Patents

Literature

32results about How to "Reduce gear noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

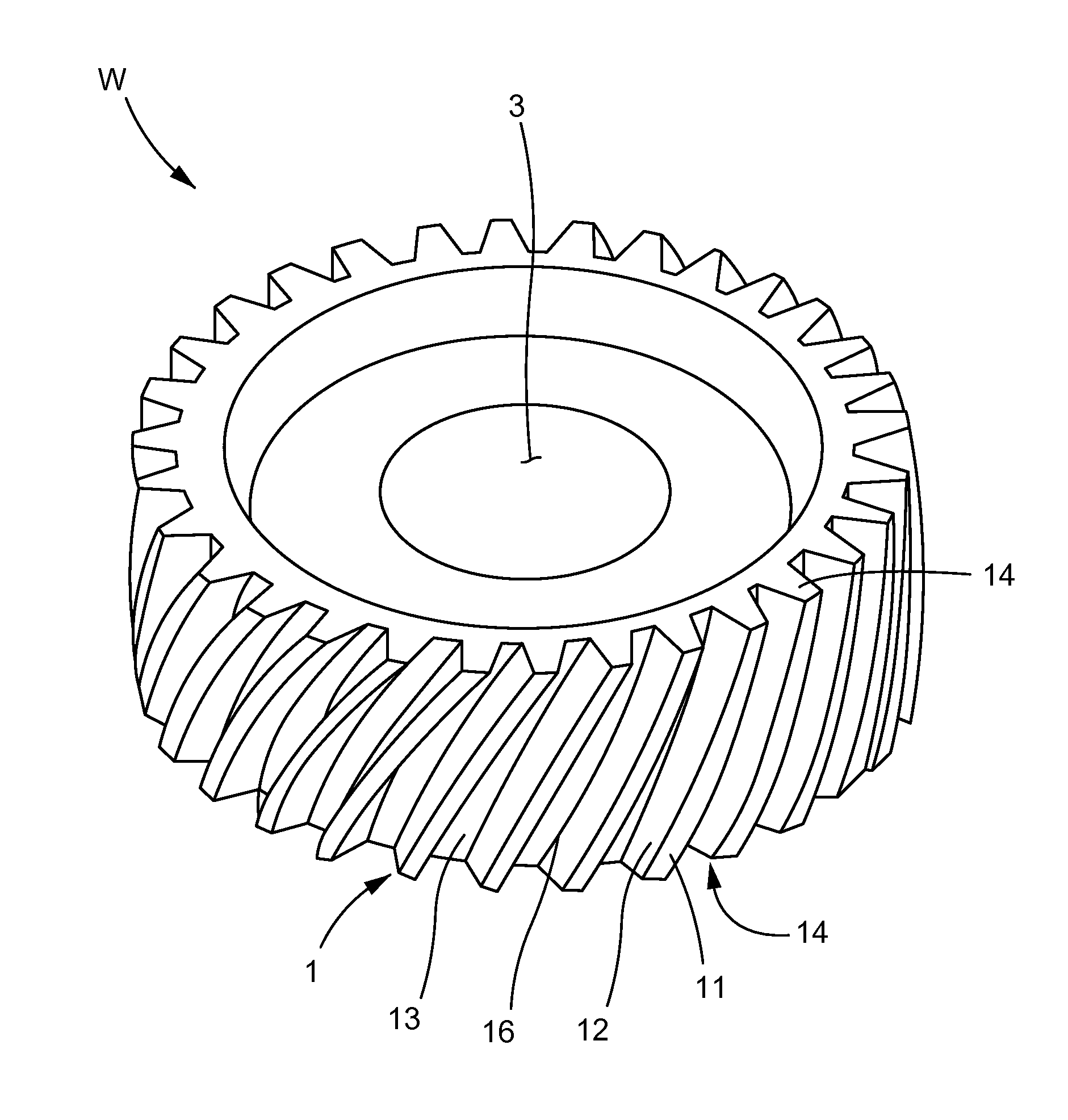

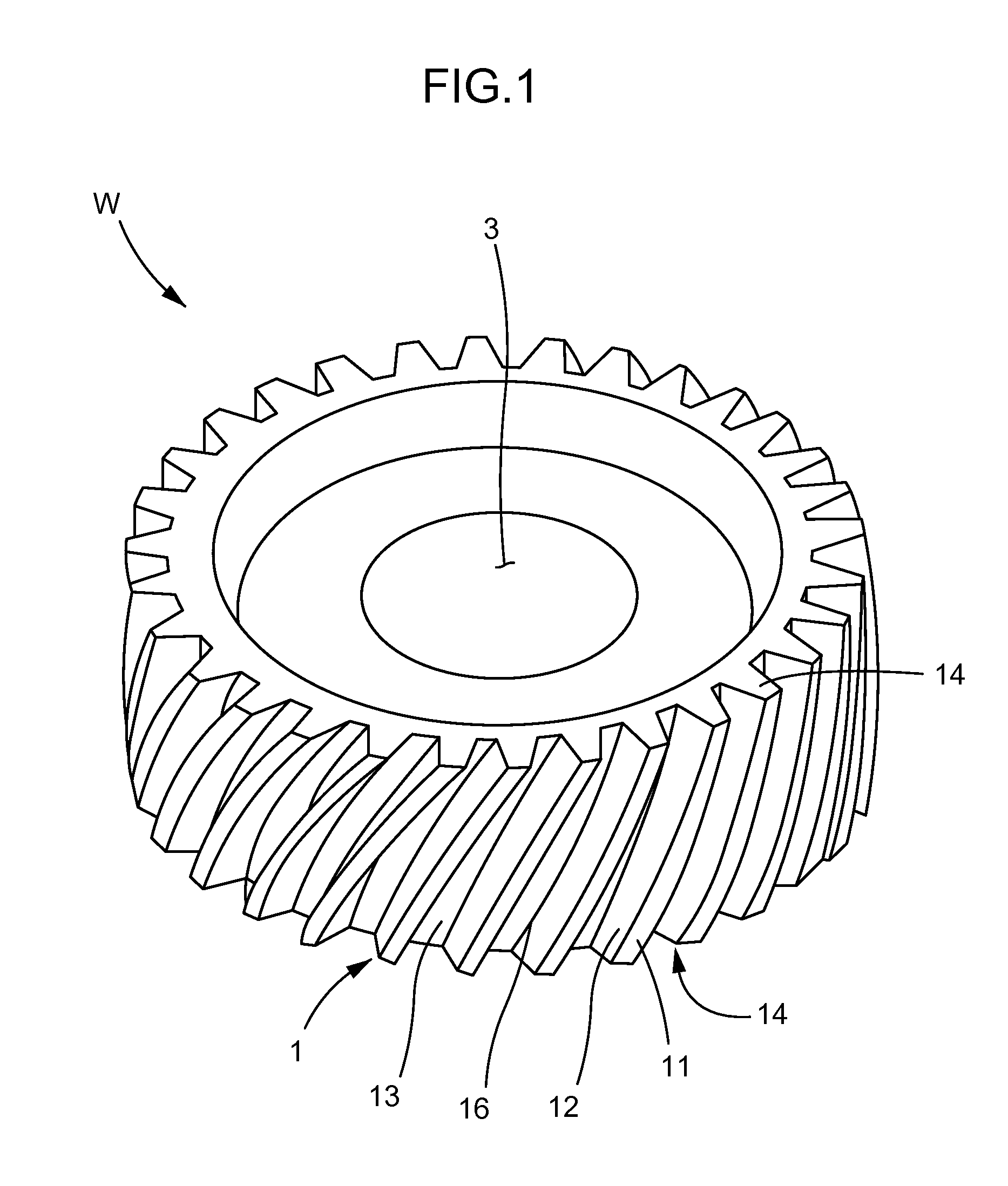

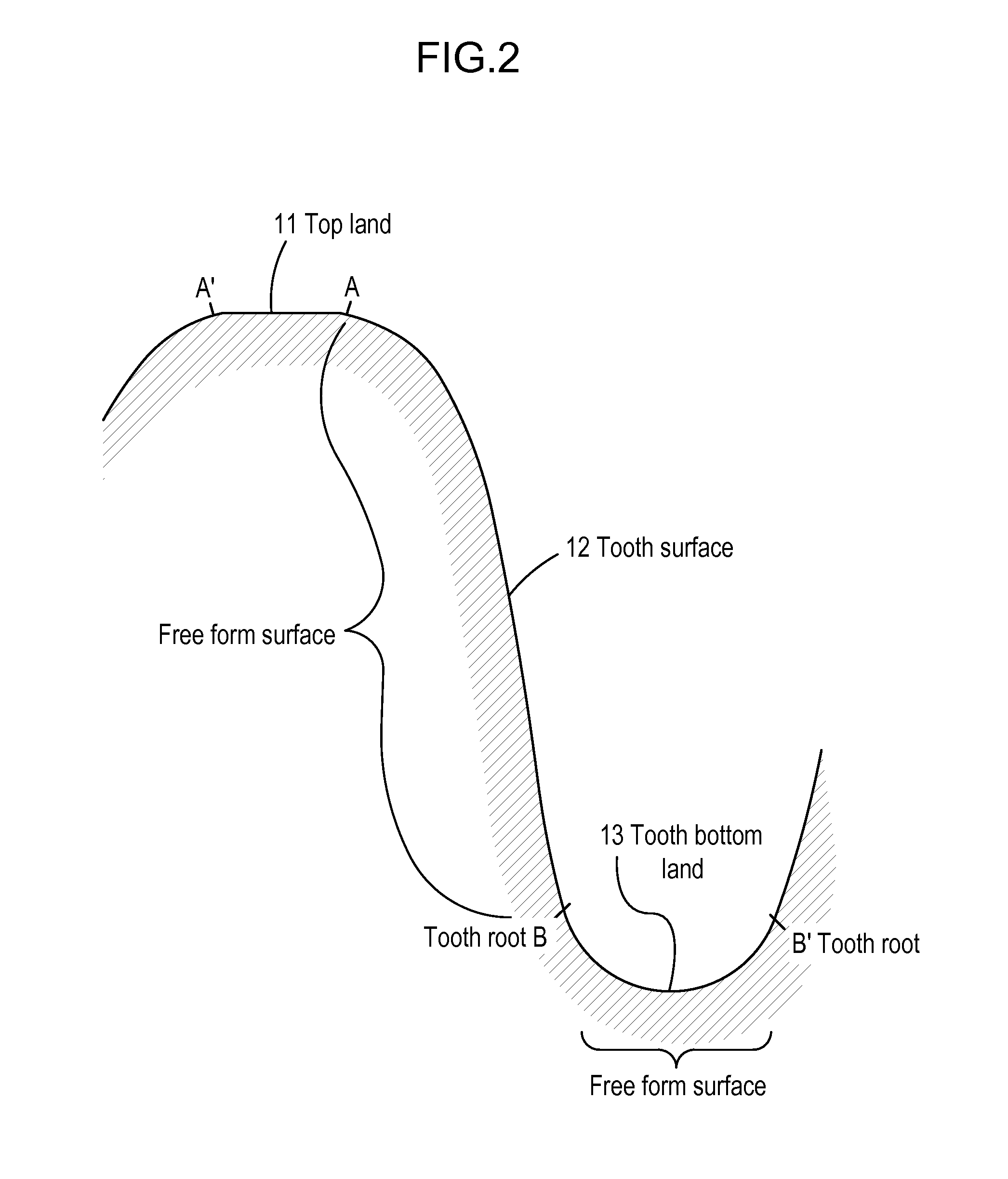

Free-form surface gear

ActiveUS20130091970A1Improve fatigue strengthIncrease contact pressureMetal-working apparatusPortable liftingContact pressureFree form

