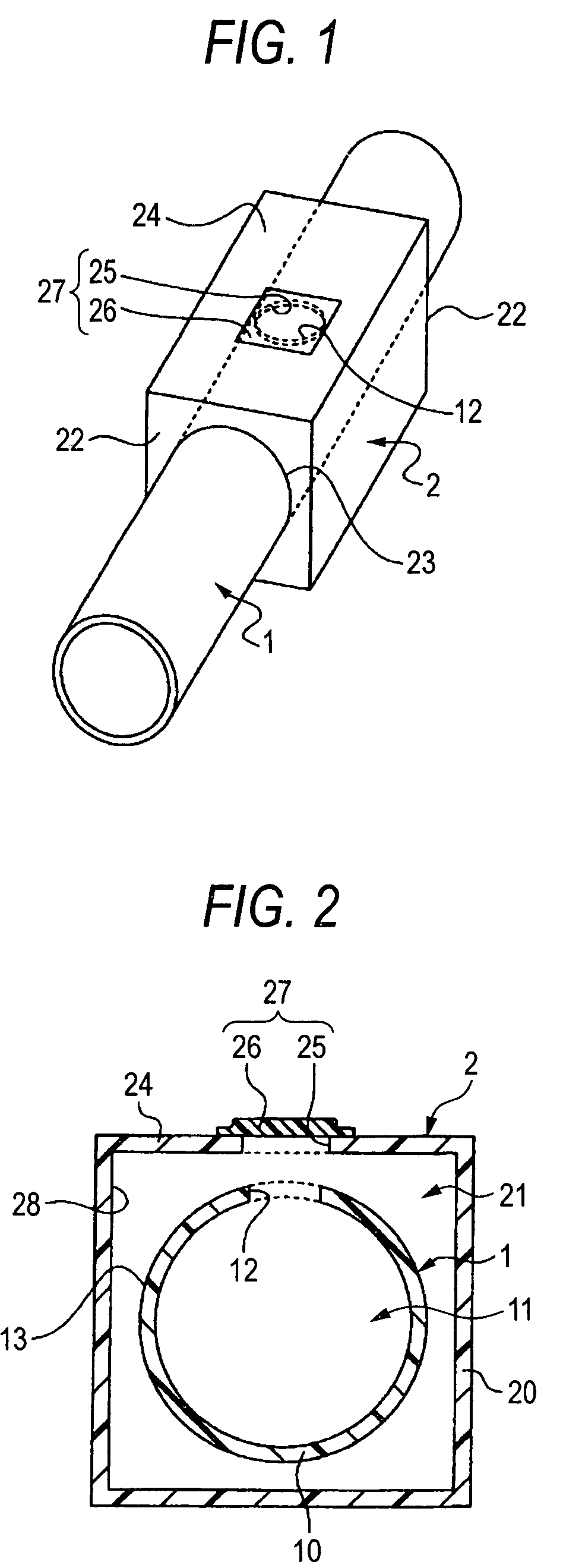

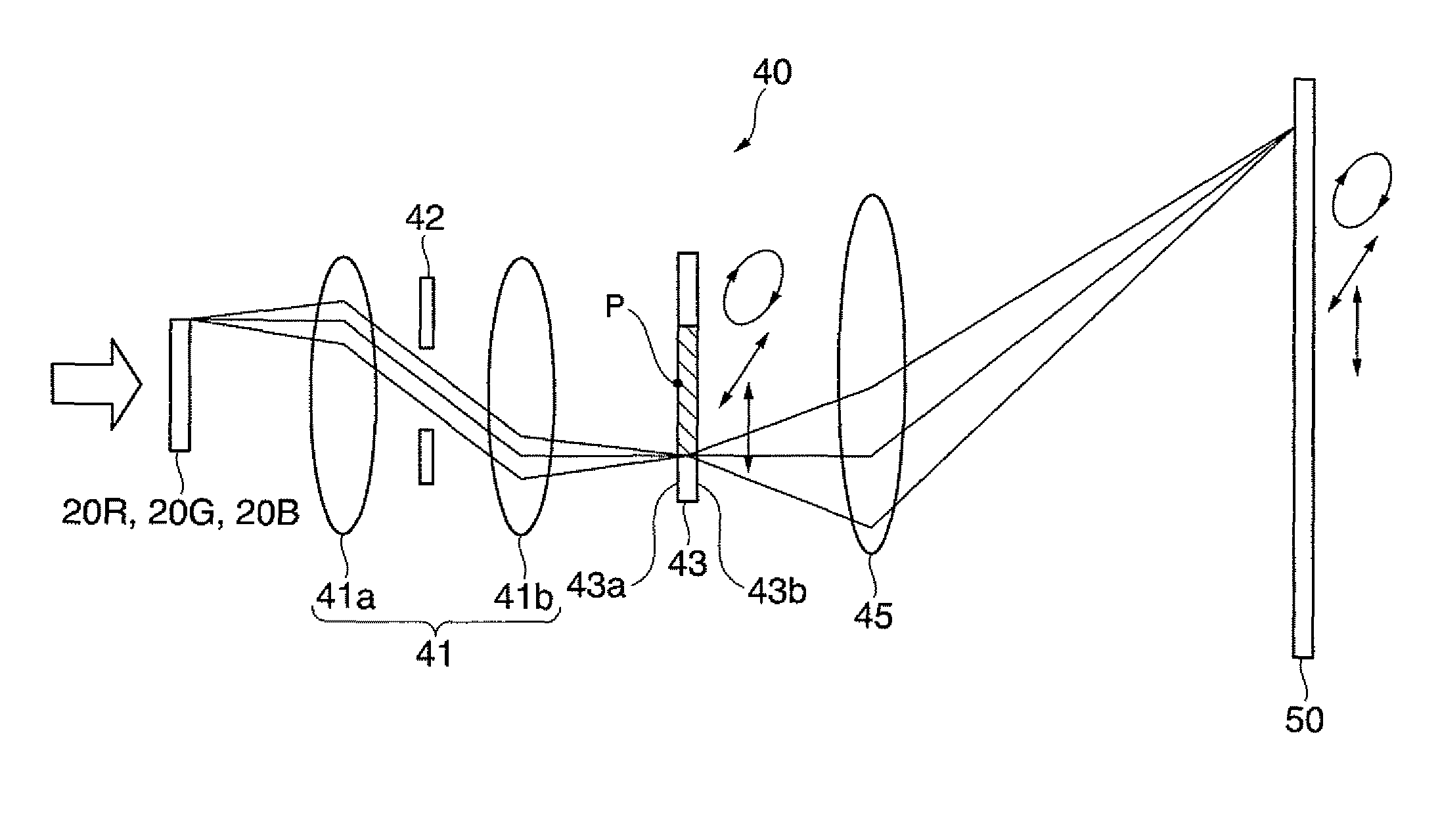

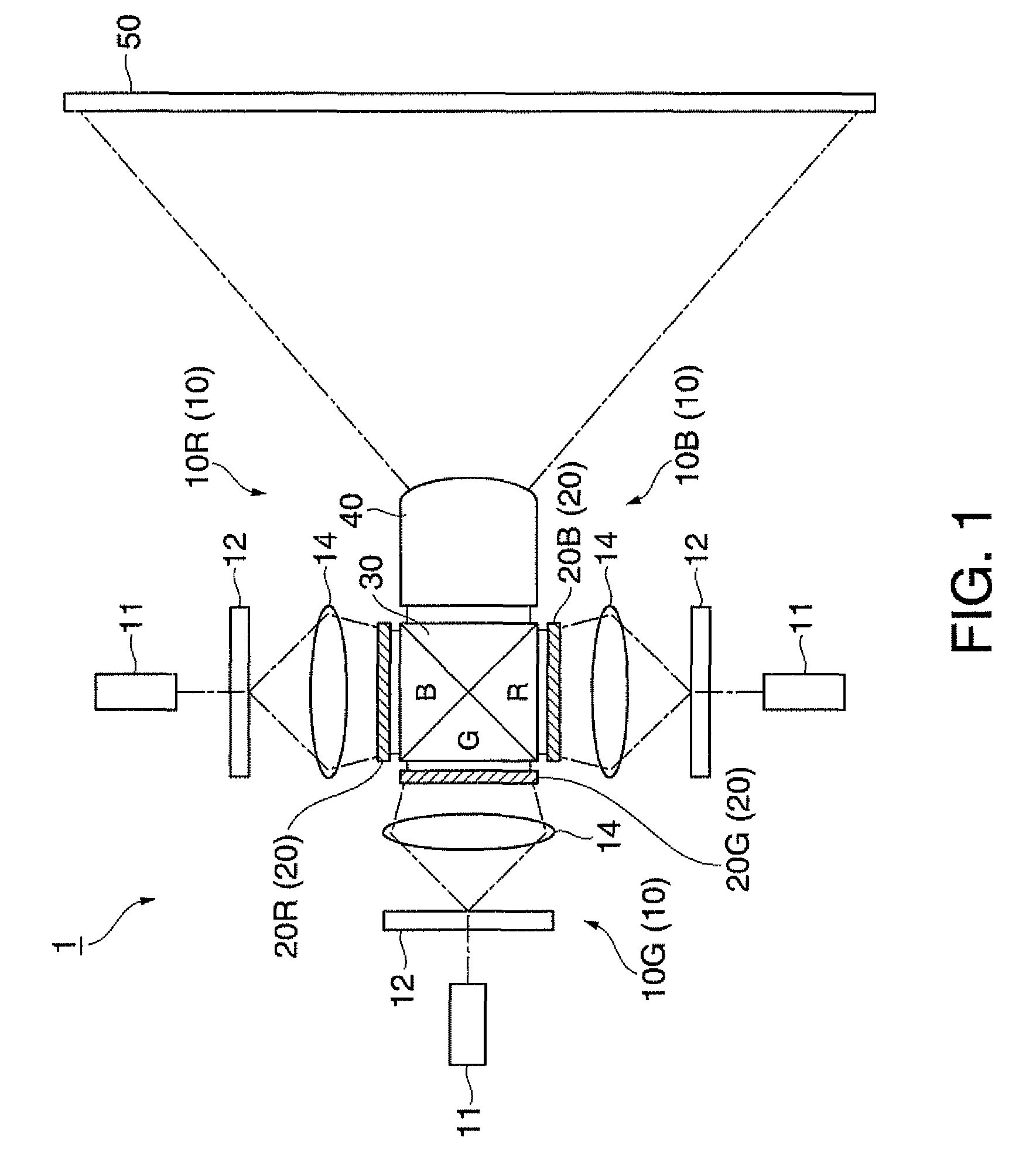

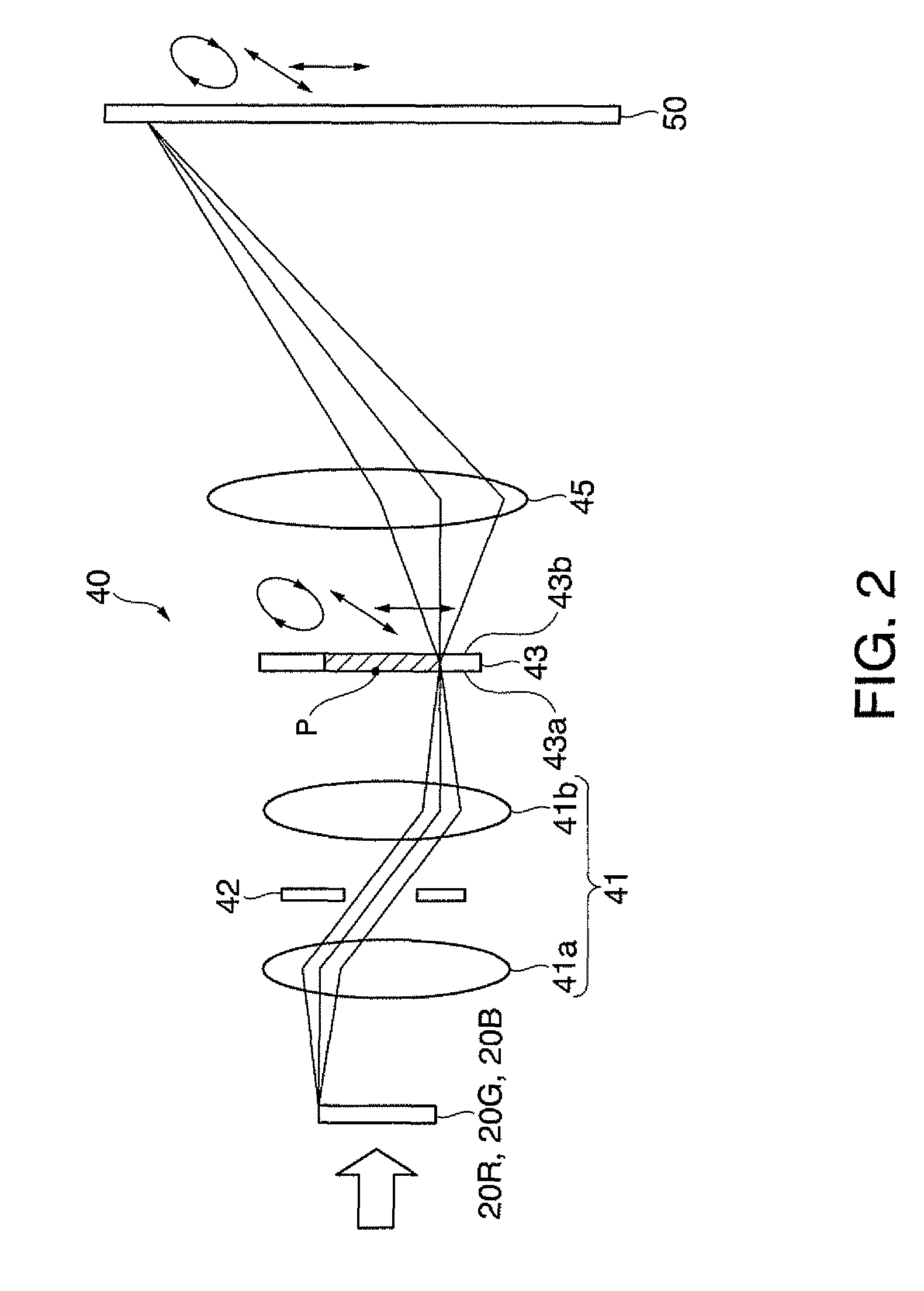

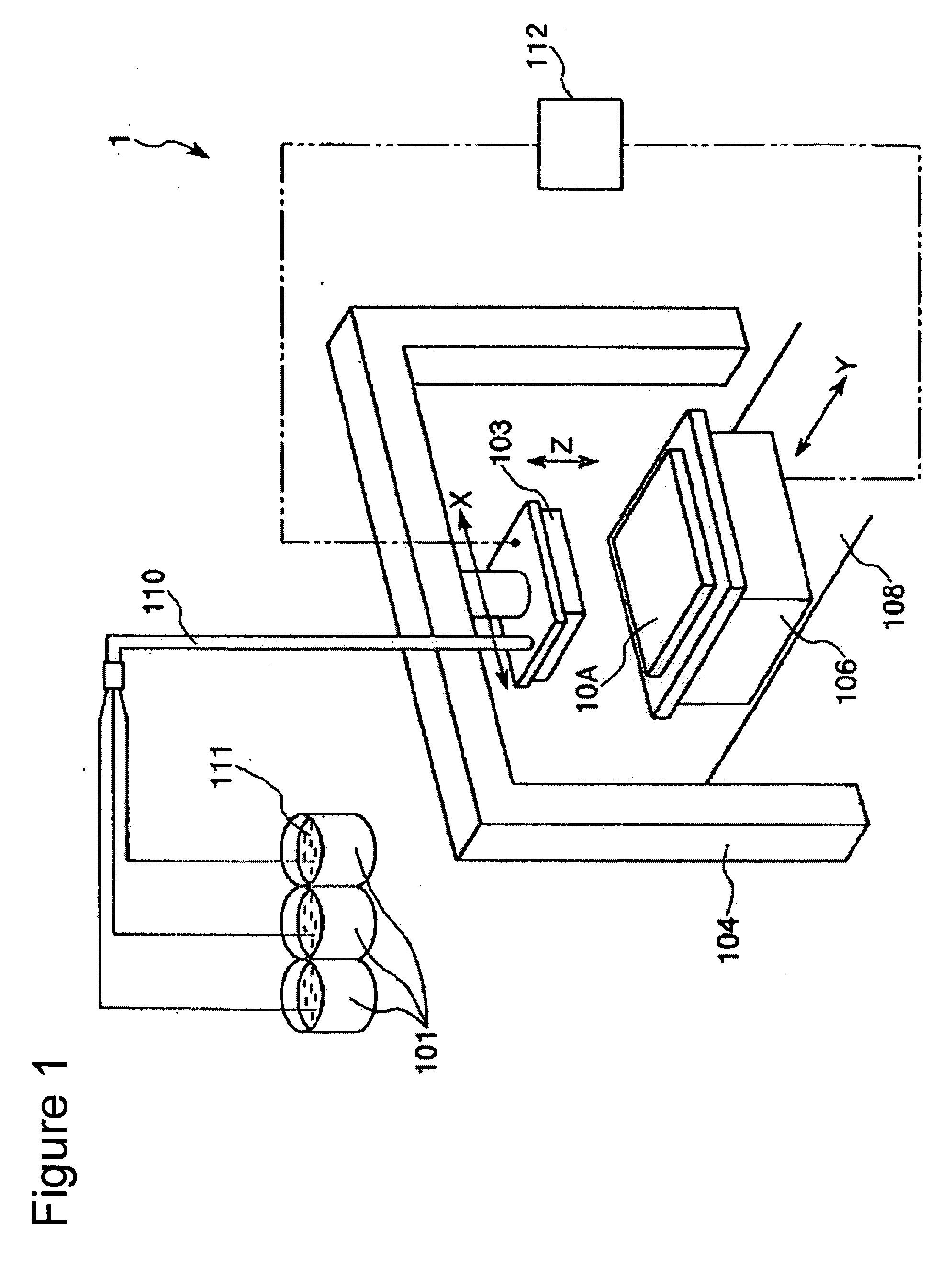

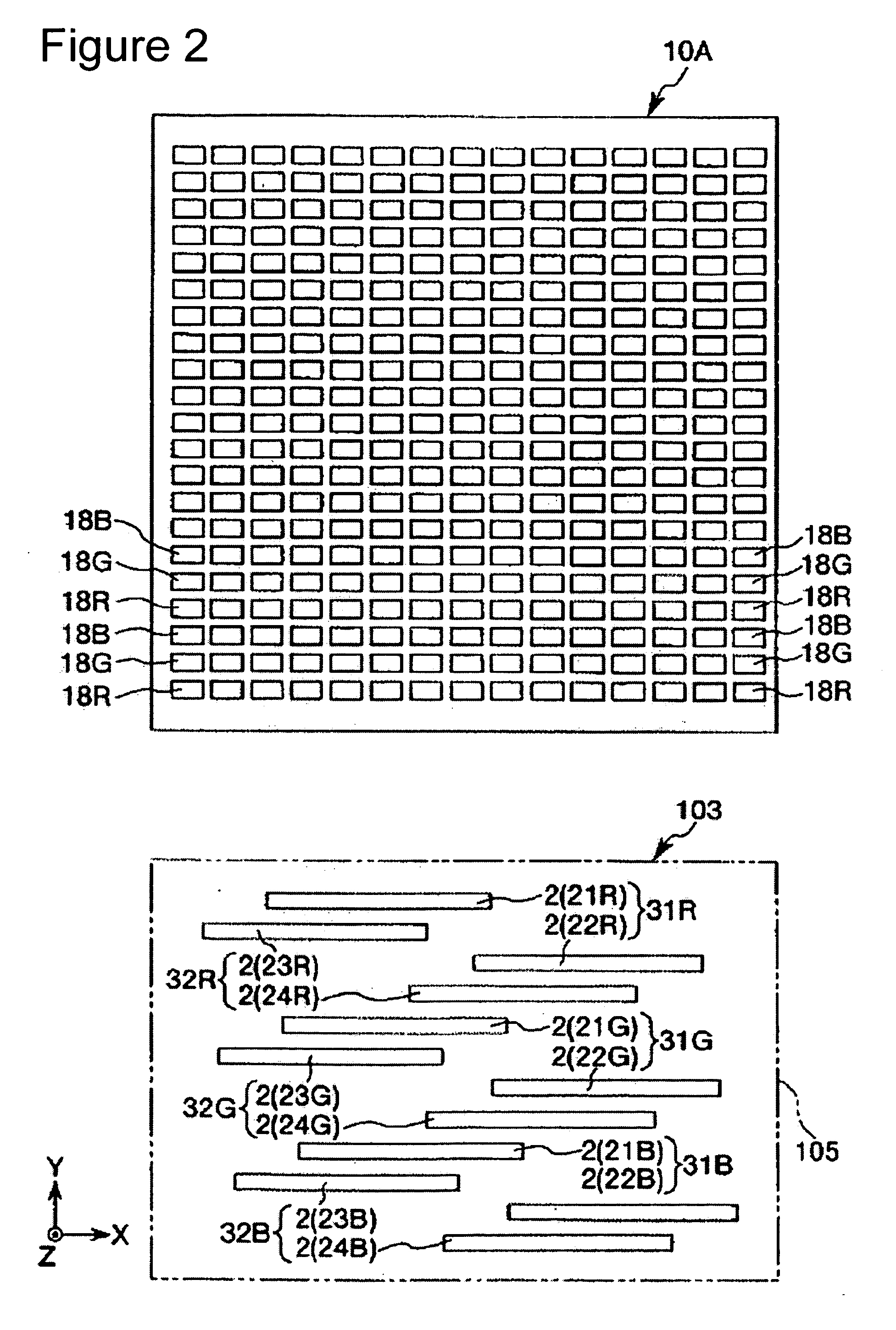

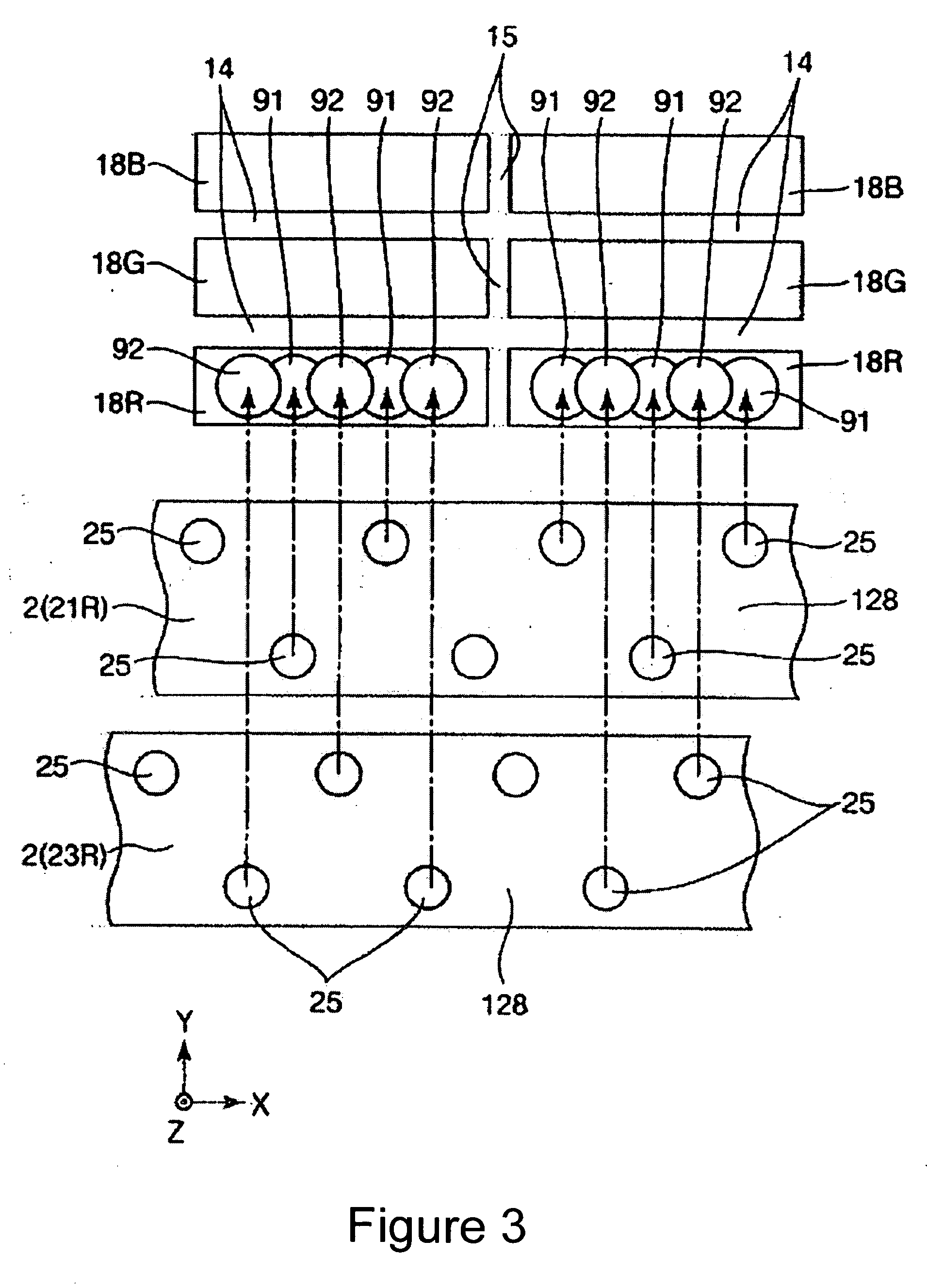

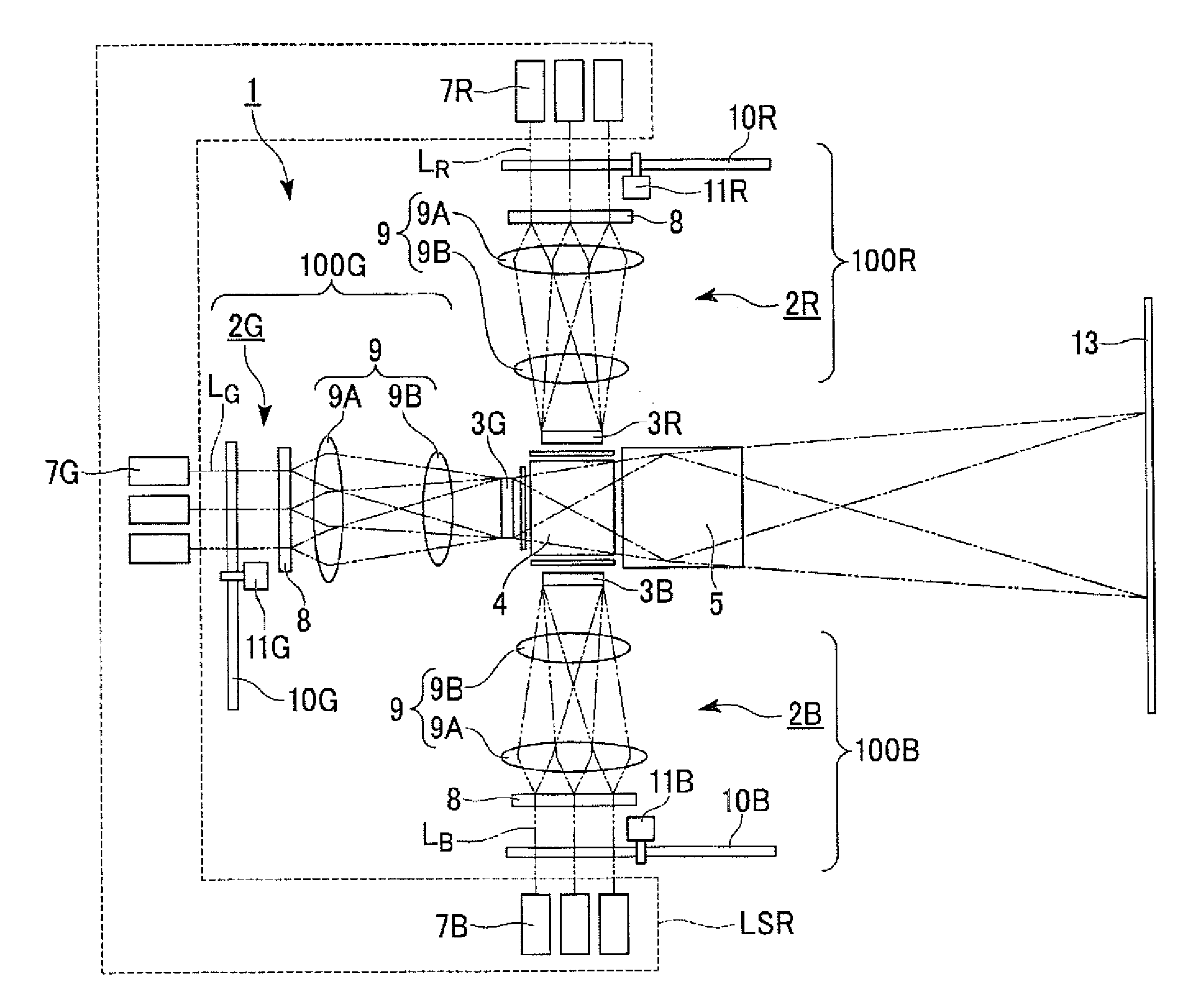

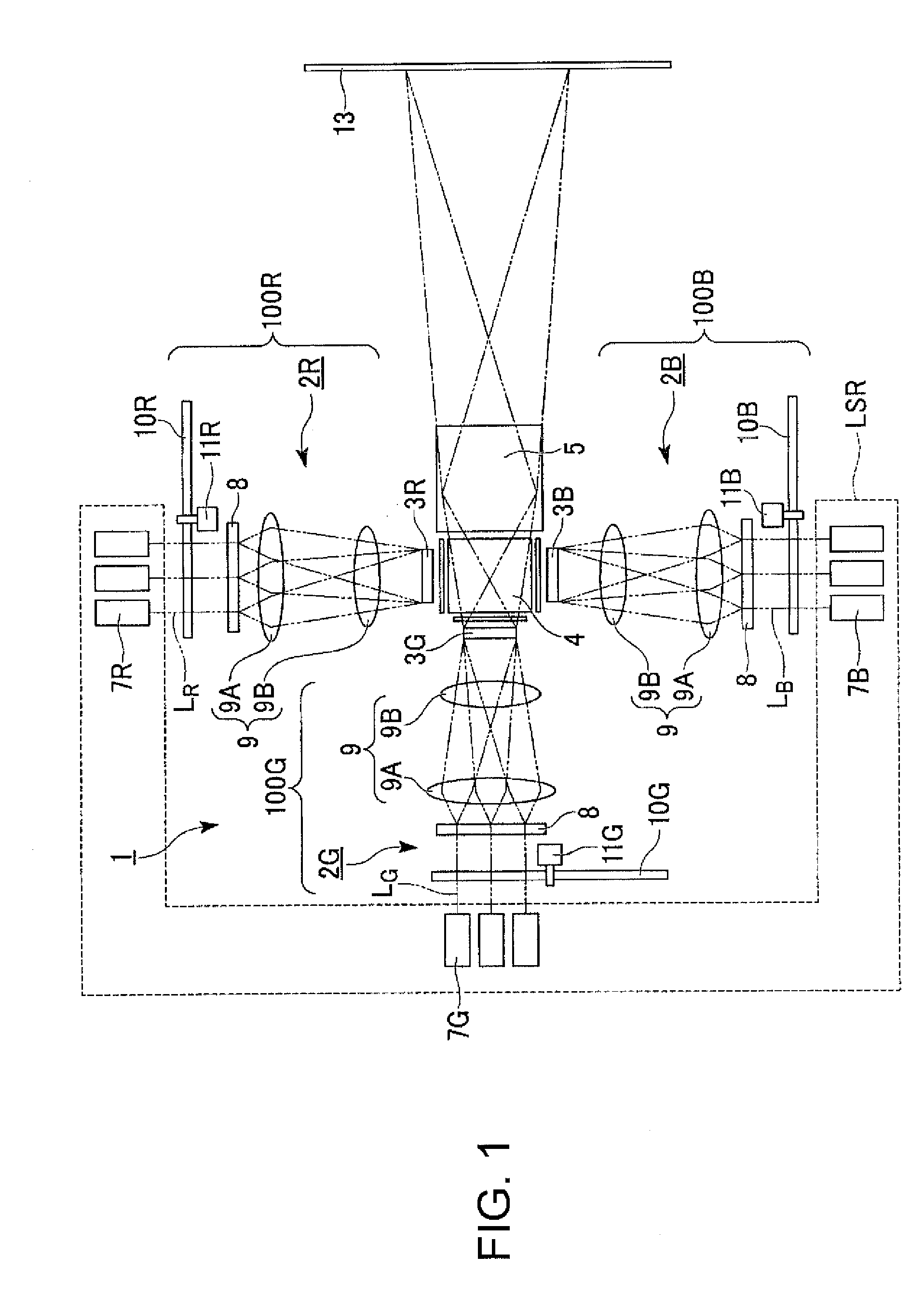

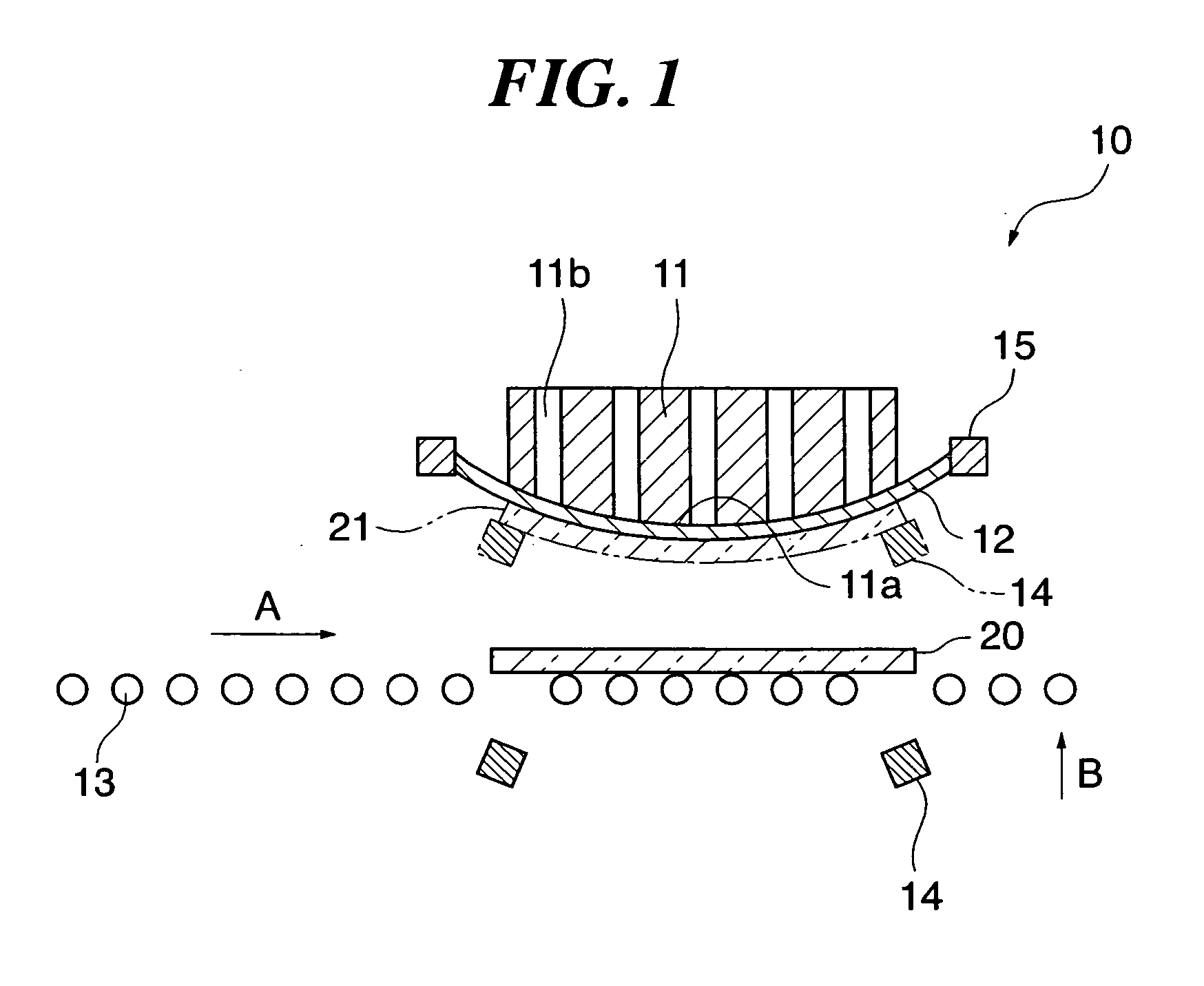

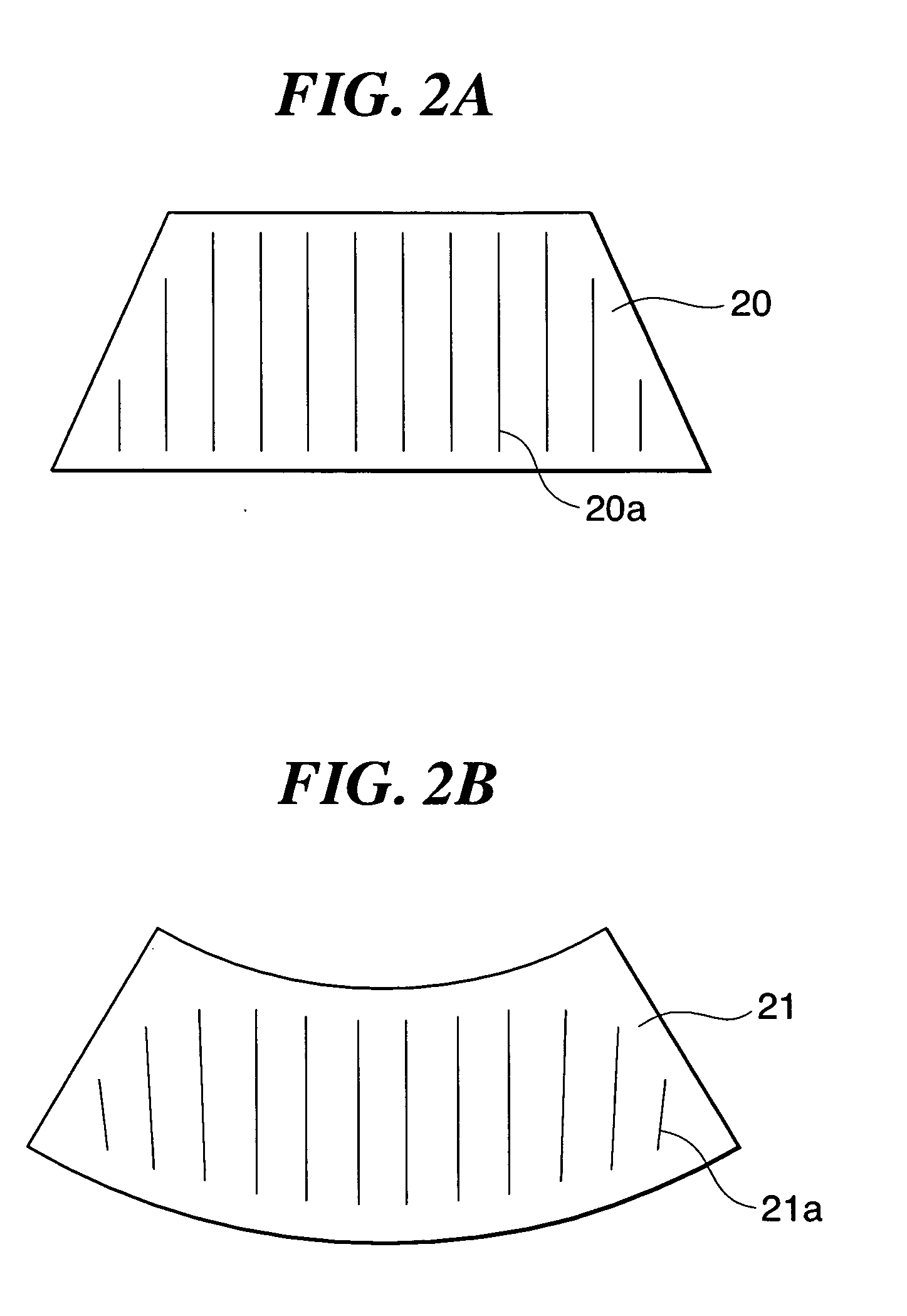

Illuminator, image display apparatus, and polarization conversion/diffusion member

InactiveUS20090161072A1Improve efficiencyReliably reducedProjectorsPolarising elementsLaser lightOptoelectronics

An illuminator that illuminates a projected surface includes a laser light source that emits laser light; a polarization converter disposed downstream of the laser light source, the polarization converter having a first area that converts the polarization direction of incident laser light into a first polarization direction and outputs the resultant laser light and a second area that converts the polarization direction of incident laser light into a second polarization direction and outputs the resultant laser light; and a light diffusion section disposed downstream of the laser light source, the light diffusion section diffusing incident laser light.