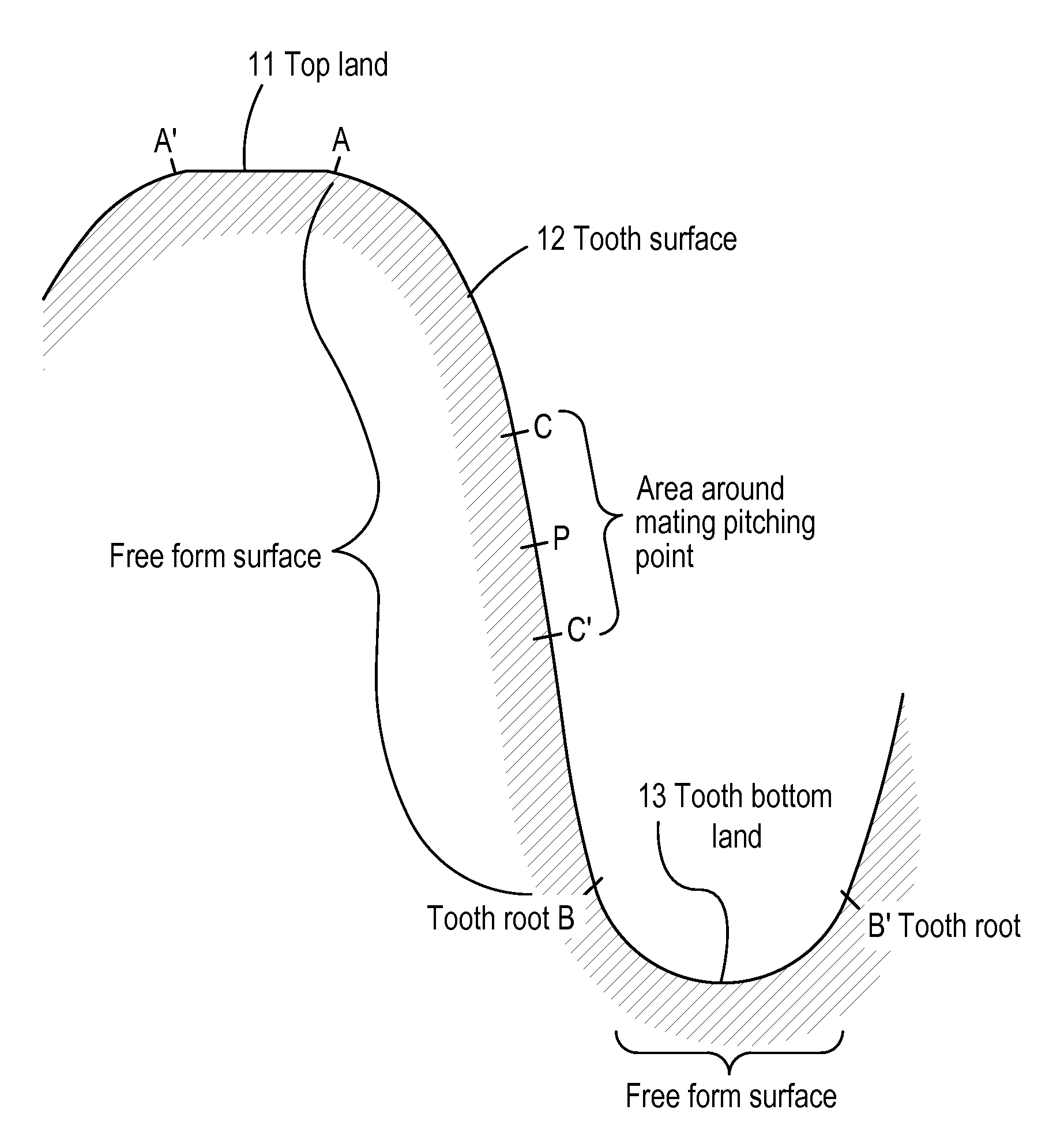

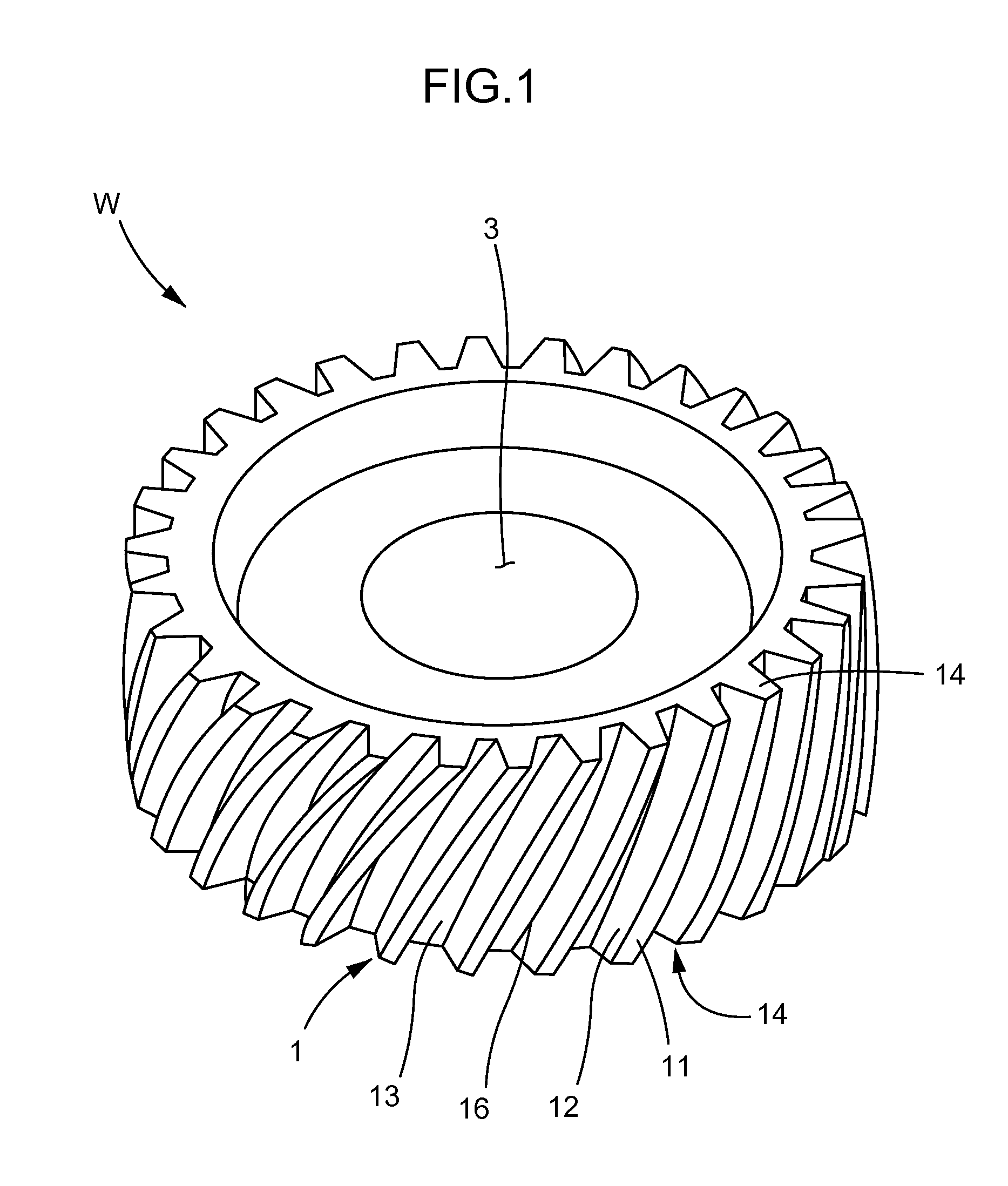

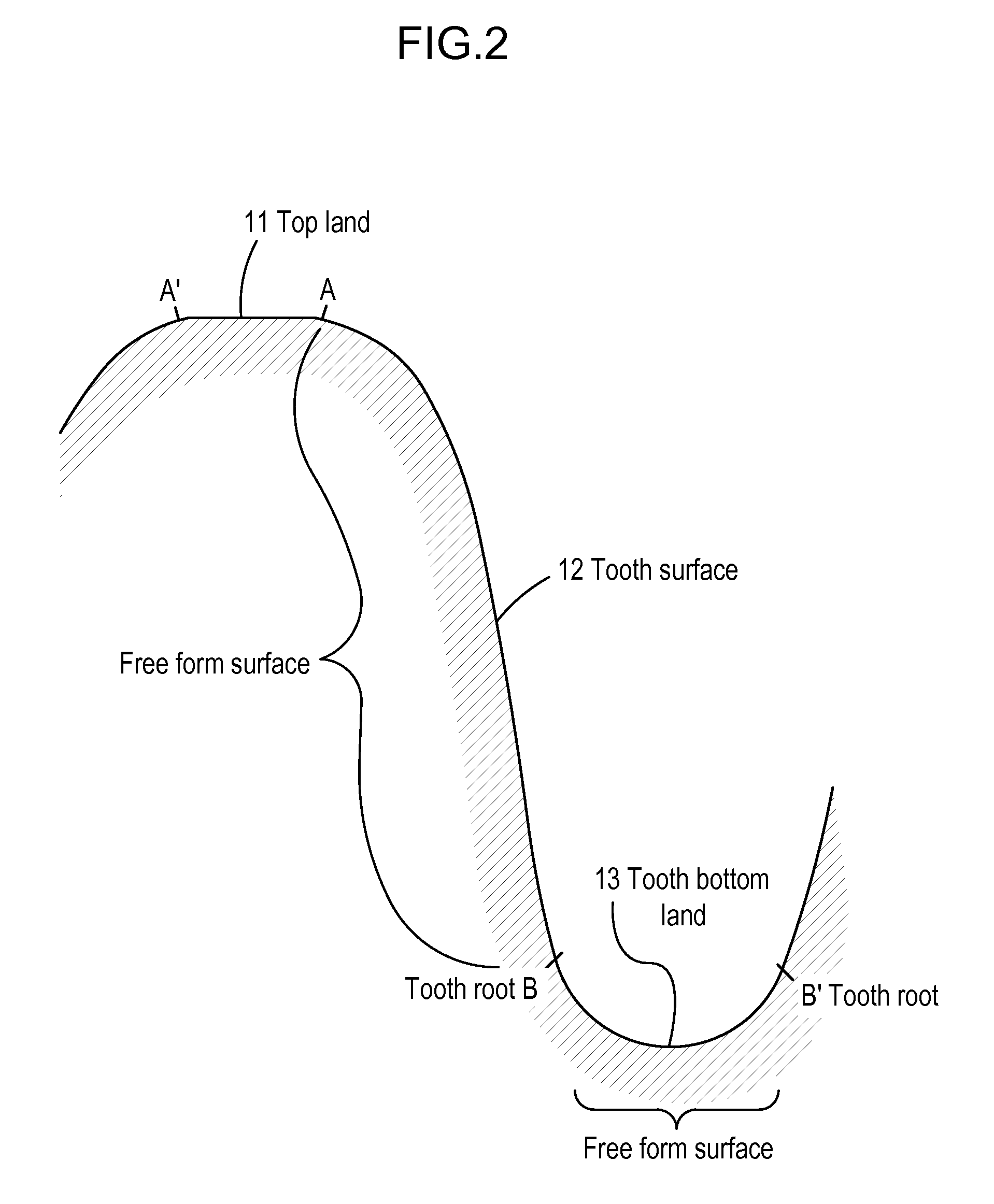

A transmission gear has a tooth surface formed of a free-form surface instead of an involute surface and a root area formed of a free-form surface instead of a trochoid surface. With such a transmission gear, the fatigue strength against contact pressure can be increased by reducing the Hertzian stress in the area around the meshing point of the tooth surface. The tooth surface is formed of a free-form surface in which the smallest radius of curvature in an area around a mating pitch point is maximized, and the fatigue strength against bending can be increased by reducing the bending stress at a tooth root portion of the bottom land. In addition, the gear noise can be reduced. The bottom land is formed of a free-form surface in which the smallest radius of curvature in an area around a tooth root is maximized.

Owner:O OKA CORP

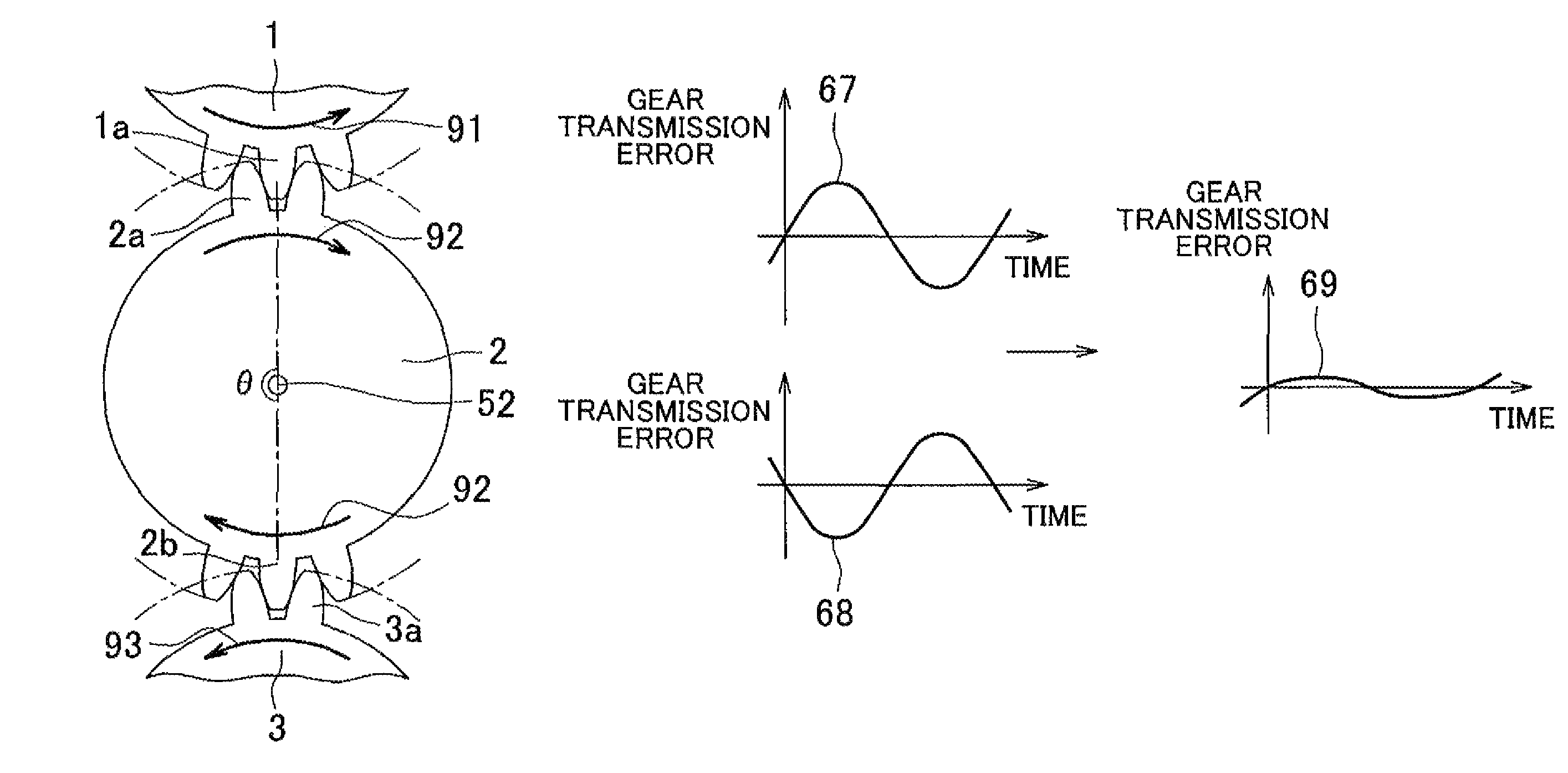

Power transmission device

InactiveUS8225690B2Reduce gear noiseExcessive gear noiseGear vibration/noise dampingToothed gearingsEngineeringMechanical engineering

A power transmission device is provided with: a first gear having a plurality of teeth that share an identical tooth profile; an intermediate gear that is engaged with the first gear; and a second gear that is engaged with the intermediate gear, and has a plurality of teeth that share an identical tooth profile, wherein the first gear and the second gear have an identical number of teeth, an identical reference diameter, and an identical reference pitch; and the tooth profile of the first gear is different from that of the second gear.

Owner:TOYOTA JIDOSHA KK

Power transmission device

InactiveUS20080196530A1Reduce gear noiseExcessive gear noiseGear vibration/noise dampingToothed gearingsEngineeringMechanical engineering

A power transmission device is provided with: a first gear having a plurality of teeth that share an identical tooth profile; an intermediate gear that is engaged with the first gear; and a second gear that is engaged with the intermediate gear, and has a plurality of teeth that share an identical tooth profile, wherein the first gear and the second gear have an identical number of teeth, an identical reference diameter, and an identical reference pitch; and the tooth profile of the first gear is different from that of the second gear

Owner:TOYOTA JIDOSHA KK

Front vehicle-body structure of vehicle

ActiveUS20190016389A1Promote absorptionImprove NVH performanceUnderstructuresSuperstructure subunitsShearing deformationEngineering

There are provided a front side frame having a closed cross section extending in a vehicle longitudinal direction and including a mount-bracket attachment part for attaching a PT mount bracket provided at a PT mount for supporting a powertrain and a crash can attached to a front end of the front side frame. The front side frame includes a compressive-deformation part which is configured to be compressively deformed in a vehicle frontal collision and extend rearward from the front end, having substantially the same sectional shape as the crash can. A gusset member for preventing shearing deformation of the closed cross section of the front side frame is provided at a portion of the front side frame between the mount-bracket attachment part and the compressive-deformation part.

Owner:MAZDA MOTOR CORP

Gear

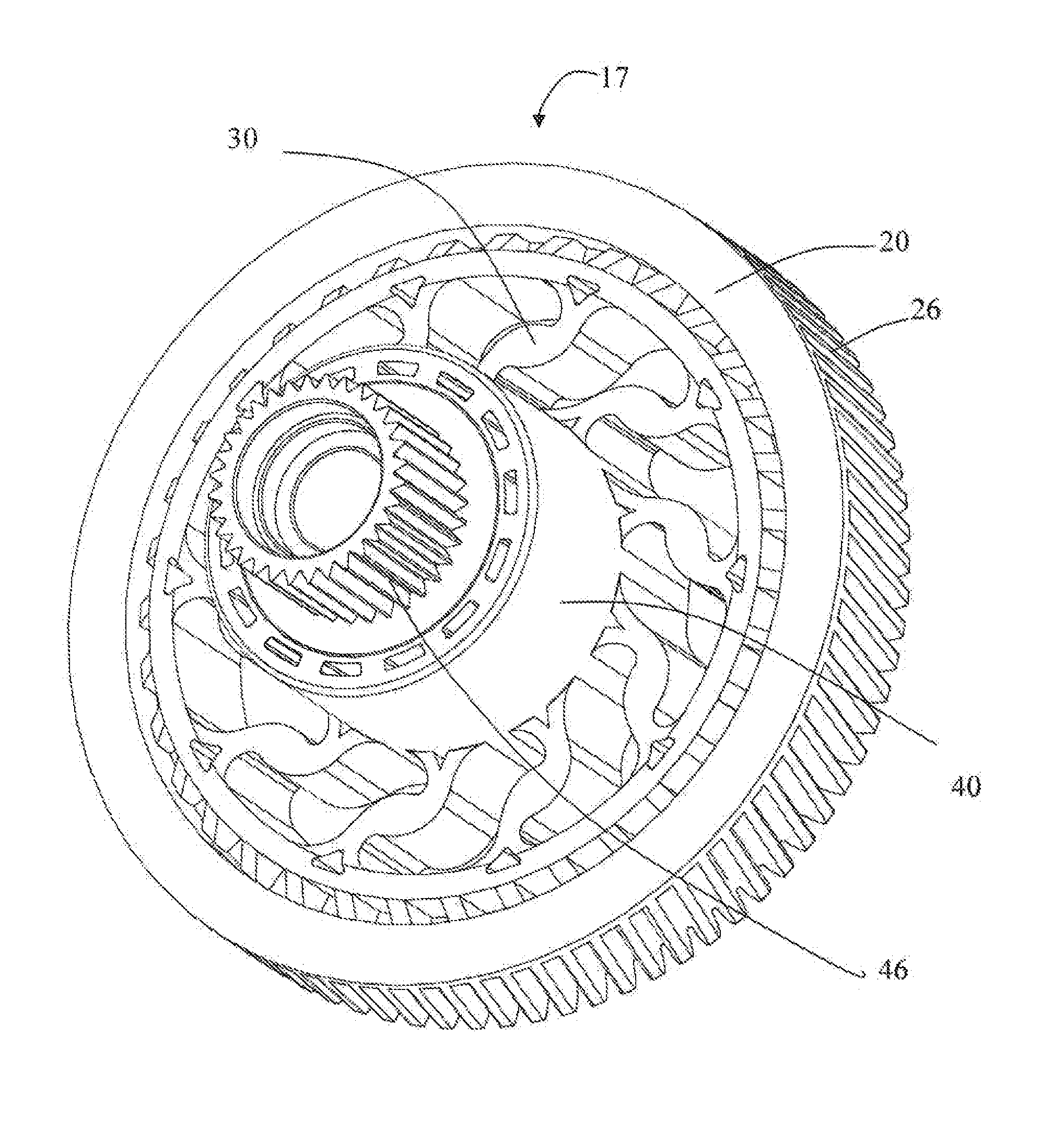

InactiveUS20150047448A1Reduce gear noiseReduce rigidityPortable liftingGearing elementsCurve shapeEngineering

A gear includes an inner ring portion, an outer ring portion, and a number of spokes connecting the inner ring portion with the outer ring portion. An outer circumferential surface of the outer ring portion is provided with teeth. Each spoke includes a curve-shaped main portion, an inner end section at an inner end of the main portion which connects to the inner ring portion, and an outer end section at an outer end of the main portion which connects to the outer ring portion. At least one of the inner end section and outer end section is formed with a furcated structure.

Owner:JOHNSON ELECTRIC SA

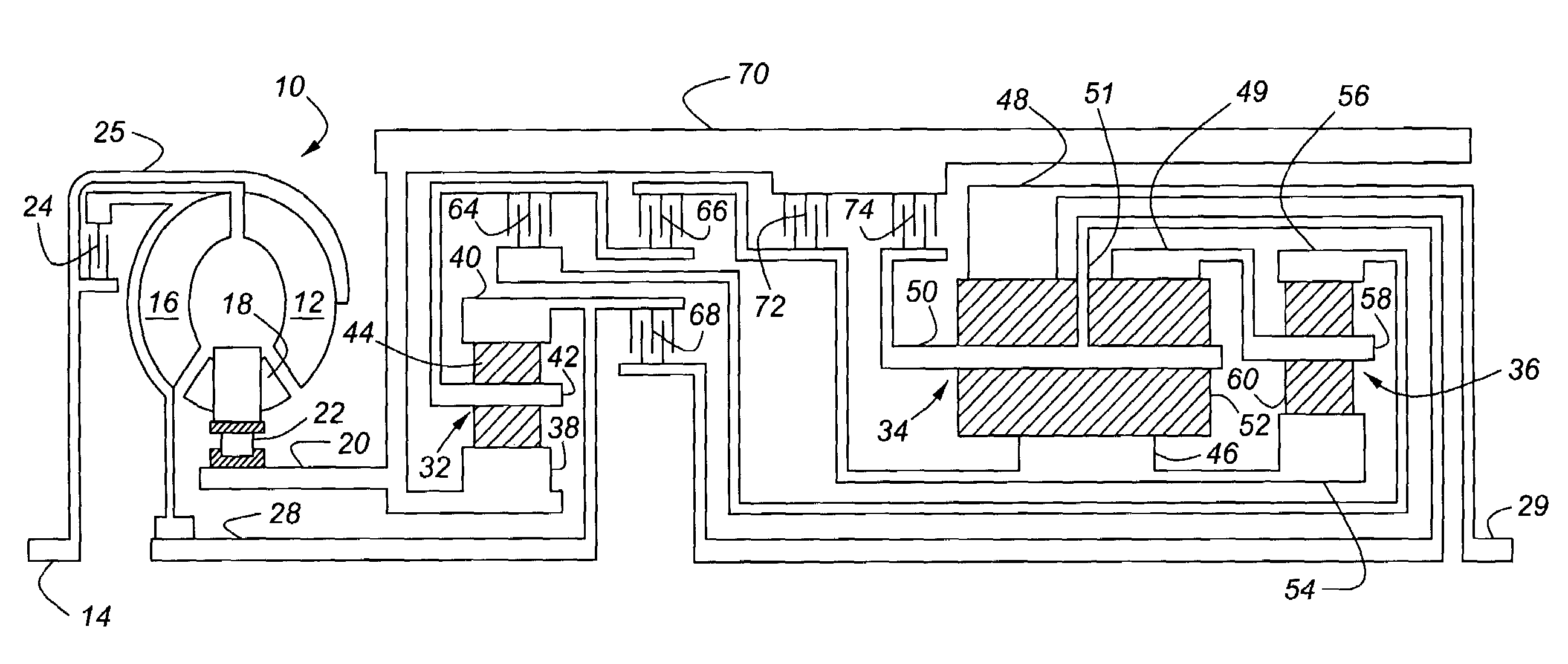

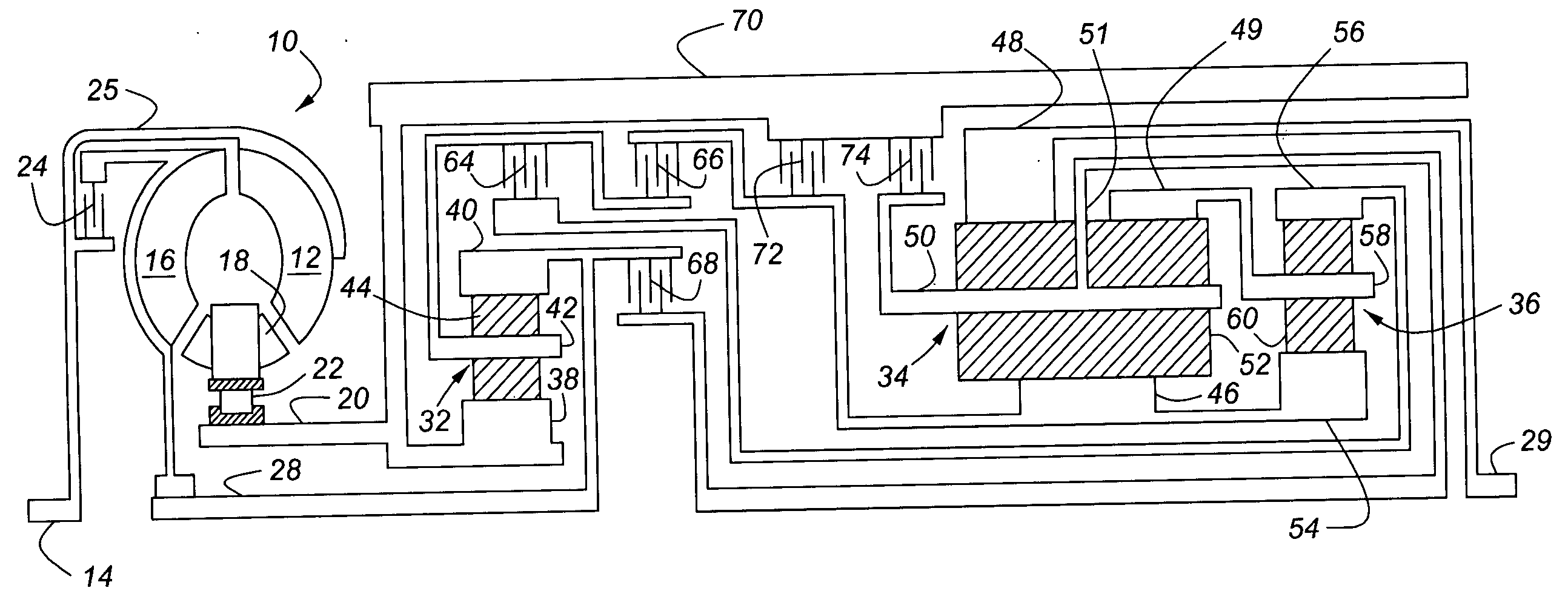

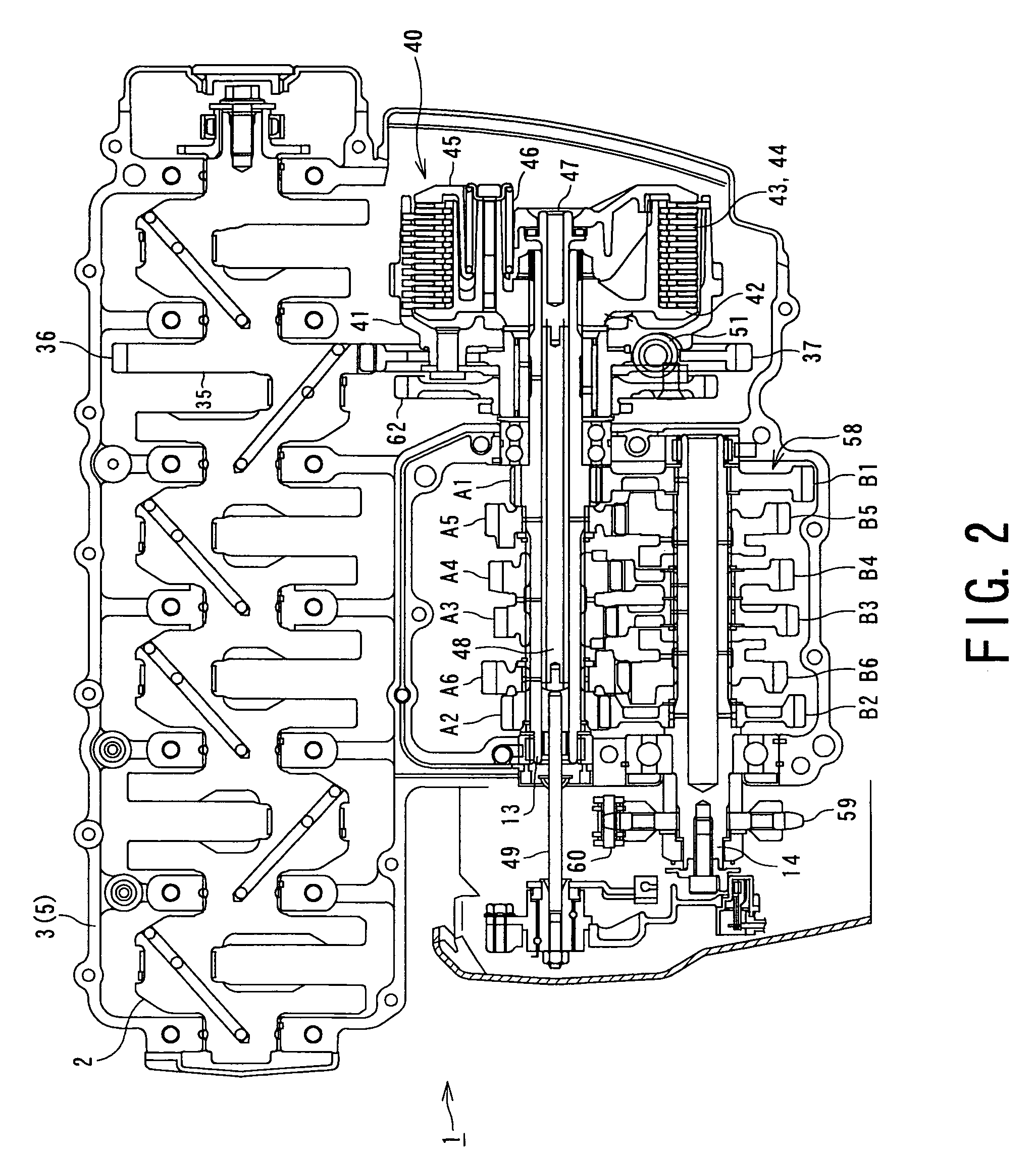

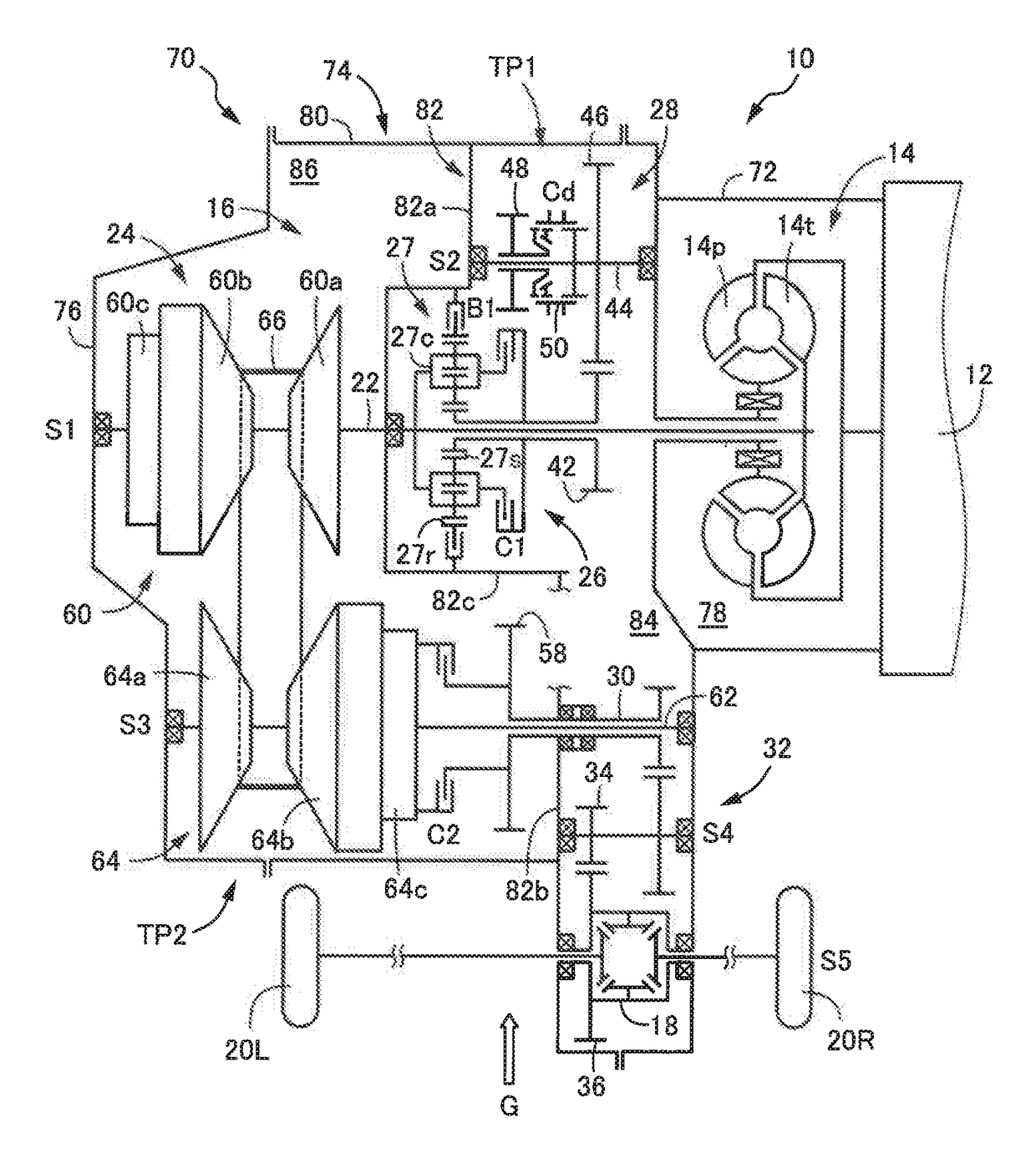

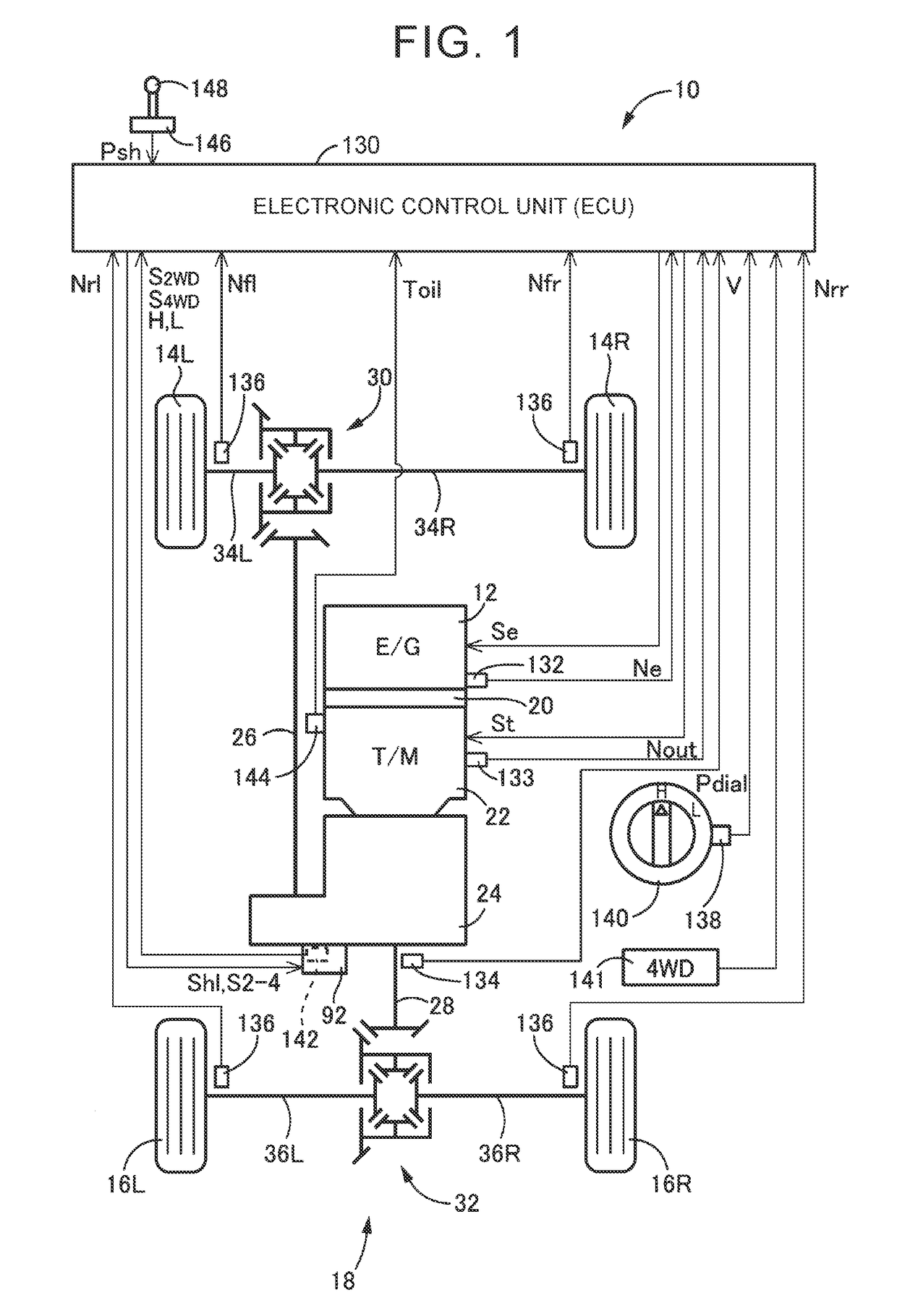

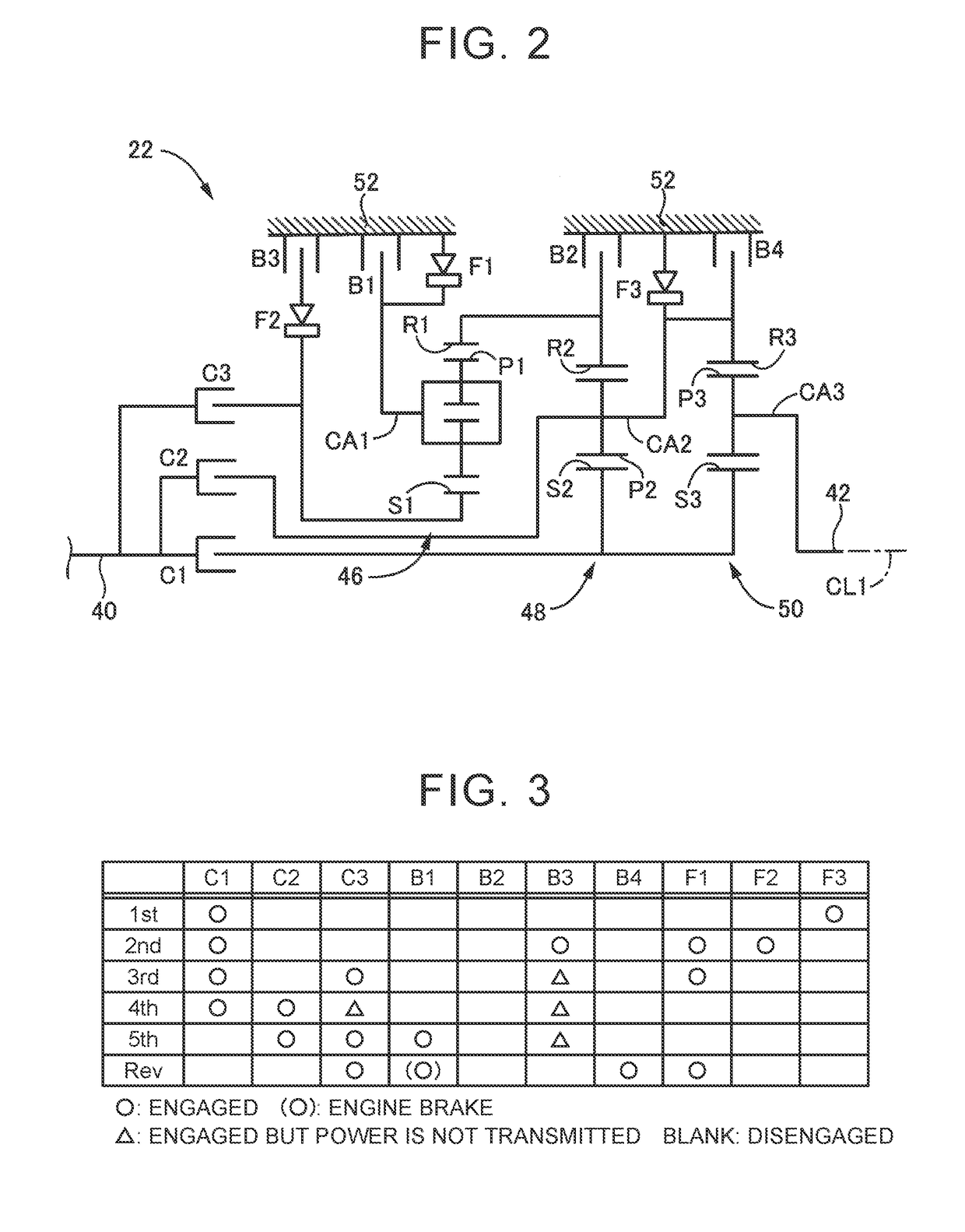

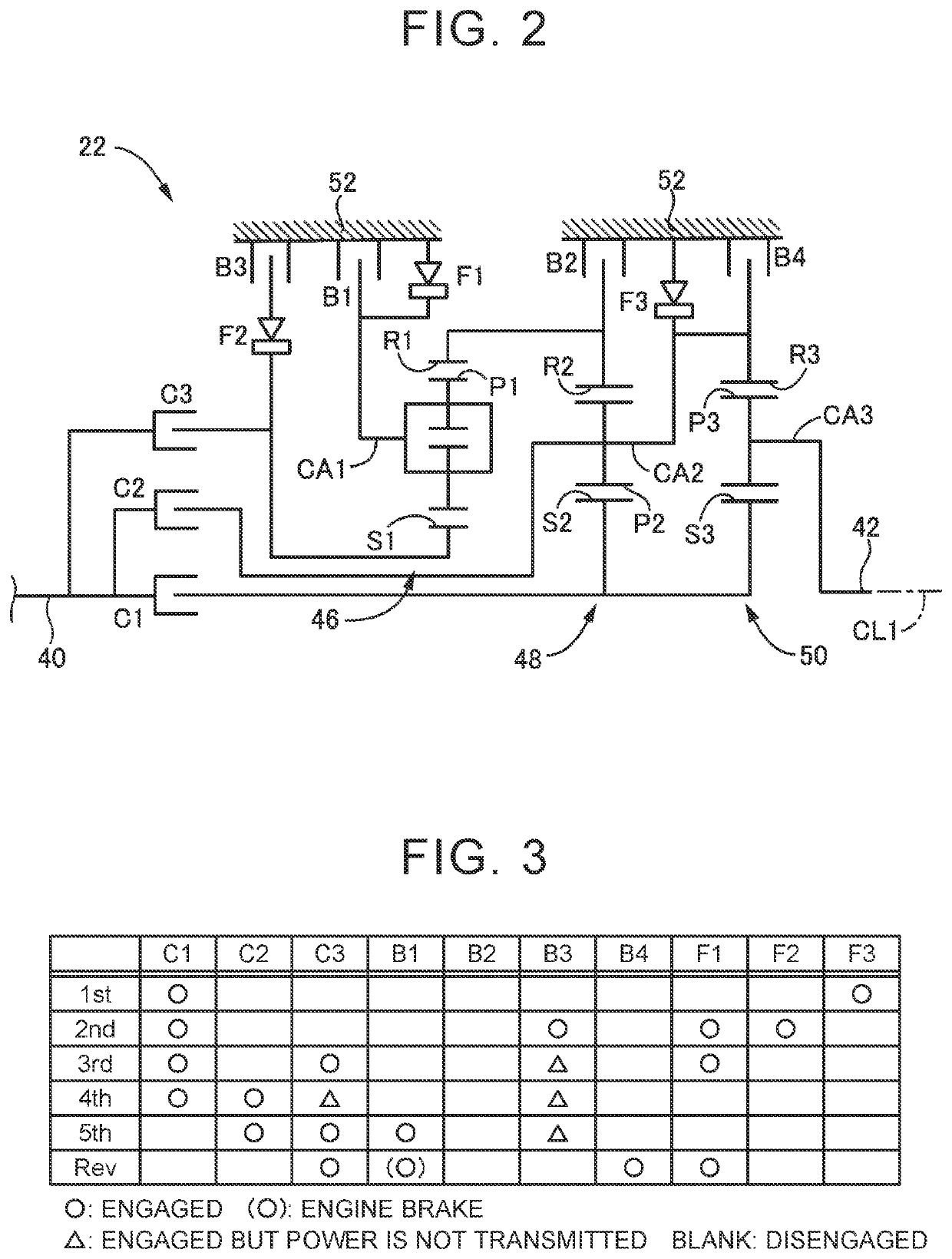