Owner:COLUMBIA PEAK VENTURES LLC

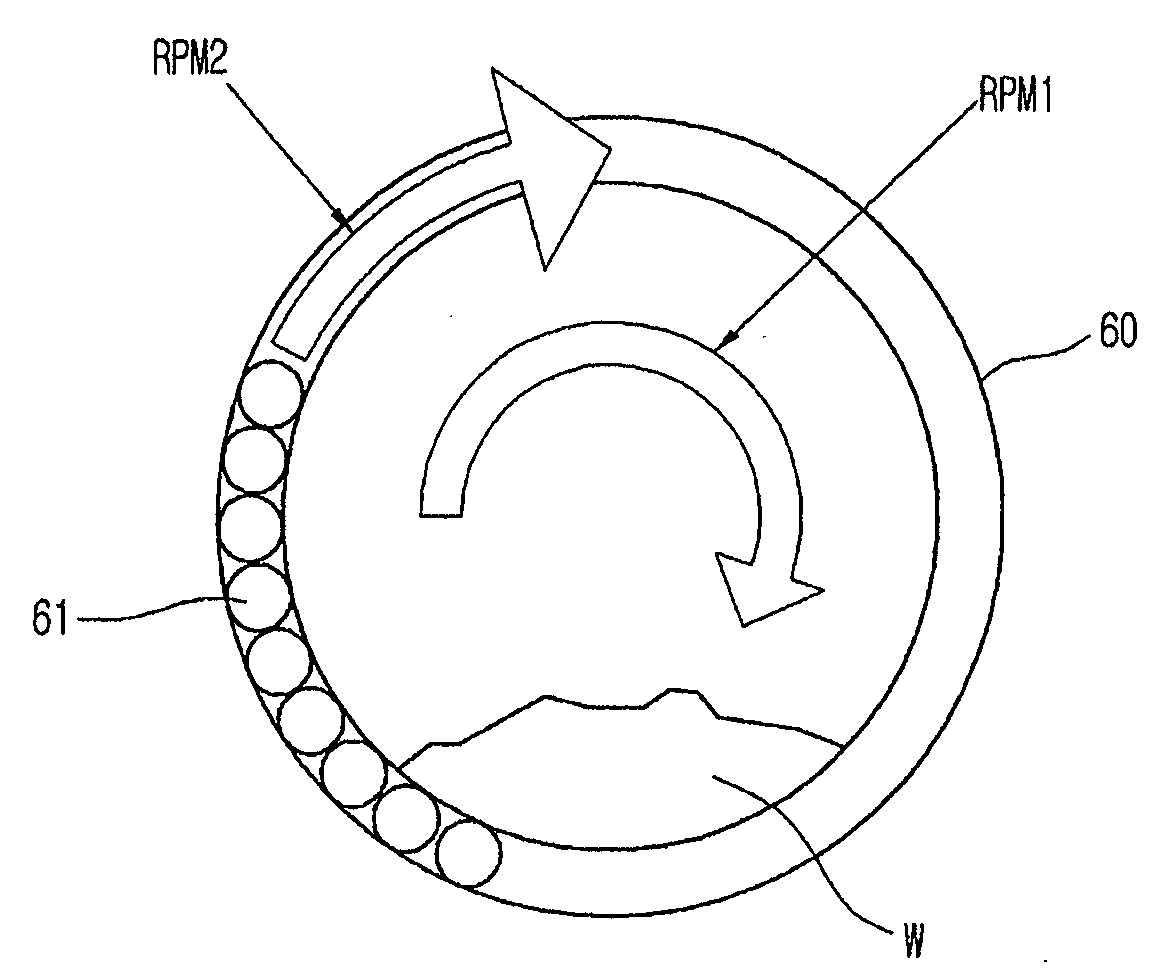

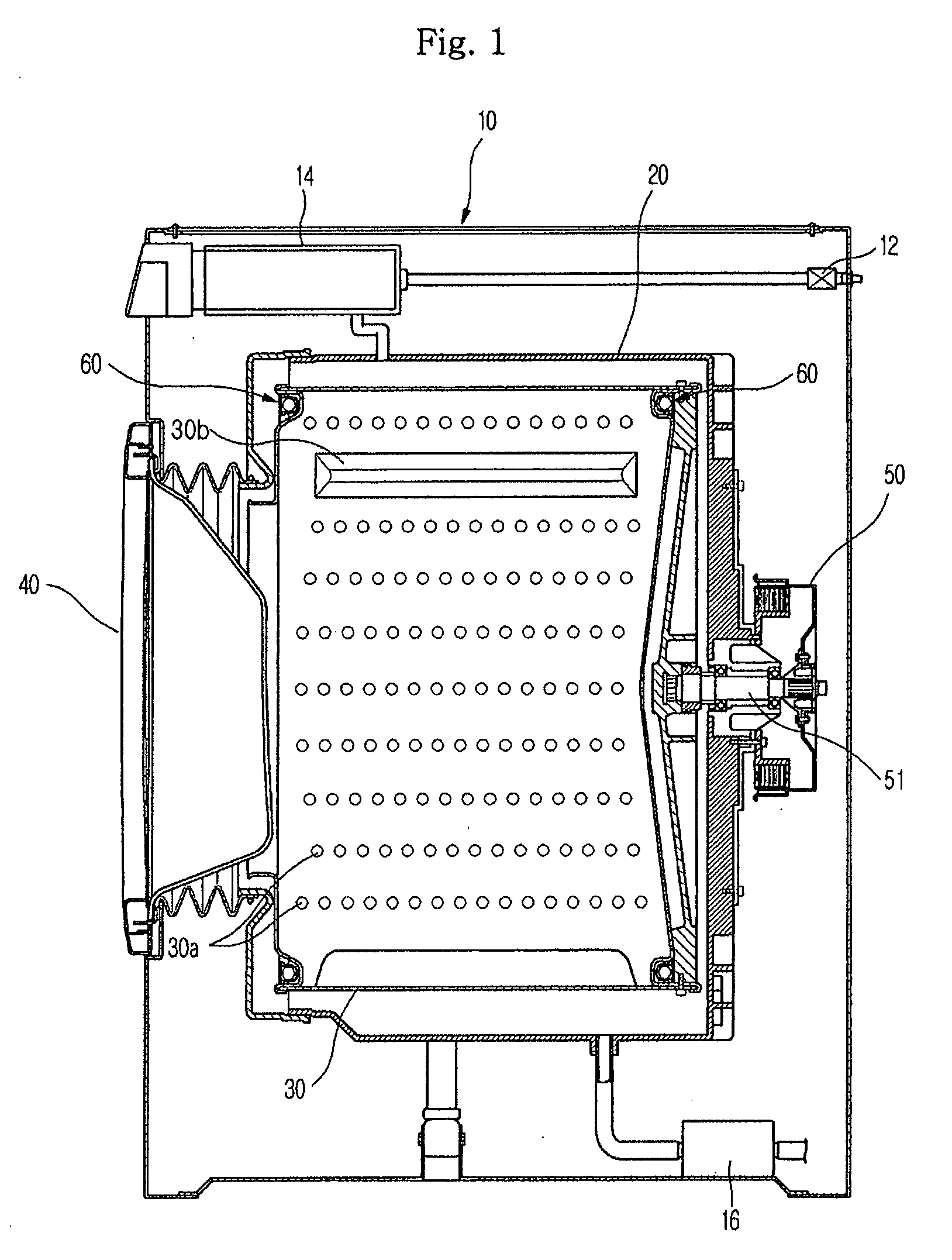

Washing machine with balancers and control method thereof

InactiveUS20080172805A1Reliably reducedOther washing machinesControl devices for washing apparatusElectric machineryEngineering

Disclosed are a washing machine and a control method thereof capable of reincreasing a number of rotations of a motor after maintaining the number of rotations at a predetermined number before excessive vibration of a water tub, braking the motor when the water tub is vibrated at more than a predetermined vibration level, and reincreasing the number of rotations, thereby reducing the excessive vibration of the water tub. The control method includes detecting the number of rotations, determining whether the detected number of rotations has reached a predetermined number, controlling the motor such that the number of rotations is maintained at the predetermined number of rotations when it is determined that the detected number of rotations has reached the predetermined number, counting the time taken to maintain the number of rotations at the predetermined number of rotations, and increasing the number of rotations after a predetermined first time has elapsed.

Owner:SAMSUNG ELECTRONICS CO LTD

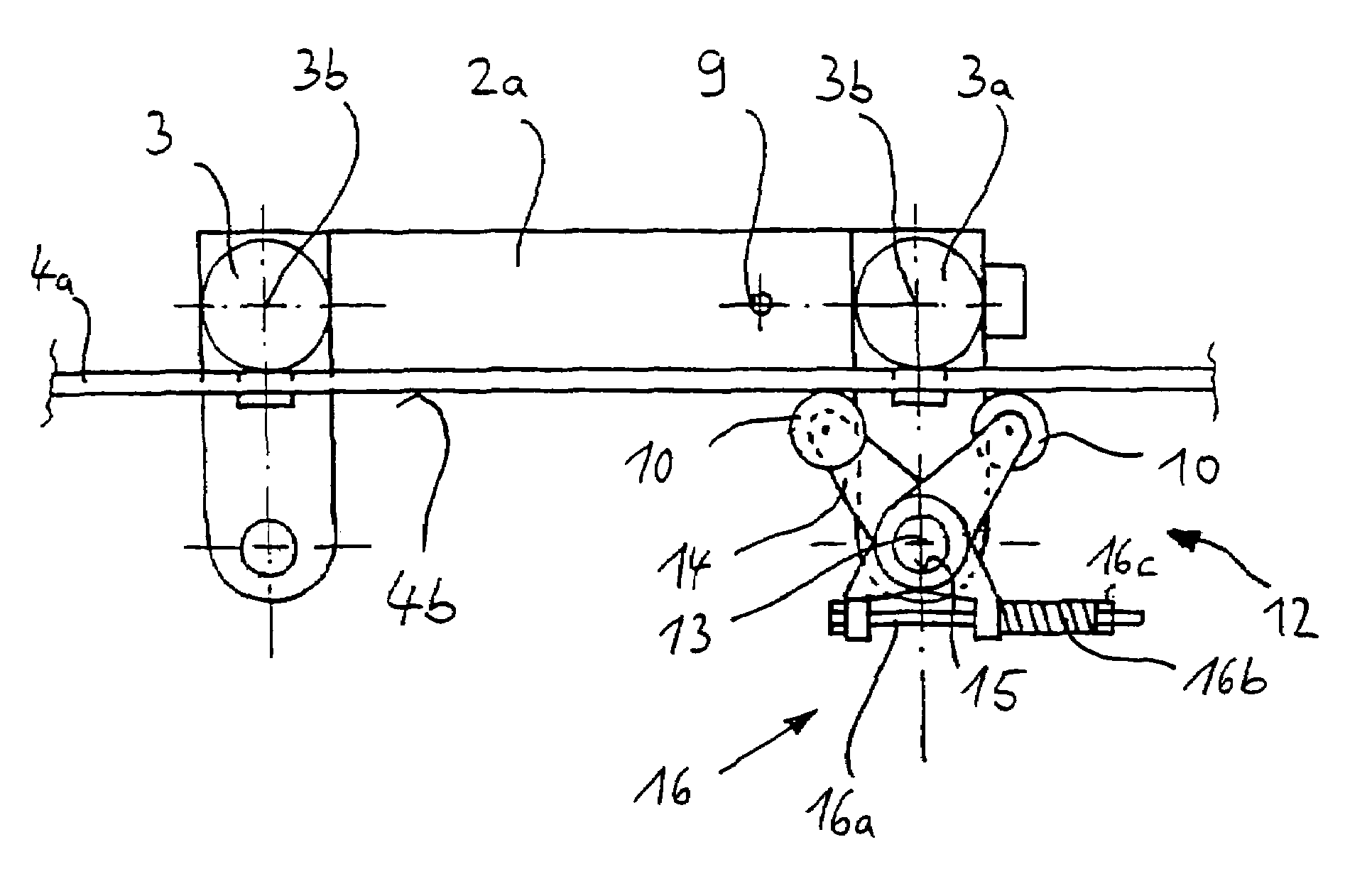

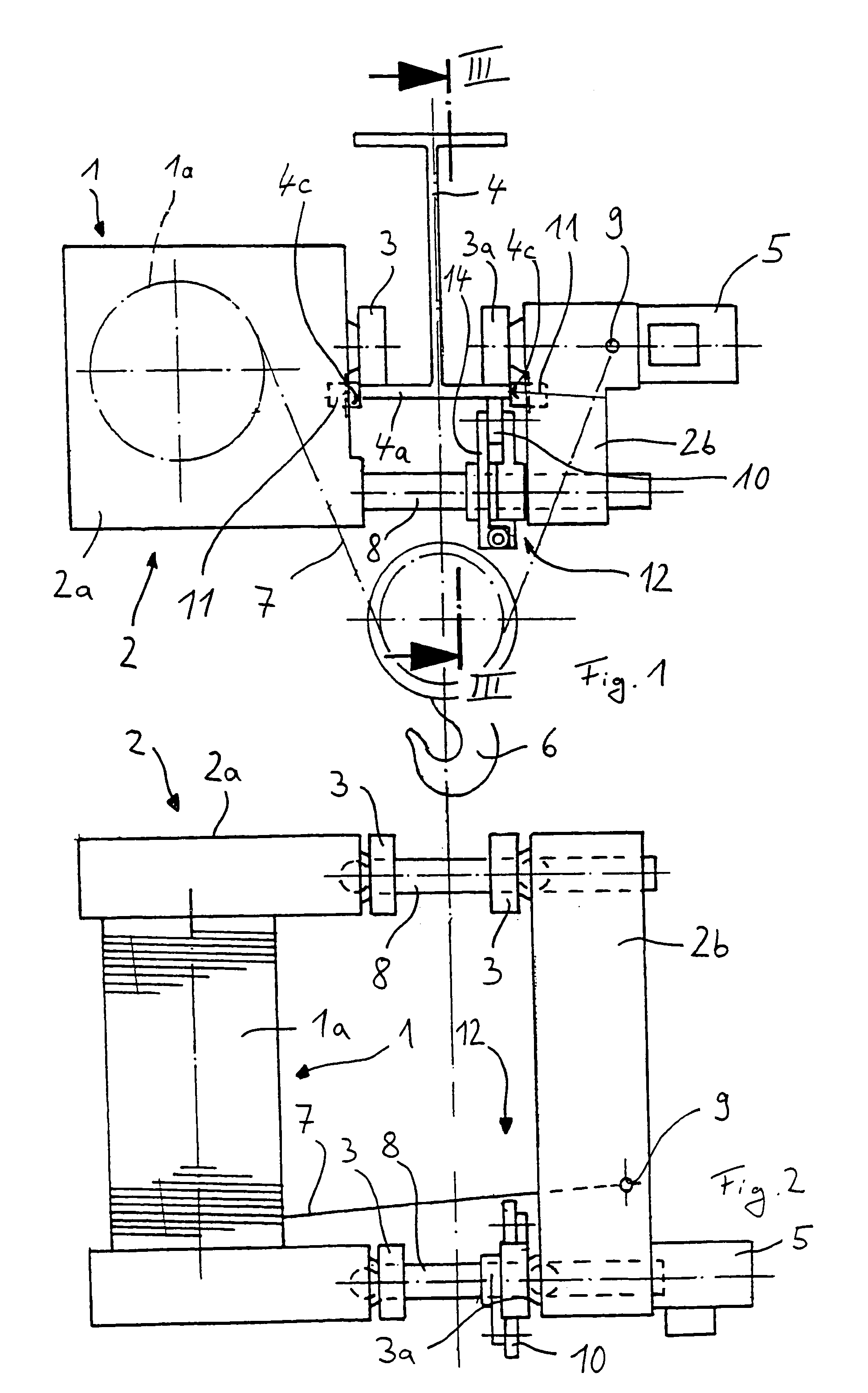

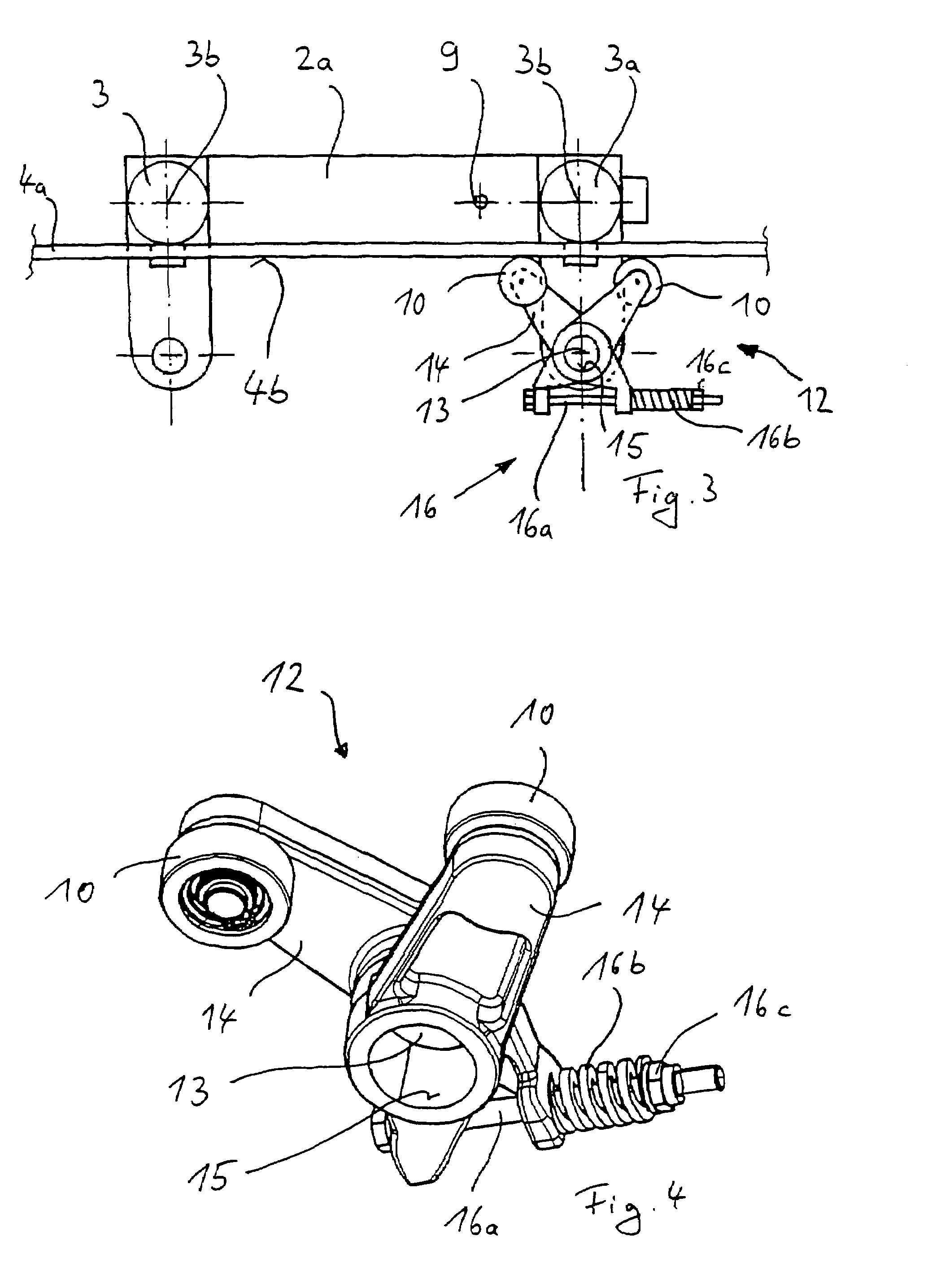

Crane trolley with low overall height

A crane trolley, especially a single-rail trolley with a short overall height, with a traveling mechanism frame (2) having a hoisting mechanism (1), which can travel by running wheels (3, 3a) on a rail, especially a lower flange (4a) of an essentially horizontal beam (4), wherein at least one running wheel (3a) can be driven, and a friction roller (10) interacting with the driven running wheel (3a) is arranged on the underside (4b) of the rail. In order to create a crane trolley that guarantees a reliable reduction in the slippage of the driven running wheel (3a) with a simple design, a pair of friction rollers (10) is provided, which may be positioned against the underside (4b) of the rail by adjusting the spacing from each other via a common pressing mechanism.

Owner:KONECRANES GLOBAL

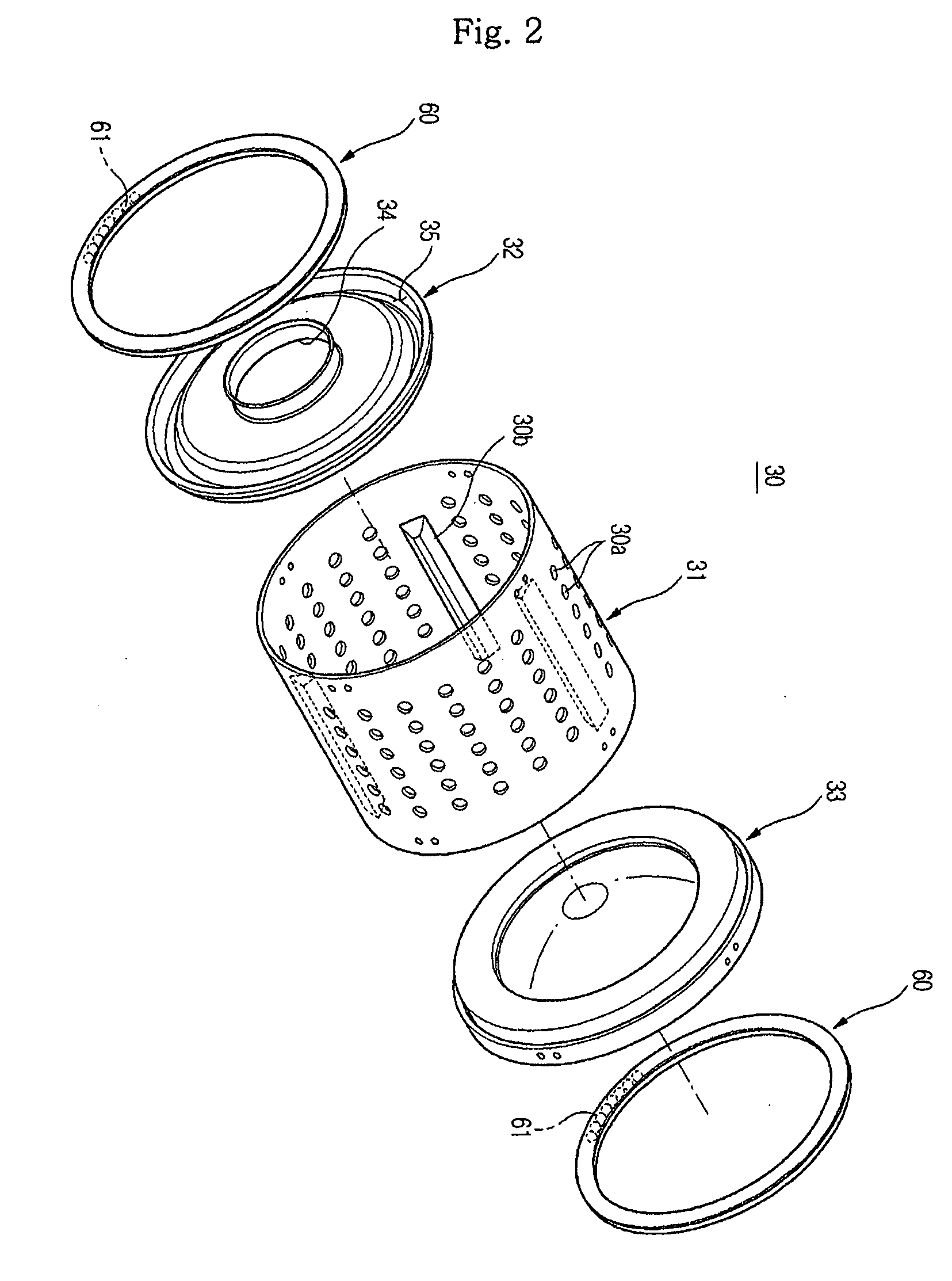

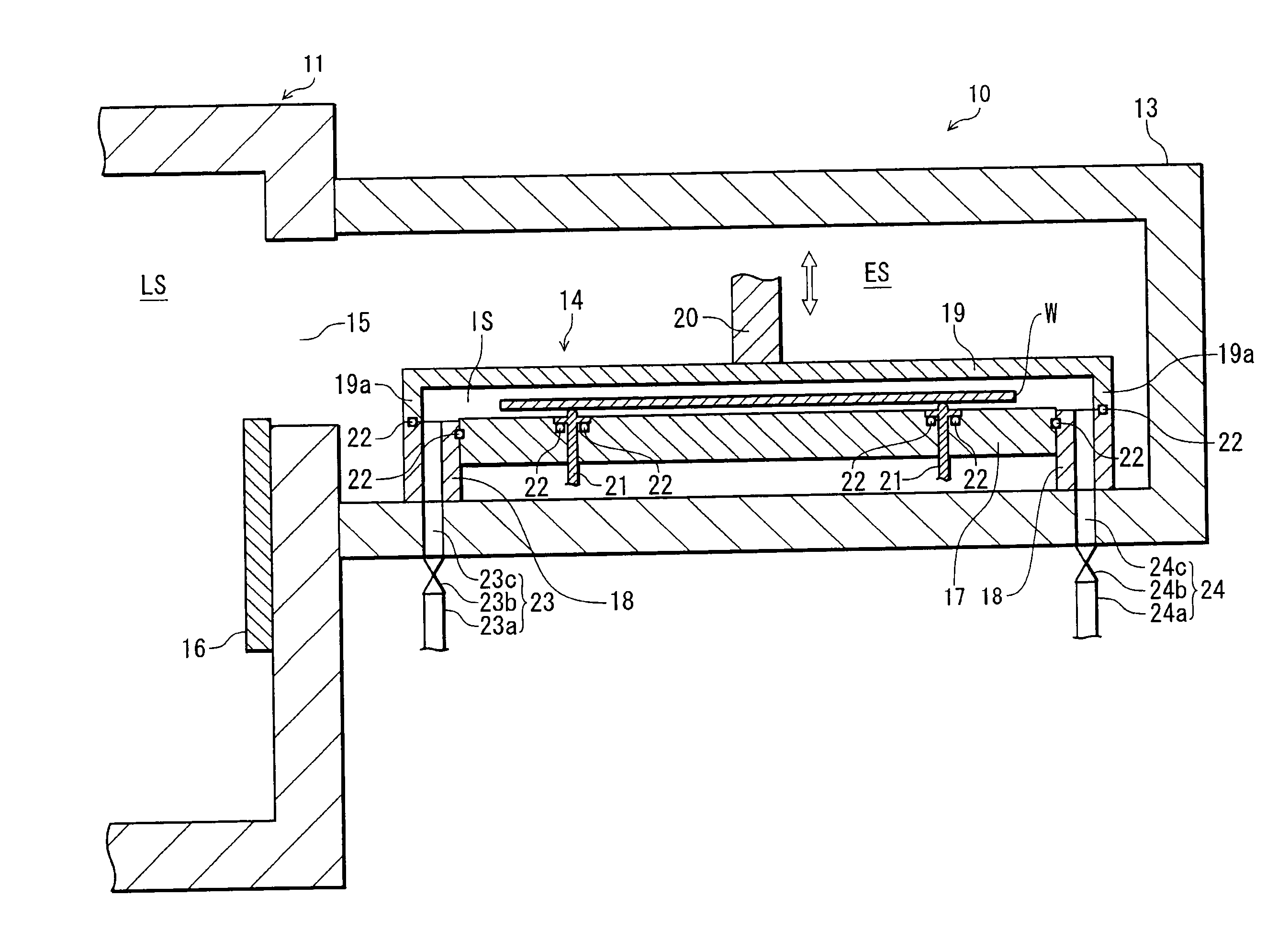

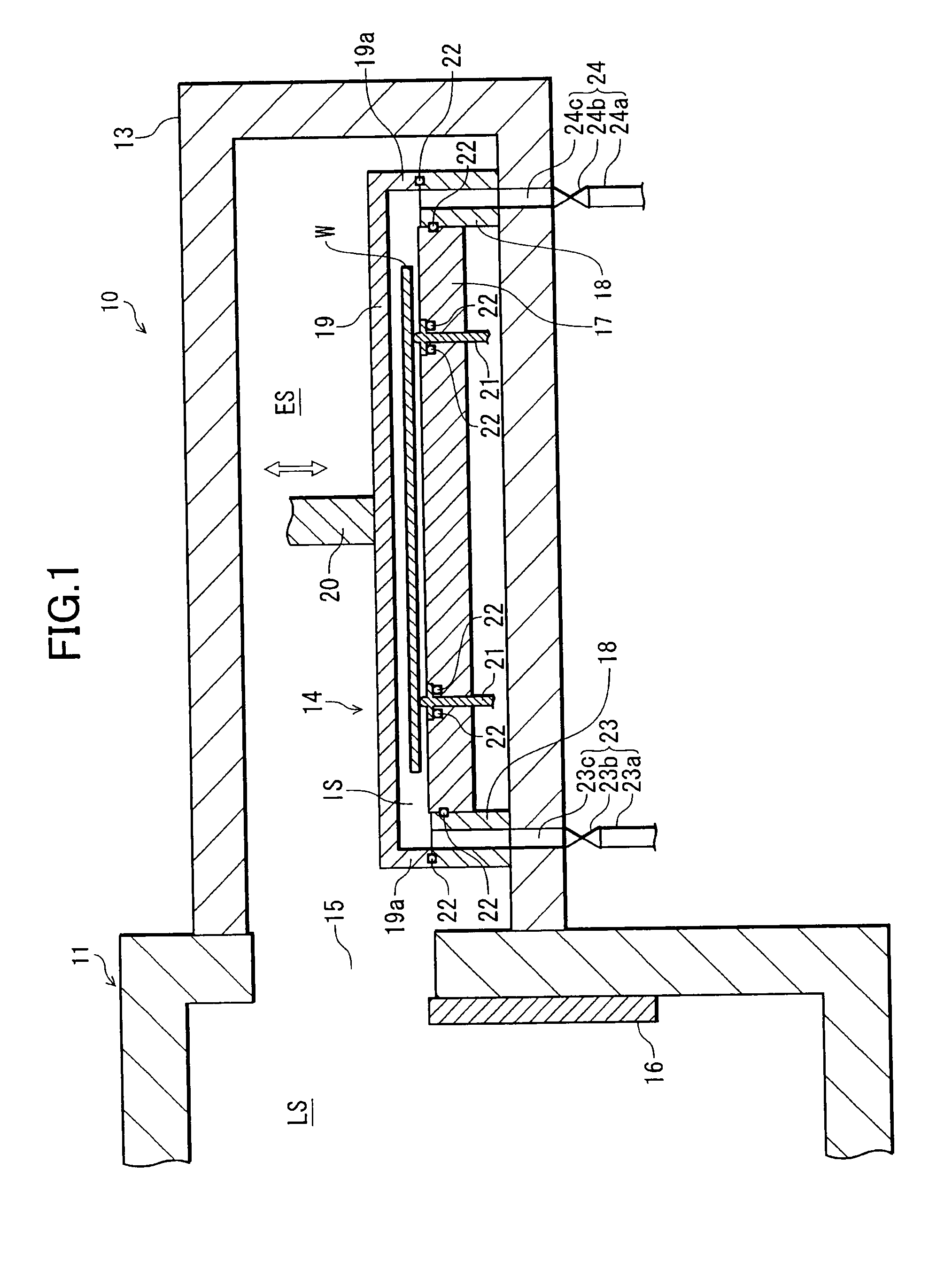

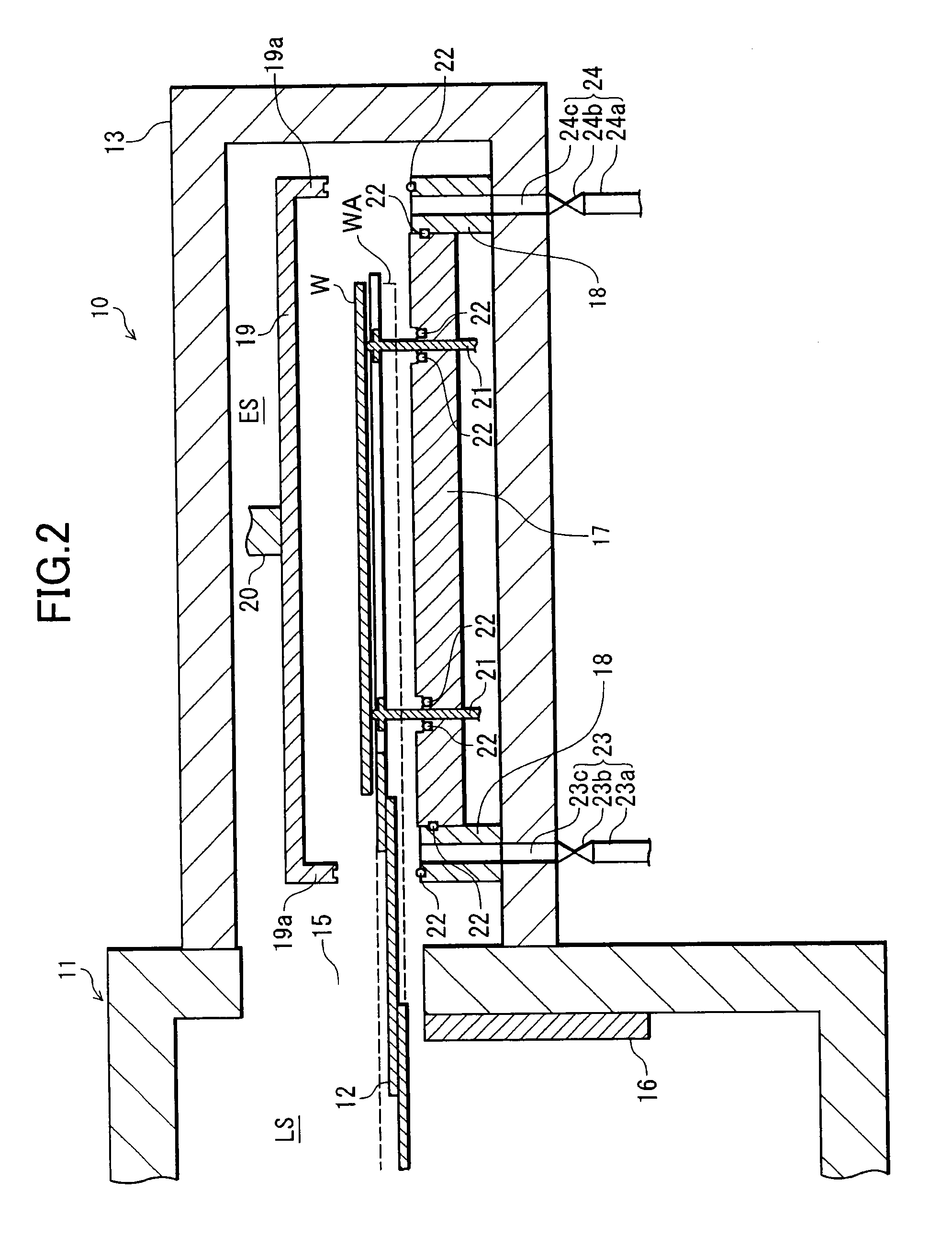

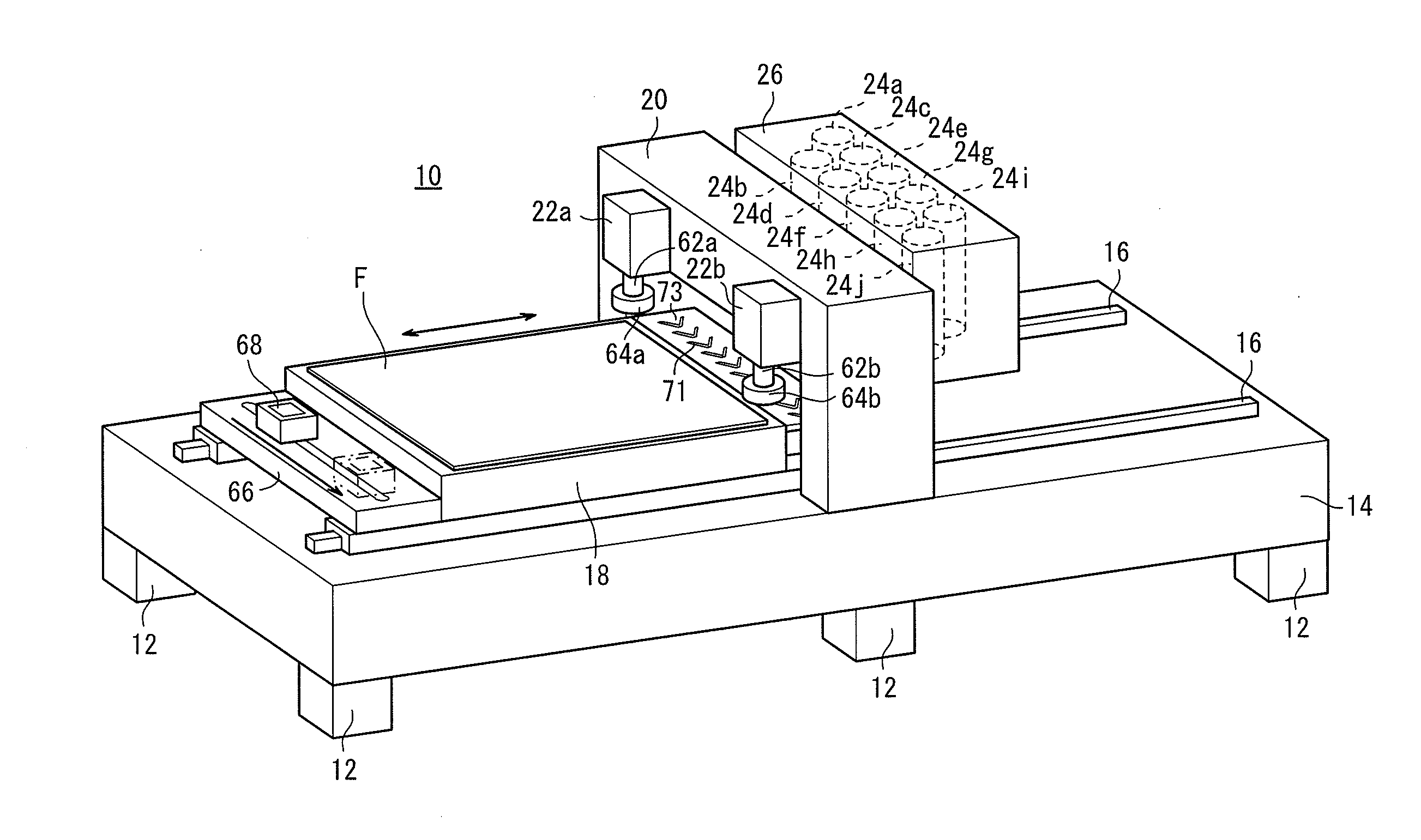

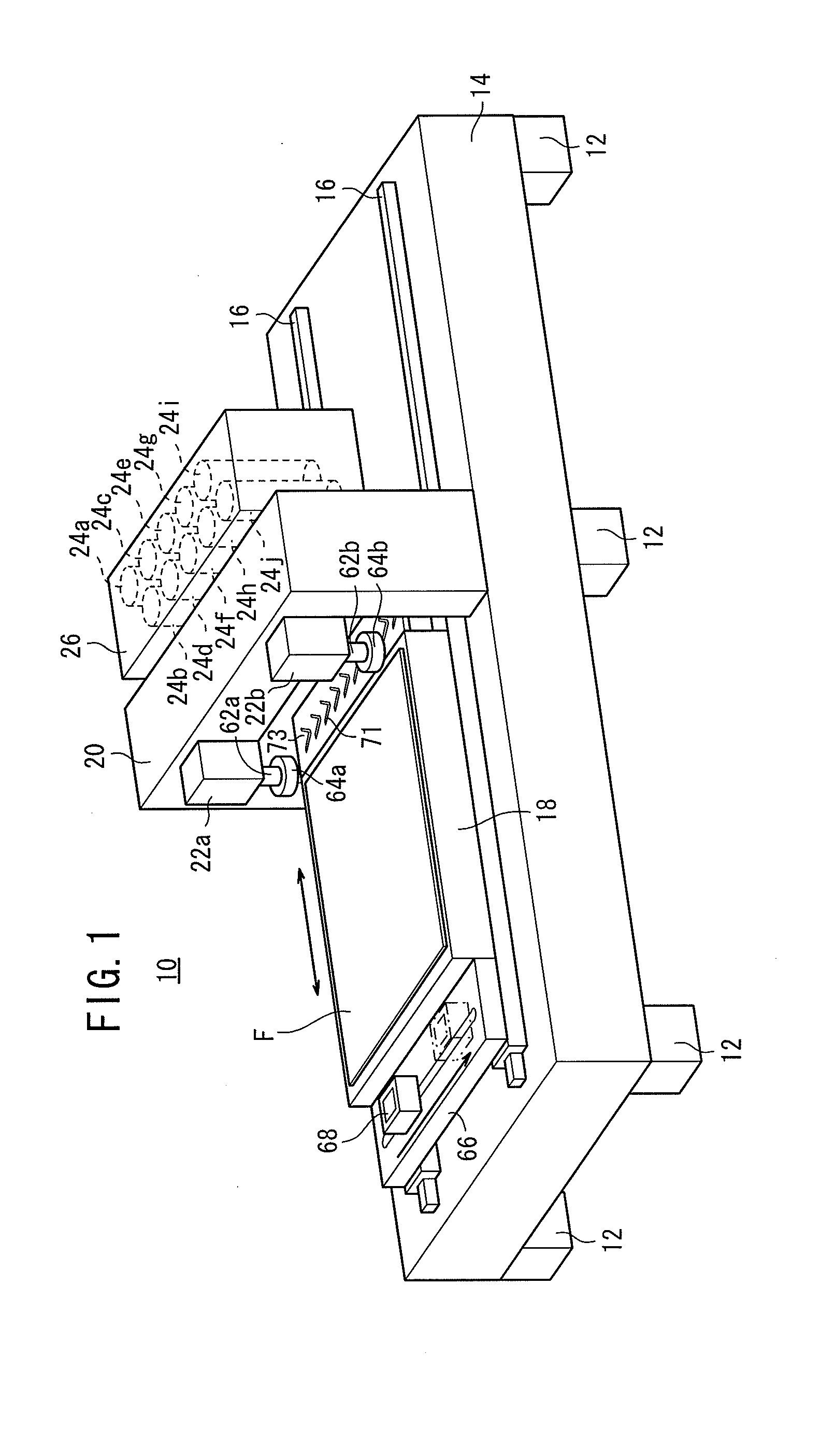

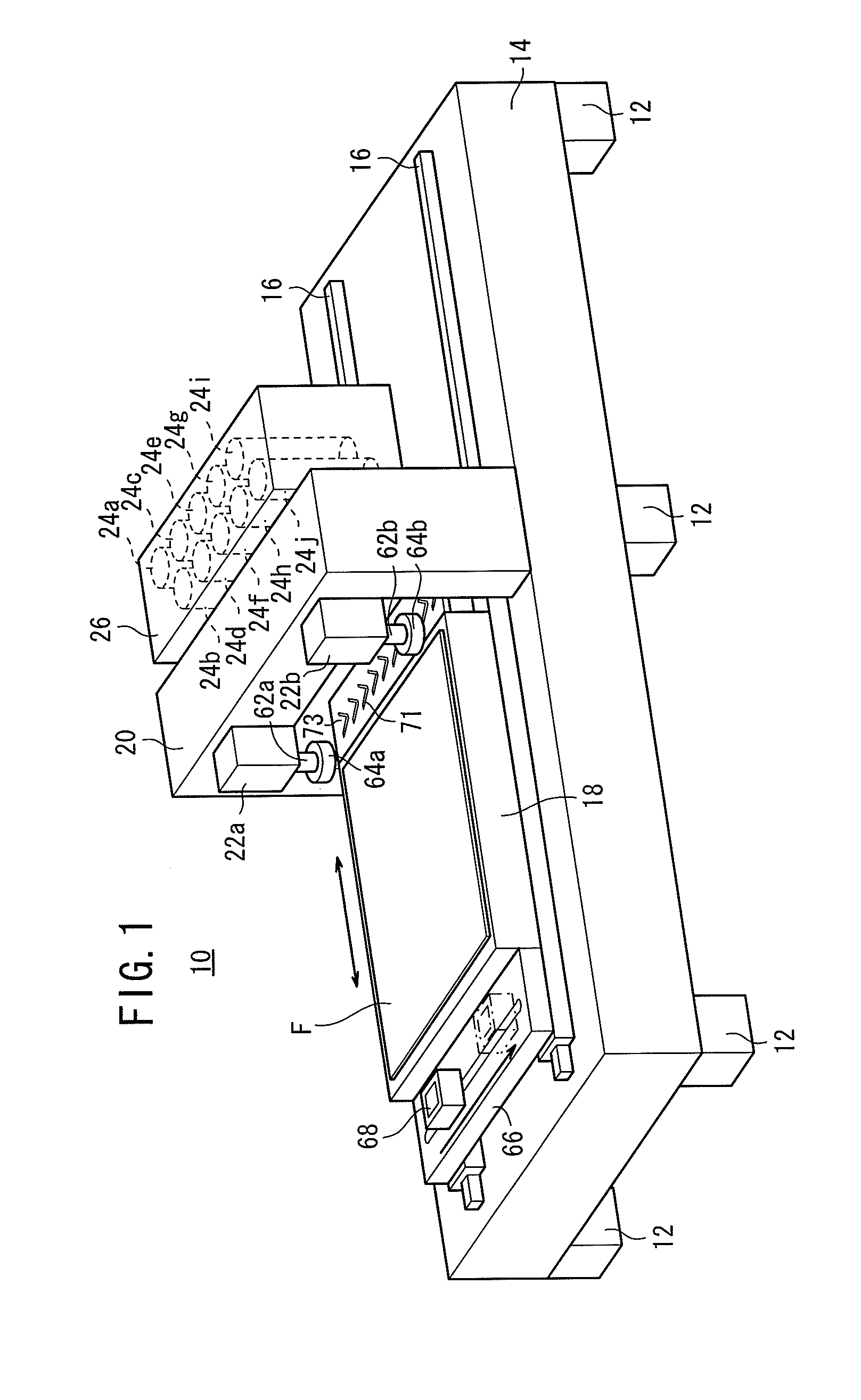

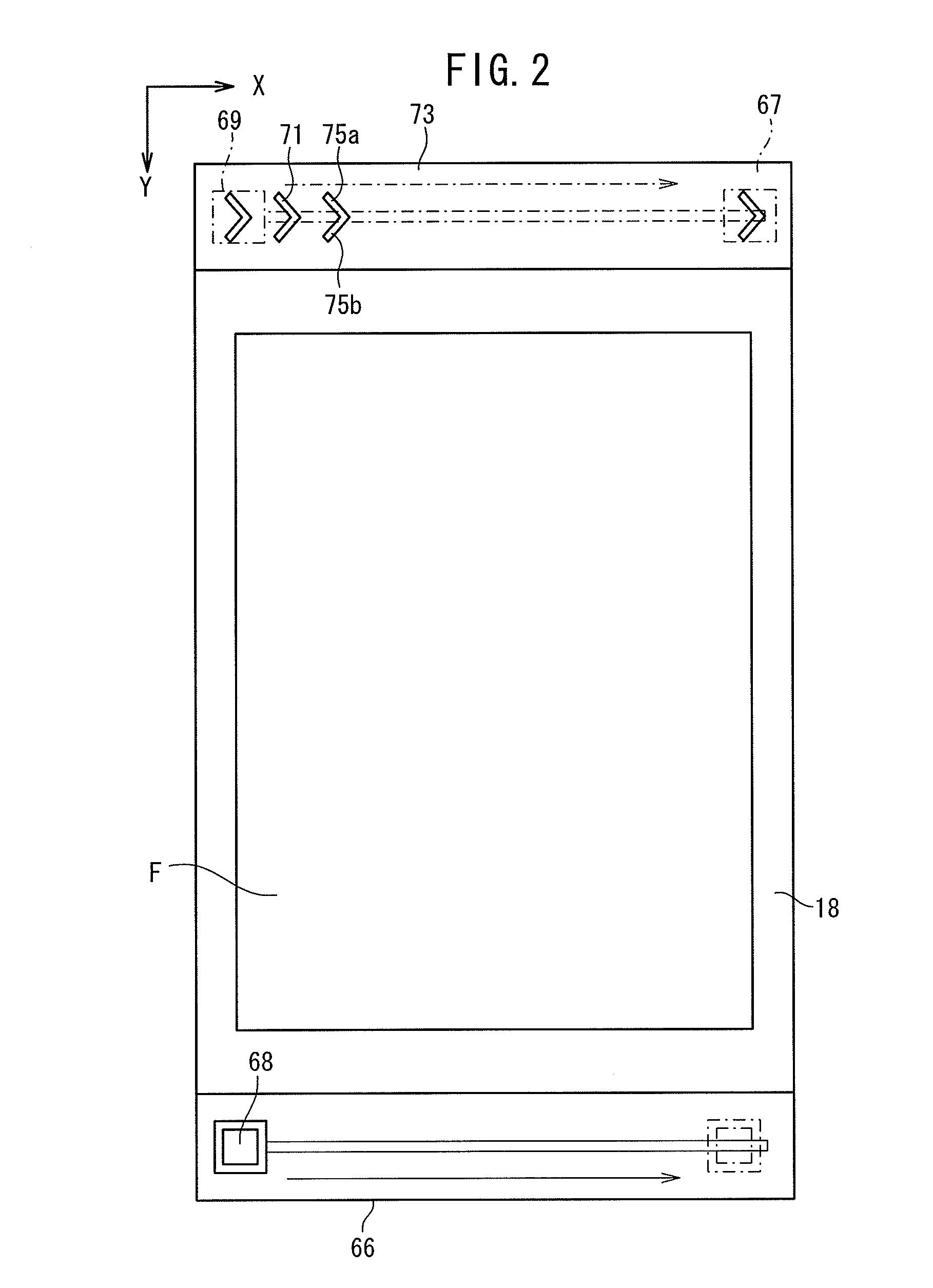

Substrate processing apparatus

ActiveUS20080179006A1Reduce capacitySimple structureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringGas supply

A substarate processing apparatus capable of reducing the capacity of a space in an internal chamber. The internal chamber is housed in a space in an external chamber. A gas supply unit supplies a process gas into the space in the internal chamber. The space in the external chamber is under a reduced pressure or filled with an inert gas. An enclosure being movable and included in the internal chamber defines the space in the internal chamber with a stage heater included in the internal chamber. When a wafer is transferred in and out by a transfer arm used to transfer the wafer, the enclosure exits out of a motion range within which the transfer arm can move.

Owner:TOKYO ELECTRON LTD

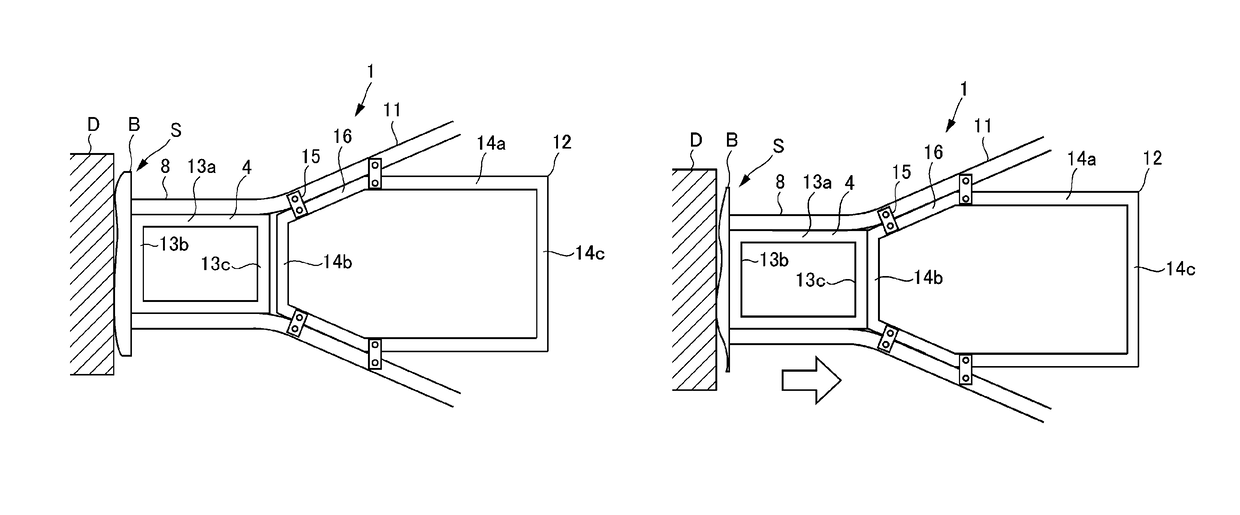

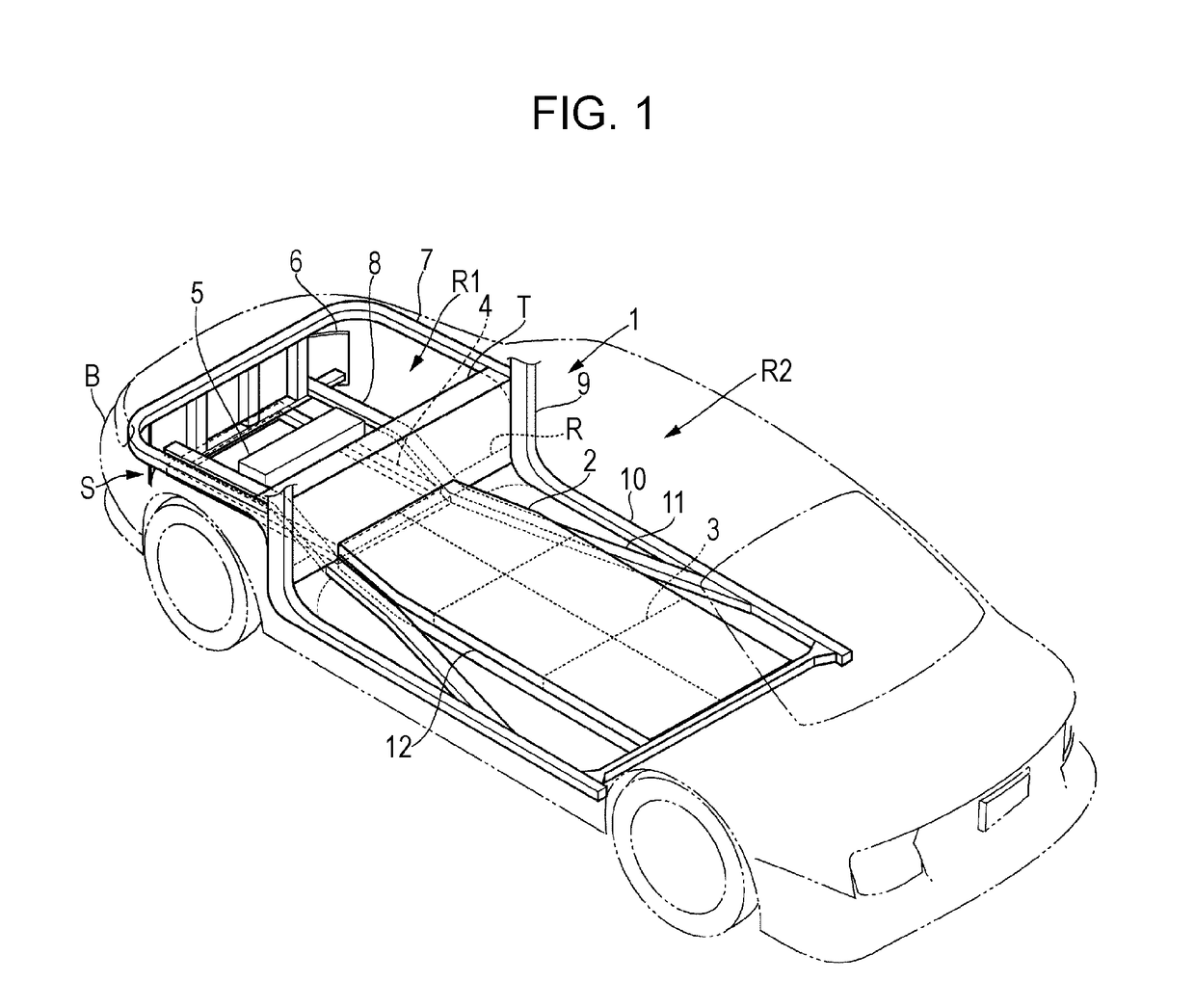

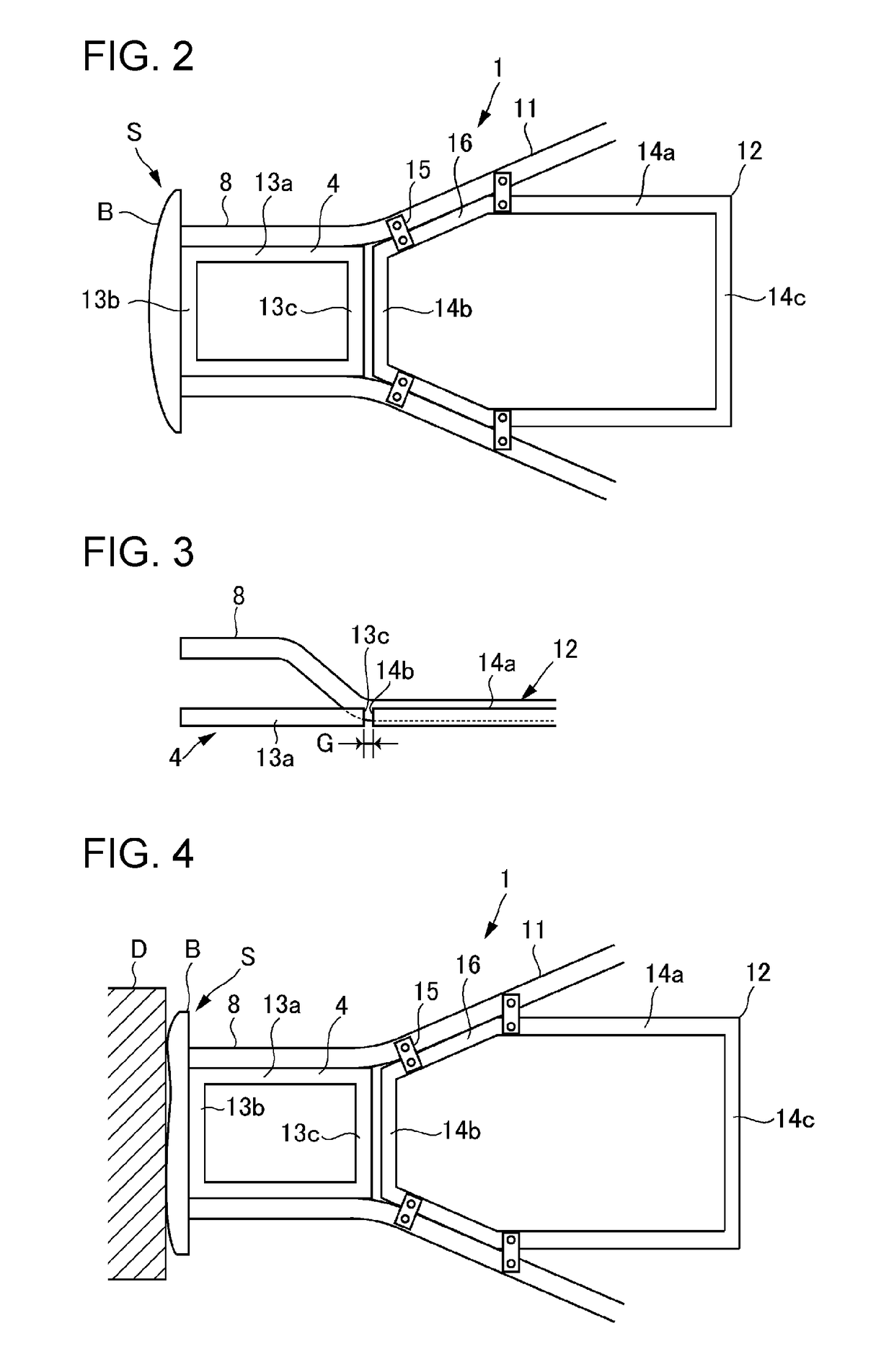

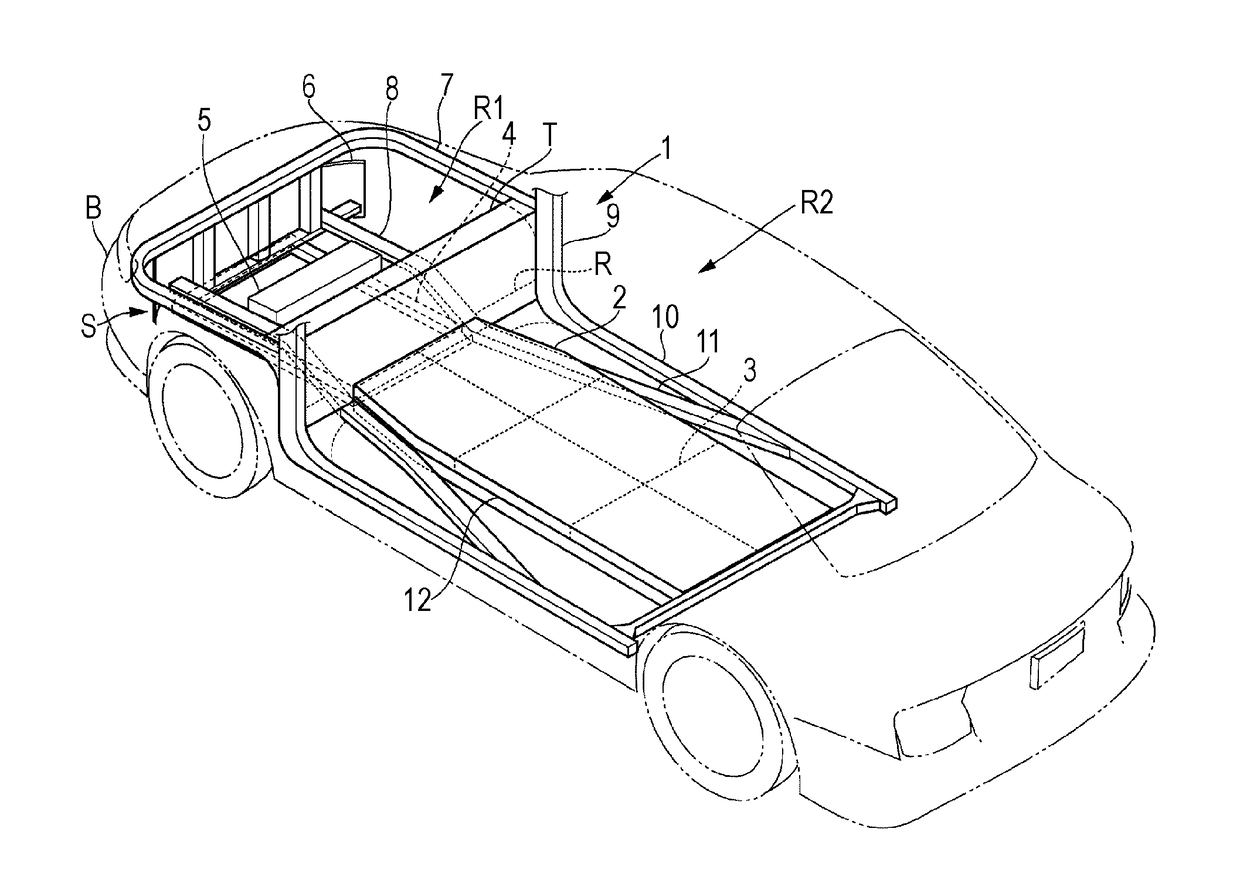

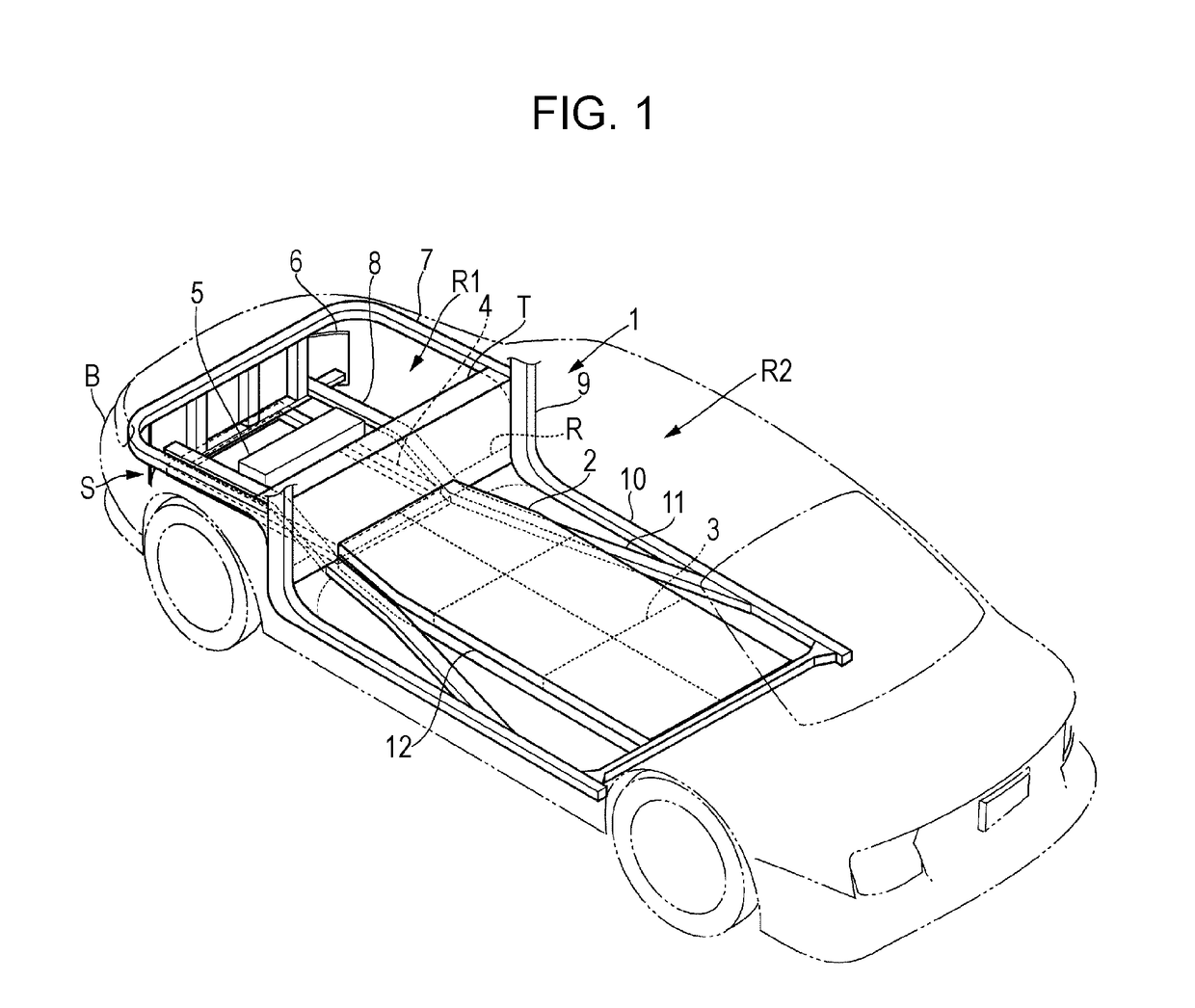

Impact load reduction structure

ActiveUS9789908B2Reliably reducedReduce shock loadElectric propulsion mountingUnderstructuresImpact loadingAutomotive engineering

An impact load reduction structure includes a battery frame and a load reduction frame. The battery frame is fixed to a vehicle body frame of an electrically-powered vehicle and supports a battery. The load reduction frame is disposed so as to extend in a front-rear direction on a front side of the battery frame. A rear section of the load reduction frame is disposed facing a front section of the battery frame with a predetermined gap therebetween such that the load reduction frame comes into contact with the battery frame when the electrically-powered vehicle is involved in a collision.

Owner:SUBARU CORP

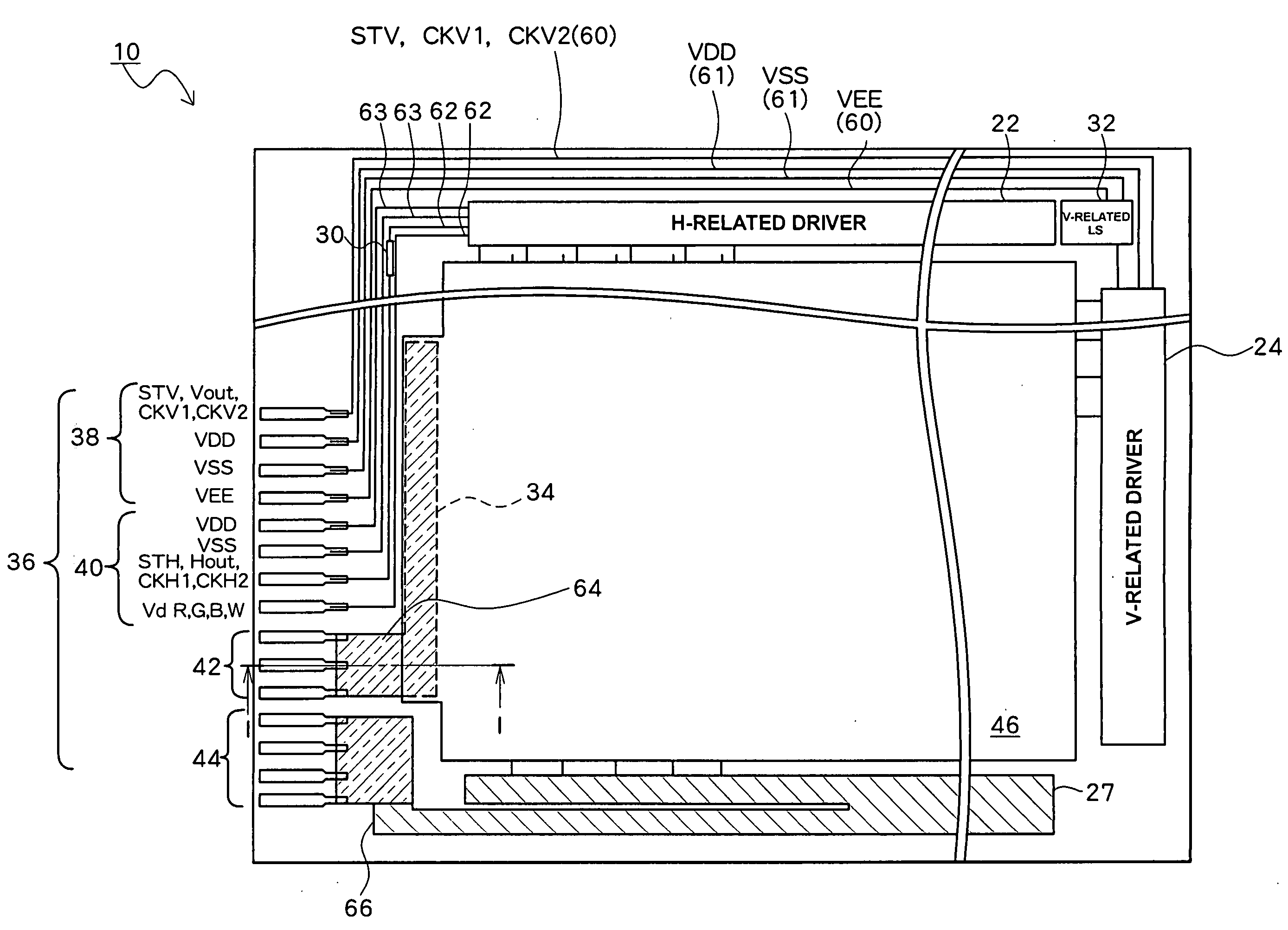

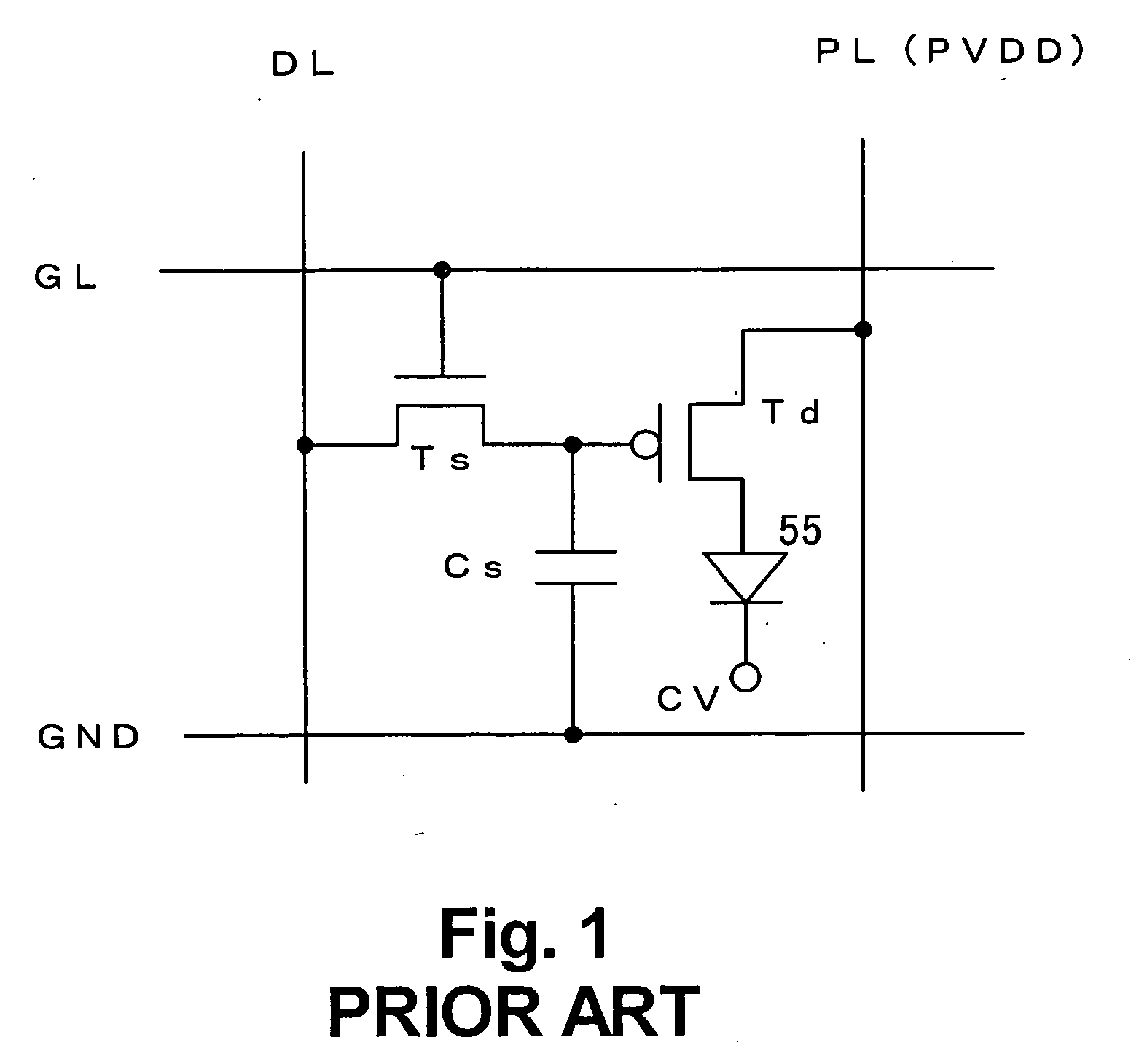

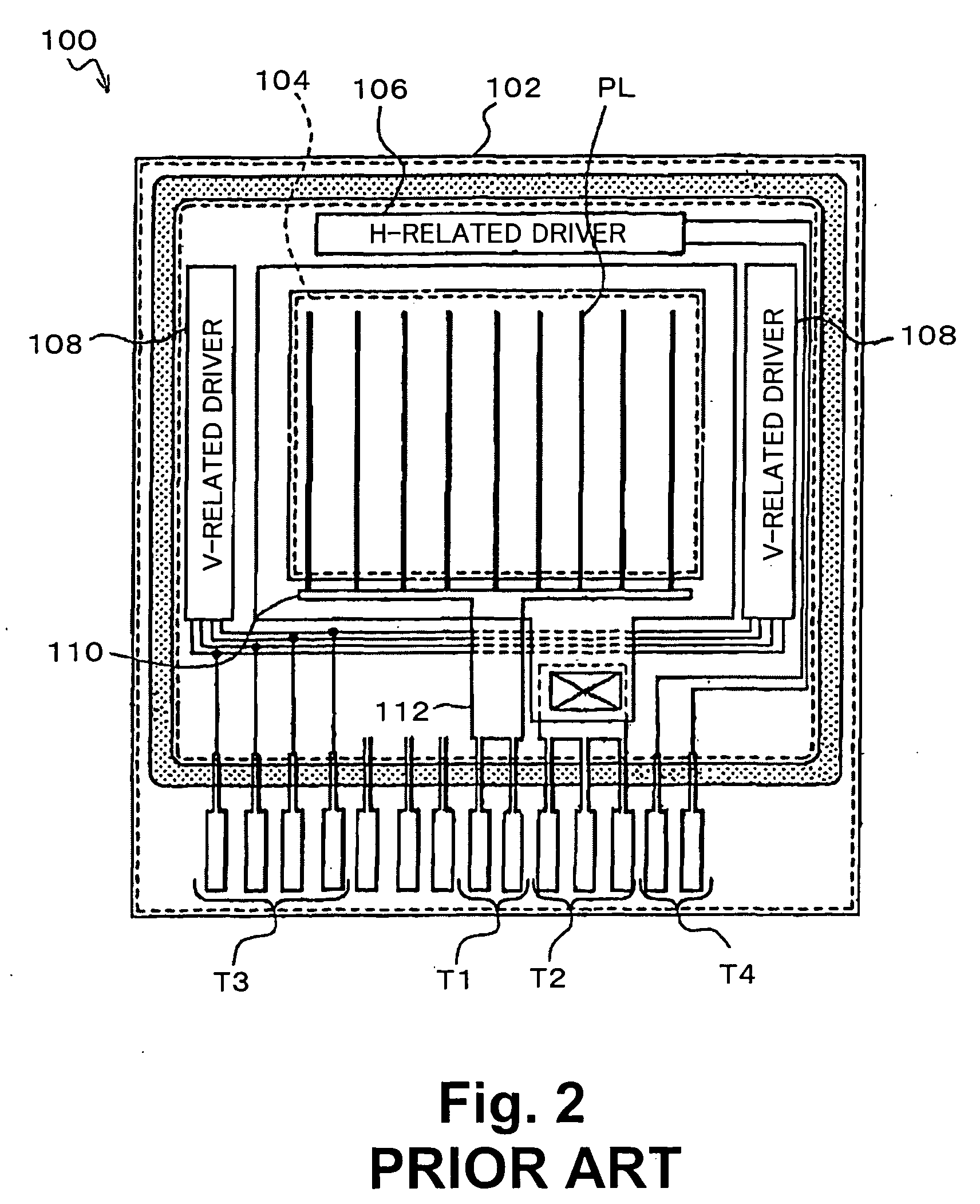

Electroluminescence display device

ActiveUS20070013629A1Reduce in quantityReduce the impactStatic indicating devicesElectroluminescent light sourcesDriver circuitDriving current

In an electroluminescence display device having, on a display panel, a display portion in which pixels are arranged in matrix, an external connection terminal is placed along a lateral side of the display panel and a vertical scan driver circuit is placed on a lateral side of the display panel which opposes the lateral side on which the external connection terminal is placed. Lines for a horizontal scan driver circuit and for the vertical scan driver circuit can be provided only on three sides of the display panel including the side on which the external connection terminal is provided, a side opposing this side, and another side. By not placing the line for the driver circuits on the remaining side, spaces can be secured on this side for a drive current line which supplies power to an electroluminescence element. With this structure, a size of a frame portion can be reduced while securing sufficient width for the drive current common line.