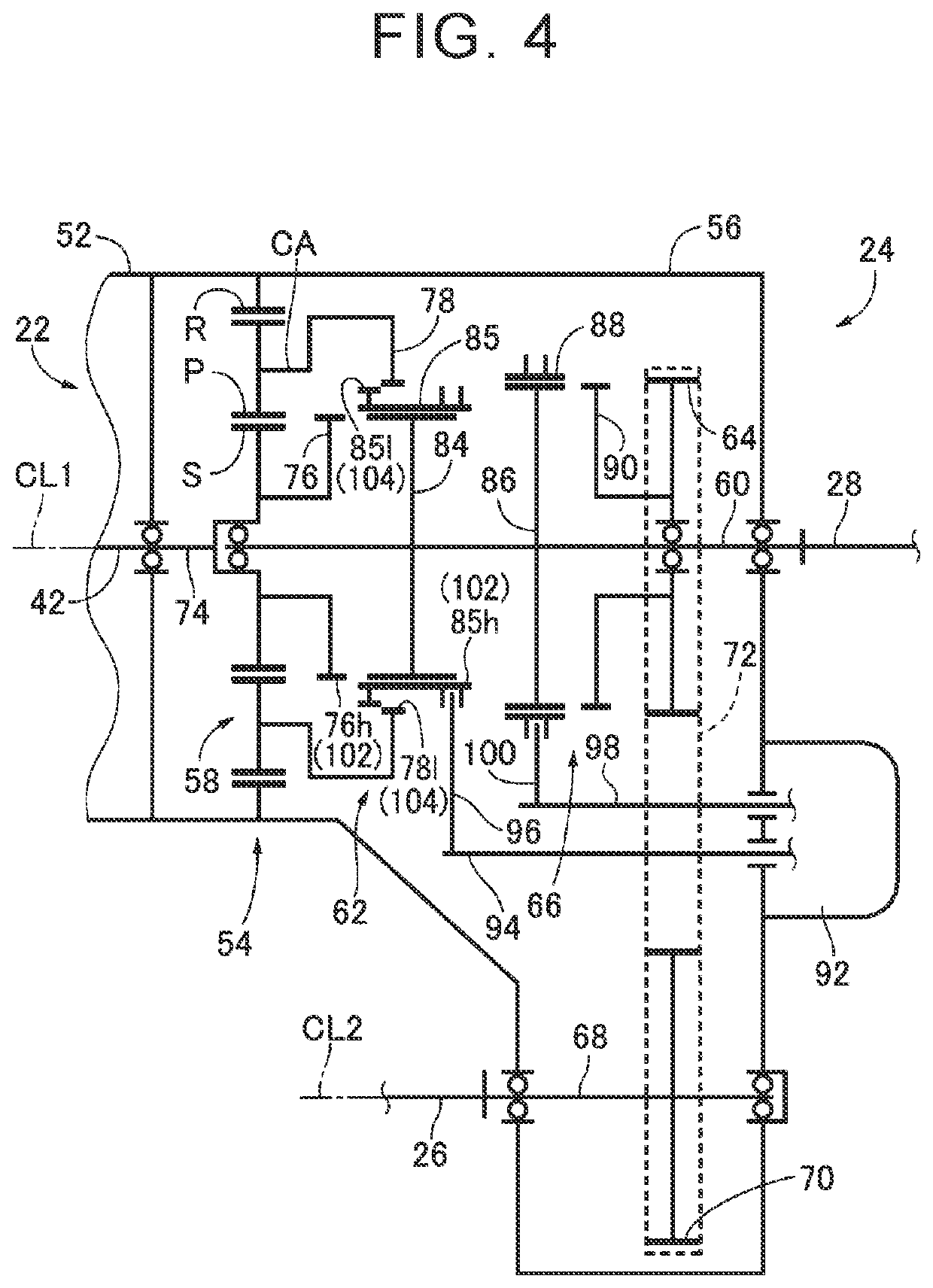

Multiple-speed automatic transmission having a two-speed input and a Simpson gearset

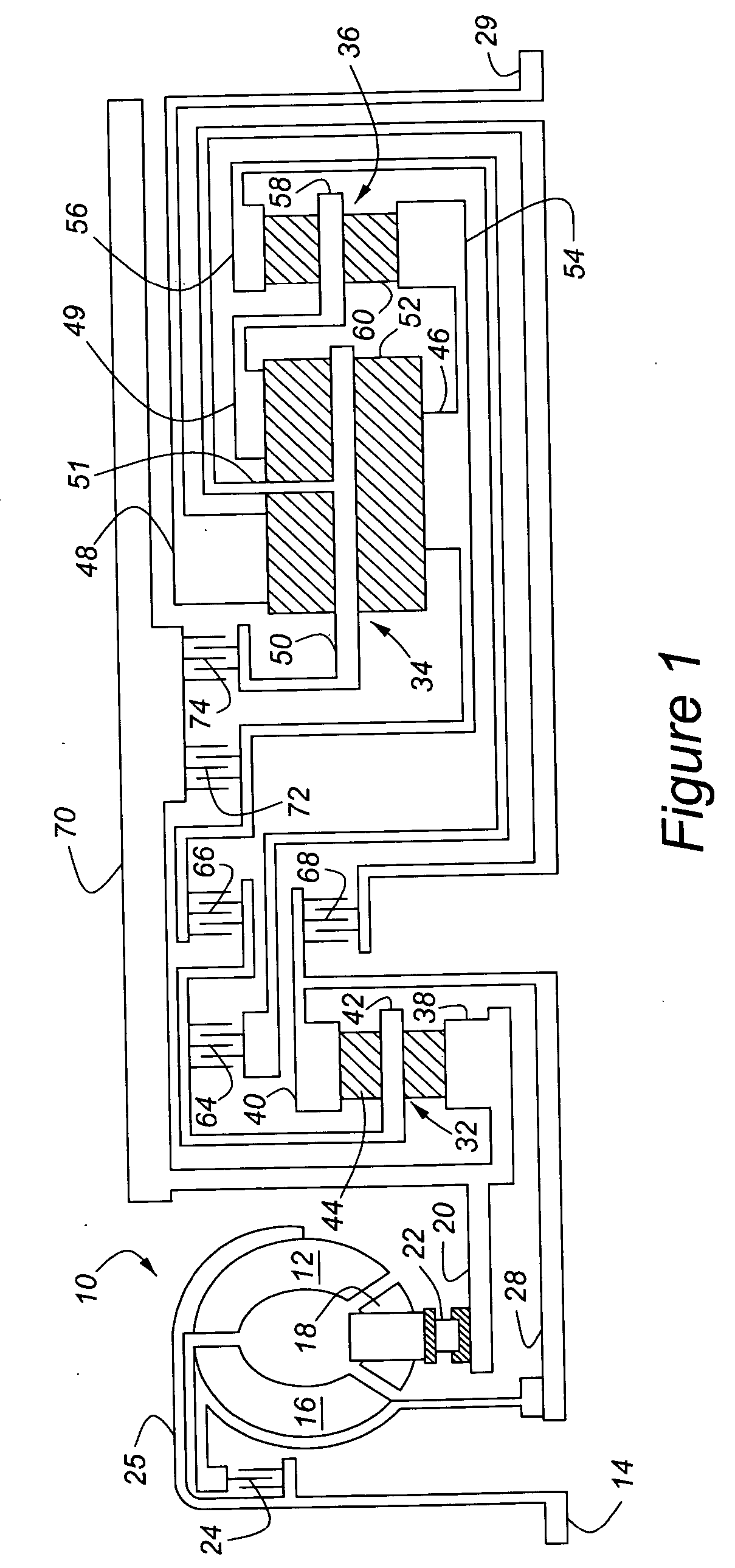

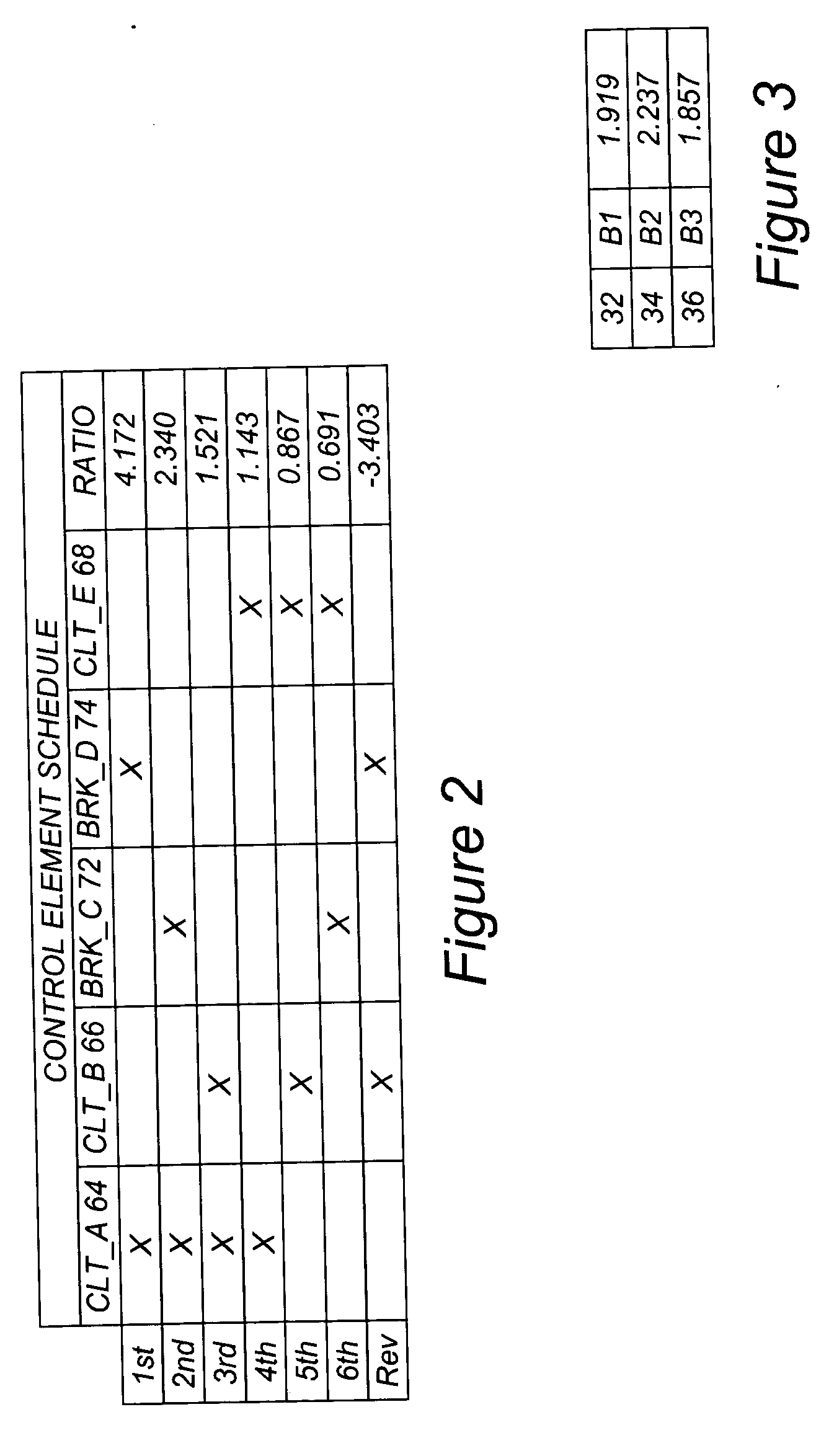

ActiveUS7235032B2Improve design flexibilityEasy to provideToothed gearingsTransmission elementsAutomatic transmissionEngineering