Owner:SANYO ELECTRIC CO LTD

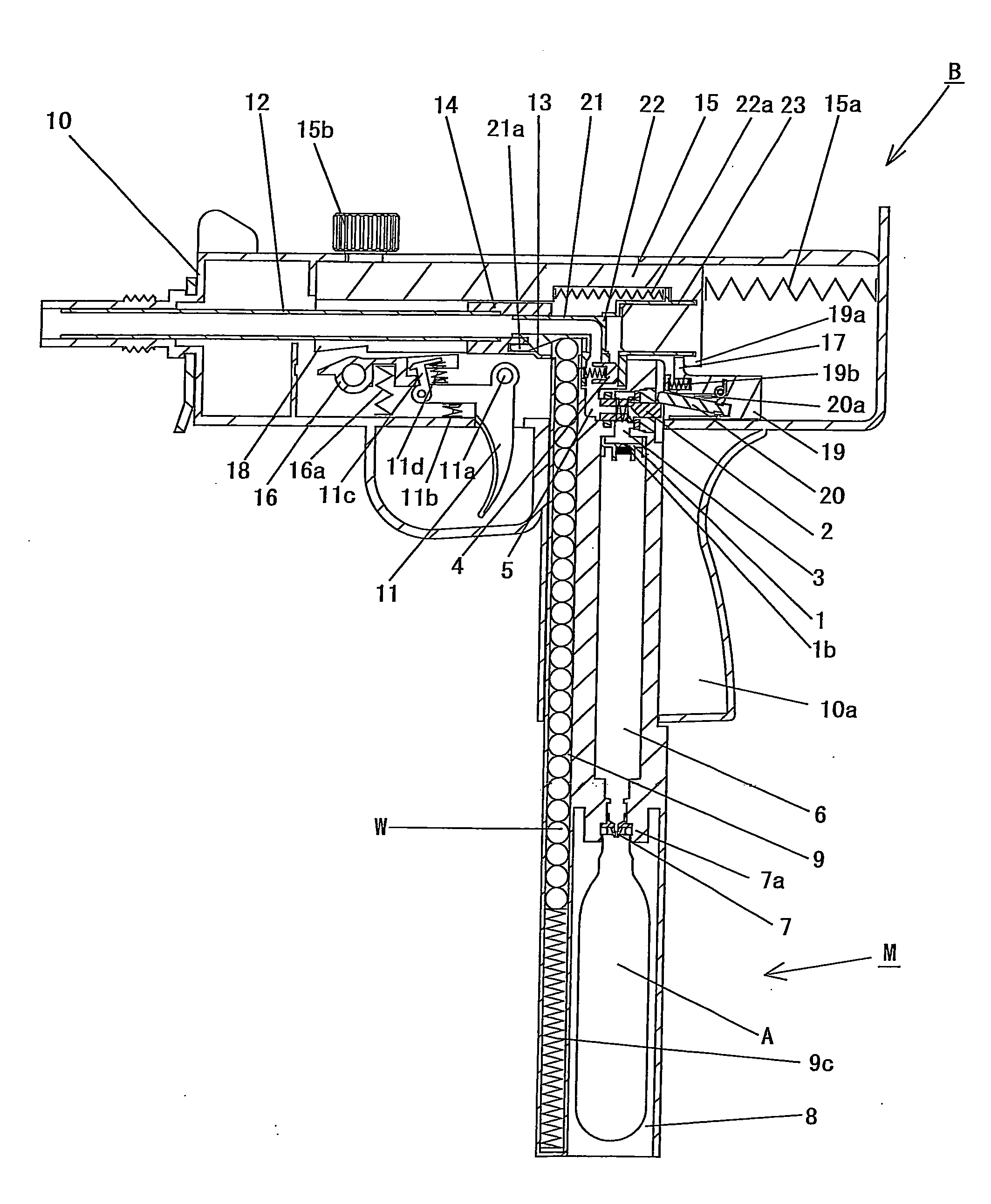

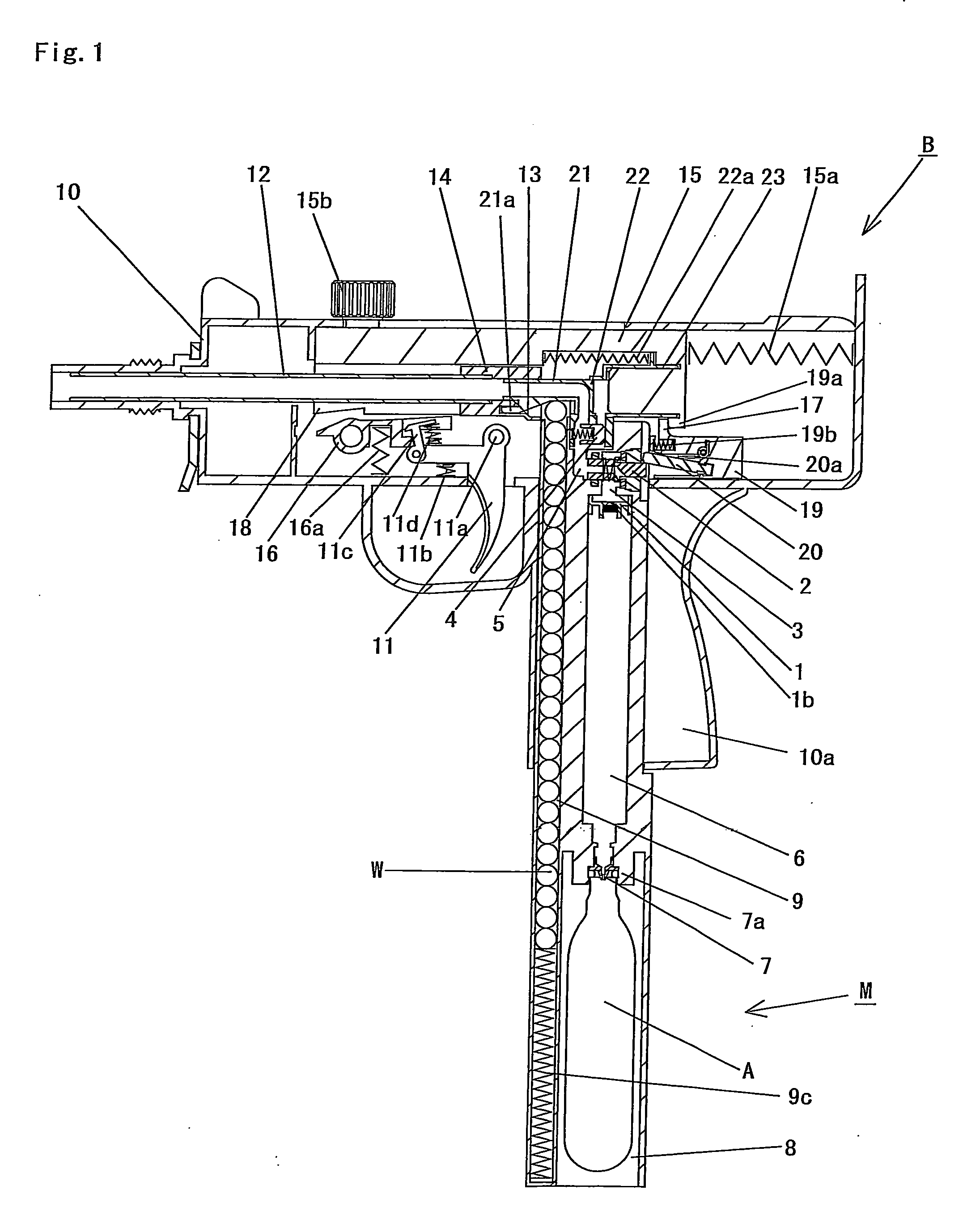

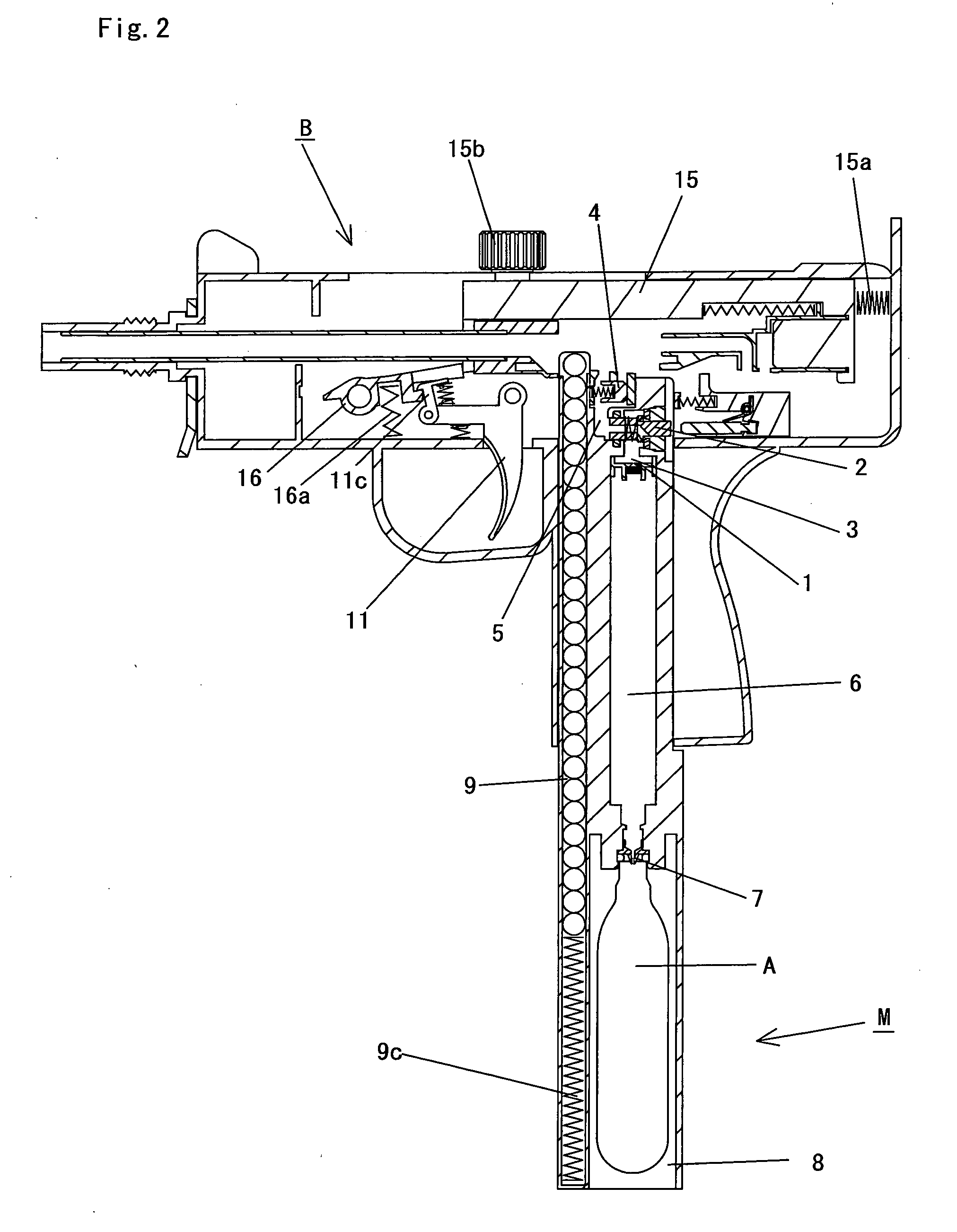

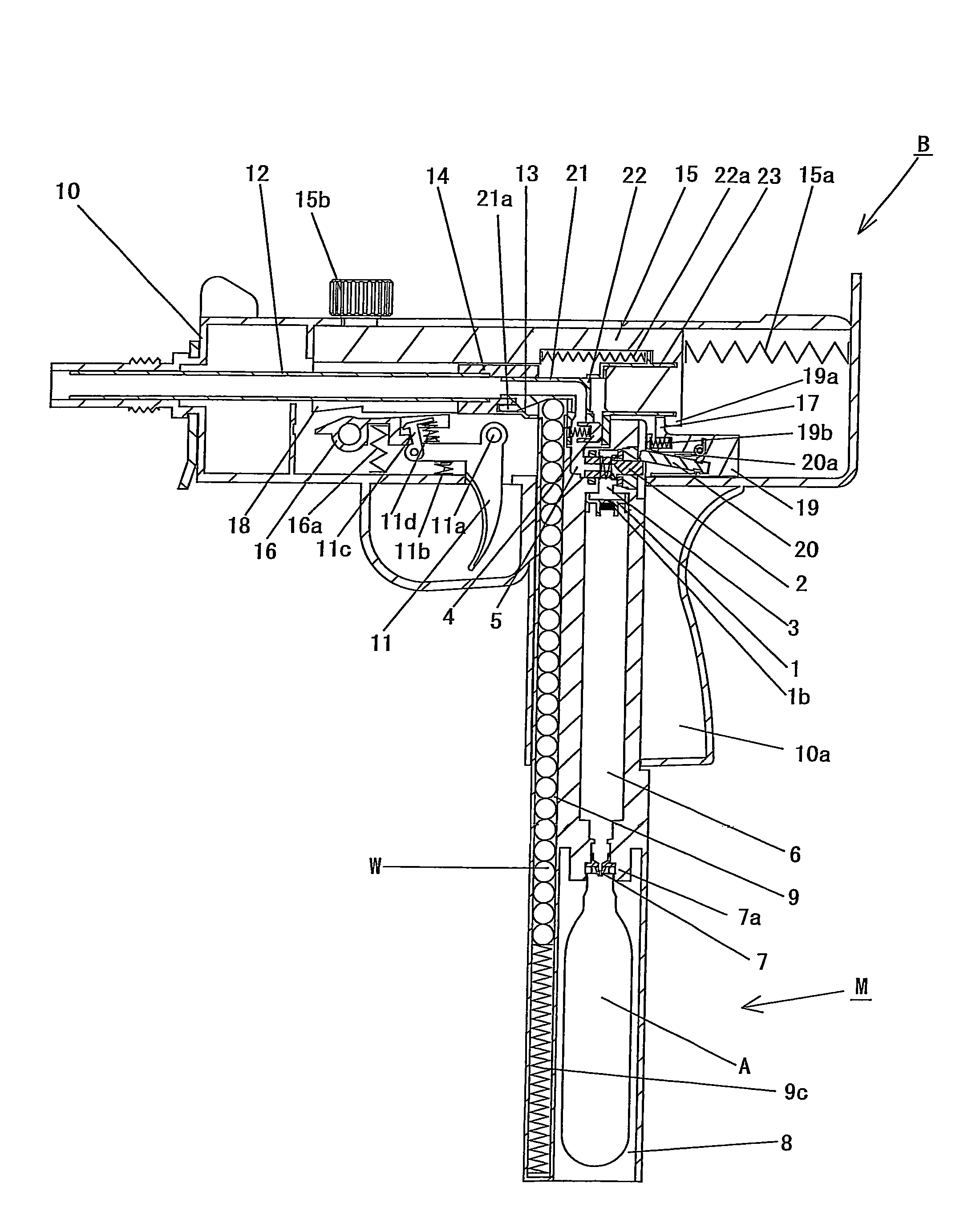

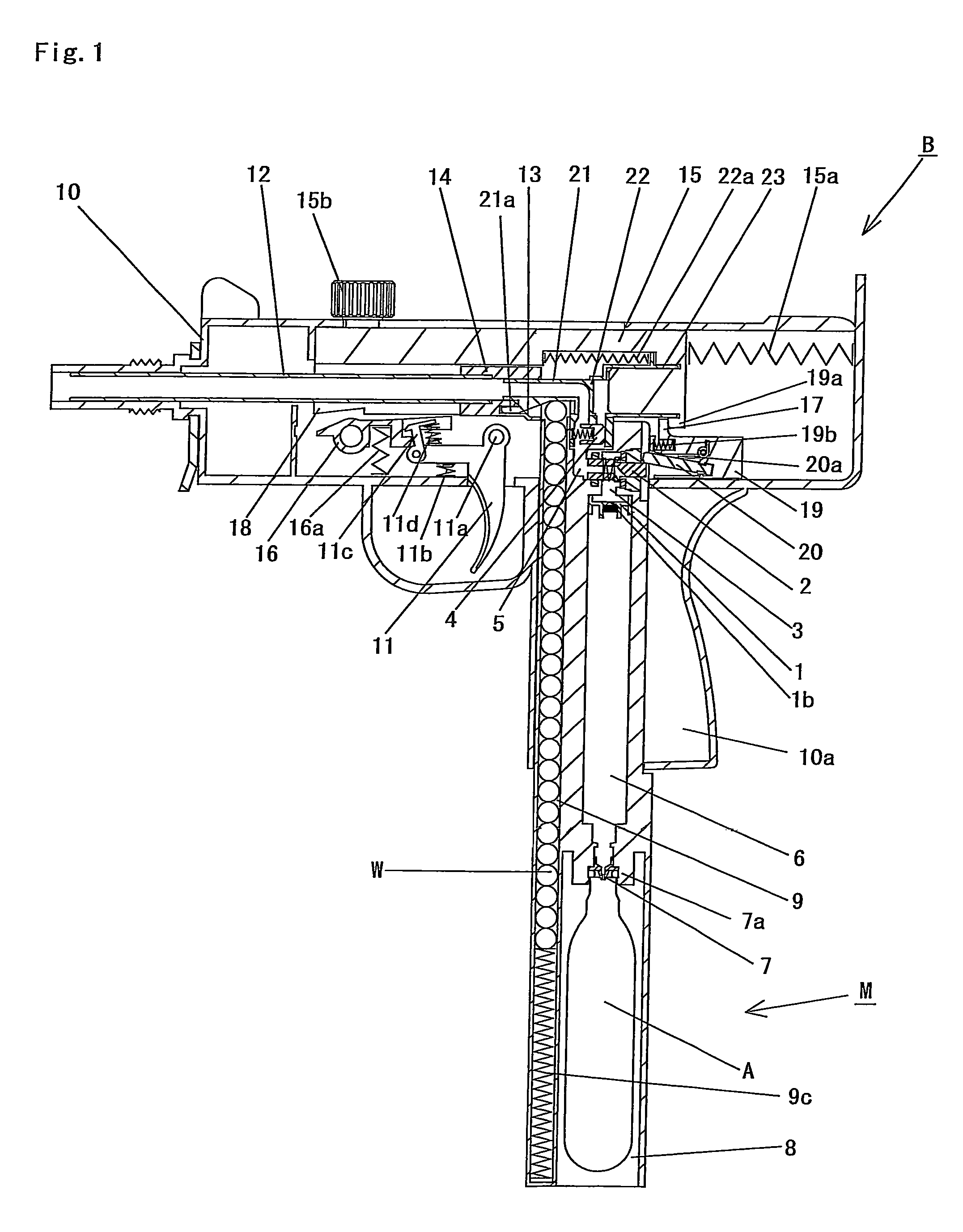

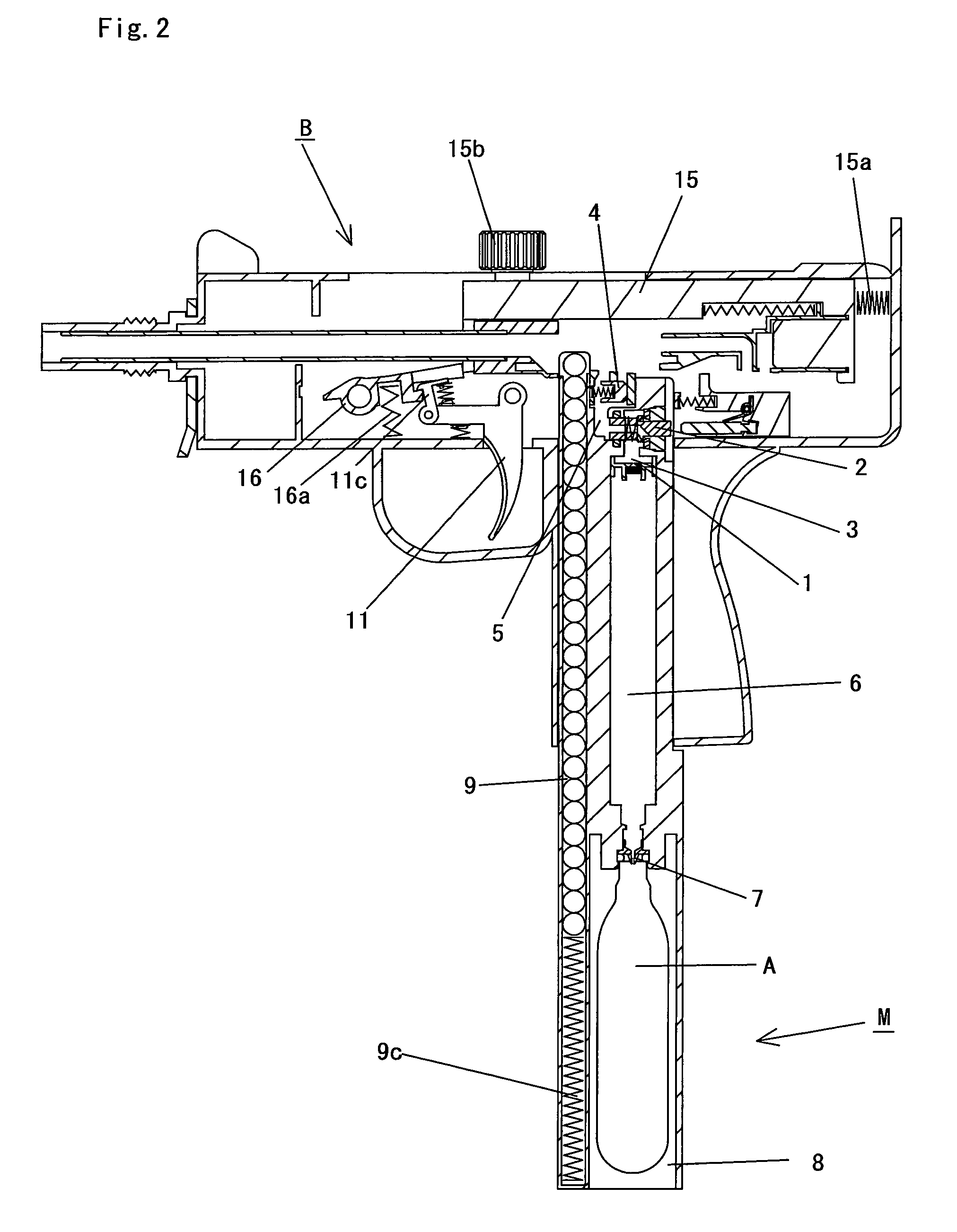

Air gun and magazine for air gun

InactiveUS20090235910A1Shorten speedReduce manufacturing costAmmunition loadingCompressed gas gunsManufacturing cost reductionEngineering

According to the present invention, by providing an extremely simple member such as a partition wall having a microscopic hole section, it is possible to reliably reduce the speed of a bullet to within a fixed speed, even a complicated decompression device such as a regulator is not provided. As a result, manufacturing time for the air gun is shortened, it is possible to lower manufacturing cost, and there is the effect of improving the manufacturing efficiency.This is because with an air gun or a magazine for an air gun of the present invention, by having a structure where the opening area of the microscopic hole section of the partition wall is smaller that the gas discharge path opening when the gas discharge path of the discharge valve is open, the gas volume per unit time that flows into the discharge valve chamber from the gas canister side by means of the microscopic holes section is smaller than the gas volume per unit time that flow out from the discharge valve chamber as a result of opening the gas discharge path of the discharge valve, which means that gas speed and gas pressure from the discharge valve chamber to the chamber where a bullet is positioned is lowered. The firing speed of a bullet is thus reduced.

Owner:MARUZEN

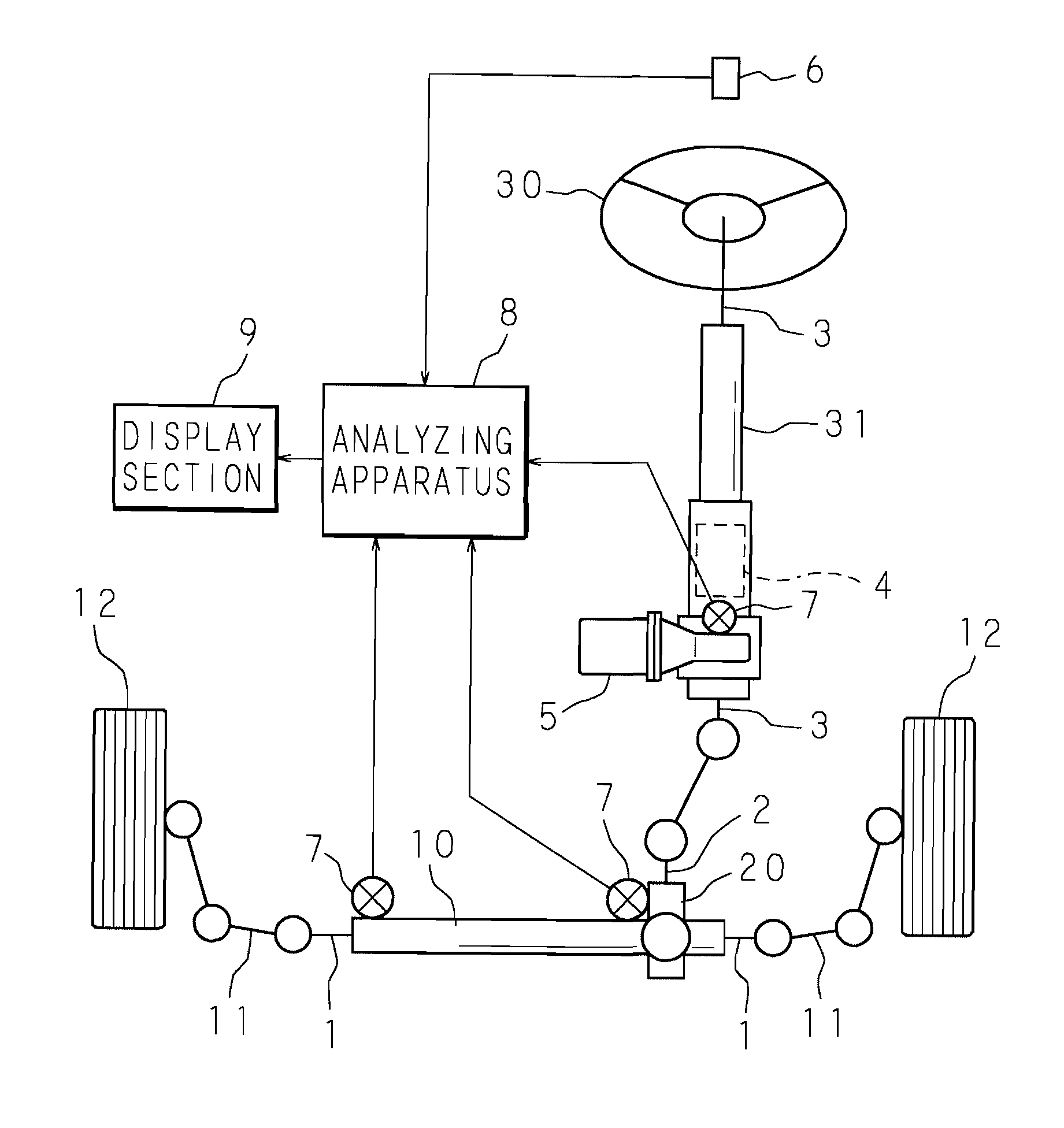

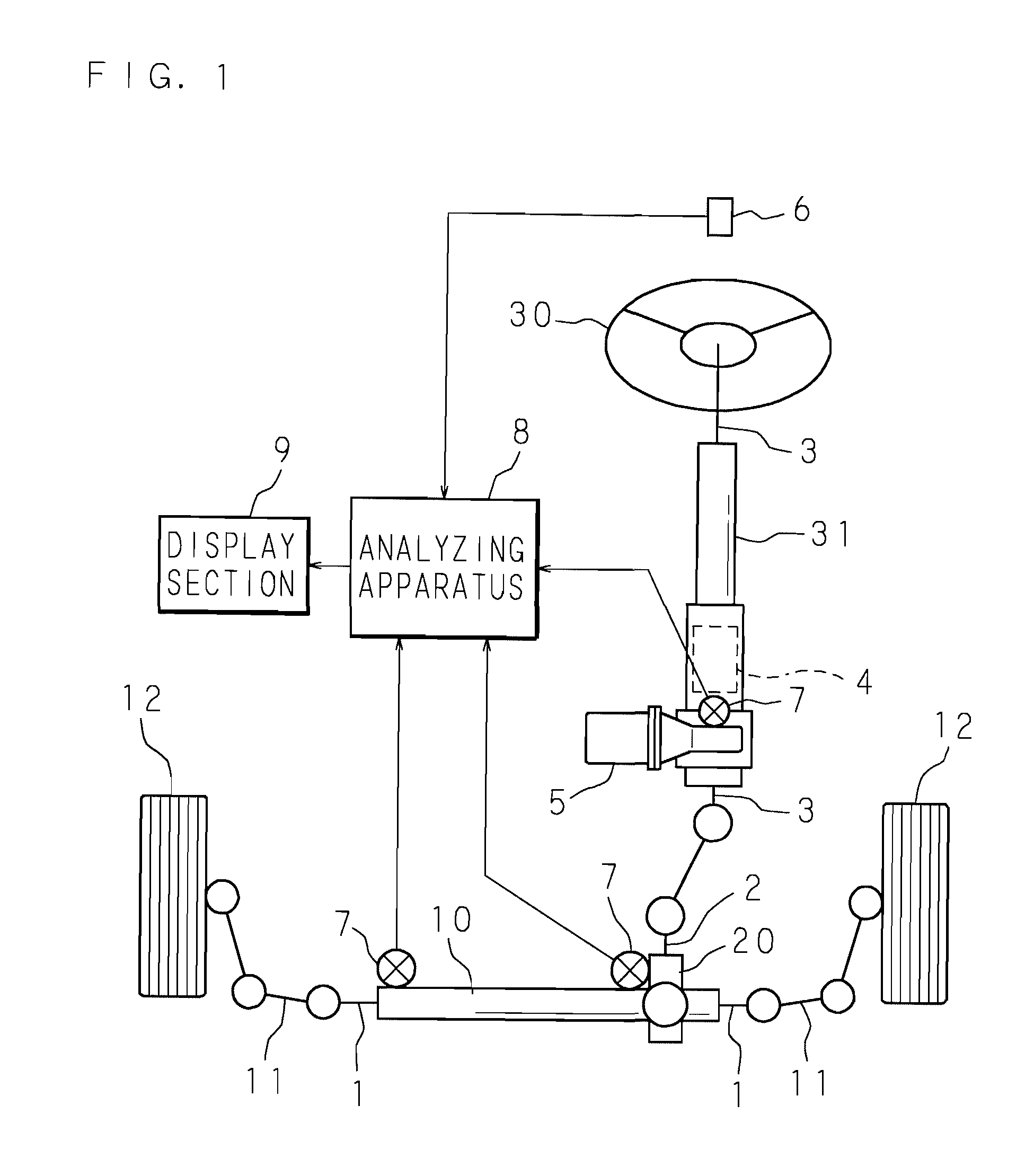

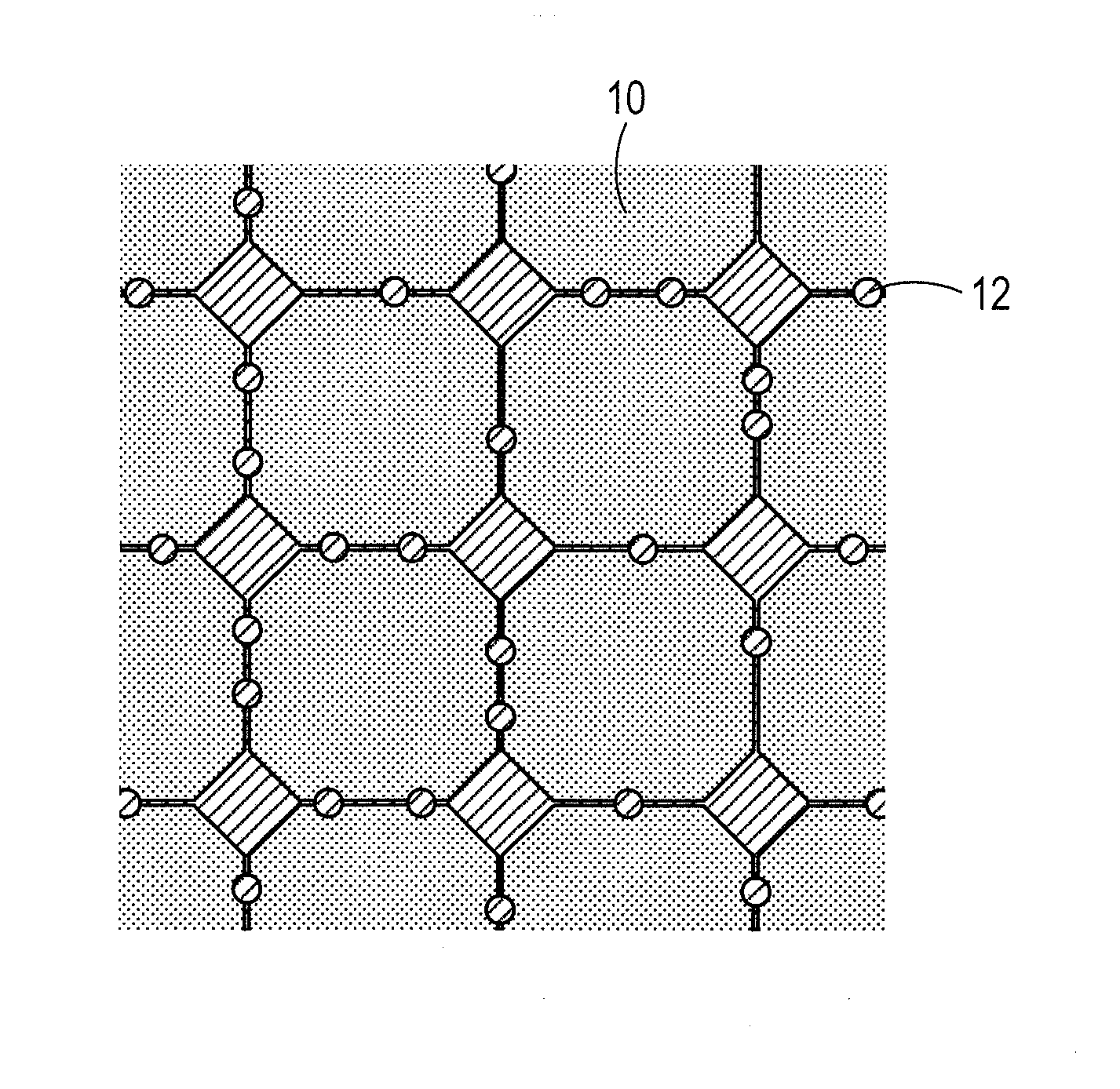

Analysis method for sound or vibration and analyzing apparatus for sound or vibration

InactiveUS20070201704A1Reliably reducedAccurate identificationVibration measurement in fluidStructural/machines measurementAcousticsAnalysis method

A detection signal of sound or vibration detected at an evaluation point is filtered so that an evaluation waveform signal is extracted. Then, a mother wavelet is derived using this. On the other hand, each of detection signals of sound or vibration detected at a plurality of candidate points is filtered so that each candidate waveform signal is extracted. These candidate waveform signals are processed by wavelet transformation using the derived mother wavelet. Then, on the basis of the result, instantaneous correlation is calculated between each candidate waveform signal and the mother wavelet. Then, on the basis of mutual comparison of the calculated instantaneous correlation, a generation source of the sound or vibration that appears at the evaluation point is identified.

Owner:JTEKT CORP +1

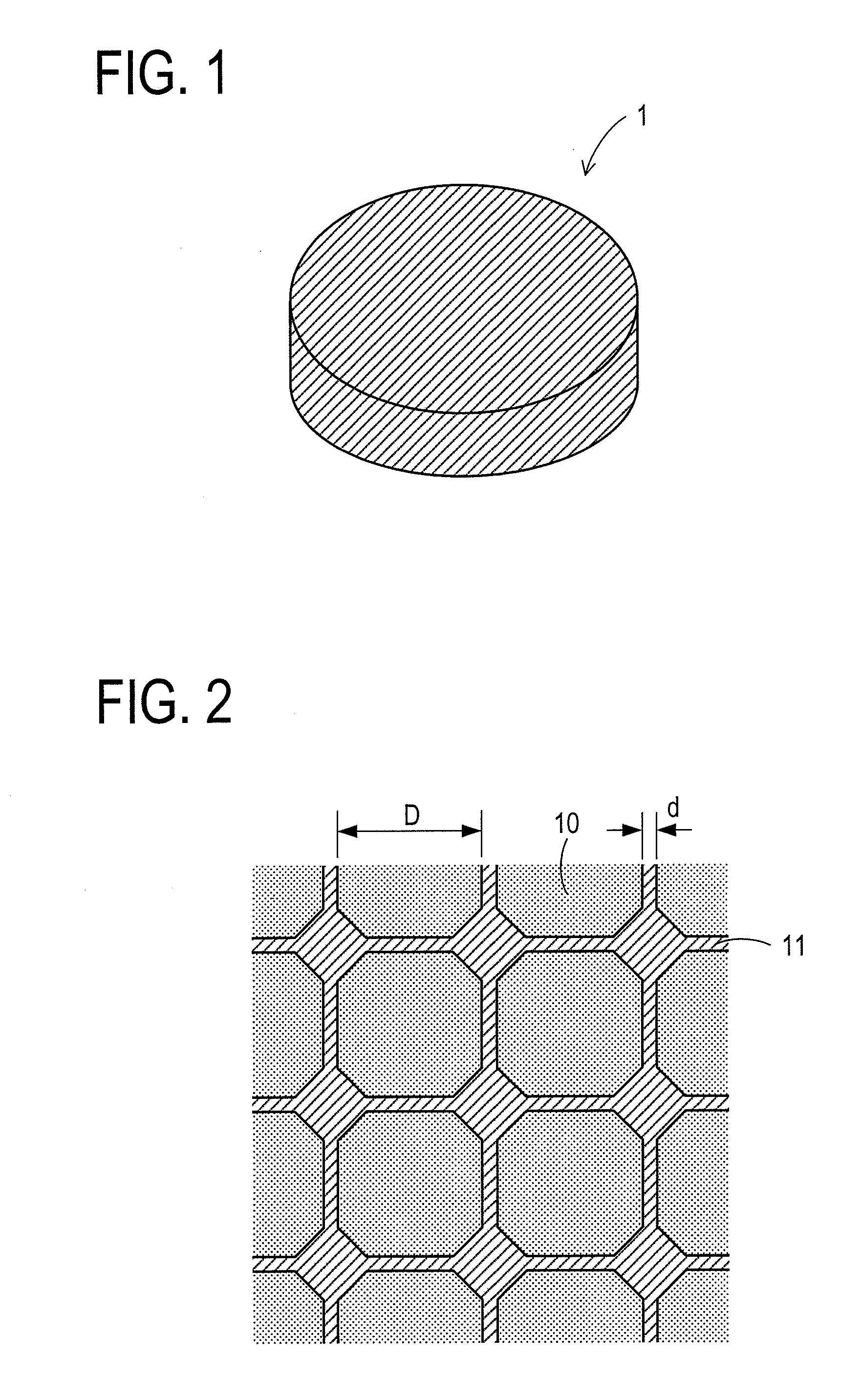

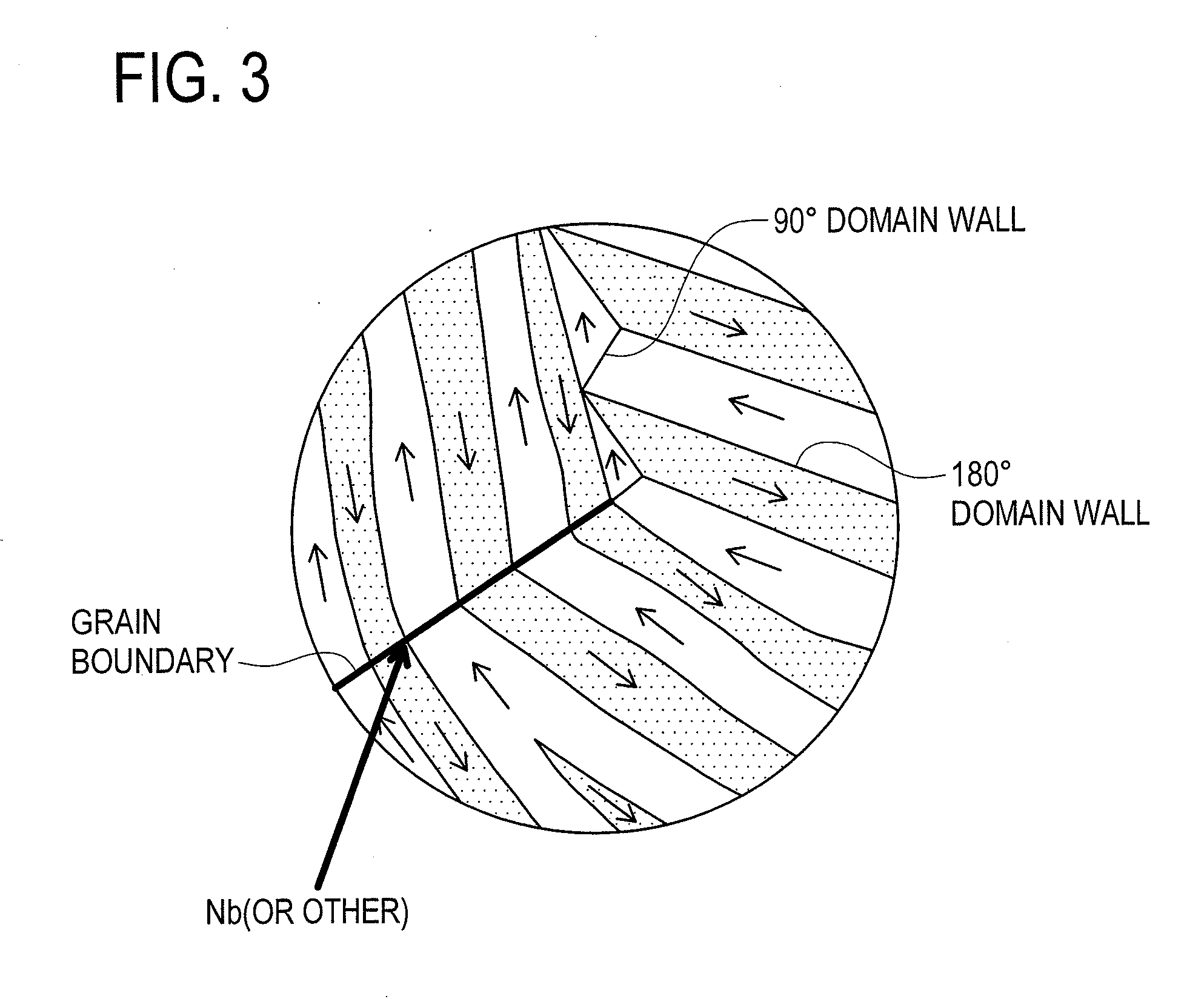

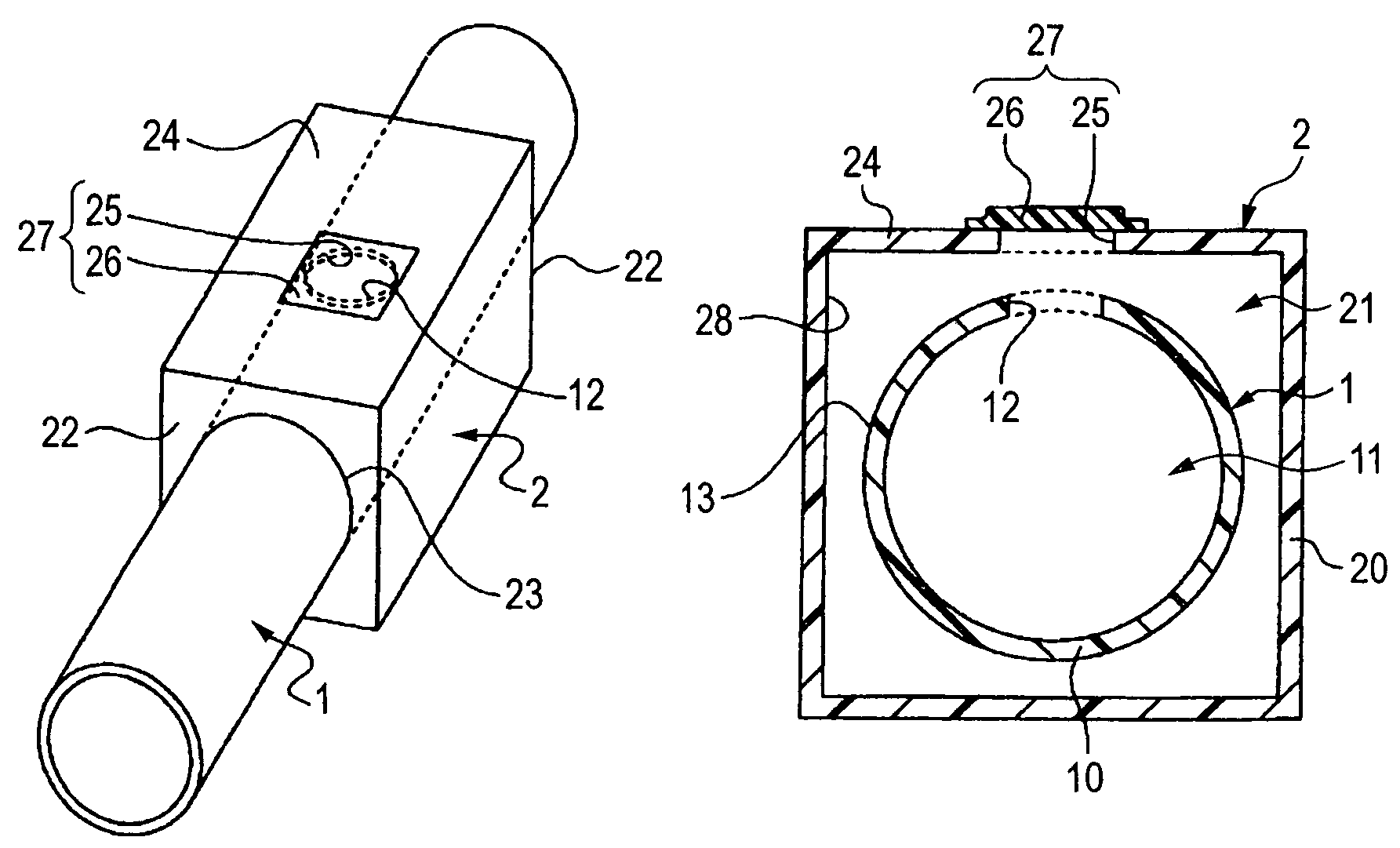

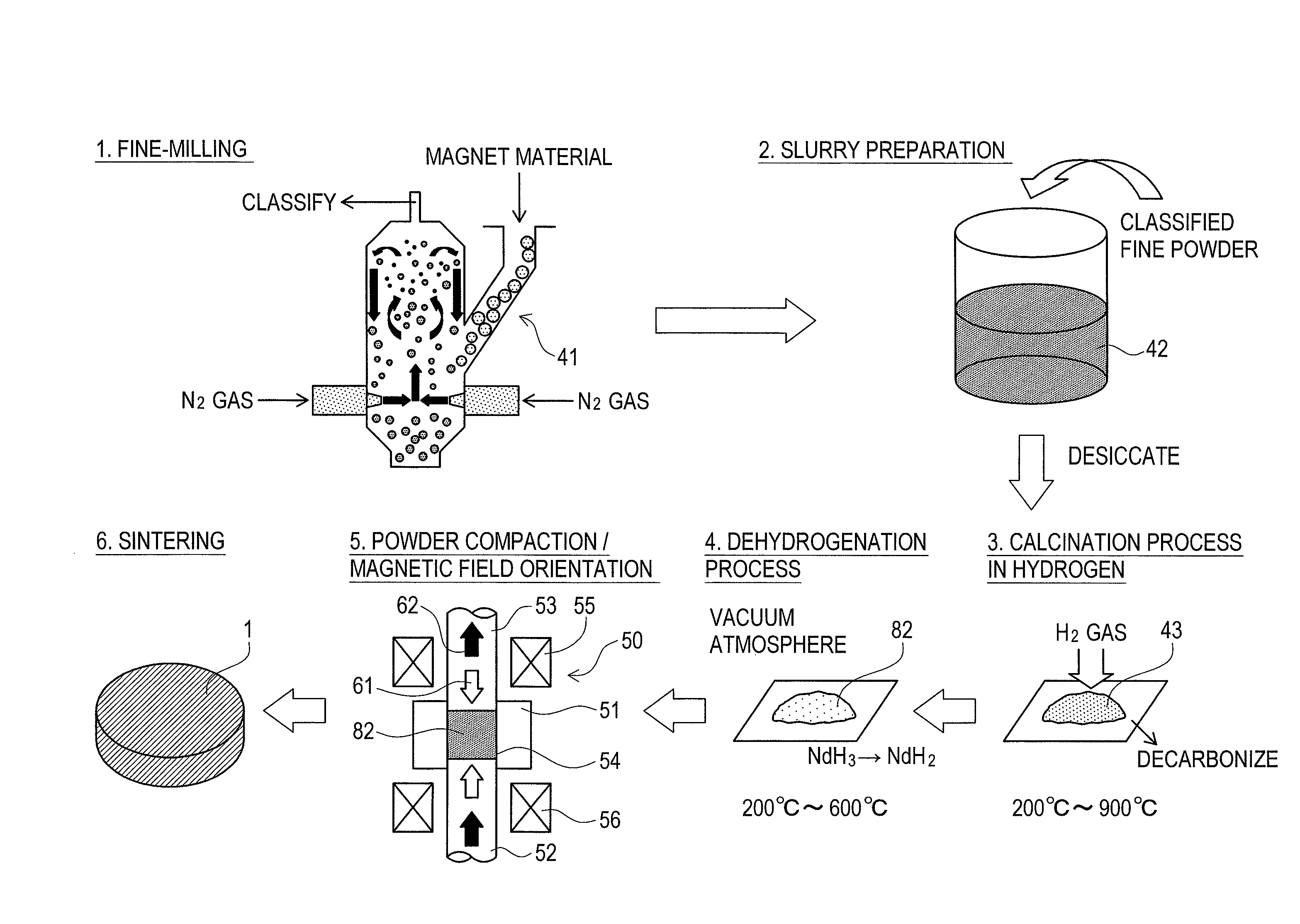

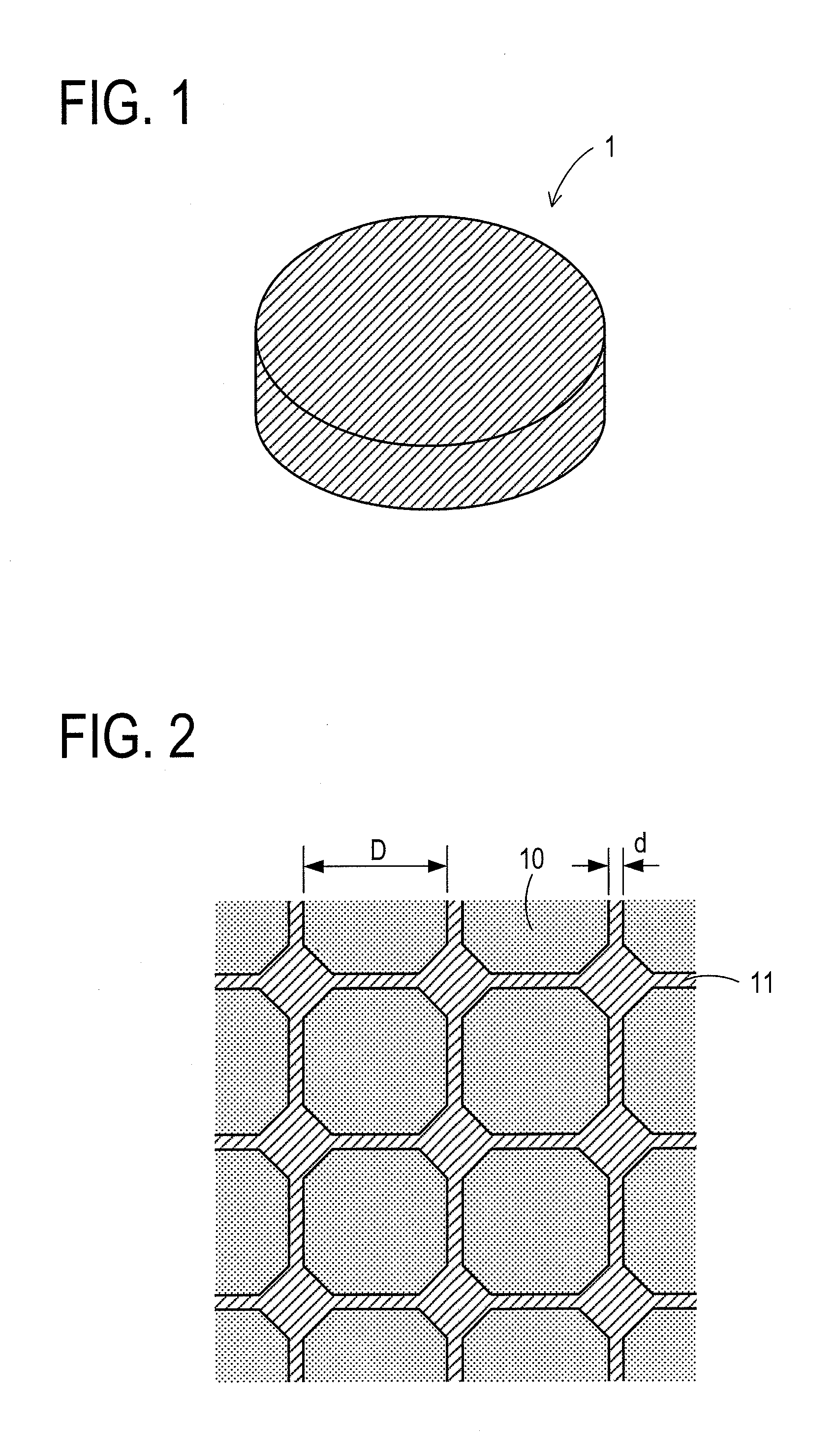

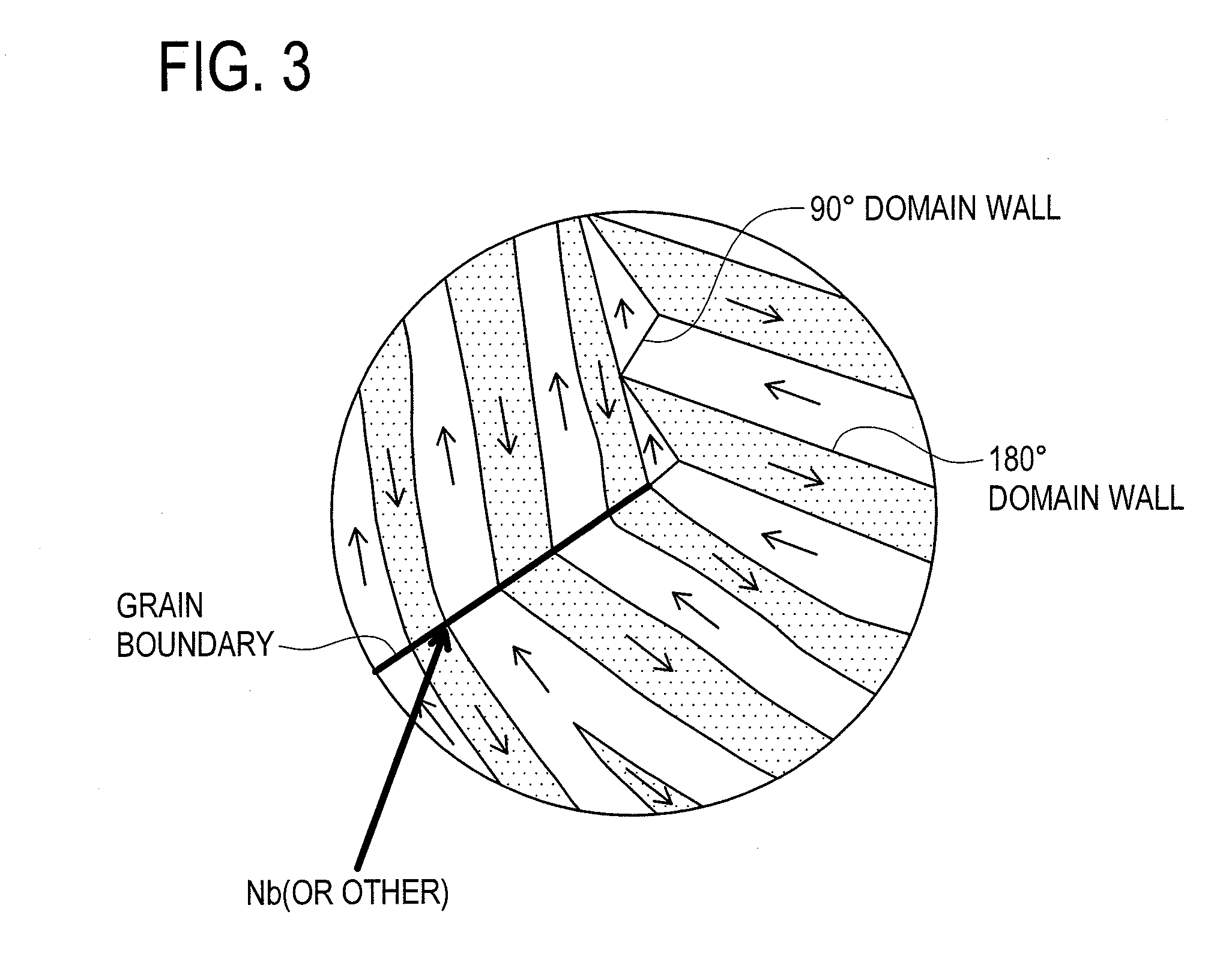

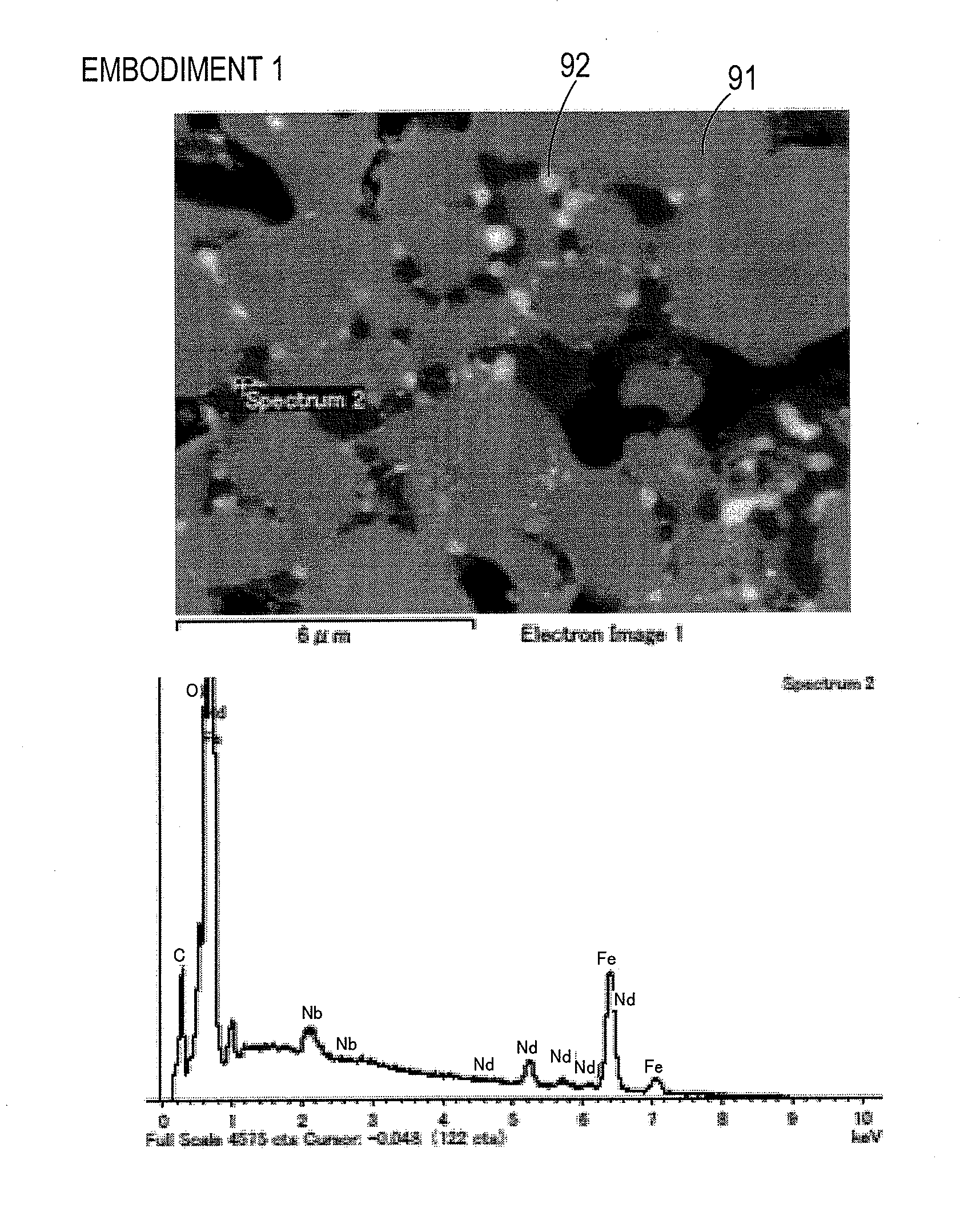

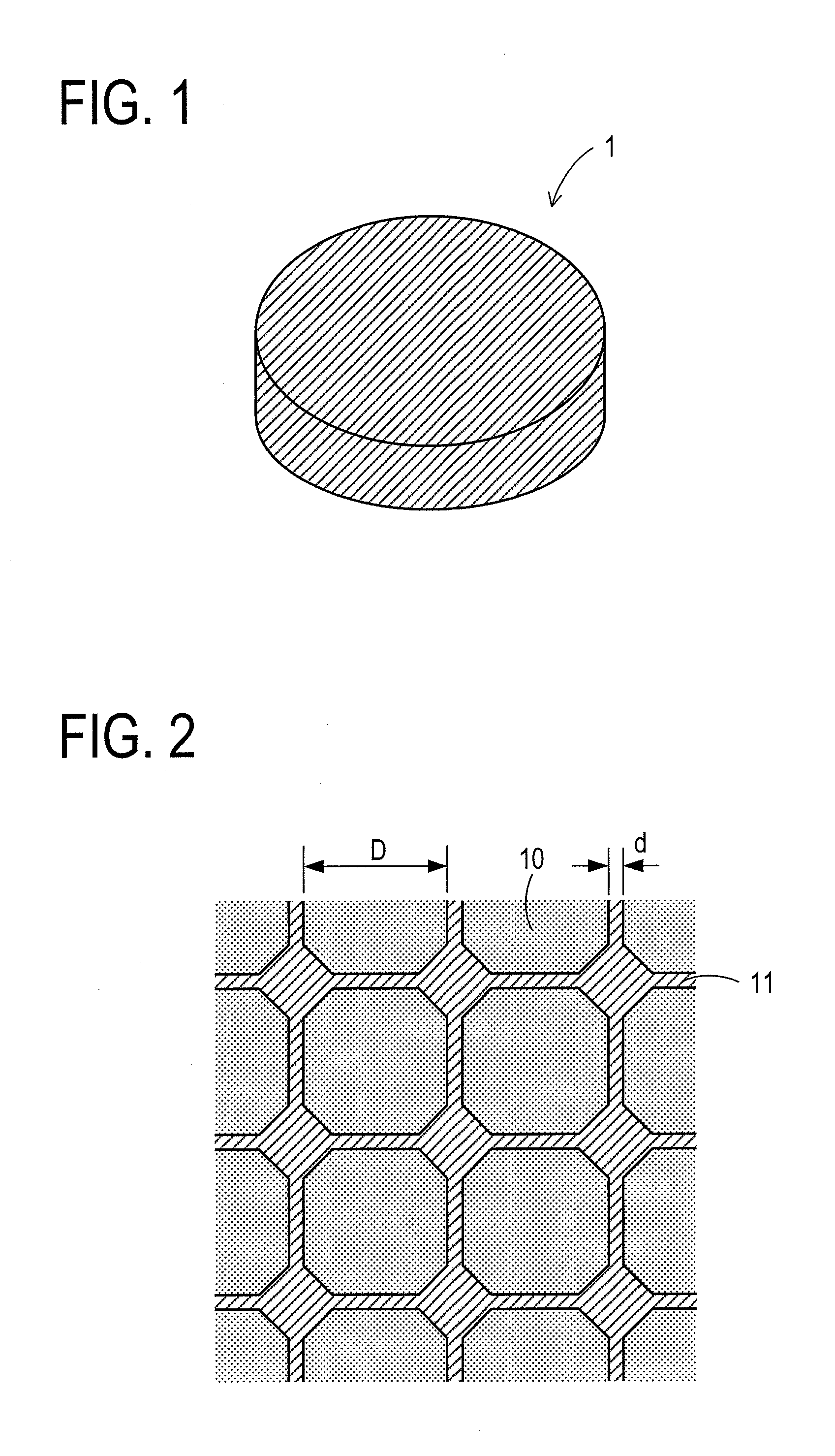

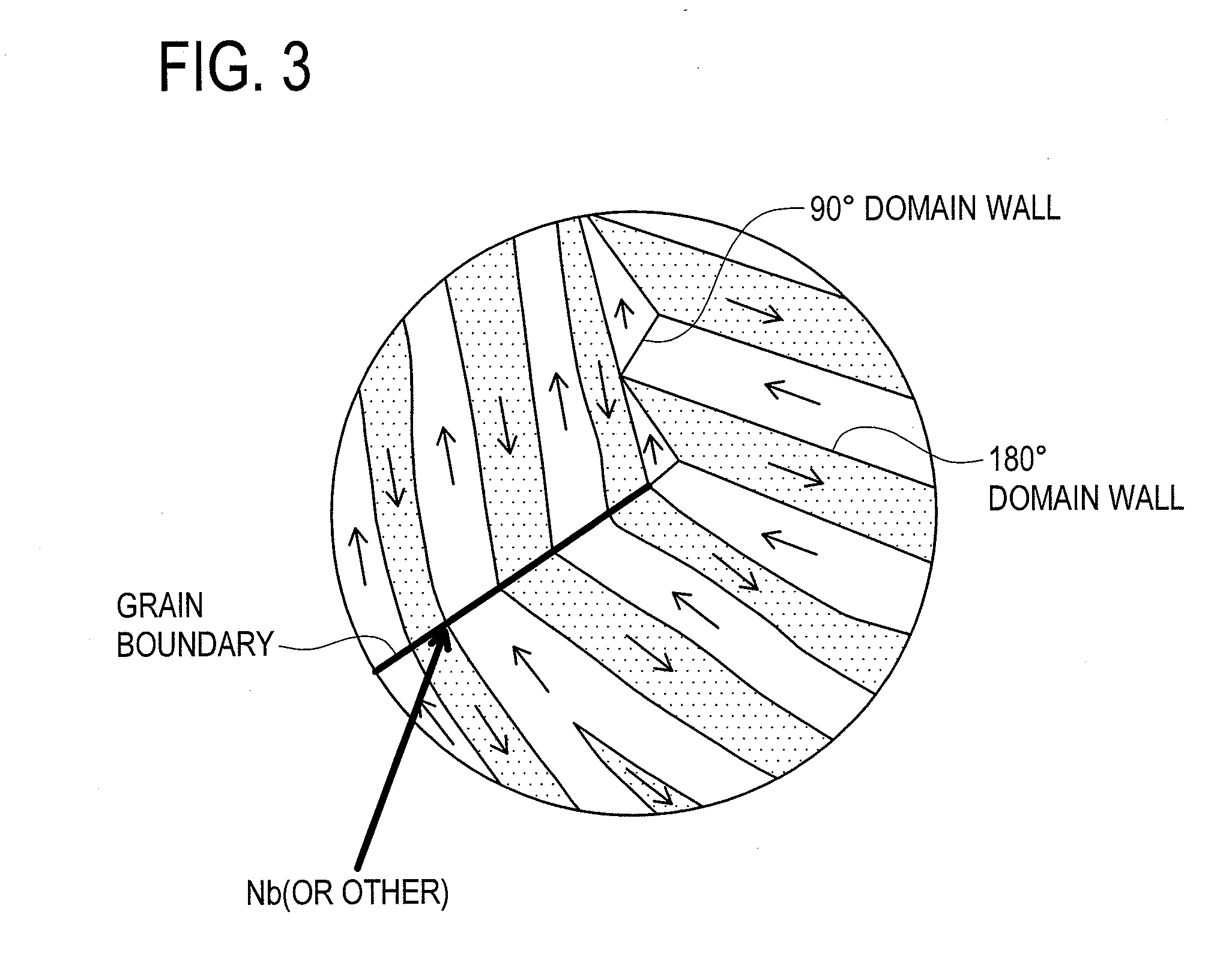

Permanent magnet and manufacturing method thereof

InactiveUS20120187327A1Improve magnetismResidual magnetic flux density decreaseMagnetic paintsTransportation and packagingNeodymium magnetHydrogen atmosphere

There are provided a permanent magnet and a manufacturing method thereof capable of decreasing an activity level of a calcined body activated by a calcination process. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, desiccated magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius. Thereafter, the powdery calcined body calcined through the calcination process in hydrogen is held for several hours in vacuum atmosphere at 200 through 600 degrees Celsius for a dehydrogenation process.

Owner:NITTO DENKO CORP

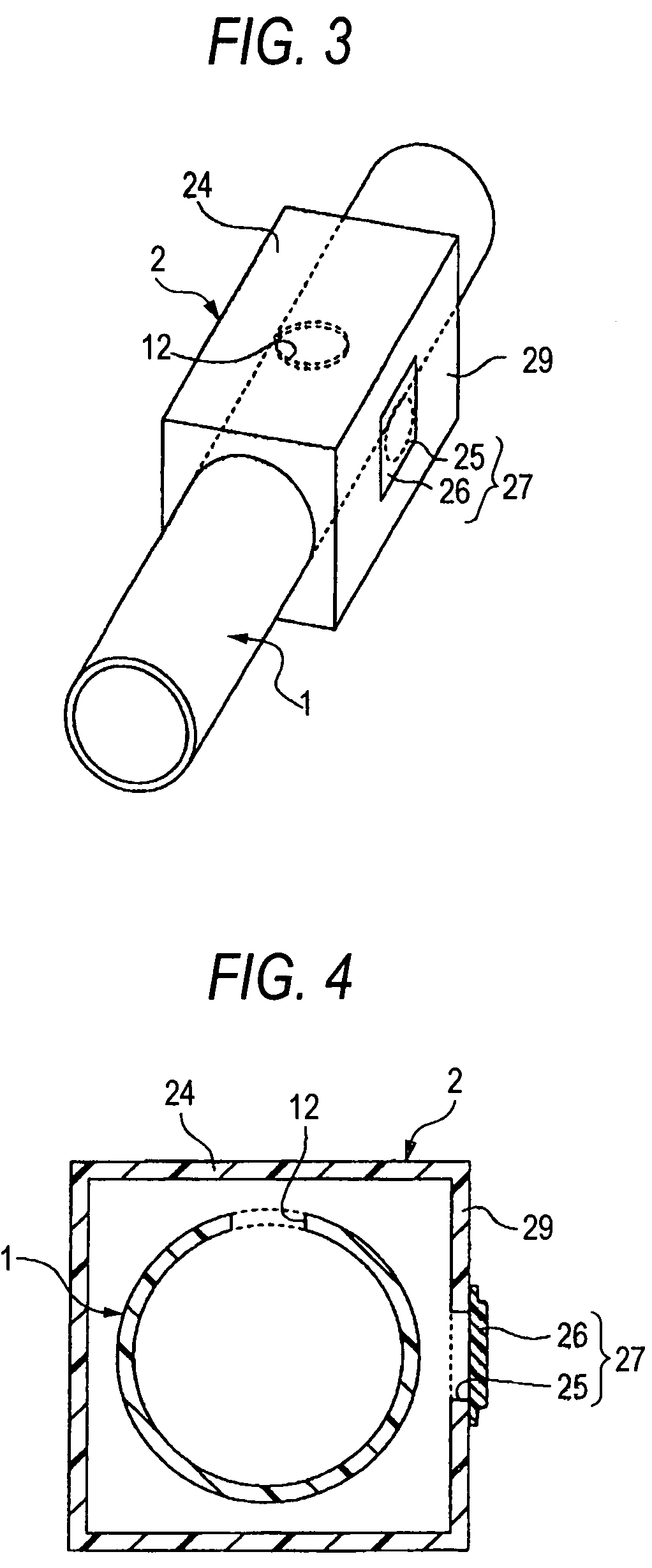

Muffler duct

InactiveUS7556123B2Reduce low frequency noiseReduce sound pressureSilencing apparatusMachines/enginesResonanceMuffler

In a muffler duct including a duct body and a resonance box, the inside of the duct body and the inside of the resonance box are made to communicate directly with each other not through a cylindrical member. In the partition wall of the resonance box, a gas vent opening portion, which is composed of a gas vent opening having a through hole shape and a gas-permeable member having a gas vent passage of a labyrinth shape for covering said gas vent opening, is formed at a position to confront a communication opening, through which the inside of the duct body and the inside of the resonance box communicate with each other.