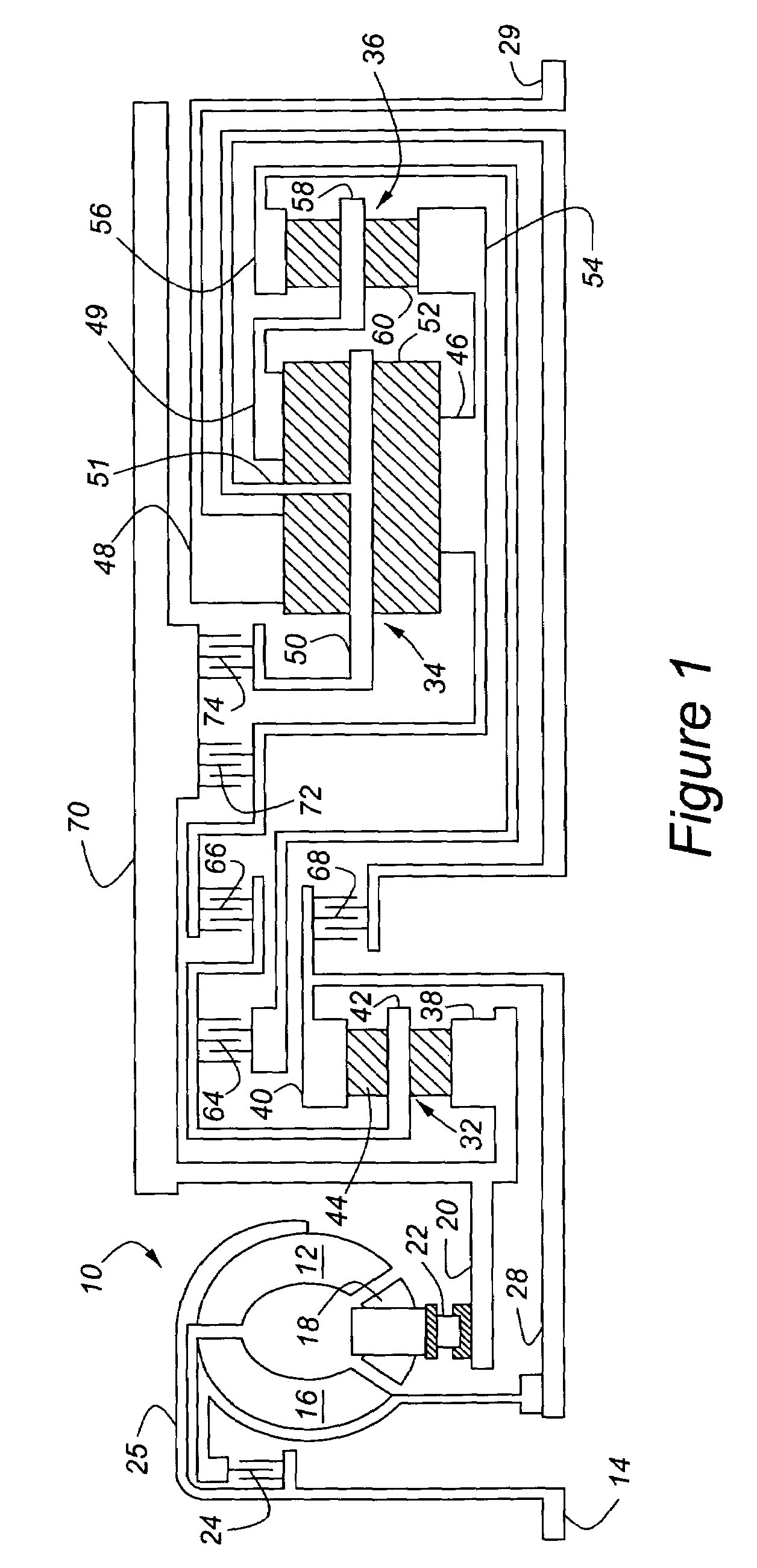

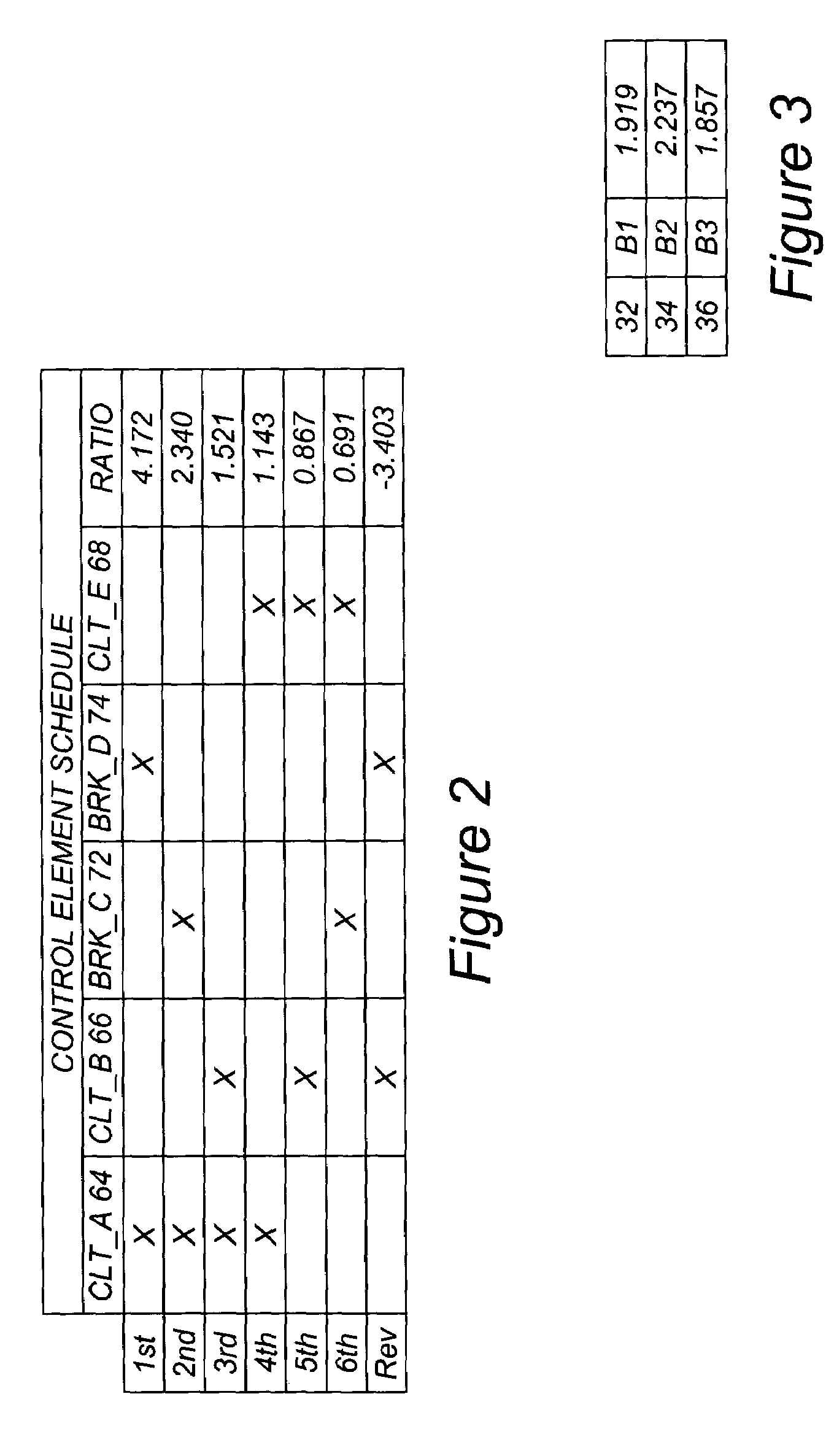

A multi-speed automatic transmission includes an input and output, first, second and three planetary gear units, each gear unit including a sun gear, a ring gear, planet pinions meshing with the sun gear and the ring gear, and a carrier rotatably supporting the planet pinions. A first brake alternately holds against rotation and releases the sun gear of the second gear unit and the sun gear of the third gear unit. A second brake alternately holds and releases the carrier of the second gear unit. A first clutch alternately connects and disconnects the carrier of the first gear unit and the ring gear of the third gear unit. A second clutch alternately disconnects and connects the carrier of the first gear unit to the sun gears of the second gear unit and third gear unit. A third clutch alternately releases and connects the input and ring gear of the first gear unit to the carrier of the second gear unit.