Owner:TOYODA GOSEI CO LTD

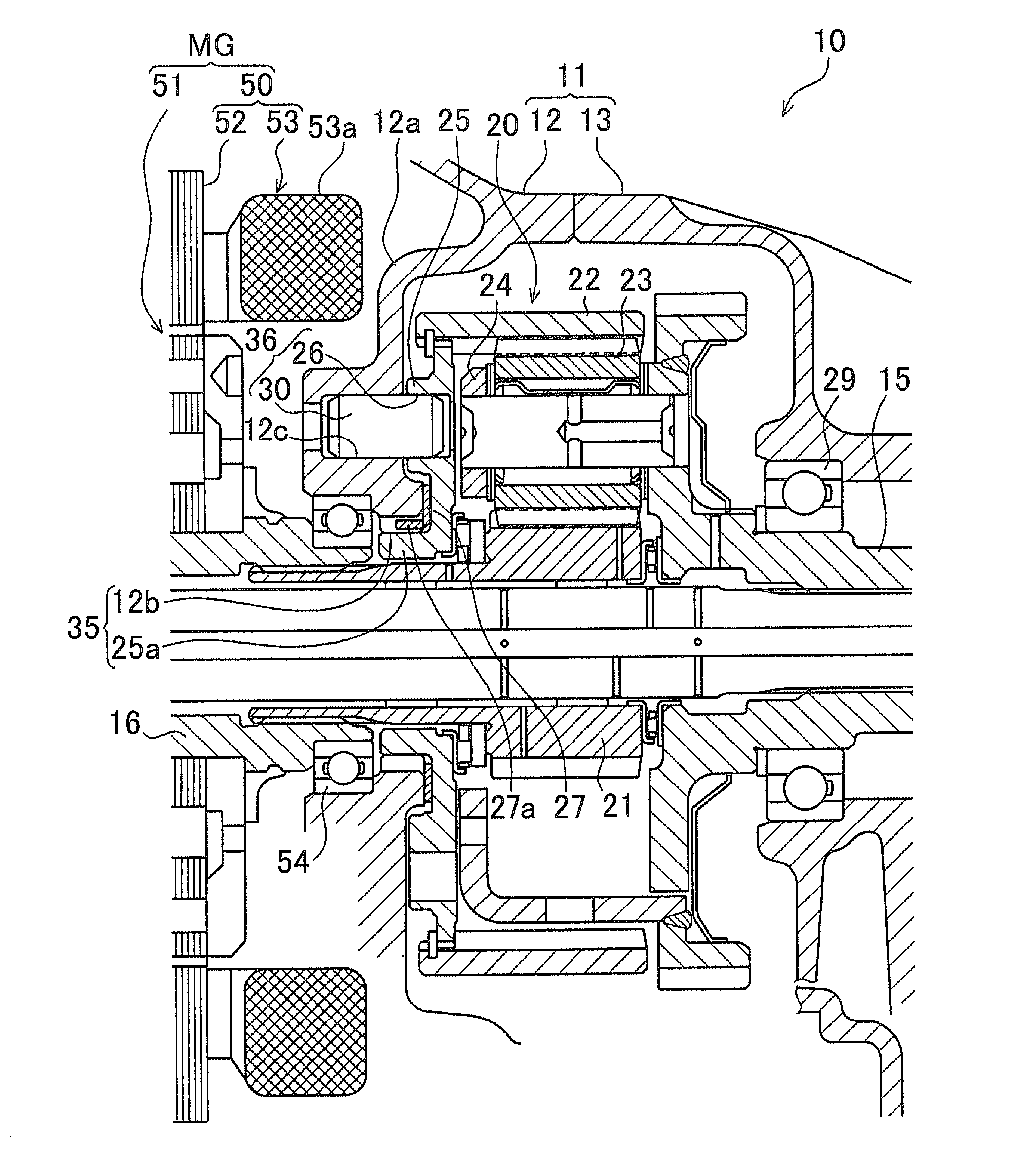

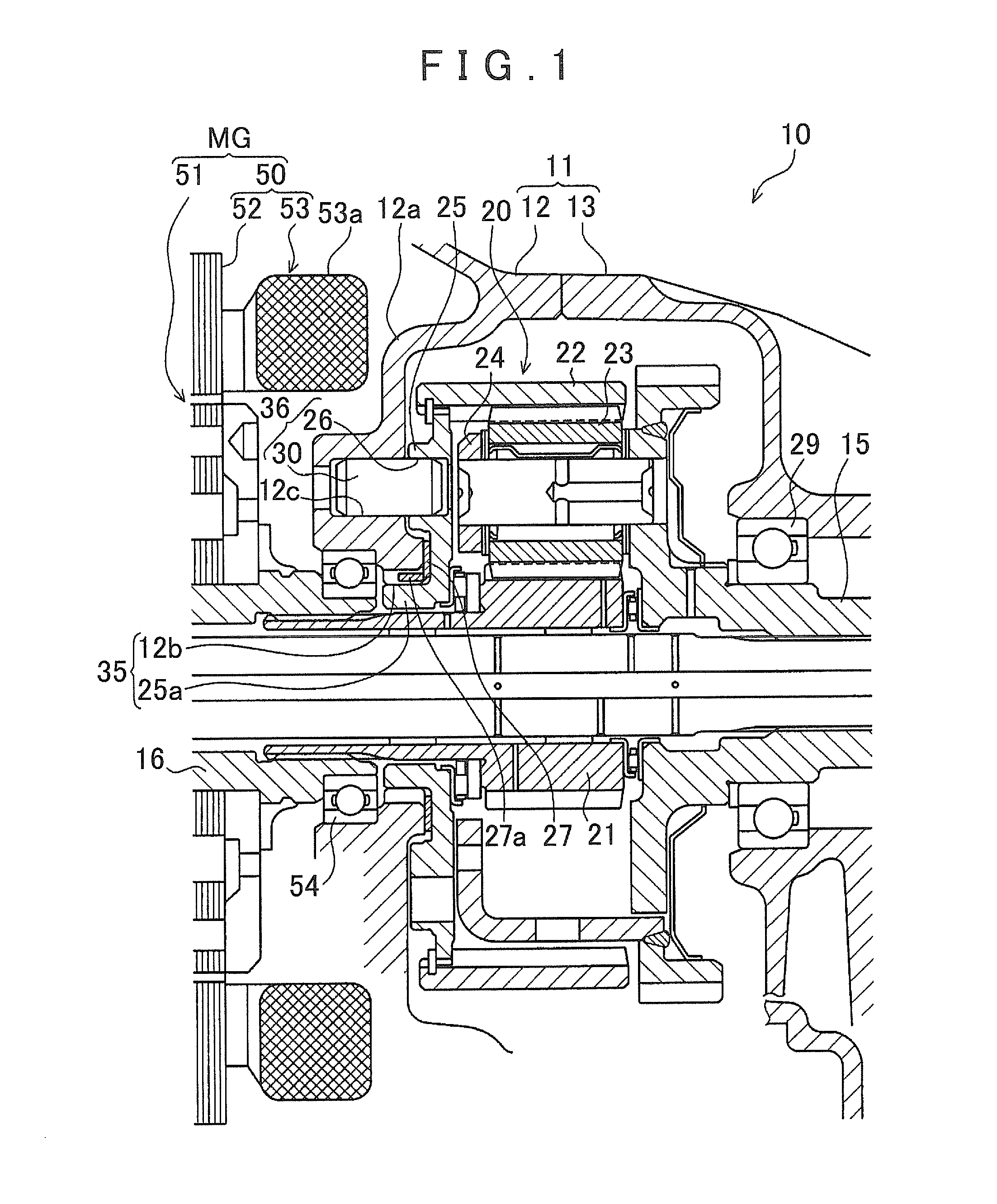

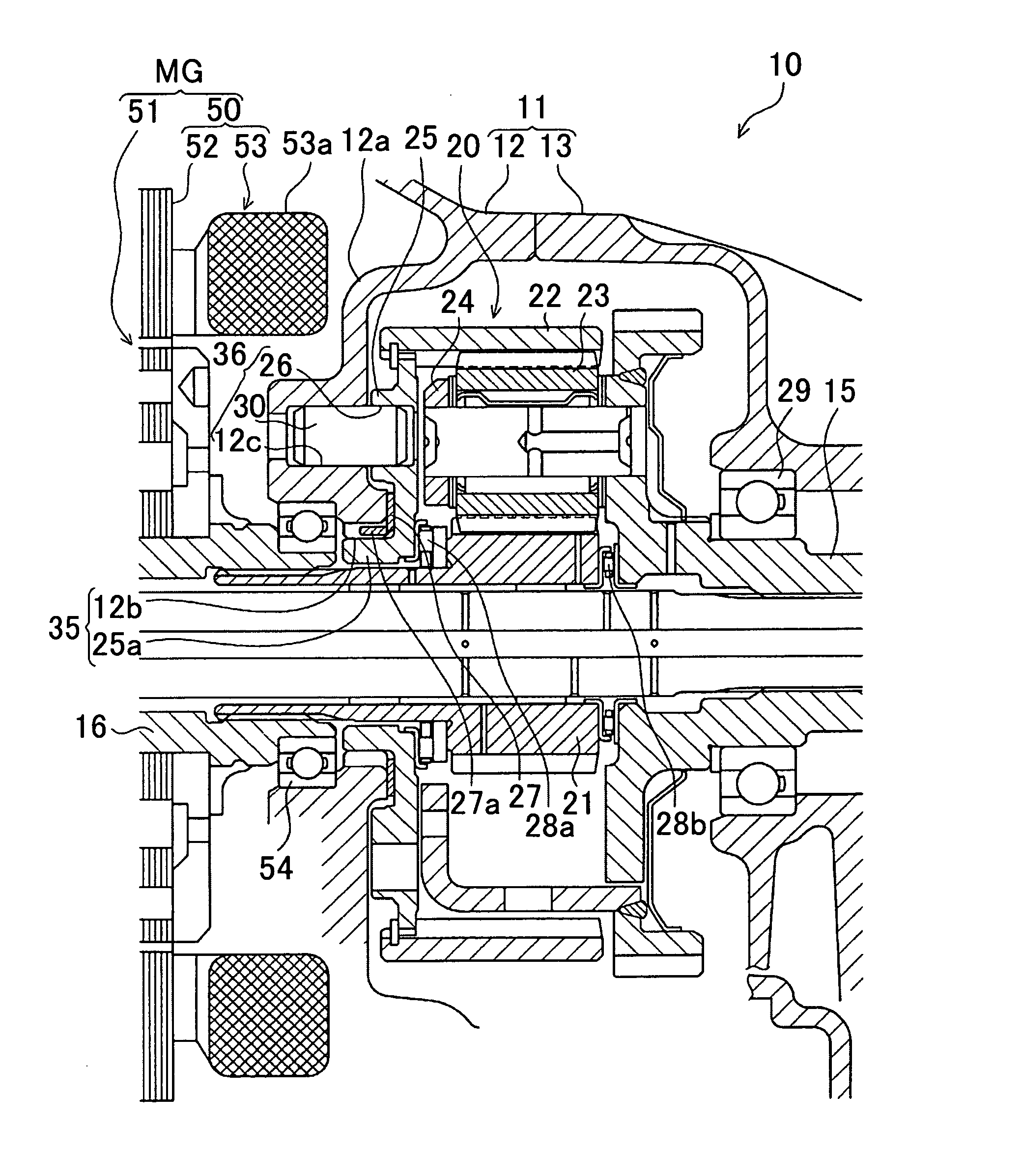

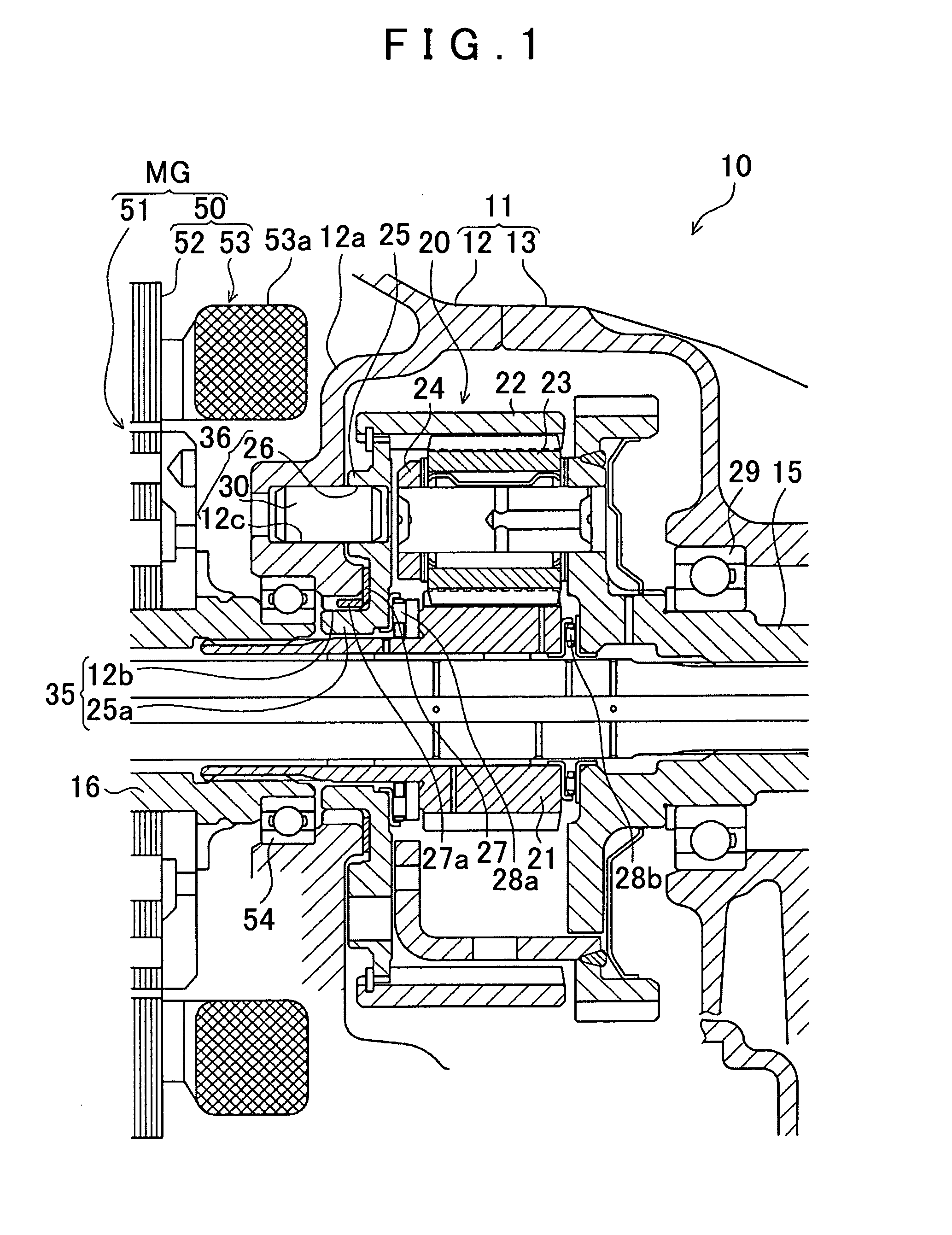

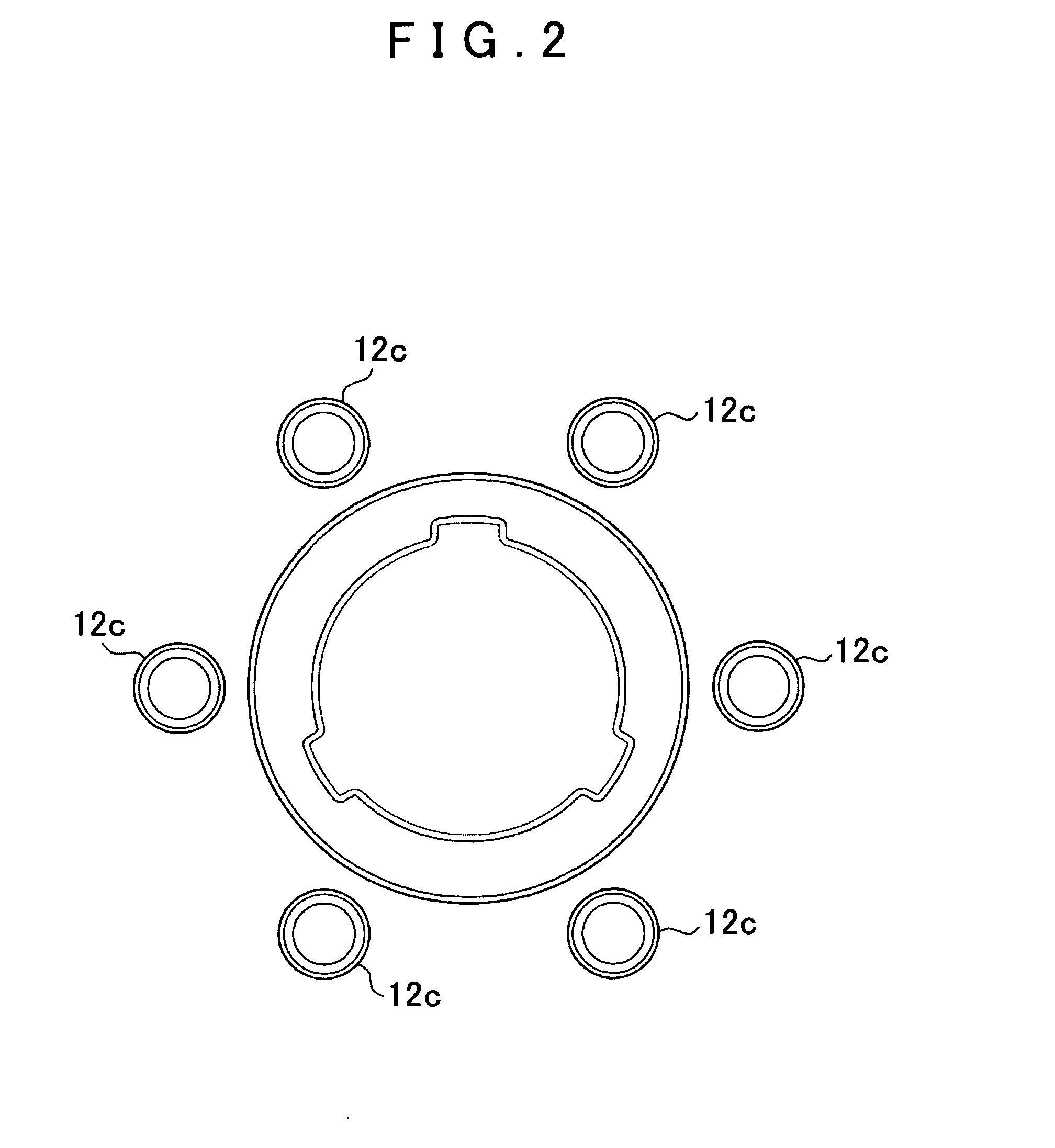

Vehicle drive apparatus

ActiveUS20130008274A1Reduction in axial sizeGear noise be reduceGear vibration/noise dampingGear lubrication/coolingMotor–generatorFlange

A vehicle drive apparatus includes a motor generator, a speed reduction mechanism connected to a rotor shaft of the motor generator, an output shaft connected to the speed reduction mechanism, an intermediate wall separating the motor generator from the speed reduction mechanism, and a bearing that is fixed to the intermediate wall and supports the rotor shaft. The motor generator, intermediate wall, speed reduction mechanism, and output shaft are disposed in this order, and a ring gear of the speed reduction mechanism is fixed. The ring gear is fixed to the intermediate wall via a ring gear flange that is positioned relative and fixed to the intermediate wall by a centering mechanism and a locking mechanism. The centering mechanism is formed by fitting a boss of the ring gear flange and the intermediate wall. The locking mechanism is disposed on an outer peripheral side relative to the centering mechanism.

Owner:AISIN AW CO LTD +1

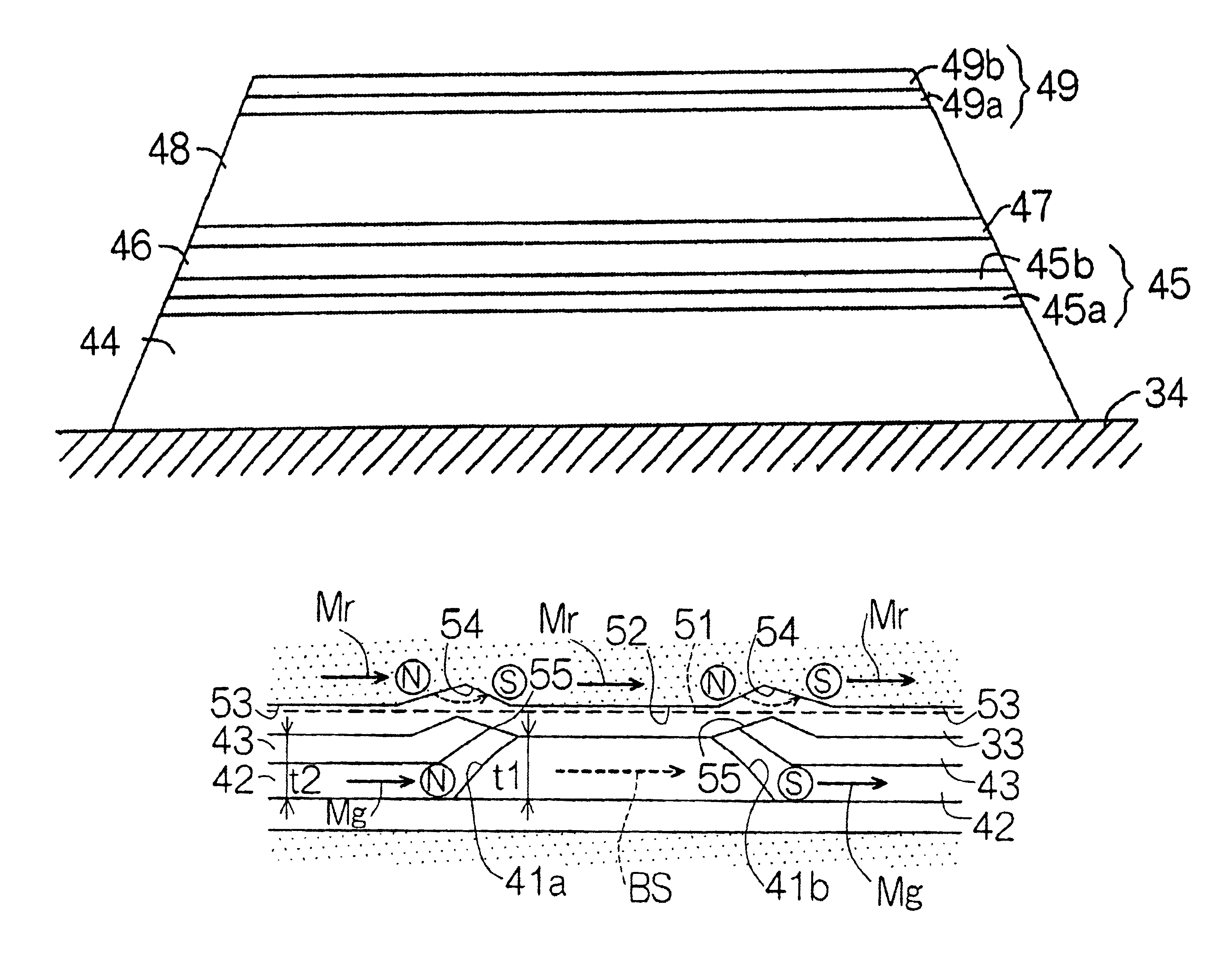

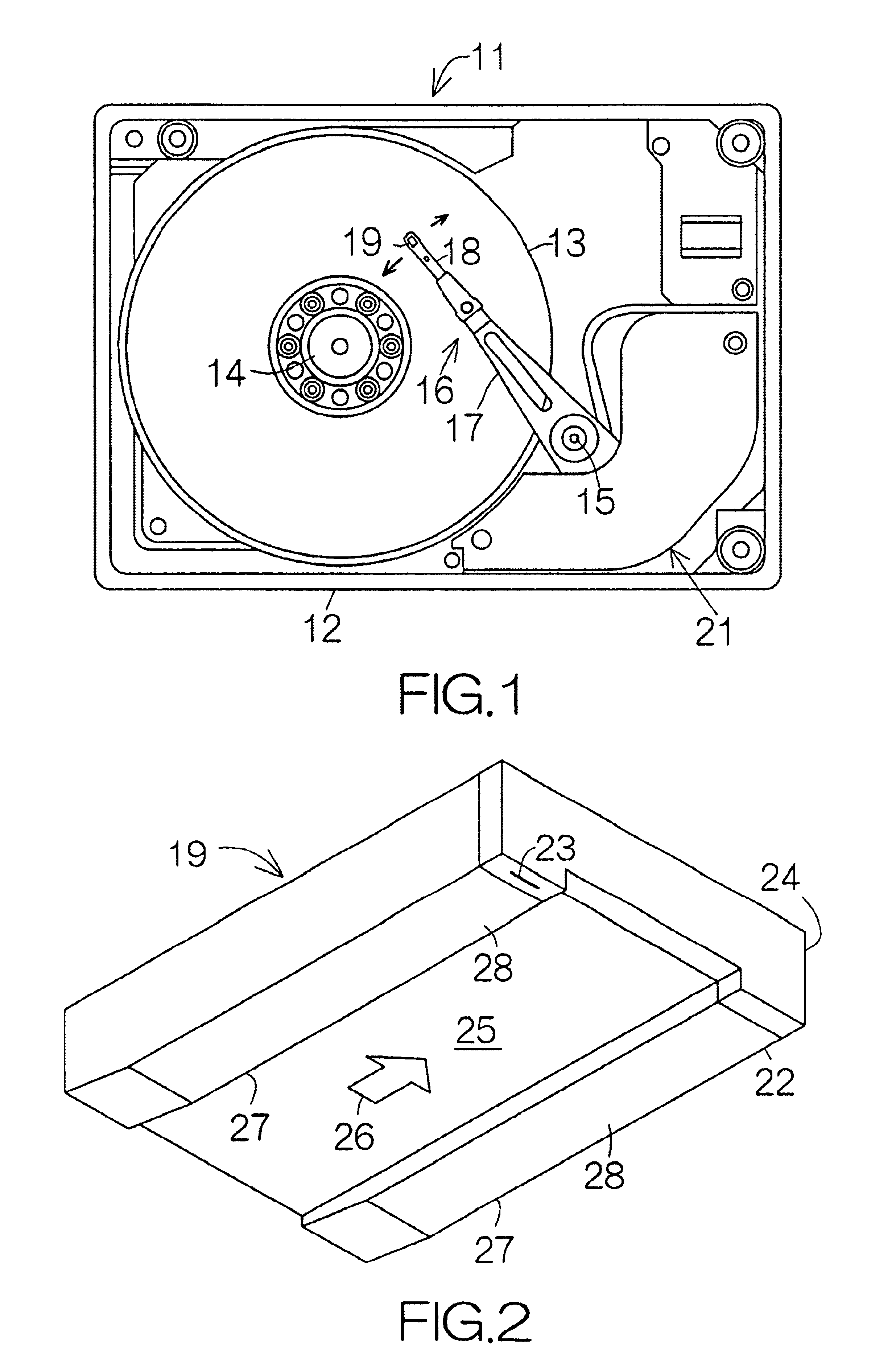

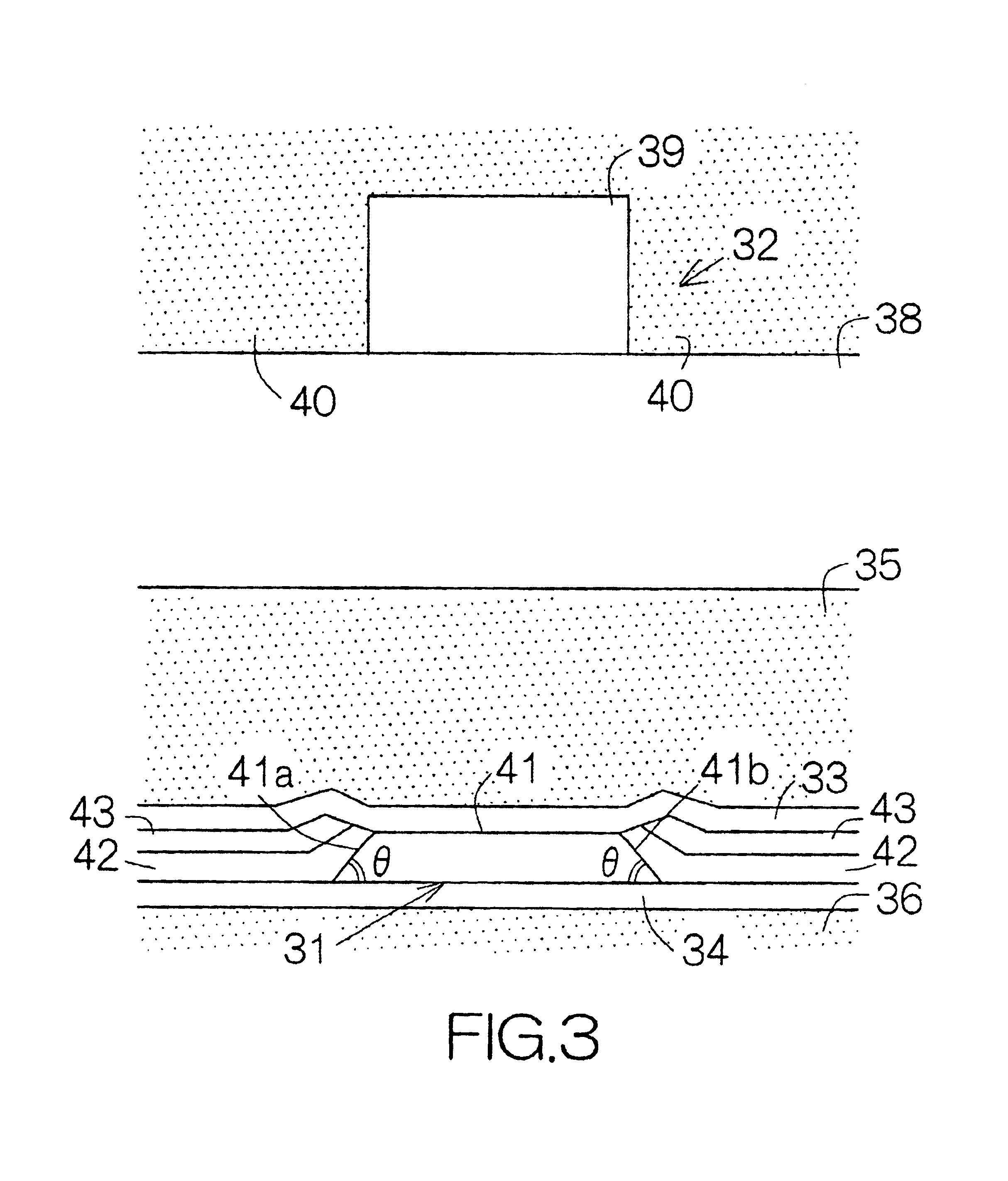

Magnetoresistive transducer having stronger longitudinal bias field

InactiveUS6876524B2Suppress DiffuseHigh strengthNanomagnetismMagnetic-field-controlled resistorsControl layerBias field

A magnetoresistive transducer includes a magnetoresistive (MR) film interposed between domain control layers along the surface of a lower non-magnetic gap layer. Lead layers are formed on the domain control layers. An upper non-magnetic gap layer and an upper shield layer are sequentially formed to extend over the MR film and the lead layers. The upper shield layer is opposed to the surfaces of the MR element and the lead layers at a flat boundary or interface. The residual magnetization is supposed to exist in the upper shield layer in the direction of the magnetization established in the domain control layers after the upper shield layer has been subjected to the applied magnetic field for the magnetization of the domain control layers. The residual magnetization can be kept continuous along the flat interface of the upper shield layer. Any magnetic poles are hardly generated along the interface of the upper shield layer. The longitudinal bias field can be prevented from receiving the interaction of the residual magnetization in the upper shield layer. Reduction in the longitudinal bias field can thus be suppressed.

Owner:FUJITSU LTD

Cutting method for glass sheet and glass sheet cutting apparatus

ActiveUS9422184B2Safe separationStrict managementGlass furnace apparatusGlass transportation apparatusGlass sheetLaser beams

Provided is a cutting method for a glass sheet, comprising radiating a laser beam to a cutting portion (C) of a glass sheet (G) having a thickness of 500 μm or less to fuse the glass sheet (G), wherein a narrowest gap between fused end surfaces (Ga1 and Gb1) of the glass sheet (G), which face each other in the cutting portion (C), is managed to satisfy a relationship of 0.1≦b / a≦2, where “a” is a thickness of the glass sheet (G) and “b” is the narrowest gap.

Owner:NIPPON ELECTRIC GLASS CO LTD

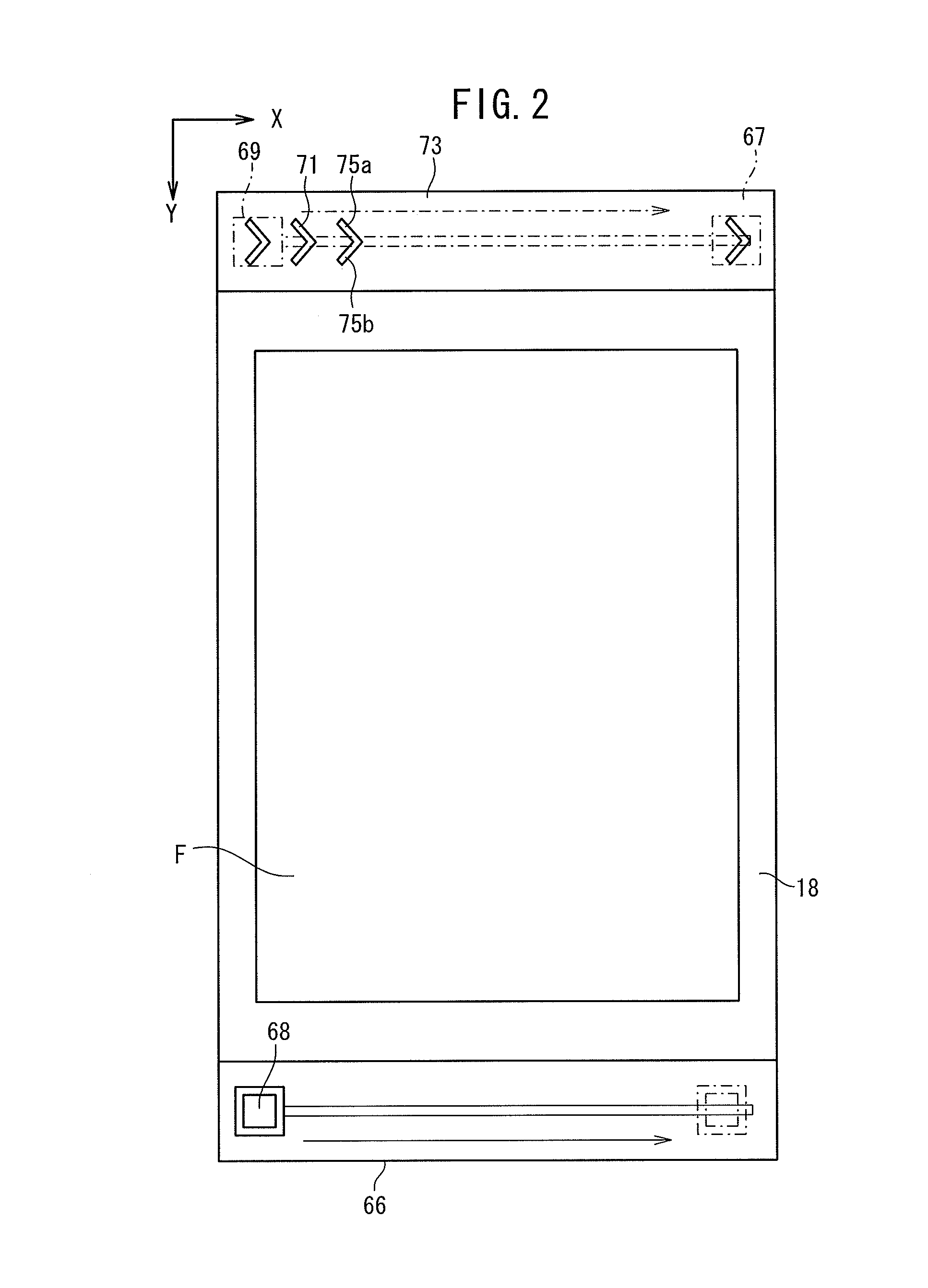

Plotting state adjusting method and device

InactiveUS20100231985A1Reliably reducedImprove visibilityRecording apparatusPhotomechanical apparatusOptical powerMirror image

It is possible to set an optical magnification capable of making a recording position shift amount with respect to Y direction of the plotting point formed by a micro mirror within an allowance range from the relationship between a Y-direction distance between mirror images obtained by projecting micro mirrors constituting a DMD onto a substrate, an inclination angle of the DMD, an image pattern recording pitch, and an optical magnification.

Owner:FUJIFILM CORP

Permanent magnet and manufacturing method thereof

InactiveUS8500921B2Improve magnetic propertiesLow densityTransportation and packagingMetal-working apparatusNeodymium magnetHydrogen atmosphere

Owner:NITTO DENKO CORP

Permanent magnet and manufacturing method thereof

InactiveUS20120182108A1Improve magnetic propertiesResidual magnetic flux density decreaseTransportation and packagingMetal-working apparatusNeodymium magnetCelsius Degree

There are provided a permanent magnet and a manufacturing method thereof capable of densely sintering the entirety of the magnet without making a gap between a main phase and a grain boundary phase in the sintered magnet. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, desiccated magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius. Thereafter, the powdery calcined body calcined through the calcination process in hydrogen is held for several hours in vacuum atmosphere at 200 through 600 degrees Celsius for a dehydrogenation process.

Owner:NITTO DENKO CORP

Illuminator, image display apparatus, and polarization conversion/diffusion member

An illuminator that illuminates a projected surface includes a laser light source that emits laser light; a polarization converter disposed downstream of the laser light source, the polarization converter having a first area that converts the polarization direction of incident laser light into a first polarization direction and outputs the resultant laser light and a second area that converts the polarization direction of incident laser light into a second polarization direction and outputs the resultant laser light; and a light diffusion section disposed downstream of the laser light source, the light diffusion section diffusing incident laser light.

Owner:COLUMBIA PEAK VENTURES LLC

Air gun and magazine for air gun

InactiveUS8127755B2Reliably reducedShorten production timeAmmunition loadingCompressed gas gunsManufacturing cost reductionEngineering

According to the present invention, by providing an extremely simple member such as a partition wall having a microscopic hole section, it is possible to reliably reduce the speed of a bullet to within a fixed speed, even a complicated decompression device such as a regulator is not provided. As a result, manufacturing time for the air gun is shortened, it is possible to lower manufacturing cost, and there is the effect of improving the manufacturing efficiency.This is because with an air gun or a magazine for an air gun of the present invention, by having a structure where the opening area of the microscopic hole section of the partition wall is smaller that the gas discharge path opening when the gas discharge path of the discharge valve is open, the gas volume per unit time that flows into the discharge valve chamber from the gas canister side by means of the microscopic holes section is smaller than the gas volume per unit time that flow out from the discharge valve chamber as a result of opening the gas discharge path of the discharge valve, which means that gas speed and gas pressure from the discharge valve chamber to the chamber where a bullet is positioned is lowered. The firing speed of a bullet is thus reduced.

Owner:MARUZEN

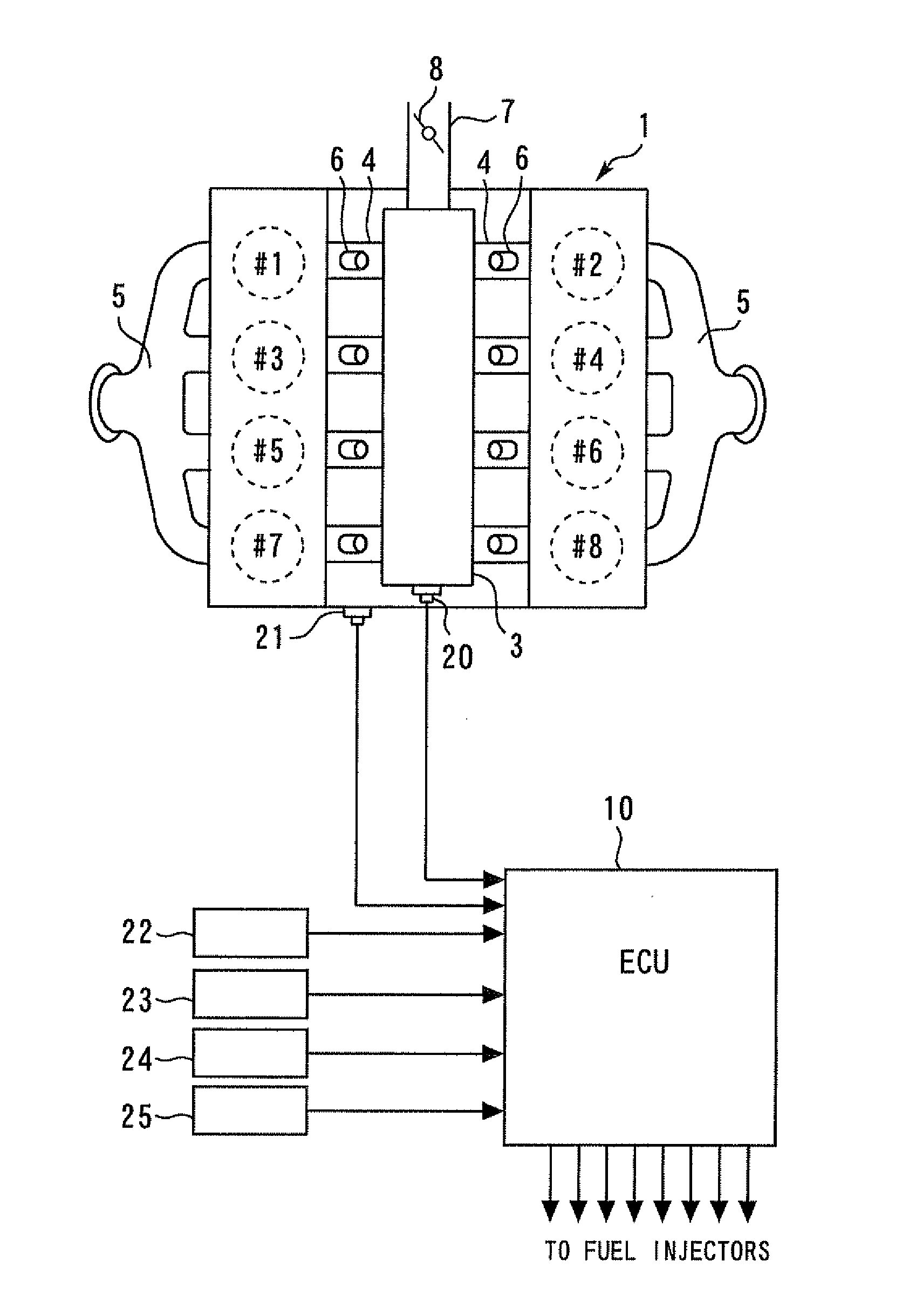

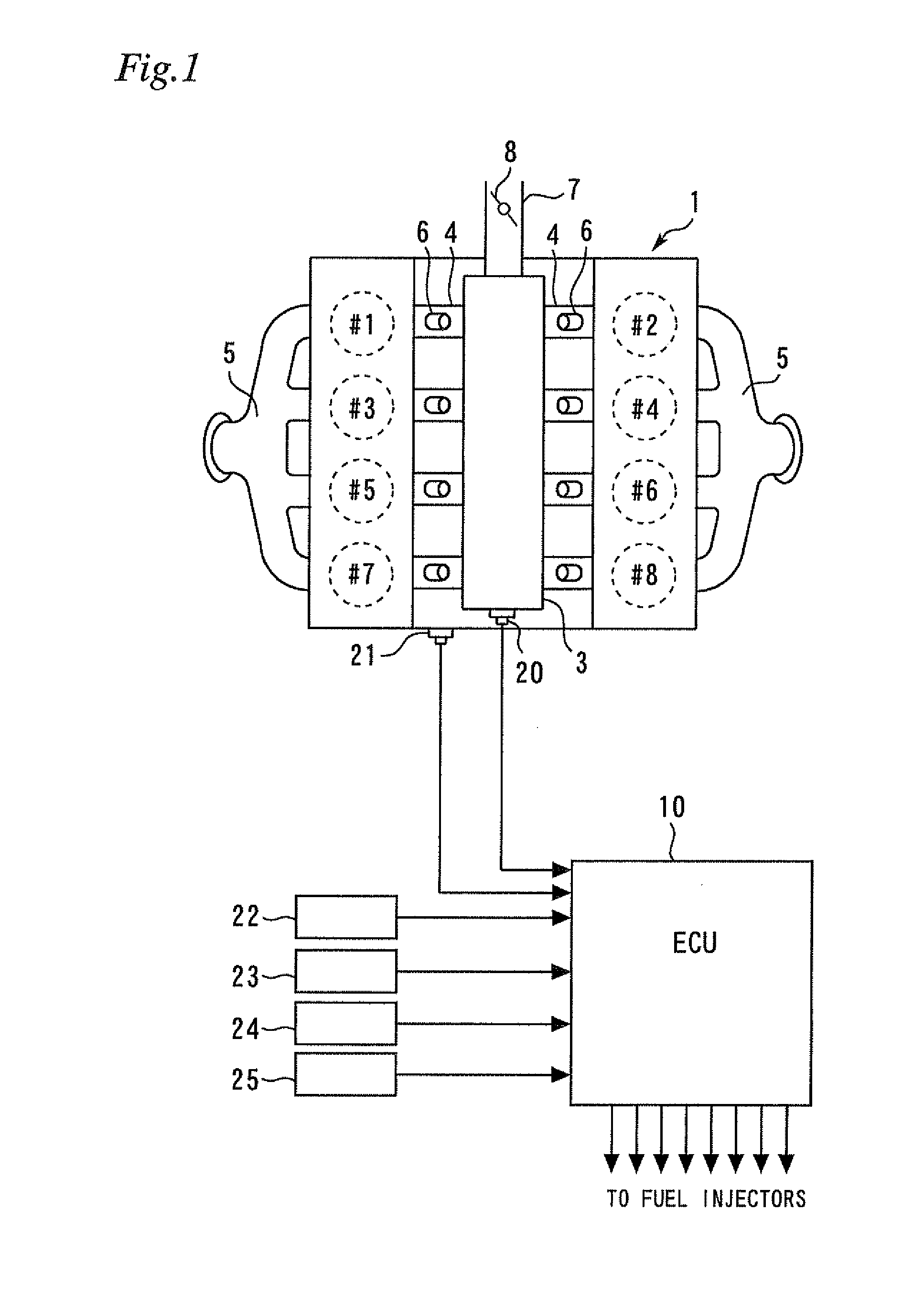

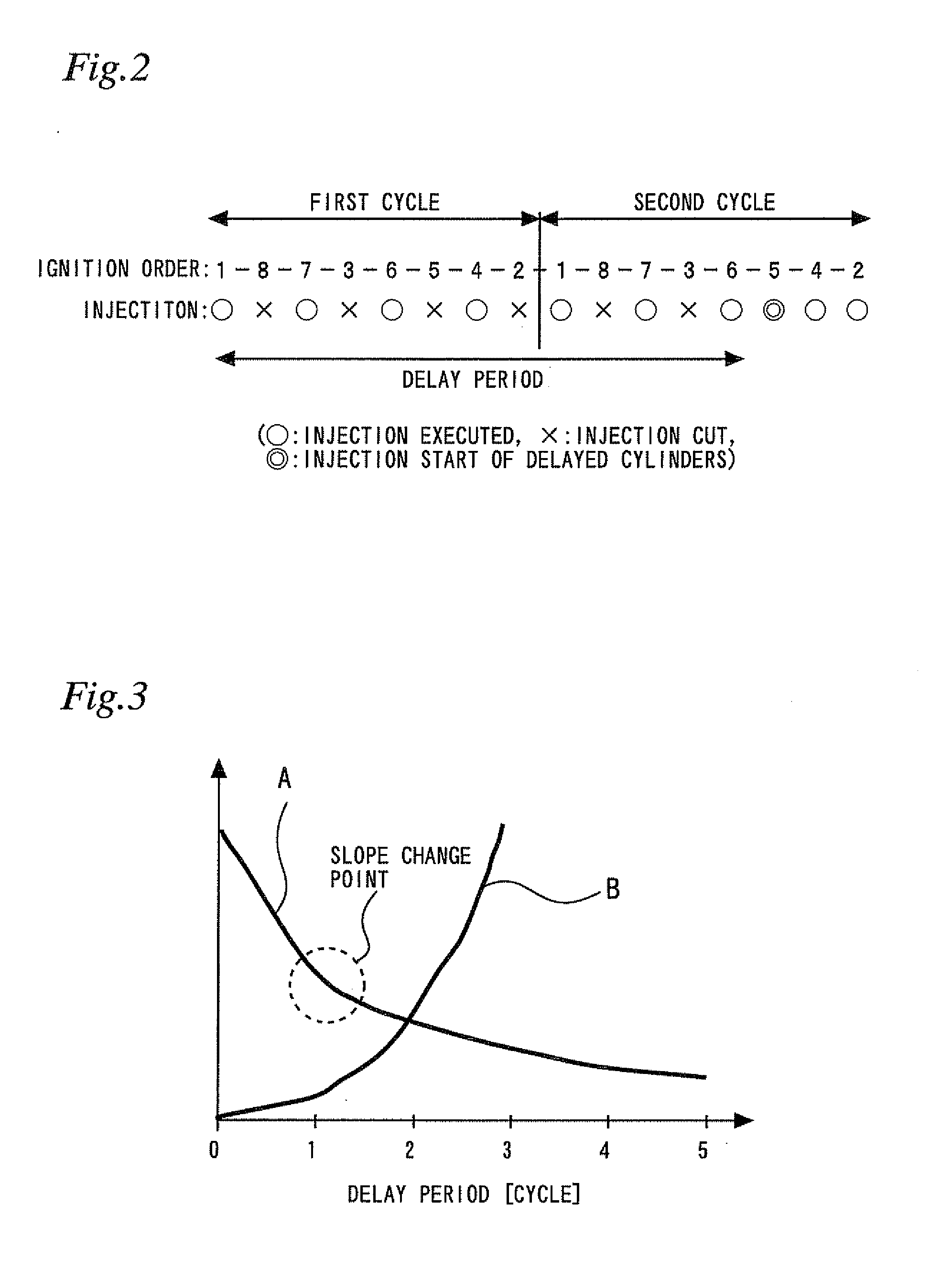

Control apparatus for internal combustion engine

ActiveUS20130255630A1Reliably reducedReduce the amount requiredElectrical controlLow pressure fuel injectionExternal combustion engineControlled combustion engine

Owner:TOYOTA JIDOSHA KK

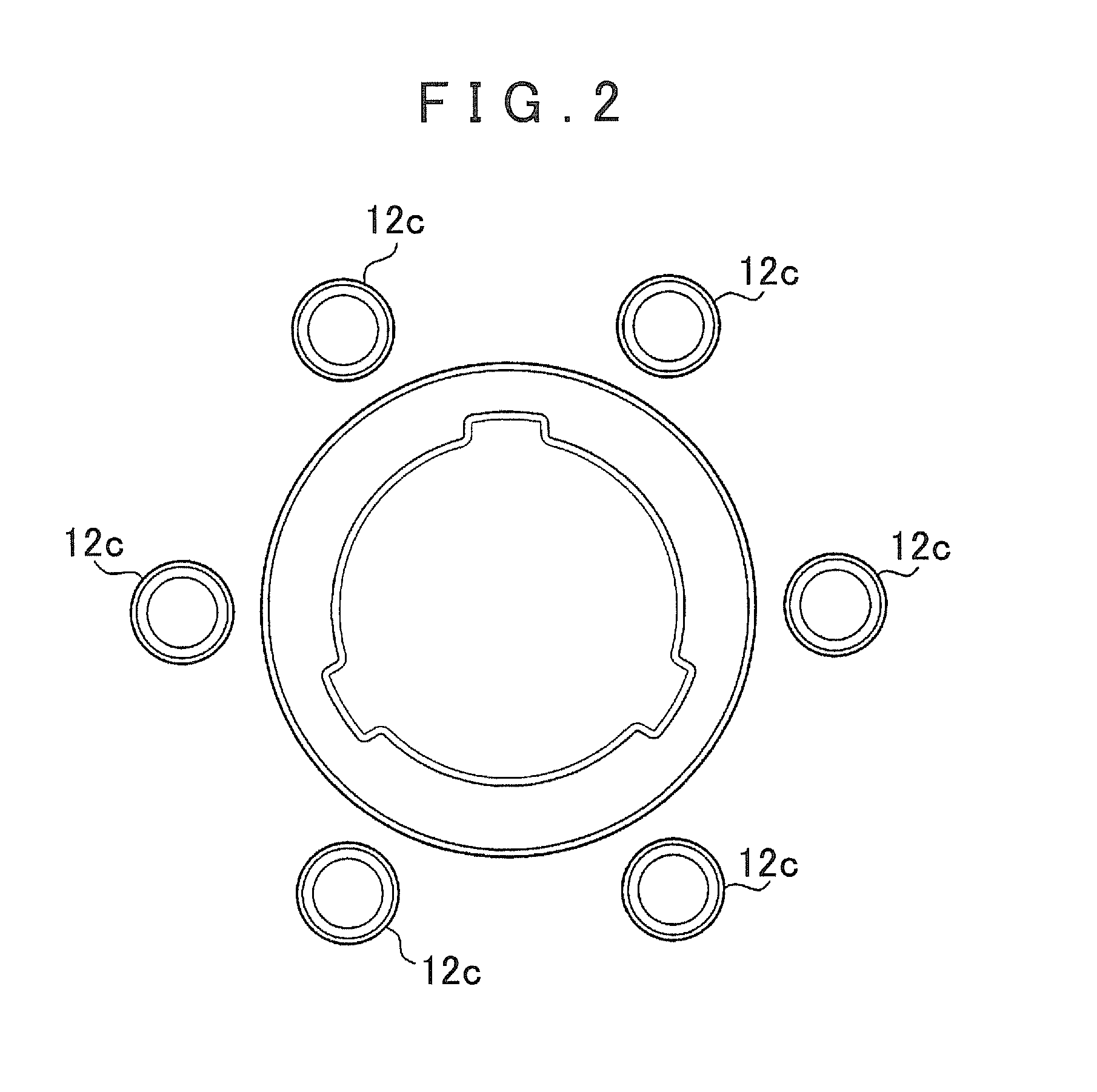

Planetary gear unit

ActiveUS20130072345A1Improve machining accuracyReduce gear noiseGearboxesGearing detailsFlangePlanet

A planetary gear unit inside a case includes coaxial sun and ring gears, a planetary pinion gear that meshes with the sun and ring gears, and a carrier that holds the planetary pinion gear, the ring gear being fixed with respect to the case, and a flange disposed inward of the ring gear. The ring gear is fixed to a case wall, via the flange, the wall extending radially inward, and the flange being prevented from rotating with respect to the wall by a rotation prevention mechanism. The rotation prevention mechanism includes a plurality of case holes on the same circle in the wall, flange holes in the flange at positions corresponding to the case holes, and rotation prevention members fitted into the case and flange holes to prevent rotation of the flange with respect to the wall with the flange relatively movable axially with respect to the wall.

Owner:AISIN AW CO LTD +1

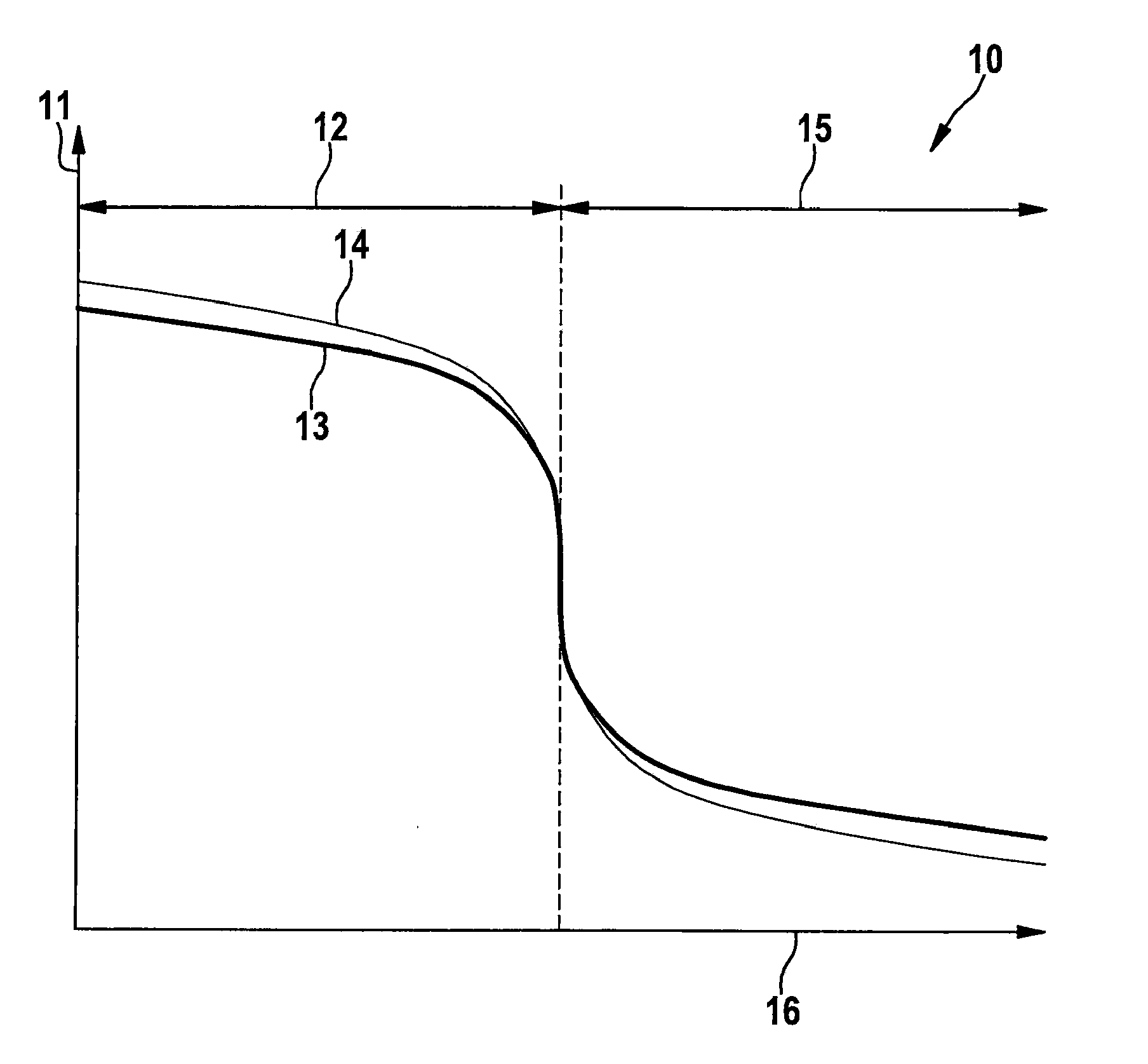

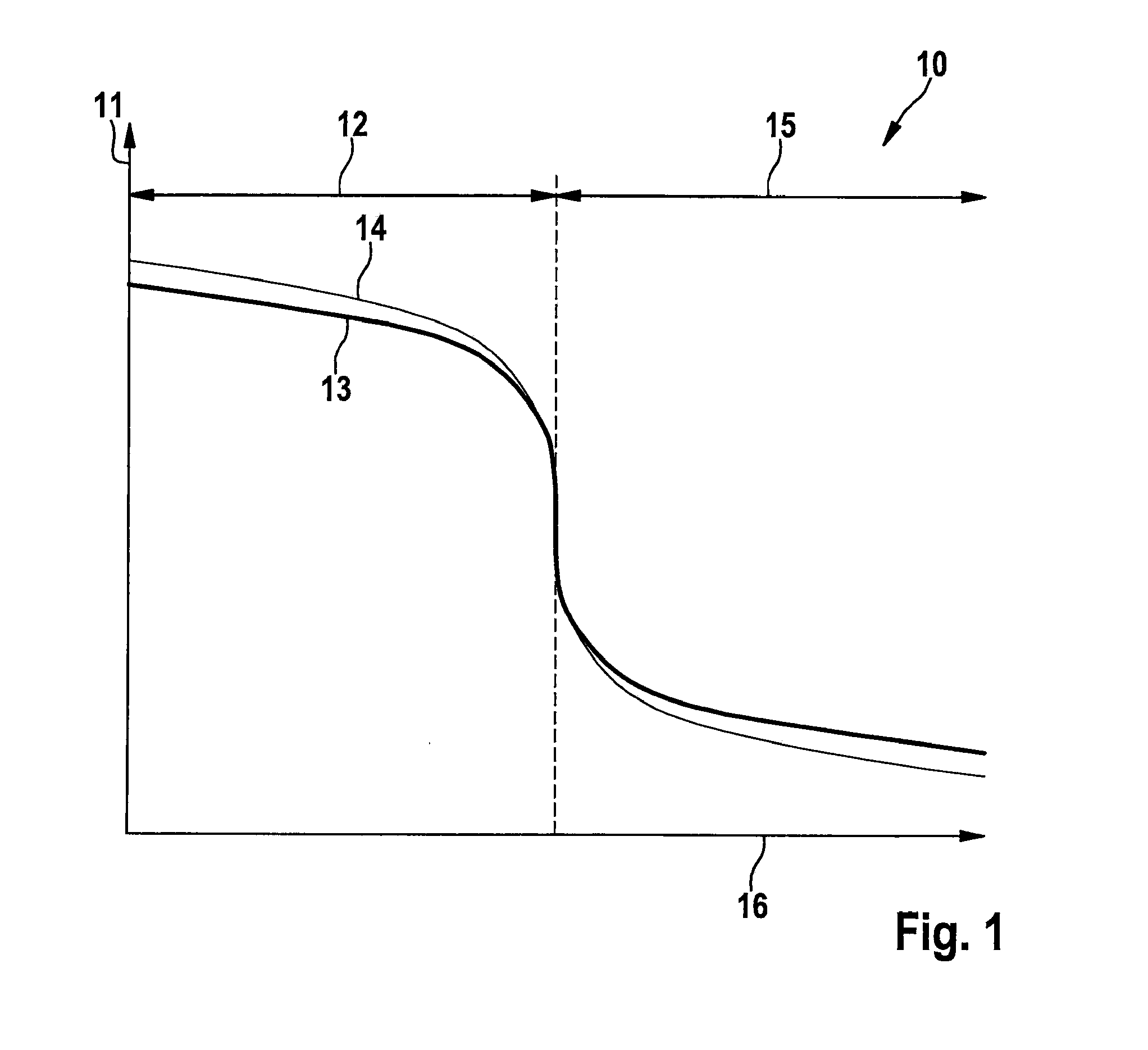

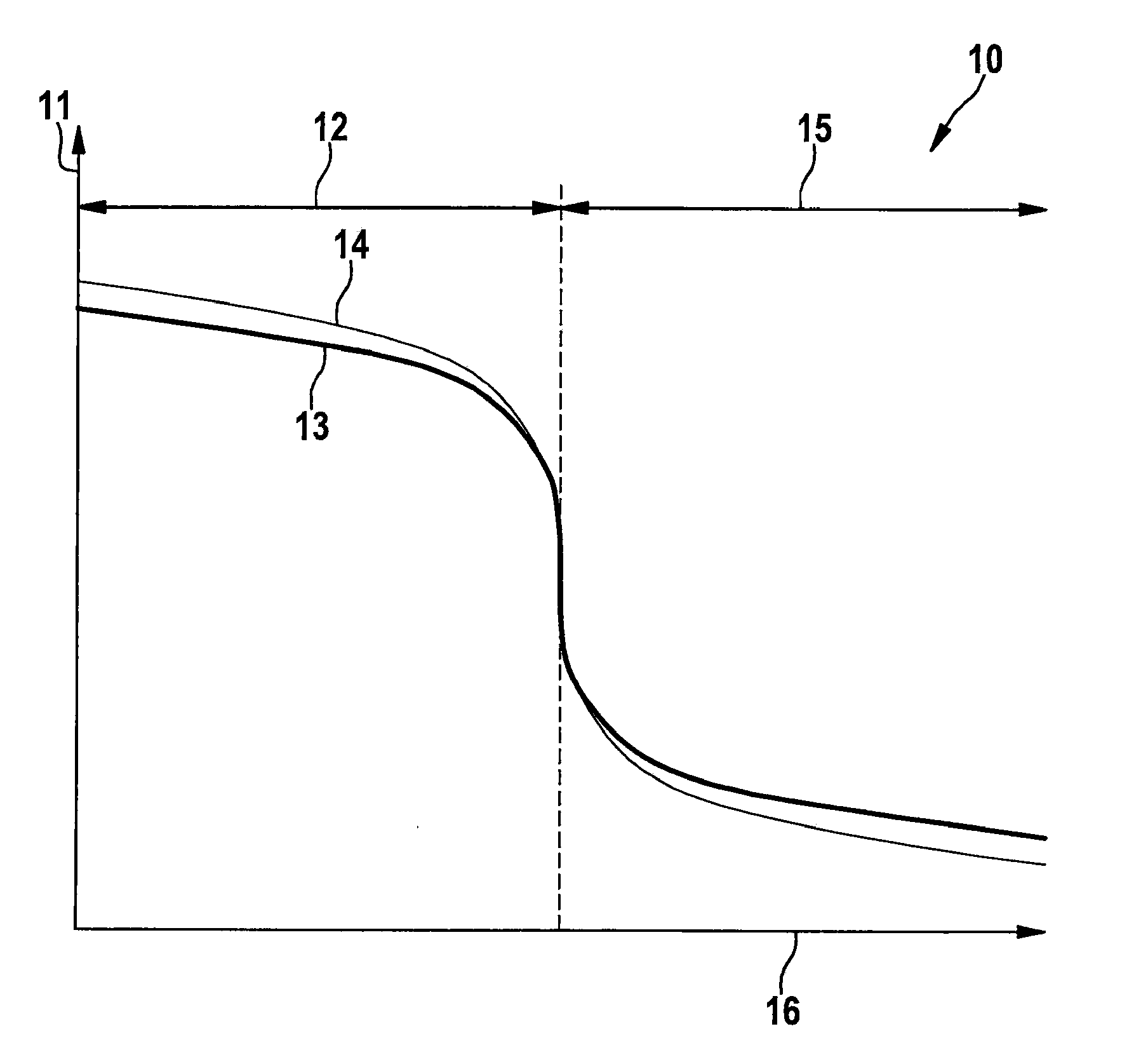

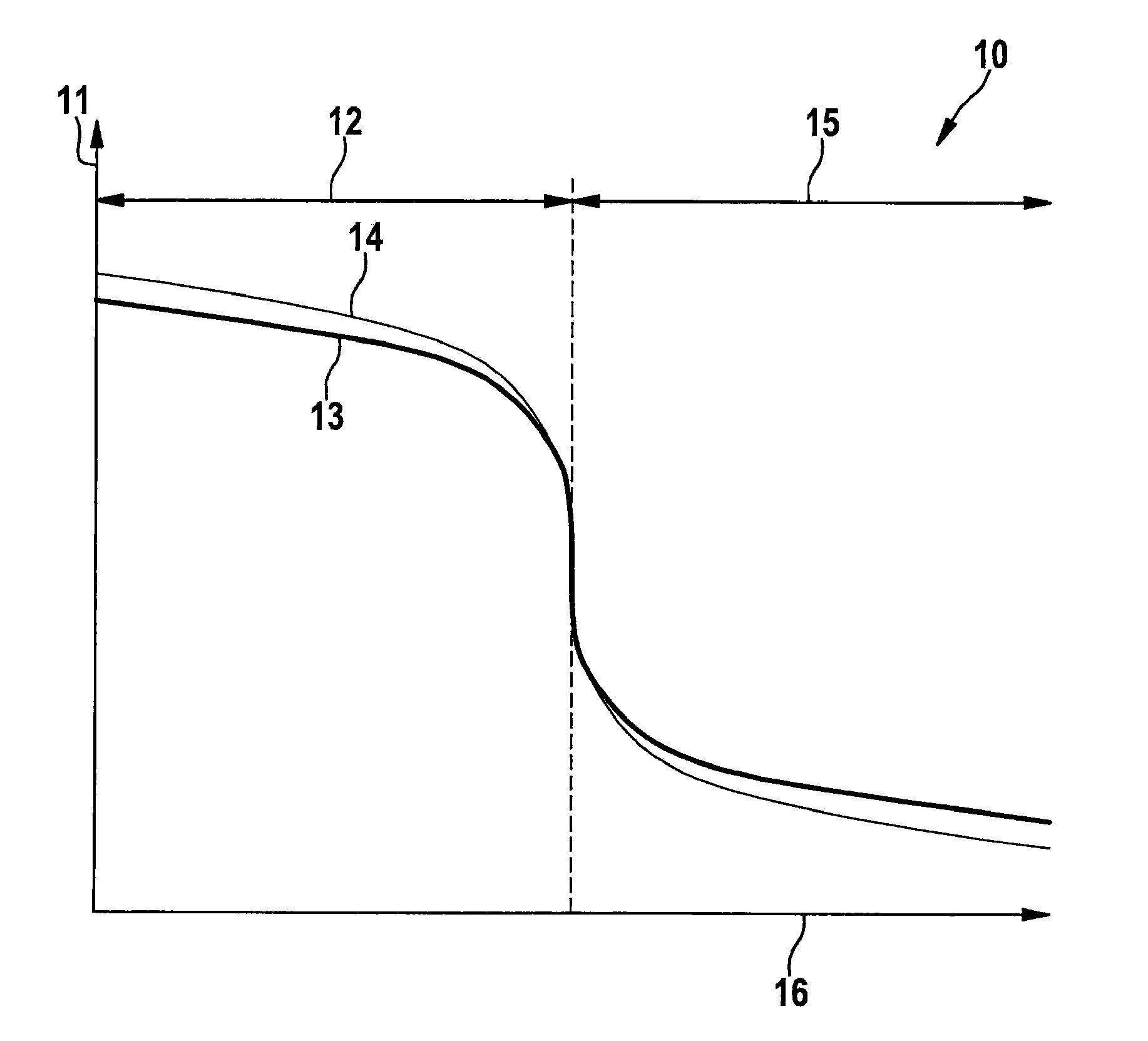

Method and device for correcting a characteristic curve of a two-step lambda oxygen sensor

ActiveUS20140007644A1Reduce voltage offsetReliably reducedElectrical controlExhaust apparatusOxygen sensorVoltage reference

A method and device for correcting a voltage-lambda characteristic curve of a two-step lambda oxygen sensor in an exhaust tract relative to a reference-voltage lambda characteristic curve of the oxygen sensor; a deviation in the characteristic curve relative to the reference characteristic curve at lambda=1 being corrected; based on a value pair on the reference-voltage lambda characteristic curve, the composition of the air-fuel mixture supplied to the engine being changed toward lambda=1; the actual value of lambda being inferred from the change in the composition of the air-fuel mixture. The adaptation of the operating parameters of the oxygen sensor is intended to eliminate the cause of a deviation. Efforts are not merely directed to adapting the deviation to the reference characteristic curve by shifting the voltage-lambda characteristic curve. Effects, which may lead to tolerance- or aging-induced falsifications of the voltage-lambda characteristic curve, can be fully compensated.

Owner:ROBERT BOSCH GMBH

Substrate having color elements, film formation method, electro optical device, and electronic equipment

InactiveUS20060159895A1Reduce color mixingQuality improvementDischarge tube luminescnet screensDecorative surface effectsEngineeringElectron

A substrate having color elements includes a base member; a bank formed over the base member, the bank defining a plurality of color element areas; and color element films formed of liquid materials of a plurality of colors deposited in the color element areas. The bank has a different-color separation bank portion positioned between color element films of different colors, and a same-color separation bank portion positioned between color element films of the same color. A height of the different-color separation bank portion is greater than a height of the same-color separation bank portion.

Owner:SEIKO EPSON CORP

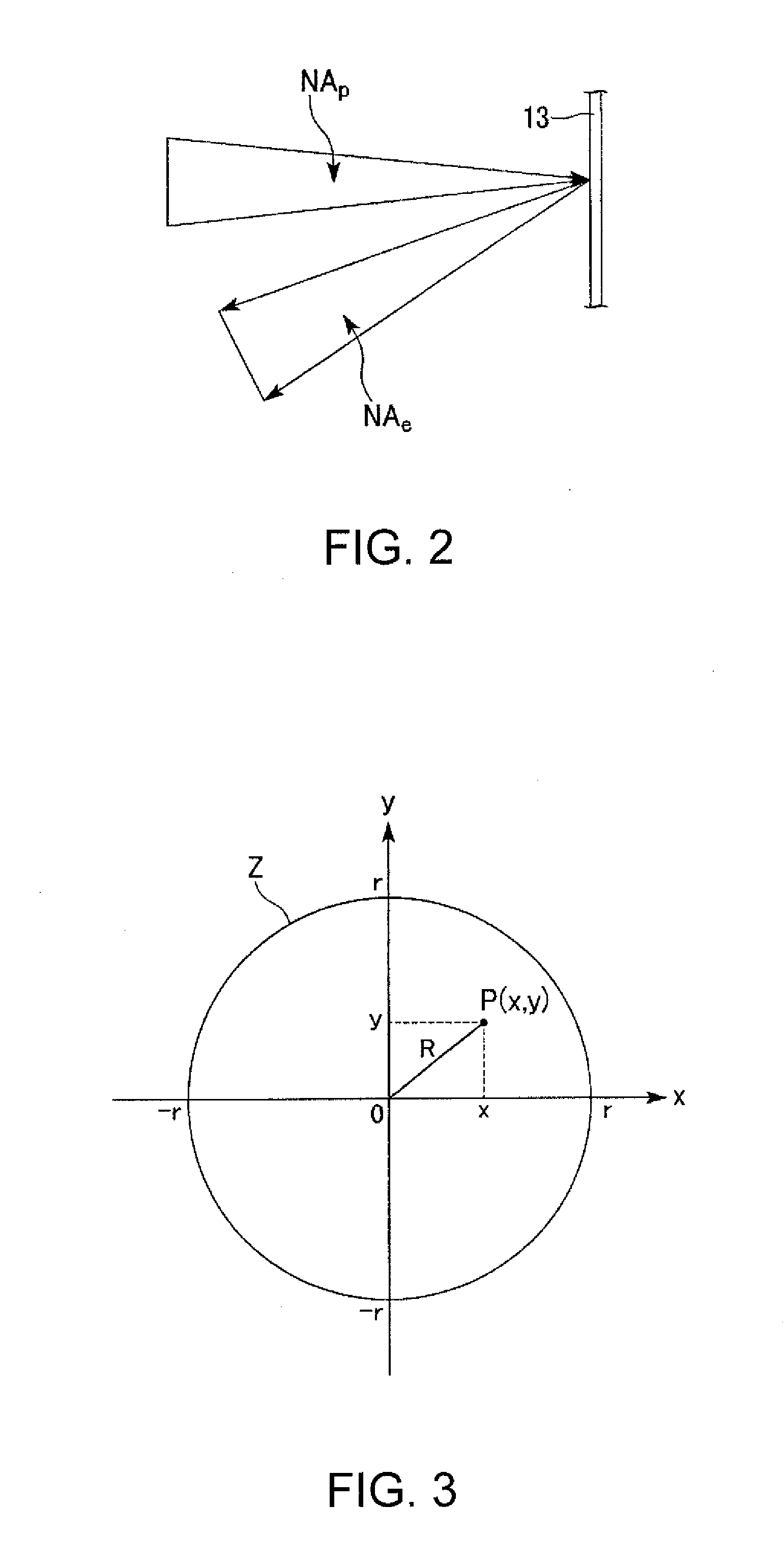

Projector

ActiveUS20160223887A1Reduce speckle noiseReliably reducedProjectorsColor television detailsIlluminanceExit pupil

A projector capable of reliably reducing speckle noise includes a light modulation element which modulates laser light, and a projection optical system on which light emitted from the light modulation element is incident. When the center coordinates of an illumination distribution of laser light in an exit pupil of the projection optical system are x=0 and y=0, normalized illumination at each coordinate is P(x,y), and a calculation range of integration is r (mm), the value of EP determined from a specific numerical expression is set in a range according to the color of laser light.