Owner:FORD GLOBAL TECH LLC

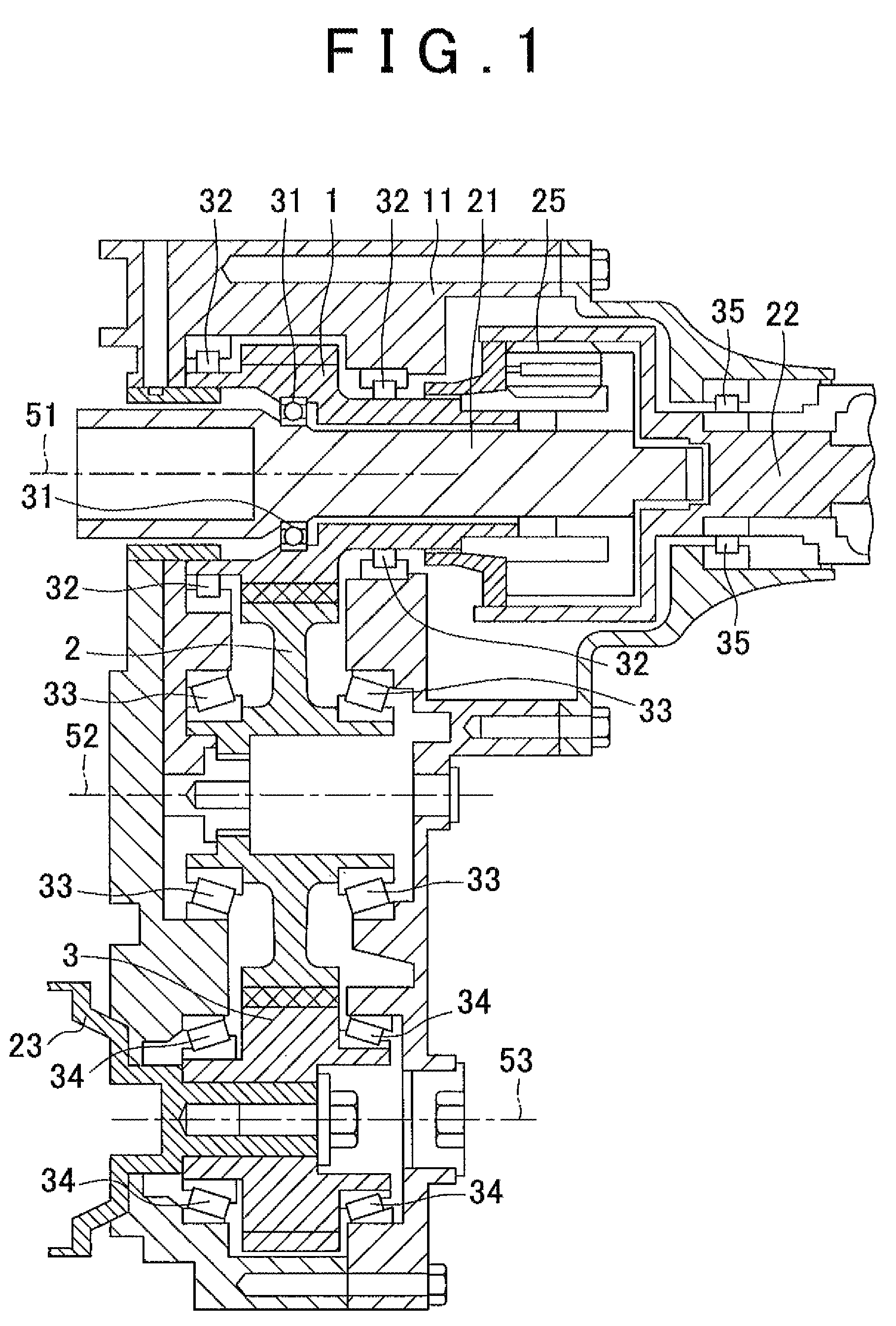

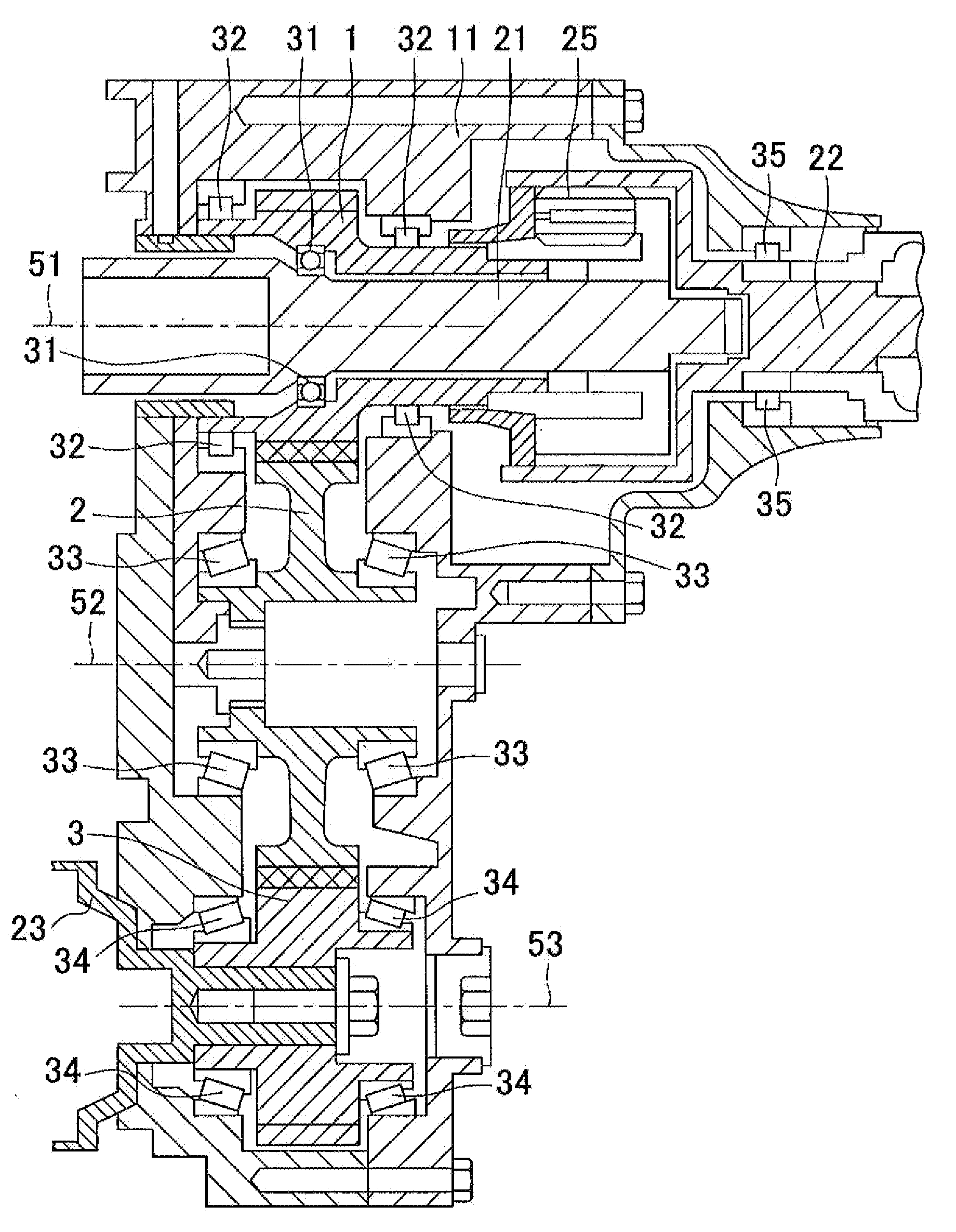

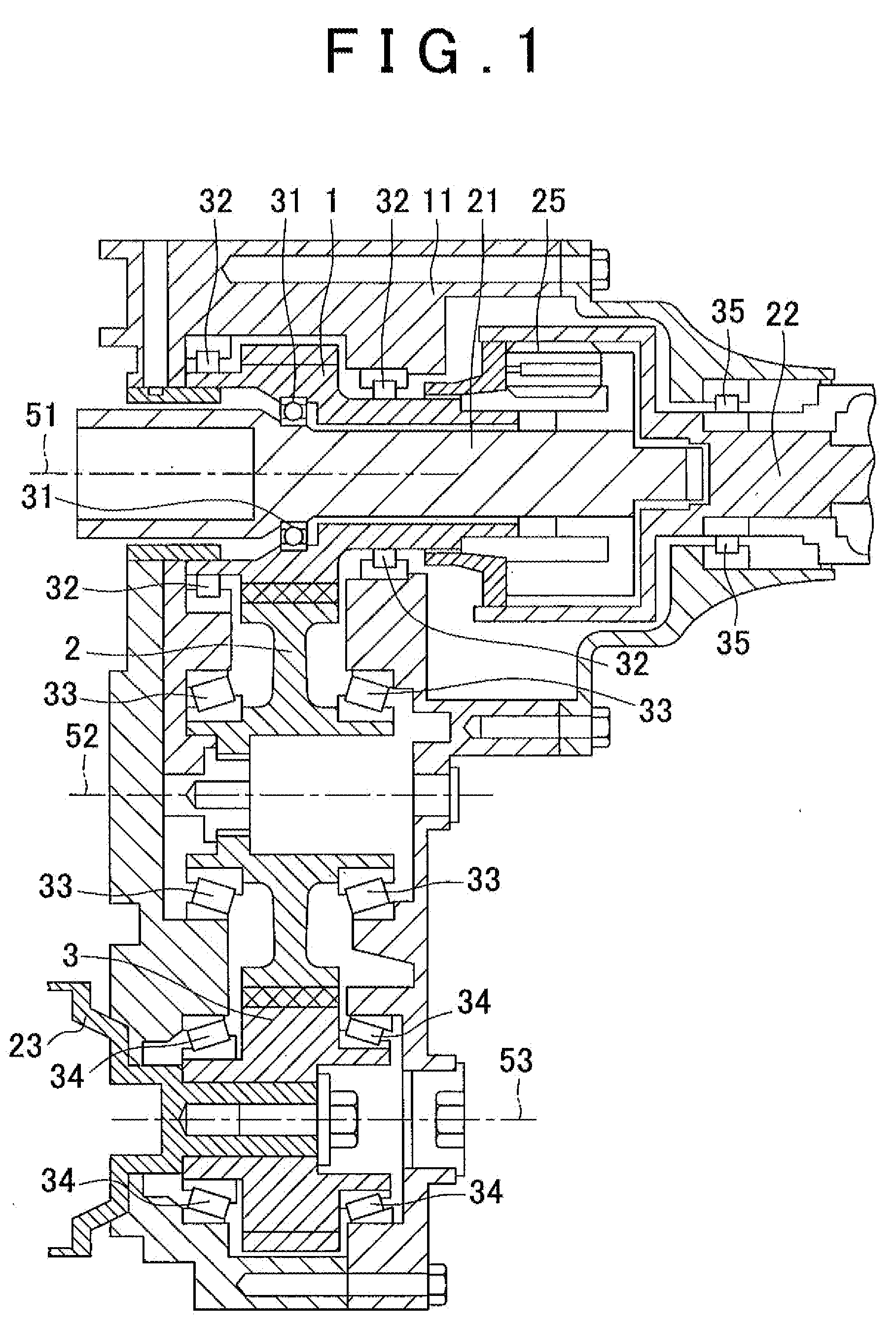

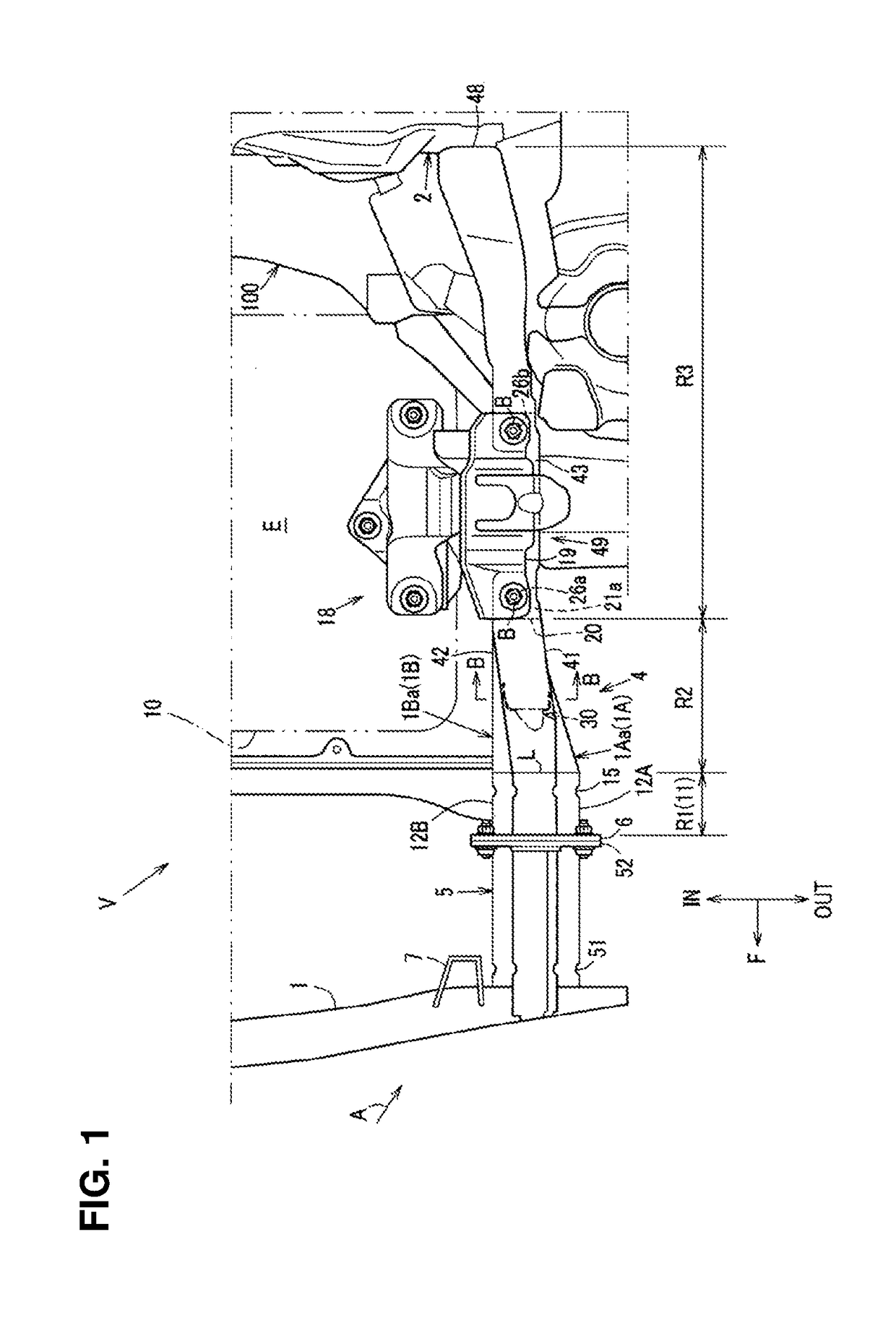

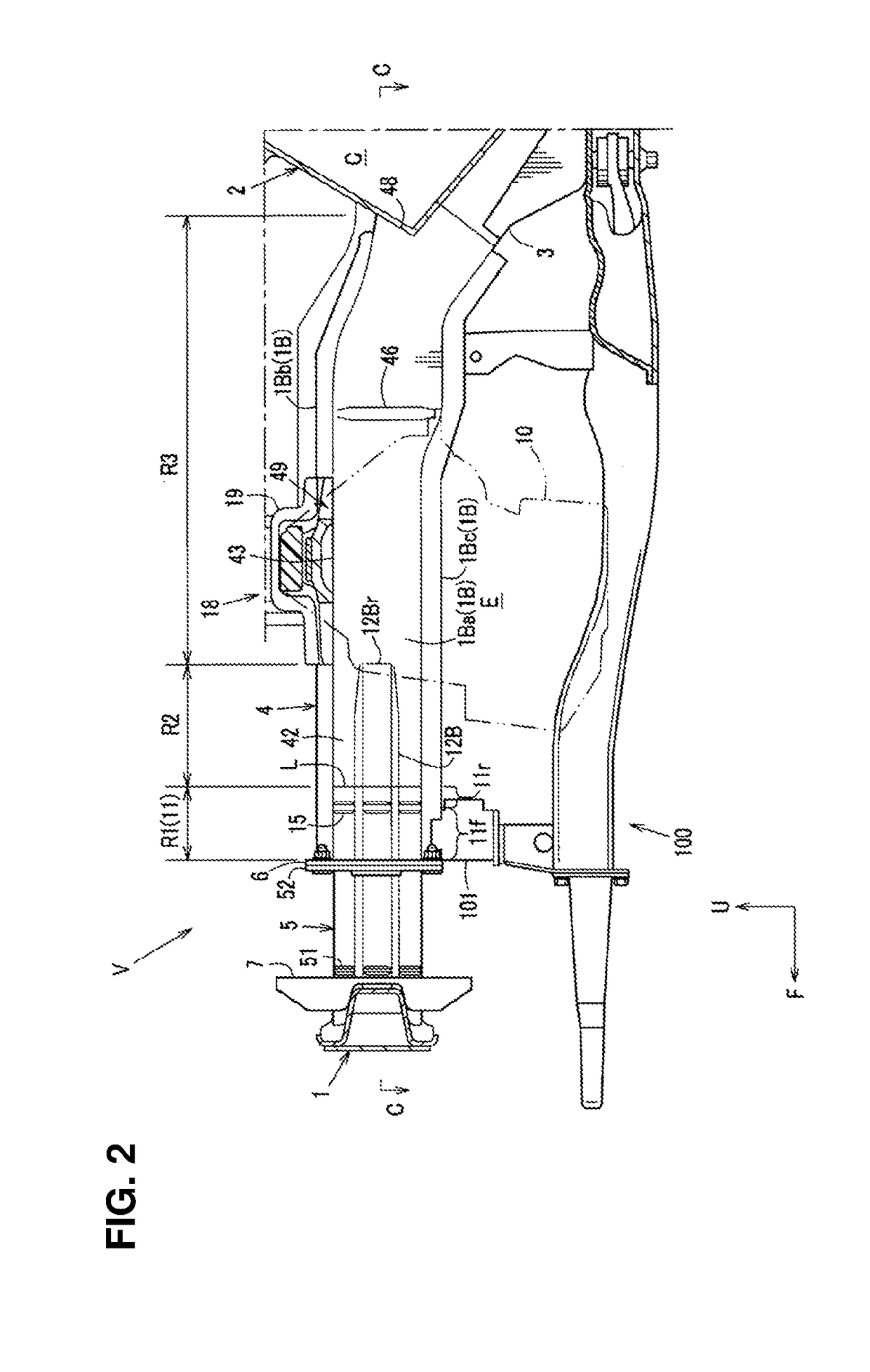

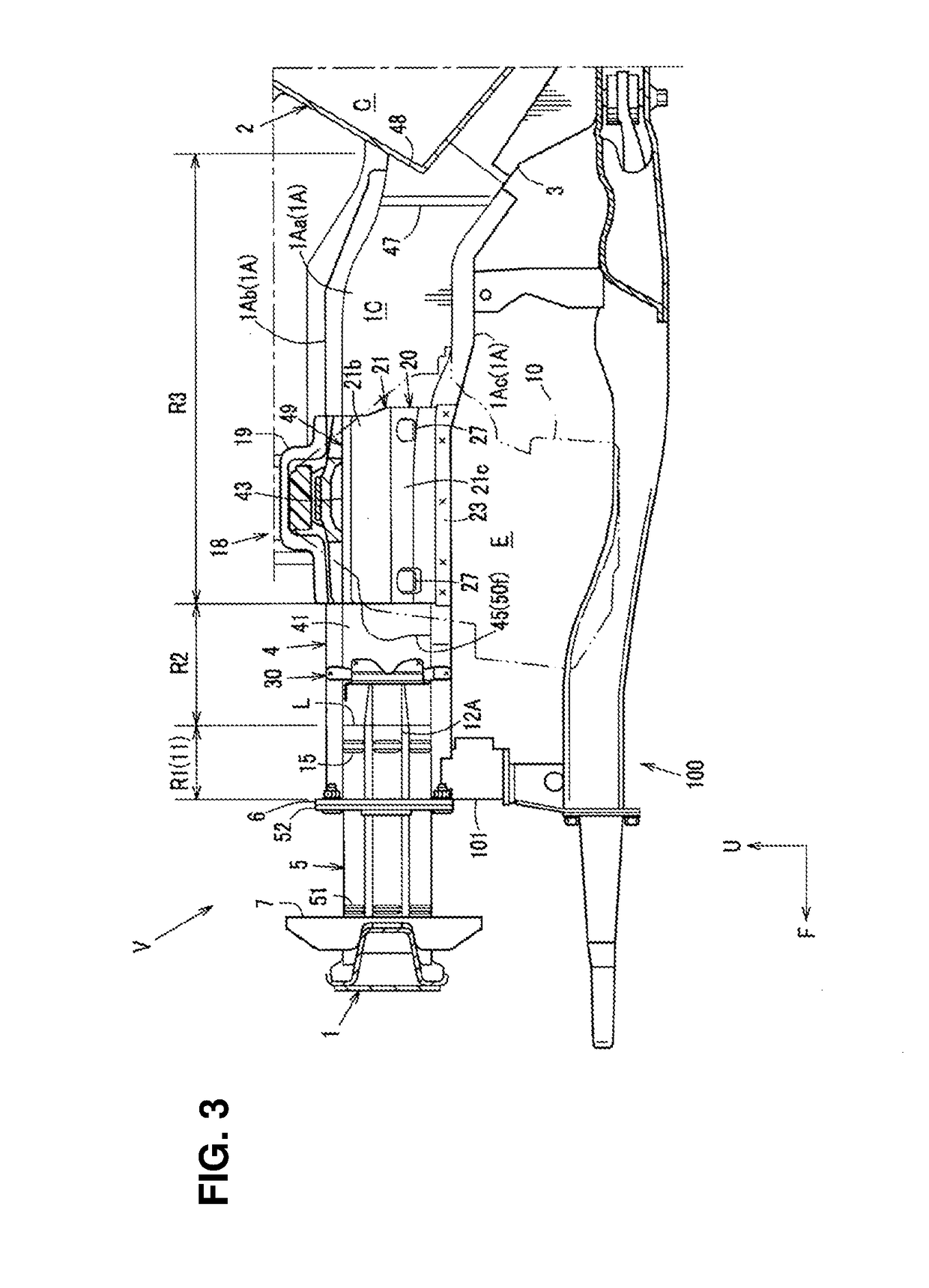

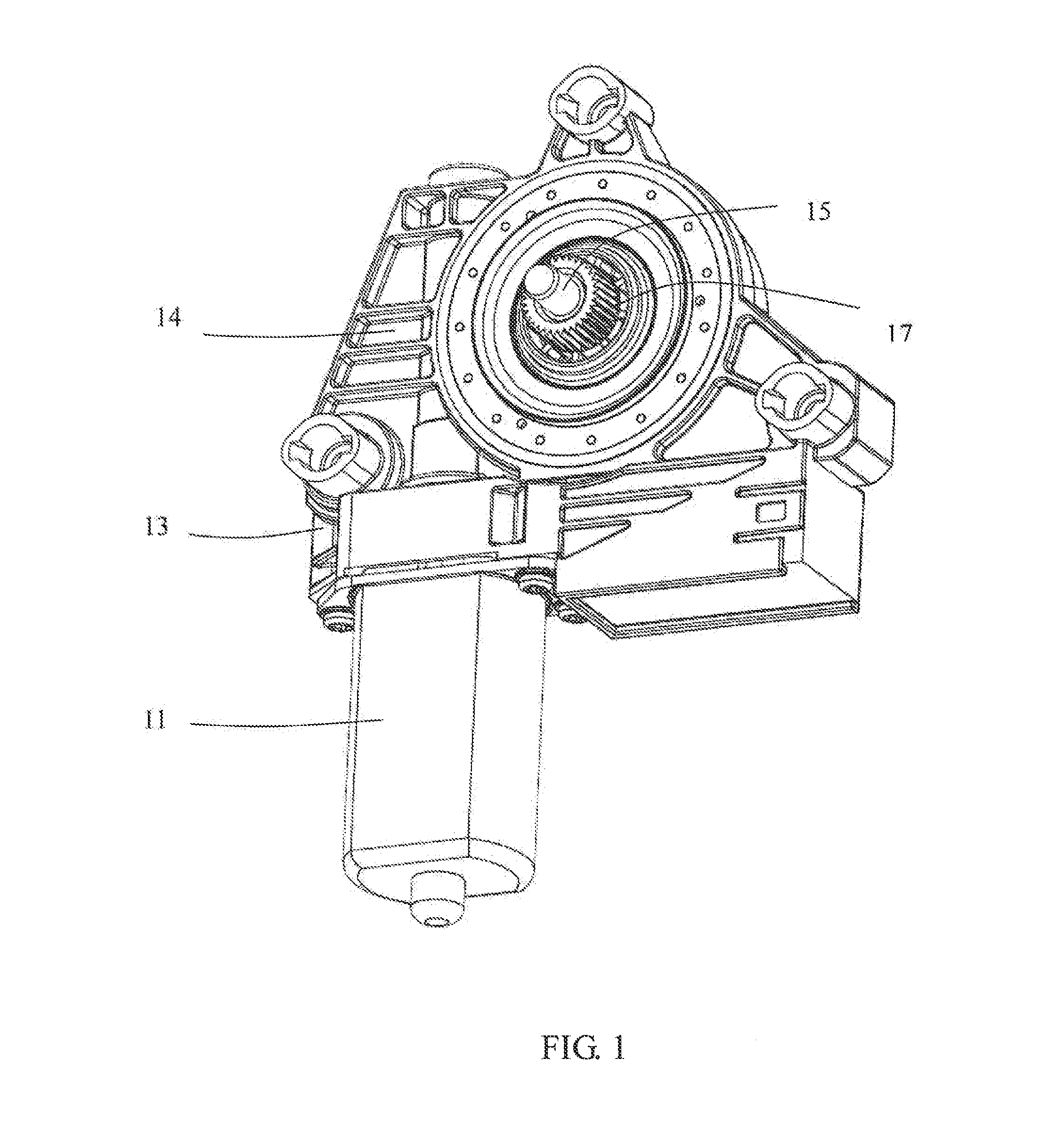

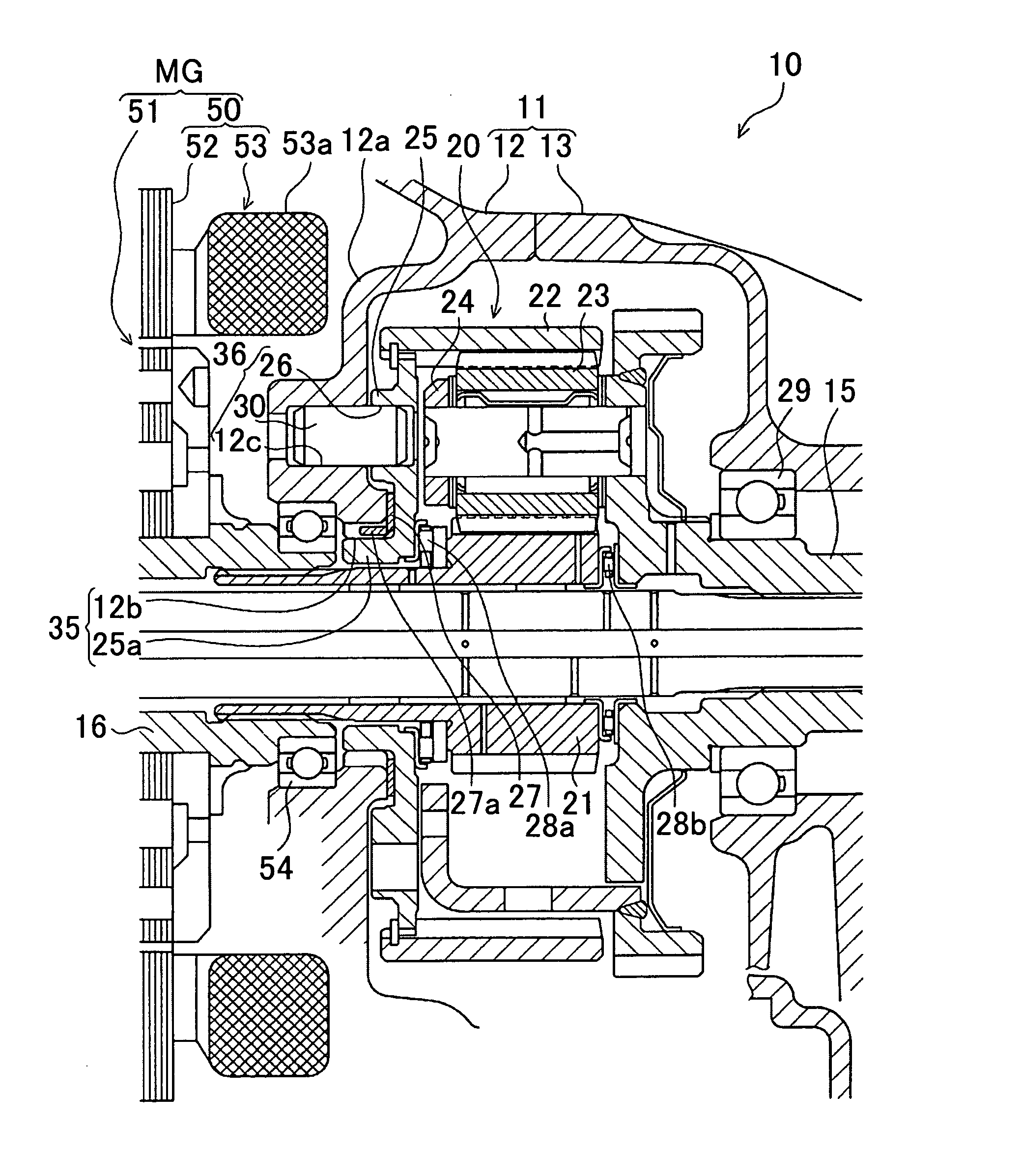

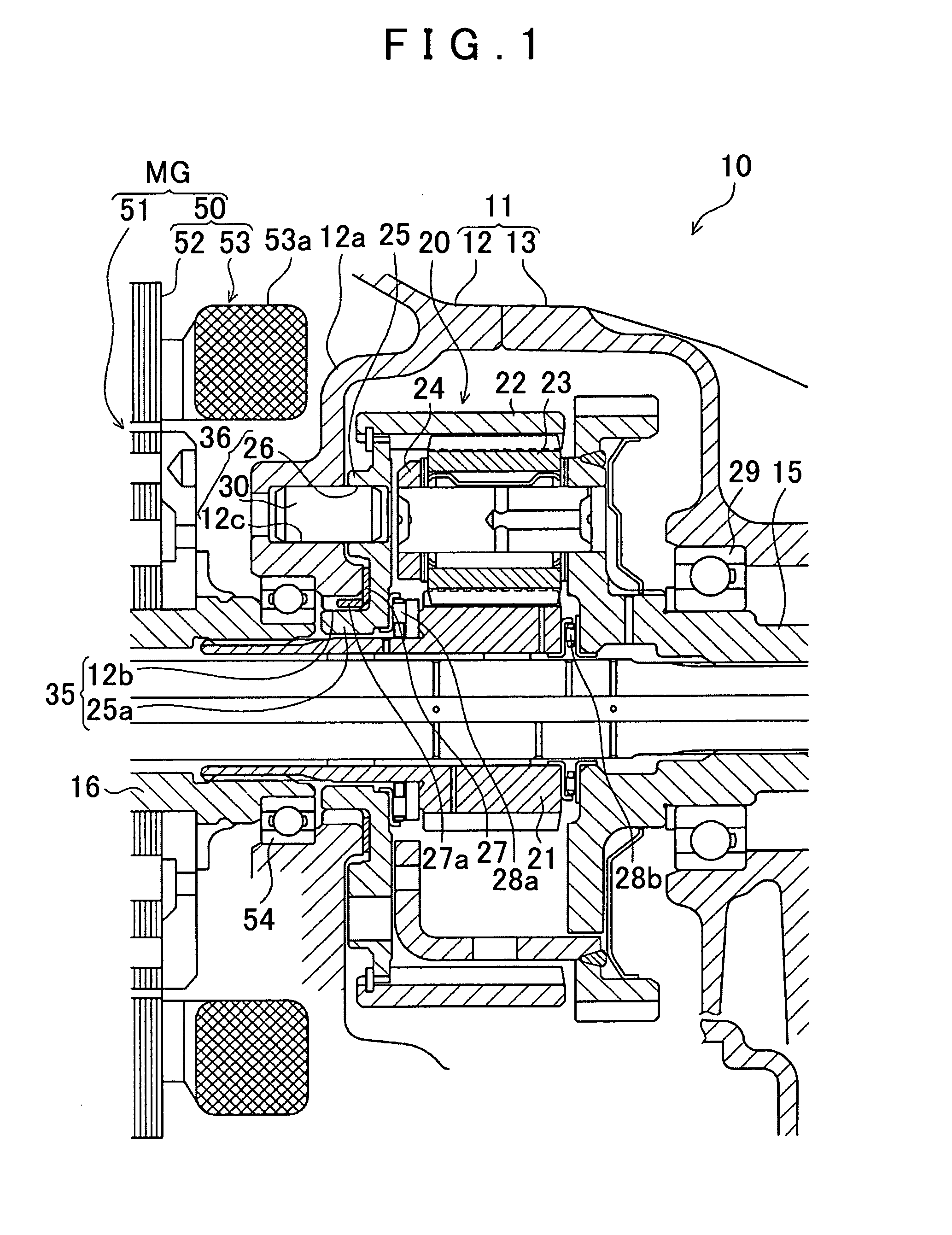

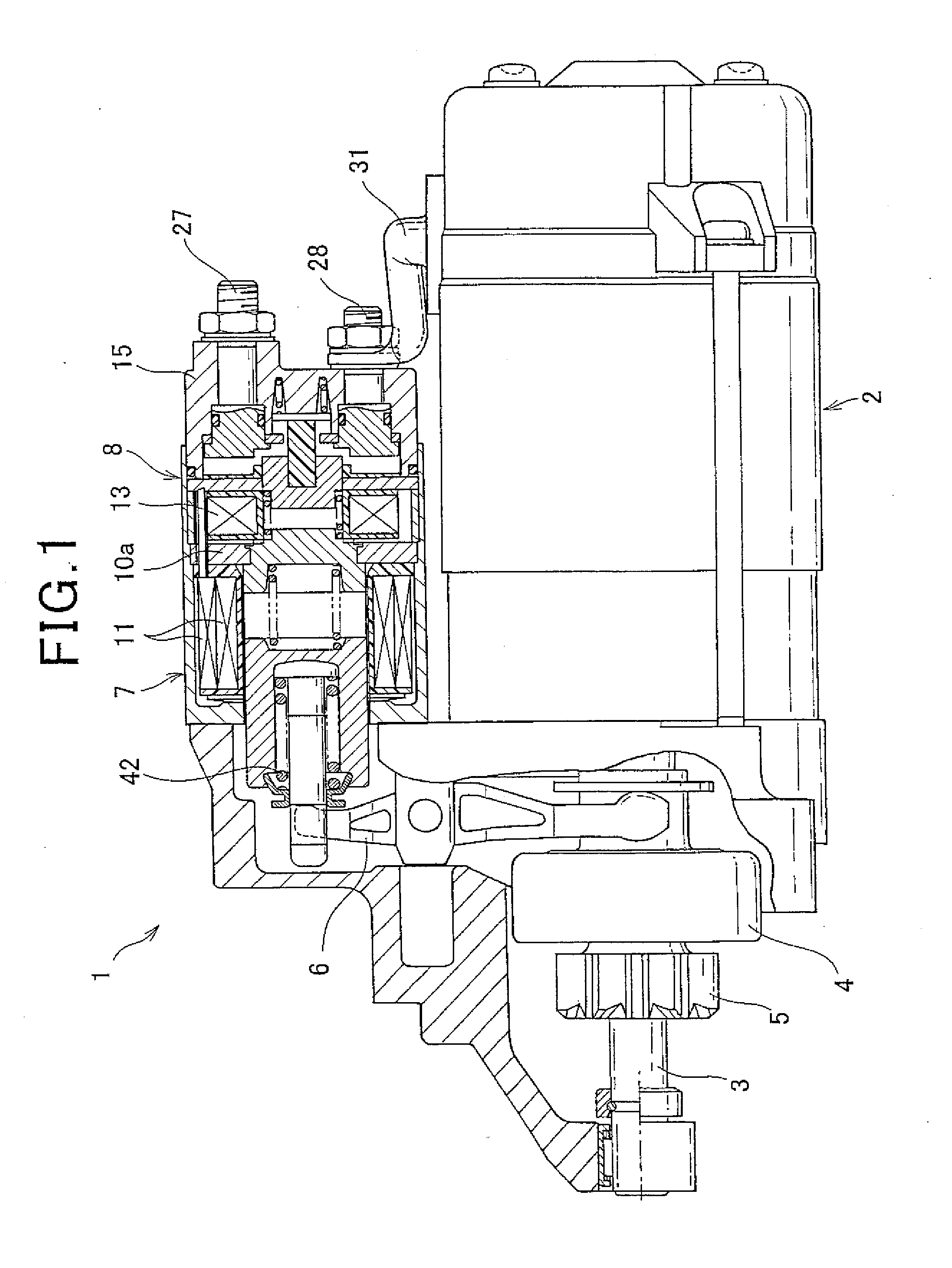

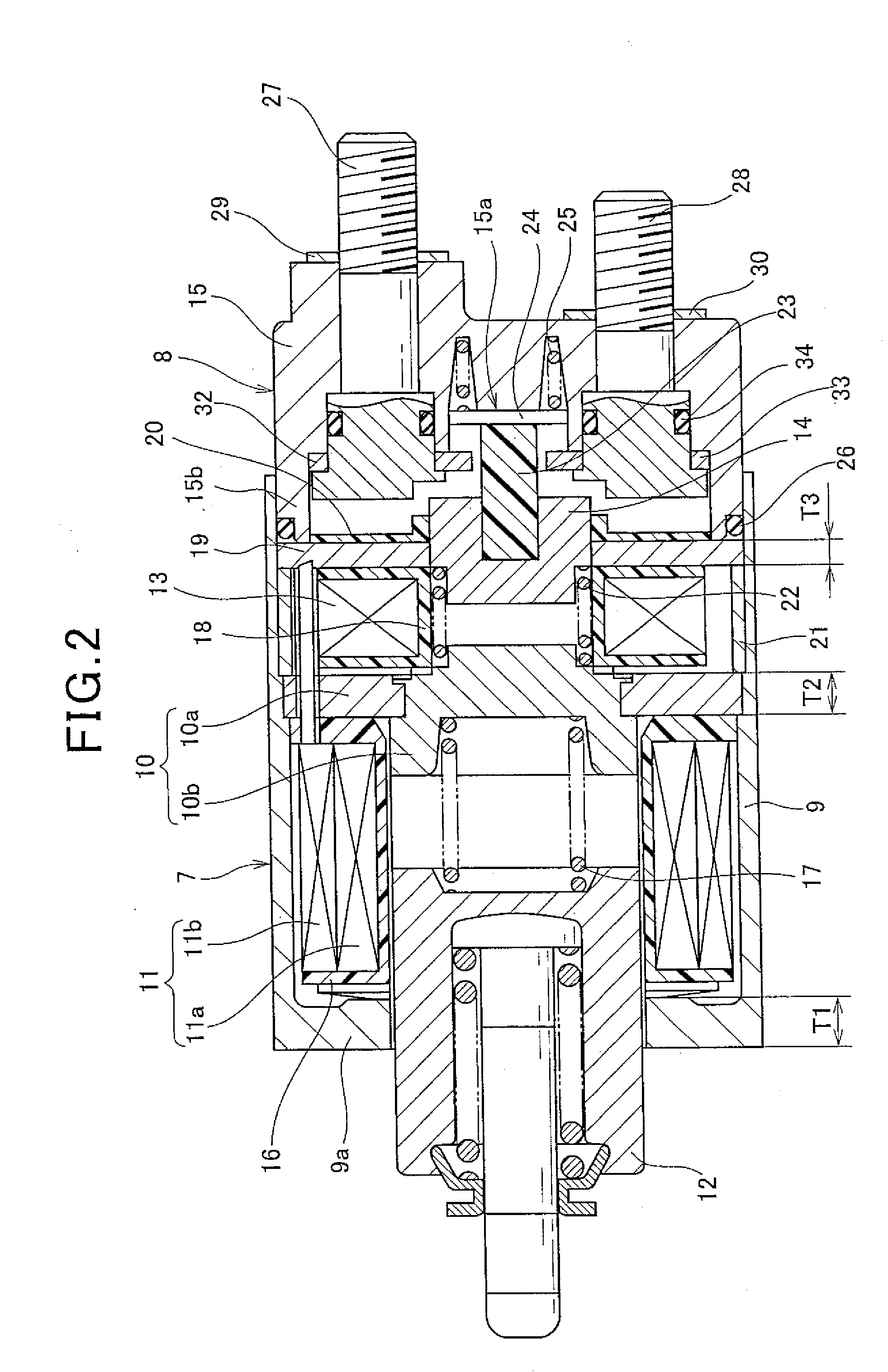

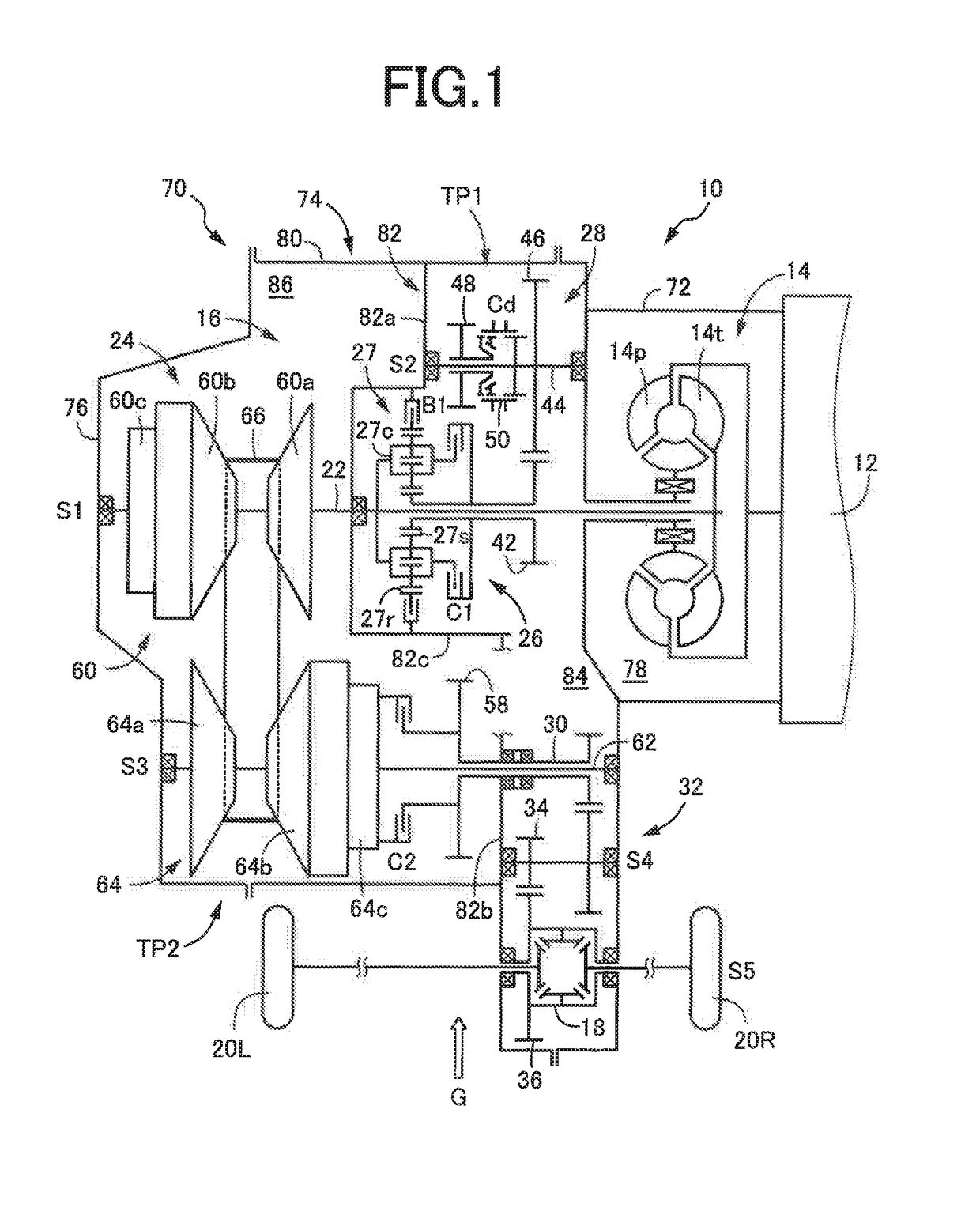

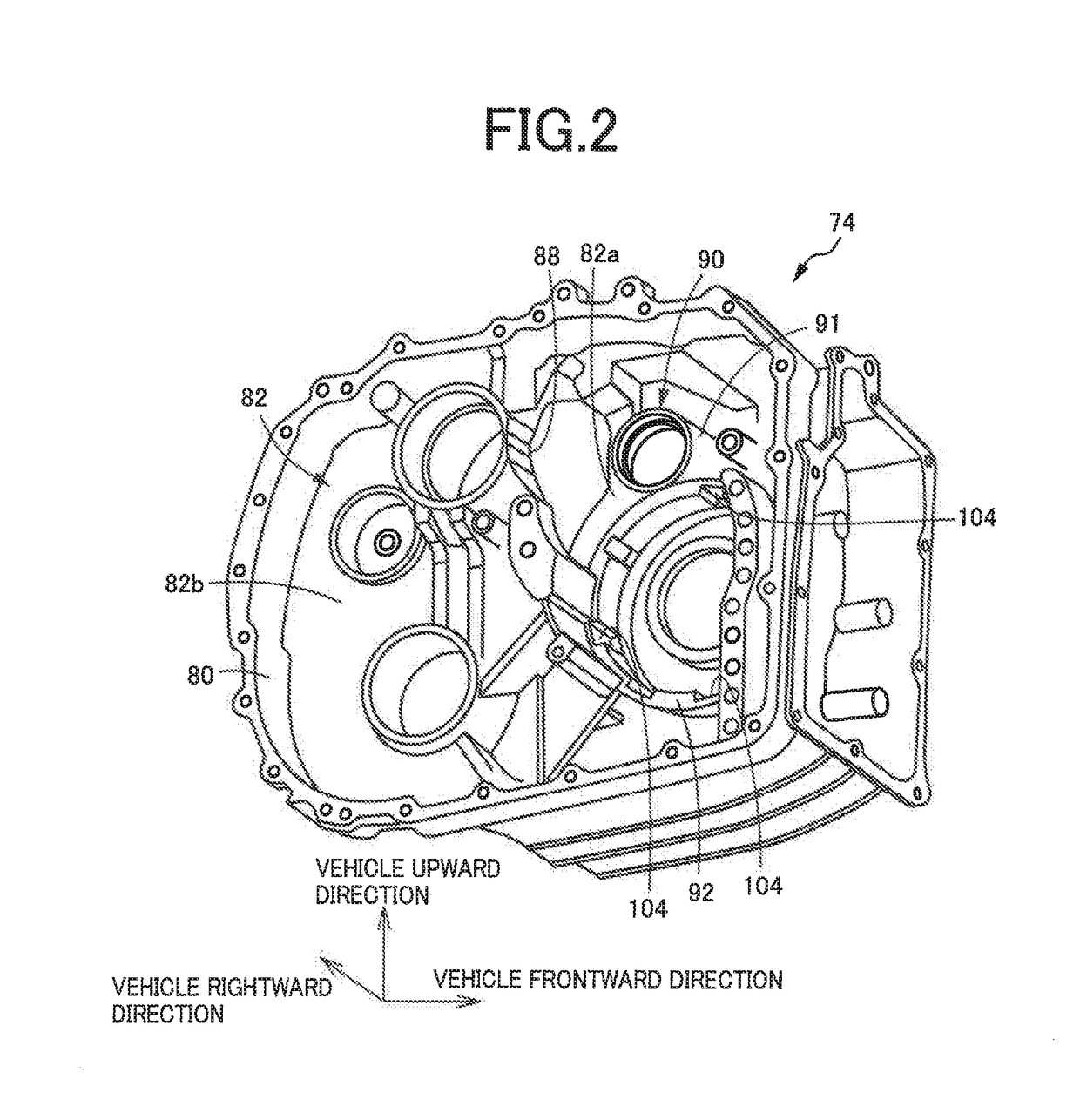

Vehicle drive apparatus

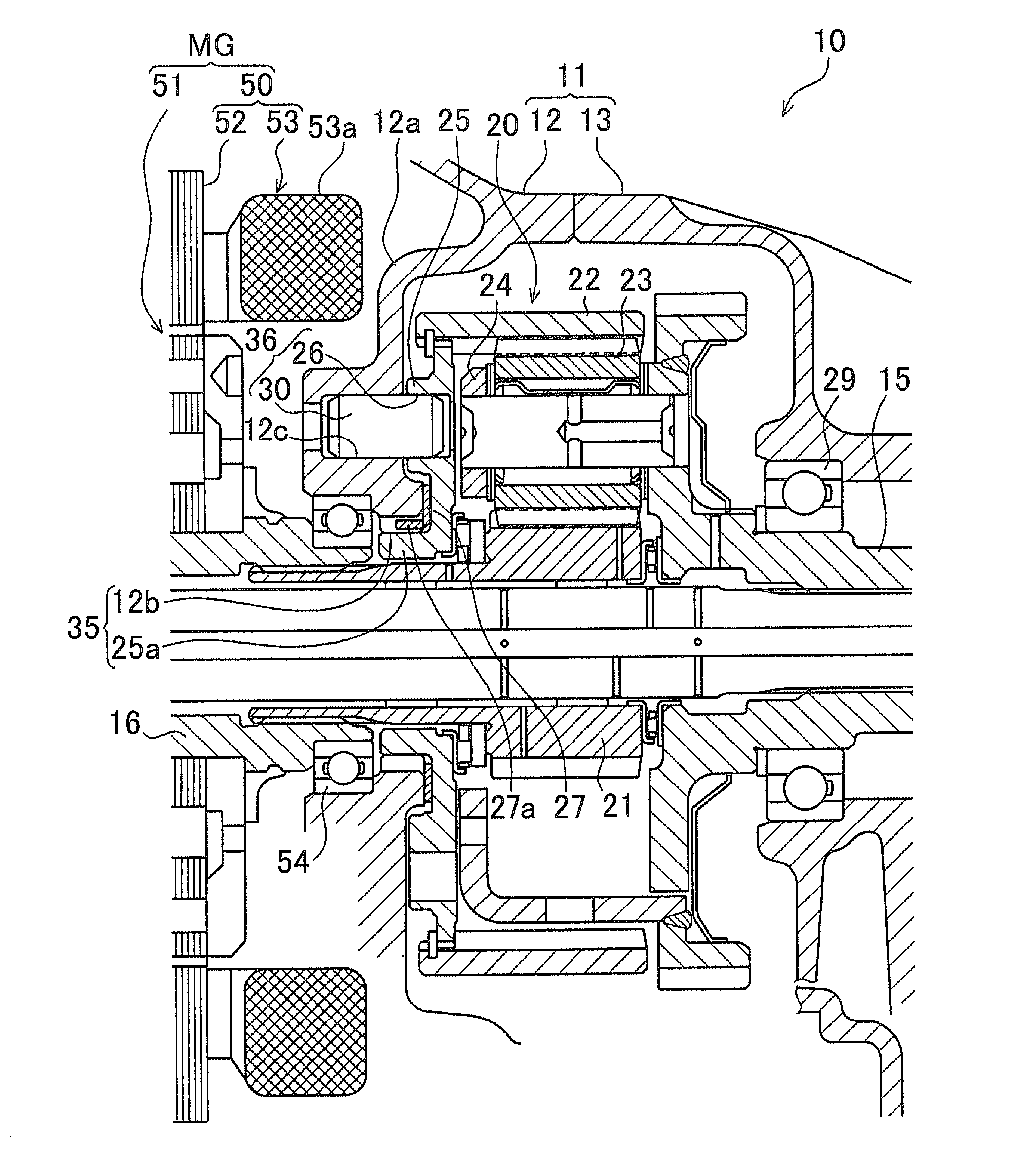

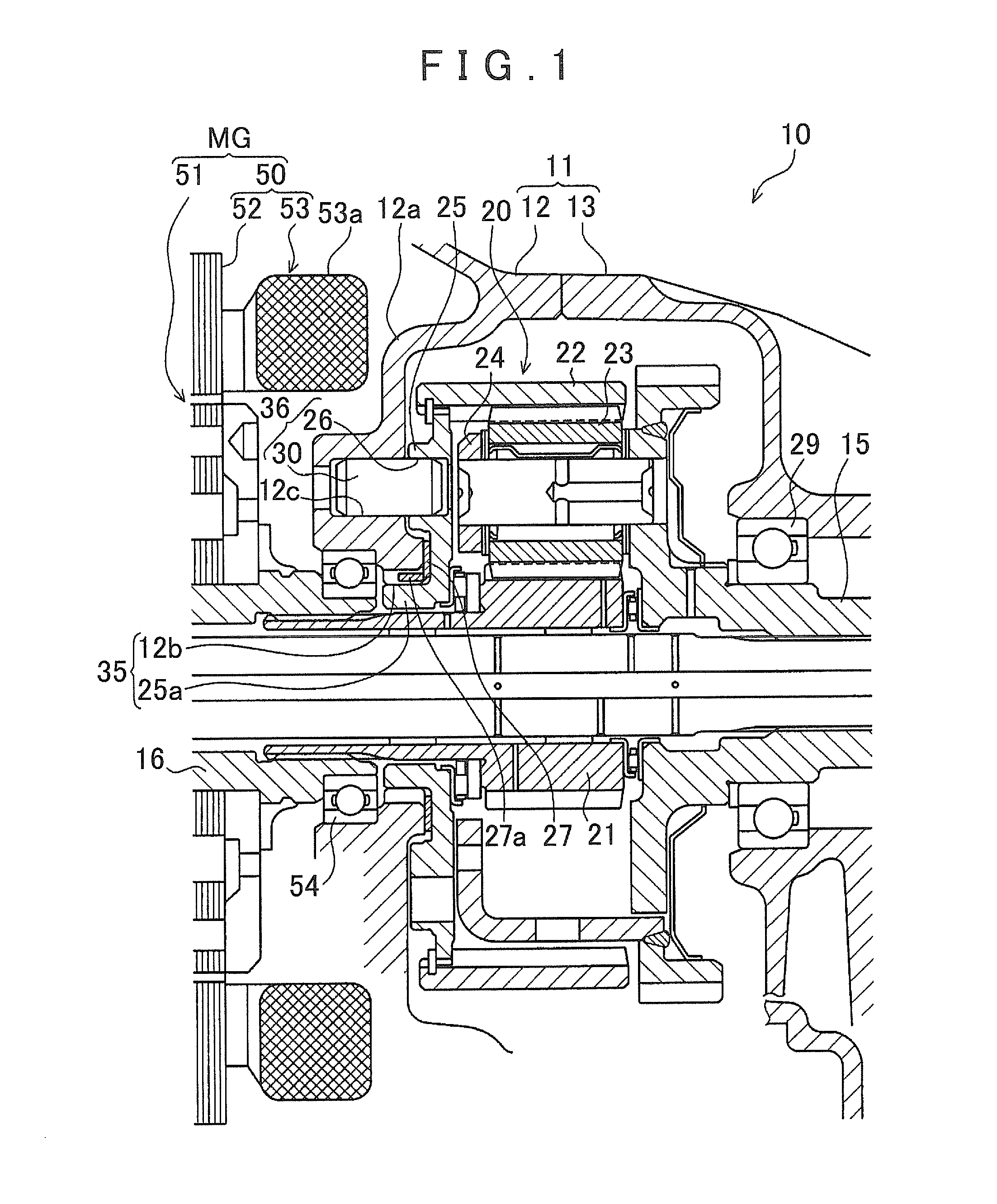

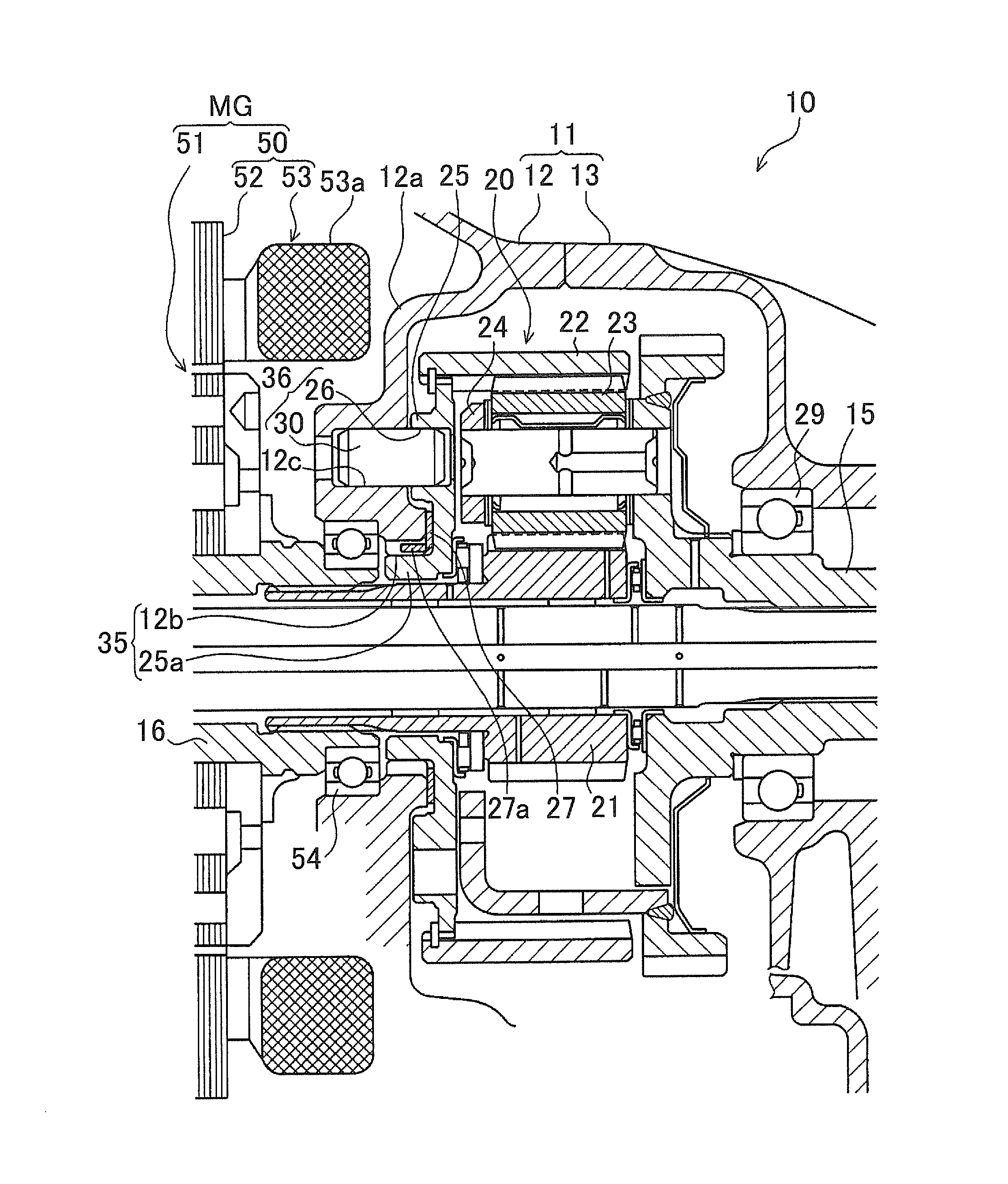

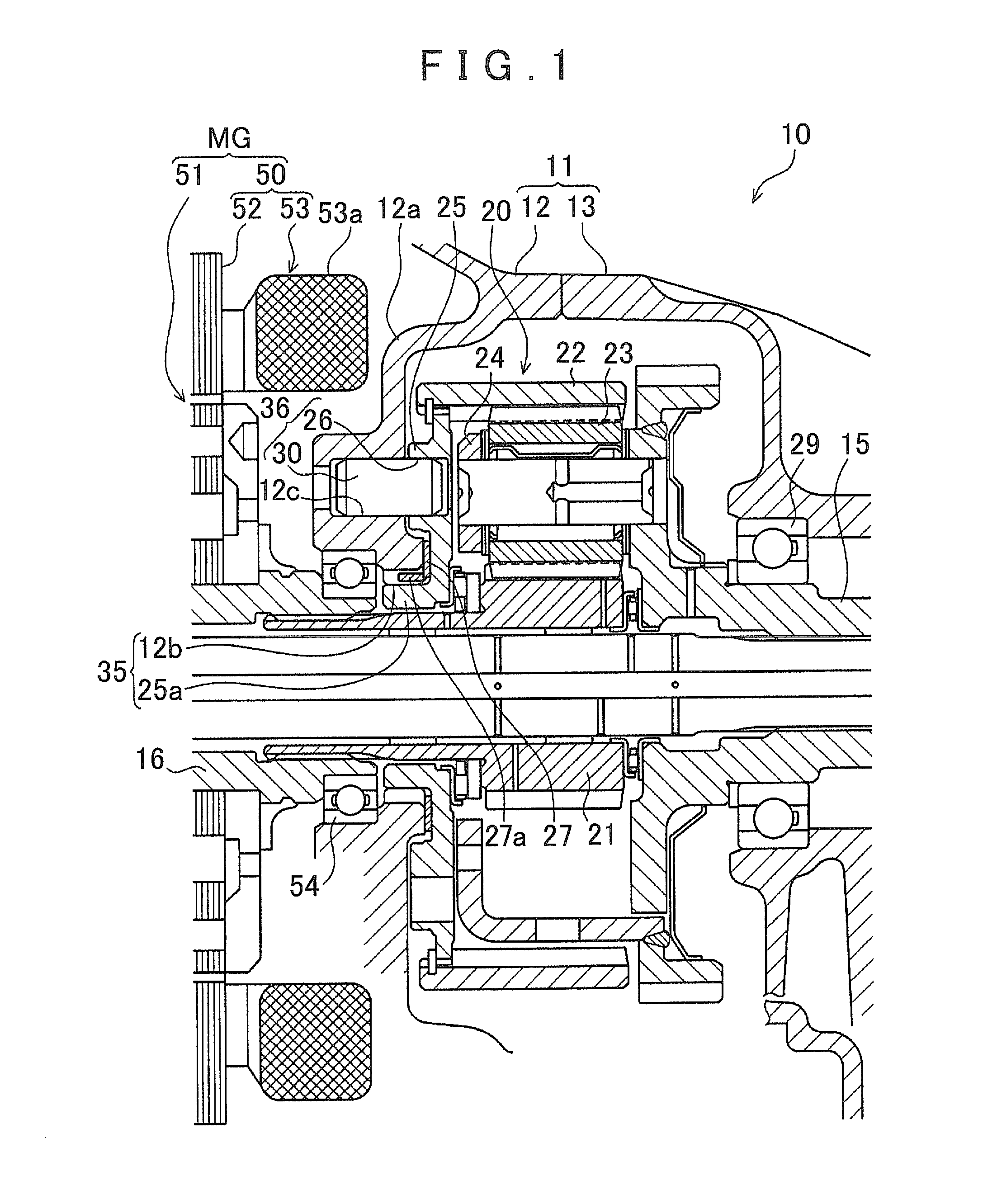

ActiveUS20130008274A1Reduction in axial sizeGear noise be reduceGear vibration/noise dampingGear lubrication/coolingMotor–generatorFlange