Owner:SEIKO EPSON CORP

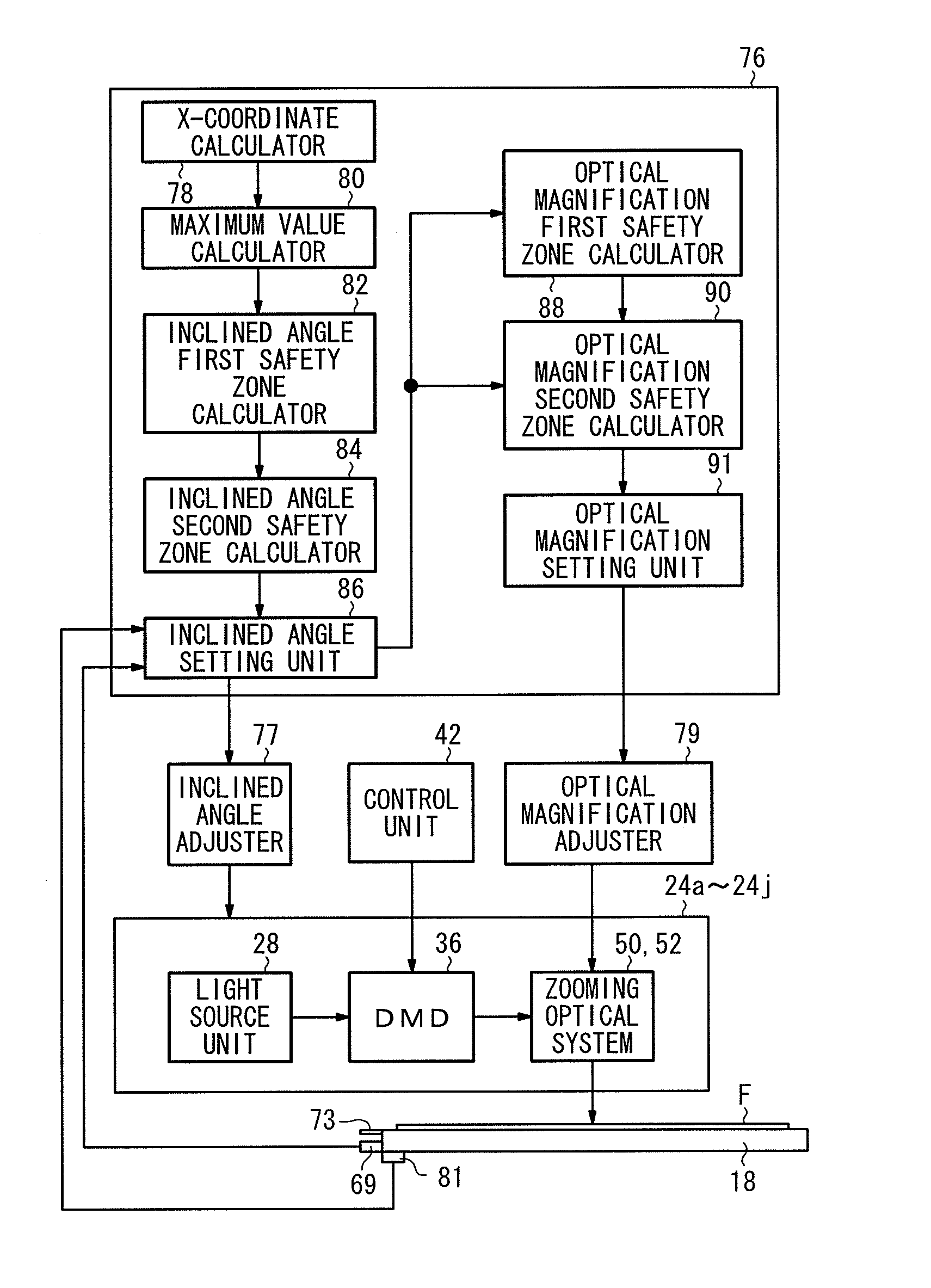

Plotting state adjusting method and device

InactiveUS20100259736A1Reliably reducedRecording apparatusPhotomechanical apparatusClassical mechanicsMirror image

An X-coordinate of a mirror image in the plotting surface of micro mirrors constituting a DMD is calculated. A first safe region of an inclination angle of the DMD where the maximum value of the X-coordinate is not greater than a predetermined threshold value is calculated. Next, simulation is performed in the first safe region and a second safe region of the inclination angle is calculated. In the second safe region, a desired inclination angle is set and adjustment is performed.

Owner:FUJIFILM CORP

Method and device for correcting a characteristic curve of a two-step lambda oxygen sensor

ActiveUS9354213B2Reduce voltage offsetReliably reducedInternal-combustion engine testingElectrical controlOxygen sensorVoltage reference

A method and device for correcting a voltage-lambda characteristic curve of a two-step lambda oxygen sensor in an exhaust tract relative to a reference-voltage lambda characteristic curve of the oxygen sensor; a deviation in the characteristic curve relative to the reference characteristic curve at lambda=1 being corrected; based on a value pair on the reference-voltage lambda characteristic curve, the composition of the air-fuel mixture supplied to the engine being changed toward lambda=1; the actual value of lambda being inferred from the change in the composition of the air-fuel mixture. The adaptation of the operating parameters of the oxygen sensor is intended to eliminate the cause of a deviation. Efforts are not merely directed to adapting the deviation to the reference characteristic curve by shifting the voltage-lambda characteristic curve. Effects, which may lead to tolerance- or aging-induced falsifications of the voltage-lambda characteristic curve, can be fully compensated.

Owner:ROBERT BOSCH GMBH

Impact load reduction structure

ActiveUS20170088181A1Reliably reducedReduce shock loadElectric propulsion mountingVehicle sub-unit featuresAutomotive engineeringEngineering

An impact load reduction structure includes a battery frame and a load reduction frame. The battery frame is fixed to a vehicle body frame of an electrically-powered vehicle and supports a battery. The load reduction frame is disposed so as to extend in a front-rear direction on a front side of the battery frame. A rear section of the load reduction frame is disposed facing a front section of the battery frame with a predetermined gap therebetween such that the load reduction frame comes into contact with the battery frame when the electrically-powered vehicle is involved in a collision.

Owner:SUBARU CORP

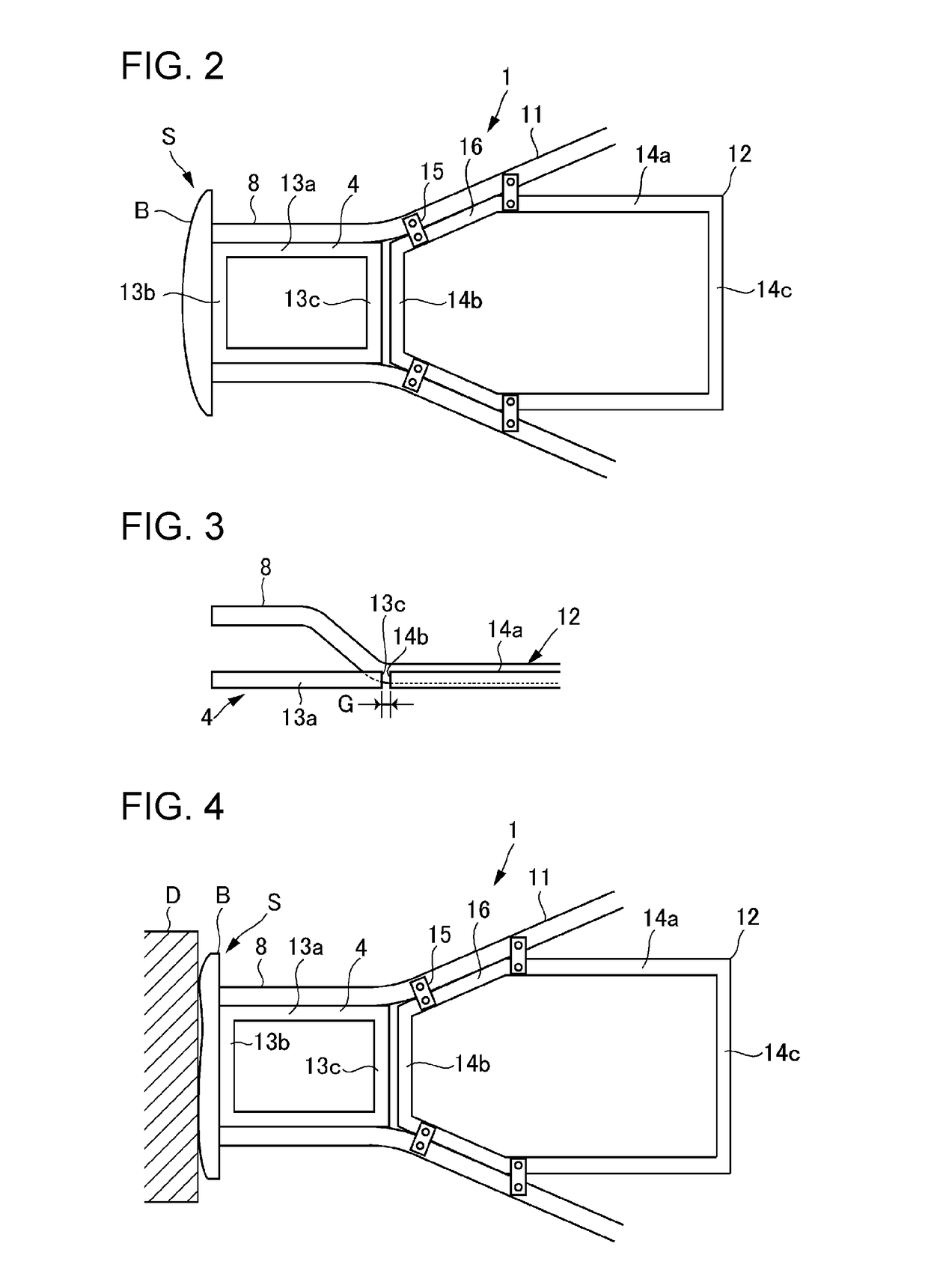

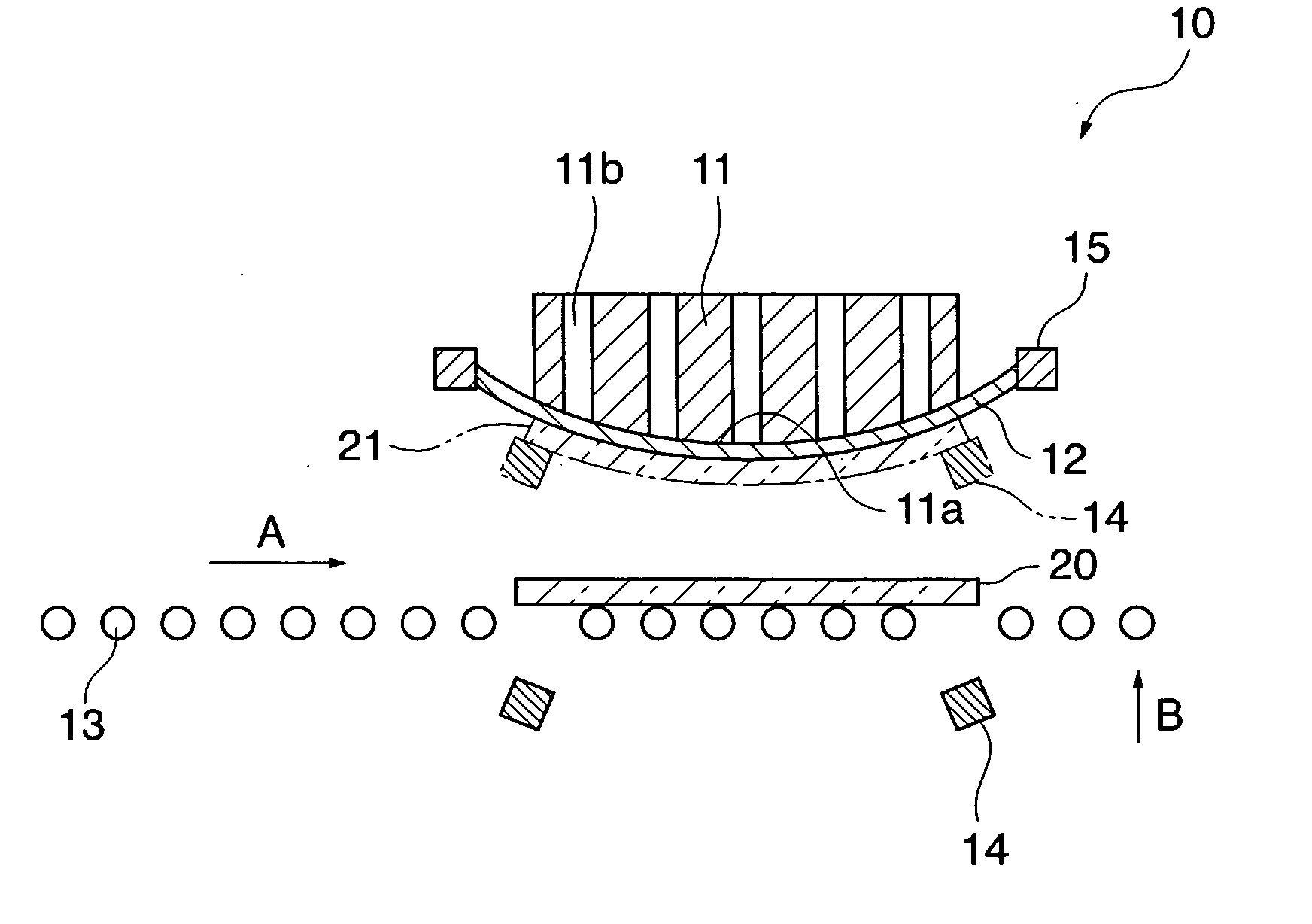

Bent glass sheet shaping method and bent glass sheet

A bent glass sheet shaping method which is capable of reducing occurrence of visibility distortions and a bent glass sheet with reduced visibility distortions. A glass sheet is heated to a shapeable temperature, a cover material is mounted onto a press die such that a direction of waves in the cover material is diagonal to a direction of distortions in the glass sheet, and the heated glass sheet with the press die is pressed.

Owner:NIPPON SHEET GLASS CO LTD

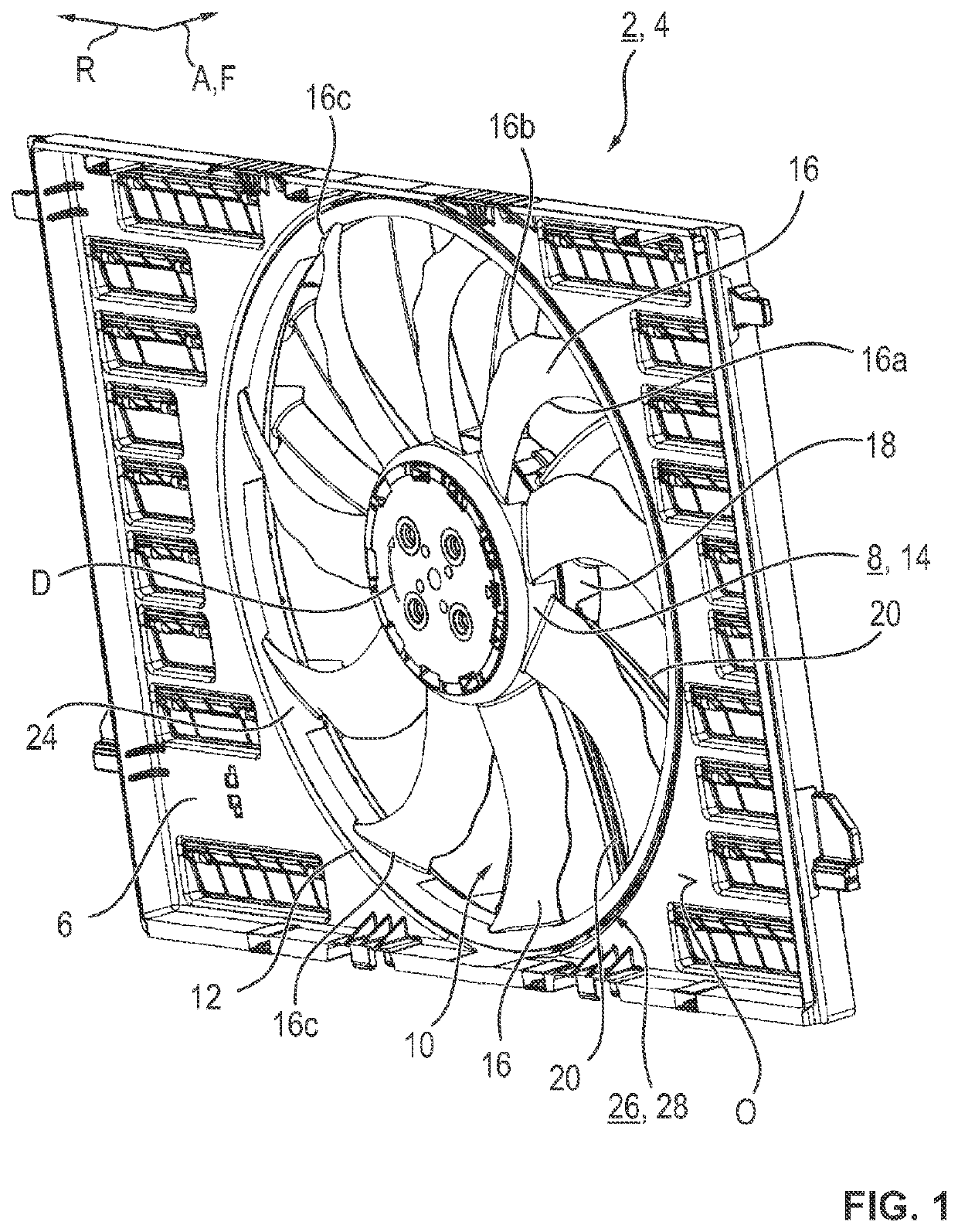

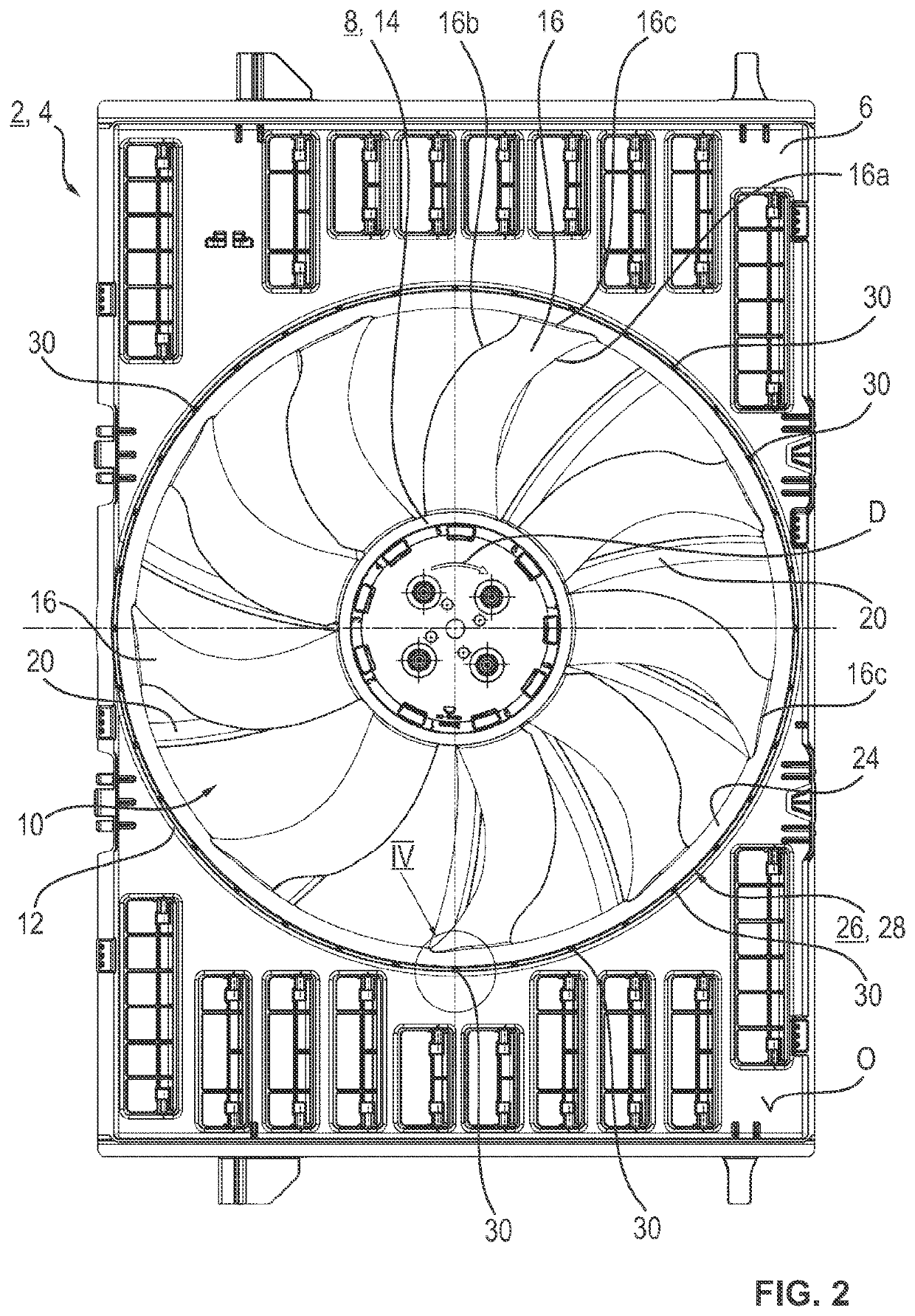

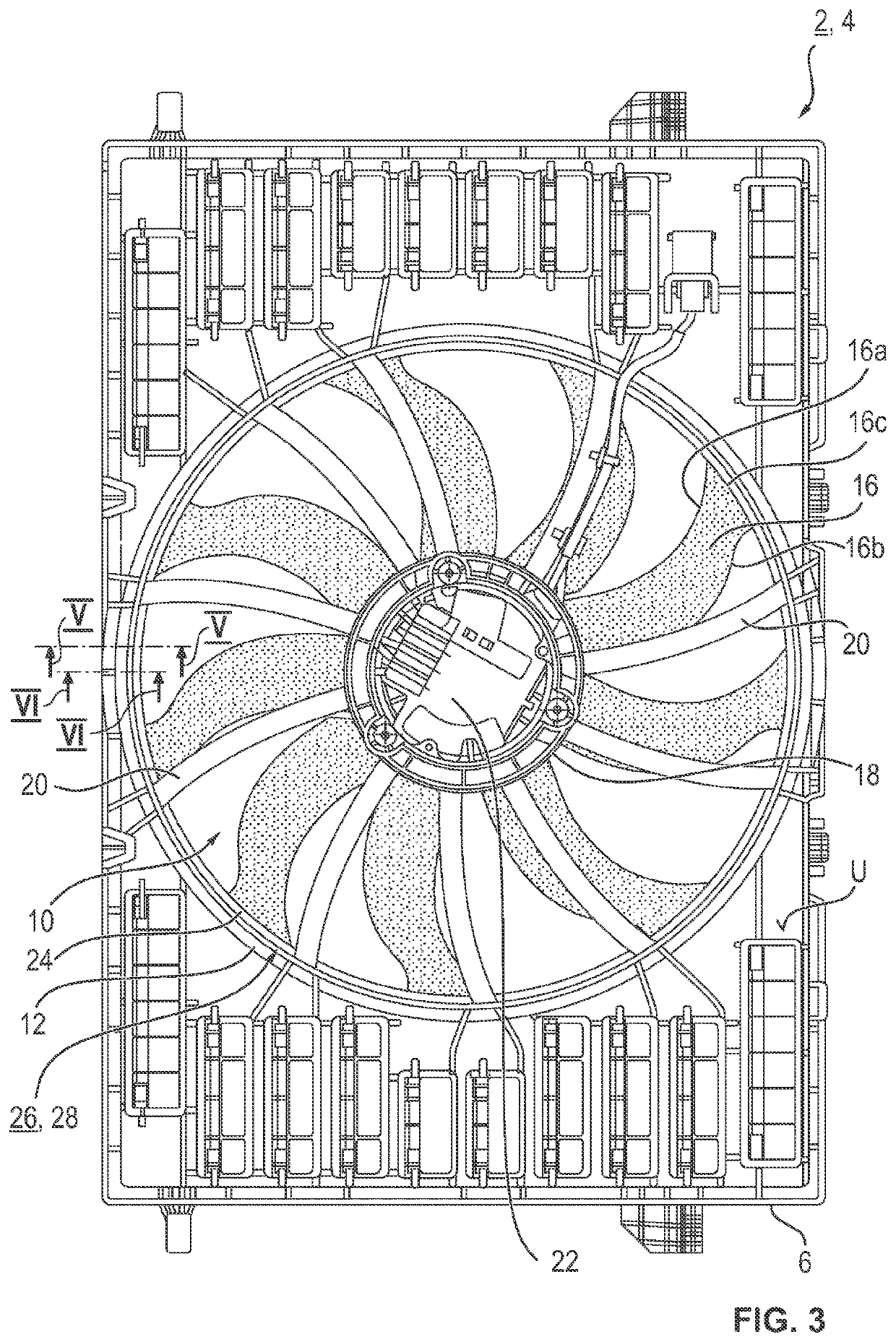

Cooling fan and cooling fan module

A cooling fan has a fan shroud with a fan wheel recess surrounded by a shroud ring and a fan wheel rotatably mounted in the fan wheel recess for conveying the air flow along a conveying direction from a shroud upper side to a shroud underside. The fan wheel has a central hub cup with radially orientated blades and an outer ring connecting the blades at the blade tip ends. A circumferential ring gap is formed between the outer ring and the shroud ring. A rib structure in the ring gap reduces swirl in a gap flow orientated against the conveying direction. A shroud ring section of the shroud ring extends axially beyond the outer ring on the shroud underside. The shroud ring section is orientated parallel or at an angle of inclination and radially inwards relative to the conveying direction.

Owner:BROSE FAHRZEUGTEILE SE & CO KGAA WUERZBURG

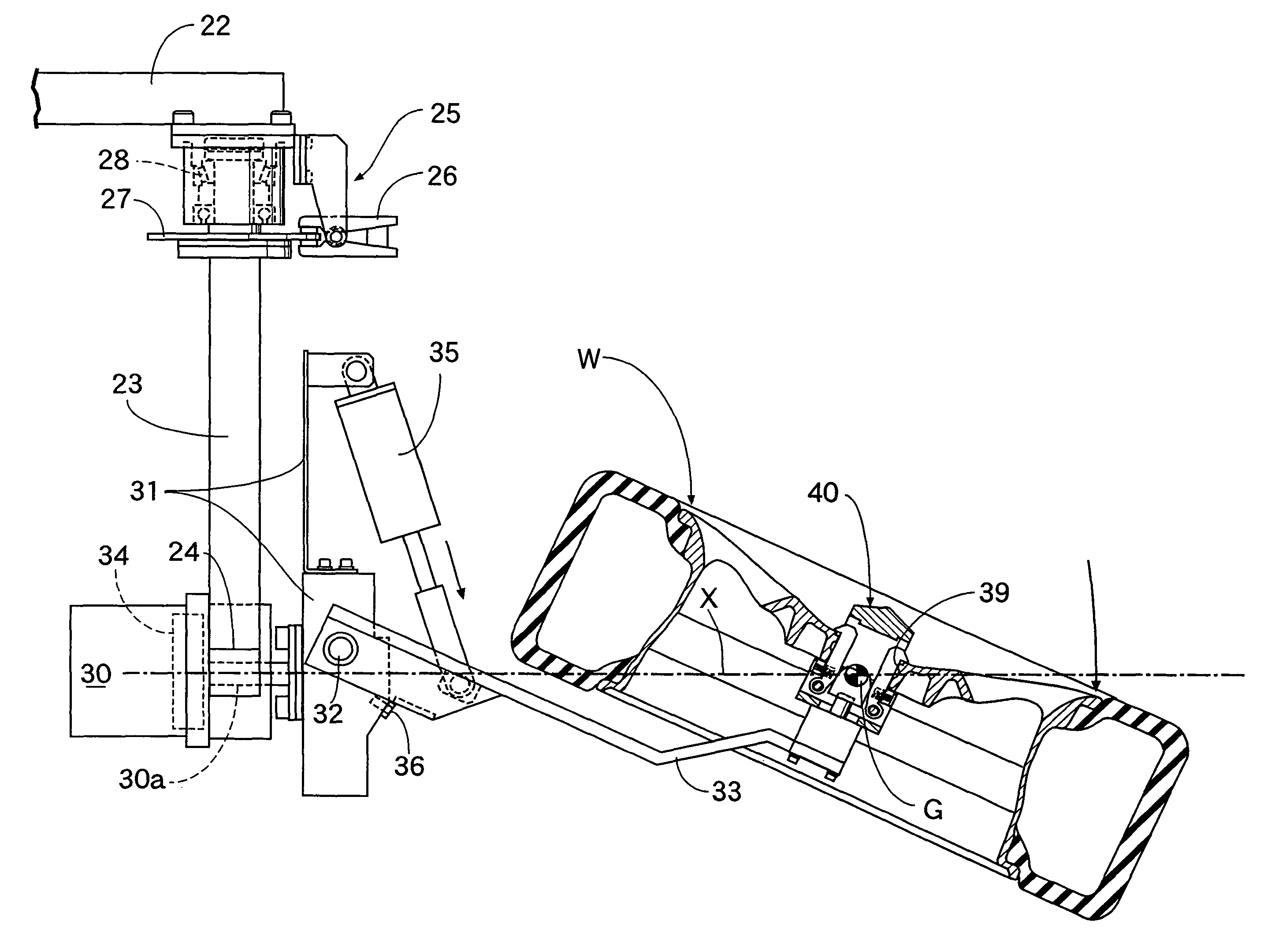

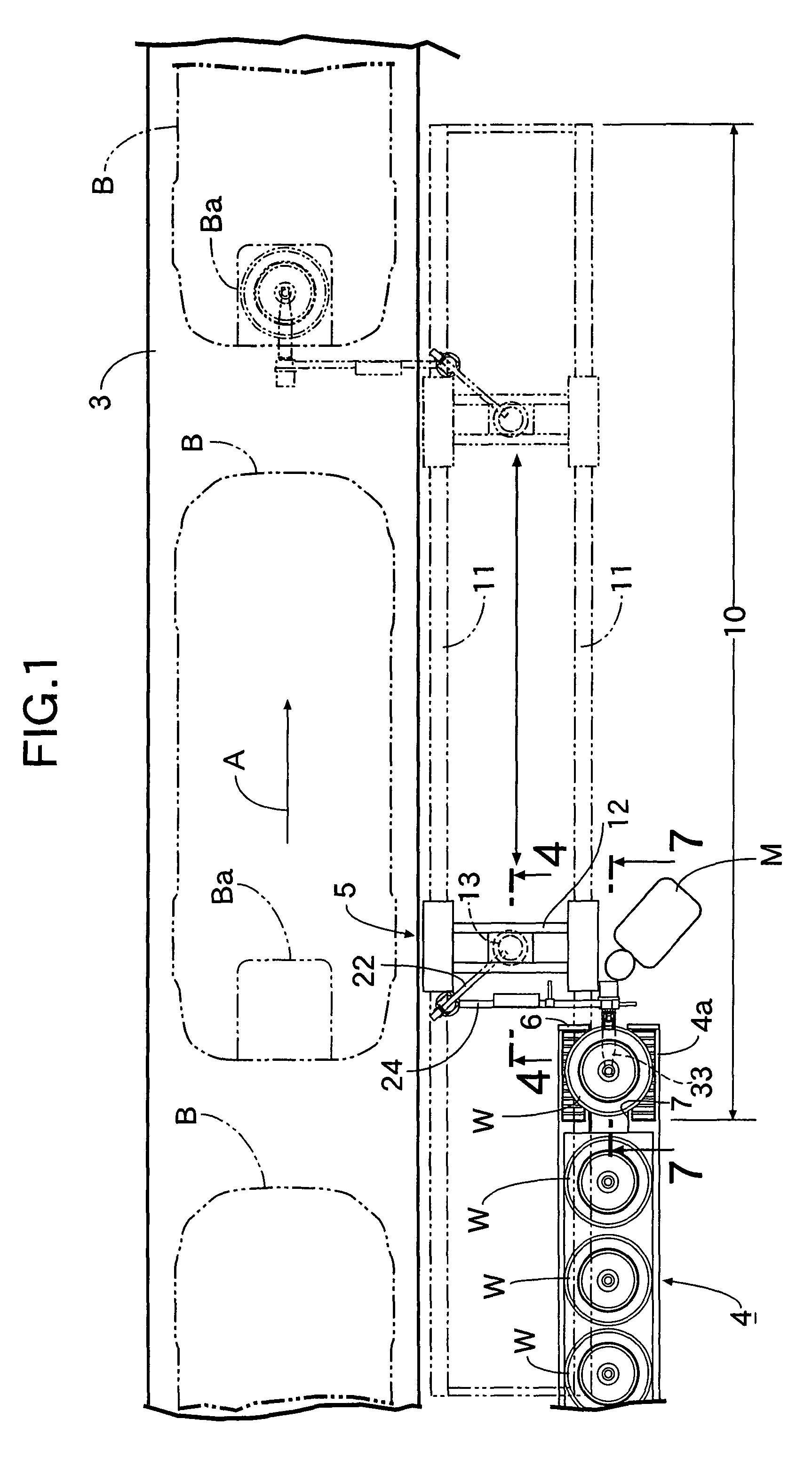

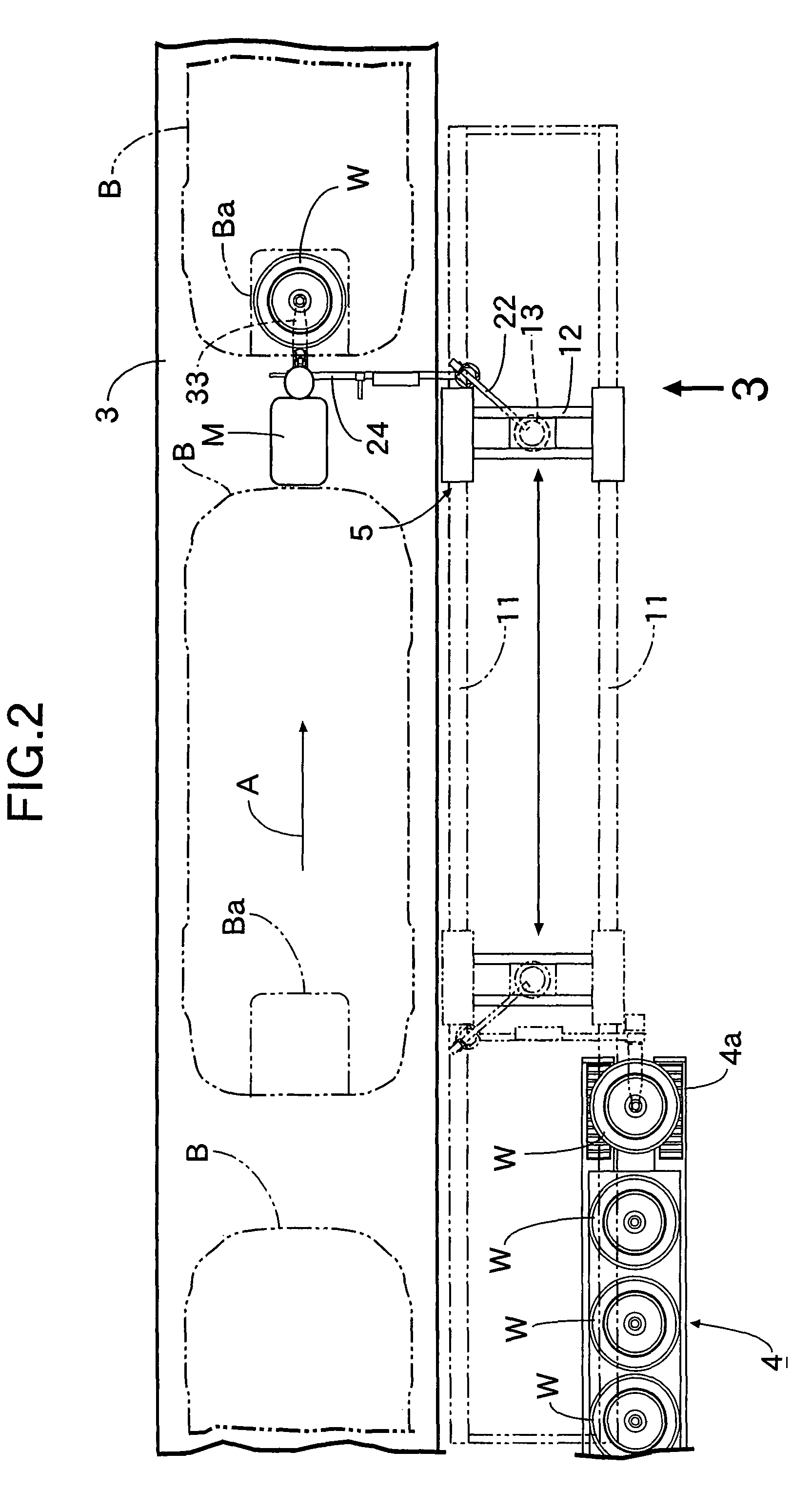

Workpiece transfer system and workpiece transfer method

InactiveUS7762757B2Reduce loadSolve the large outputProgramme-controlled manipulatorAmmunition loadingTransfer systemEngineering

A workpiece transfer system includes a bracket rotatably supported on a support part, a rotary drive mechanism provided on the support part in order to rotate the bracket, a workpiece support arm swingably and axially supported on the bracket, a swing drive mechanism provided on the bracket in order to swing the workpiece support arm, and a workpiece retainer provided on a tip end part of the workpiece support arm and retaining a workpiece that is to be transferred, the workpiece being inclined by operation of the swing drive mechanism when the rotary drive mechanism is operated so that a center of gravity of the workpiece comes on the vicinity of an axis of rotation of the rotary drive mechanism. This reduces the rotational load on the rotary drive mechanism, and since a small size and a reduction in weight can be achieved for the system, the workpiece transfer system and method enables a single worker to easily give a workpiece an inclination and inversion attitude change.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com