A vehicle drive apparatus includes a motor generator, a speed reduction mechanism connected to a rotor shaft of the motor generator, an output shaft connected to the speed reduction mechanism, an intermediate wall separating the motor generator from the speed reduction mechanism, and a bearing that is fixed to the intermediate wall and supports the rotor shaft. The motor generator, intermediate wall, speed reduction mechanism, and output shaft are disposed in this order, and a ring gear of the speed reduction mechanism is fixed. The ring gear is fixed to the intermediate wall via a ring gear flange that is positioned relative and fixed to the intermediate wall by a centering mechanism and a locking mechanism. The centering mechanism is formed by fitting a boss of the ring gear flange and the intermediate wall. The locking mechanism is disposed on an outer peripheral side relative to the centering mechanism.

Owner:AISIN AW CO LTD +1

Free-form surface gear

ActiveUS9091338B2Improve fatigue strengthIncrease contact pressureMetal-working apparatusPortable liftingContact pressureRooted tooth

A transmission gear has a tooth surface formed of a free-form surface instead of an involute surface and a root area formed of a free-form surface instead of a trochoid surface. With such a transmission gear, the fatigue strength against contact pressure can be increased by reducing the Hertzian stress in the area around the meshing point of the tooth surface. The tooth surface is formed of a free-form surface in which the smallest radius of curvature in an area around a mating pitch point is maximized, and the fatigue strength against bending can be increased by reducing the bending stress at a tooth root portion of the bottom land. In addition, the gear noise can be reduced. The bottom land is formed of a free-form surface in which the smallest radius of curvature in an area around a tooth root is maximized.

Owner:O OKA CORP

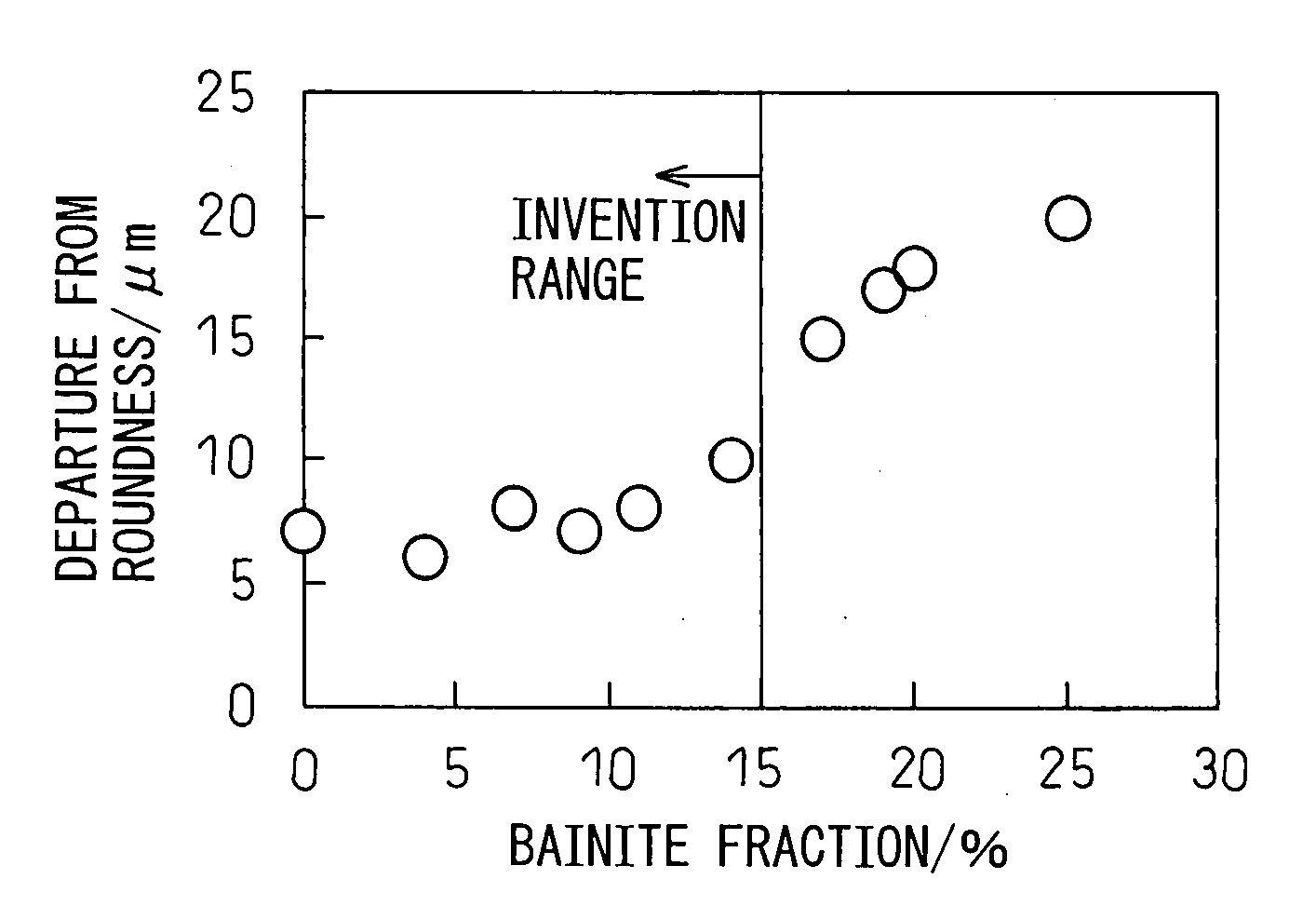

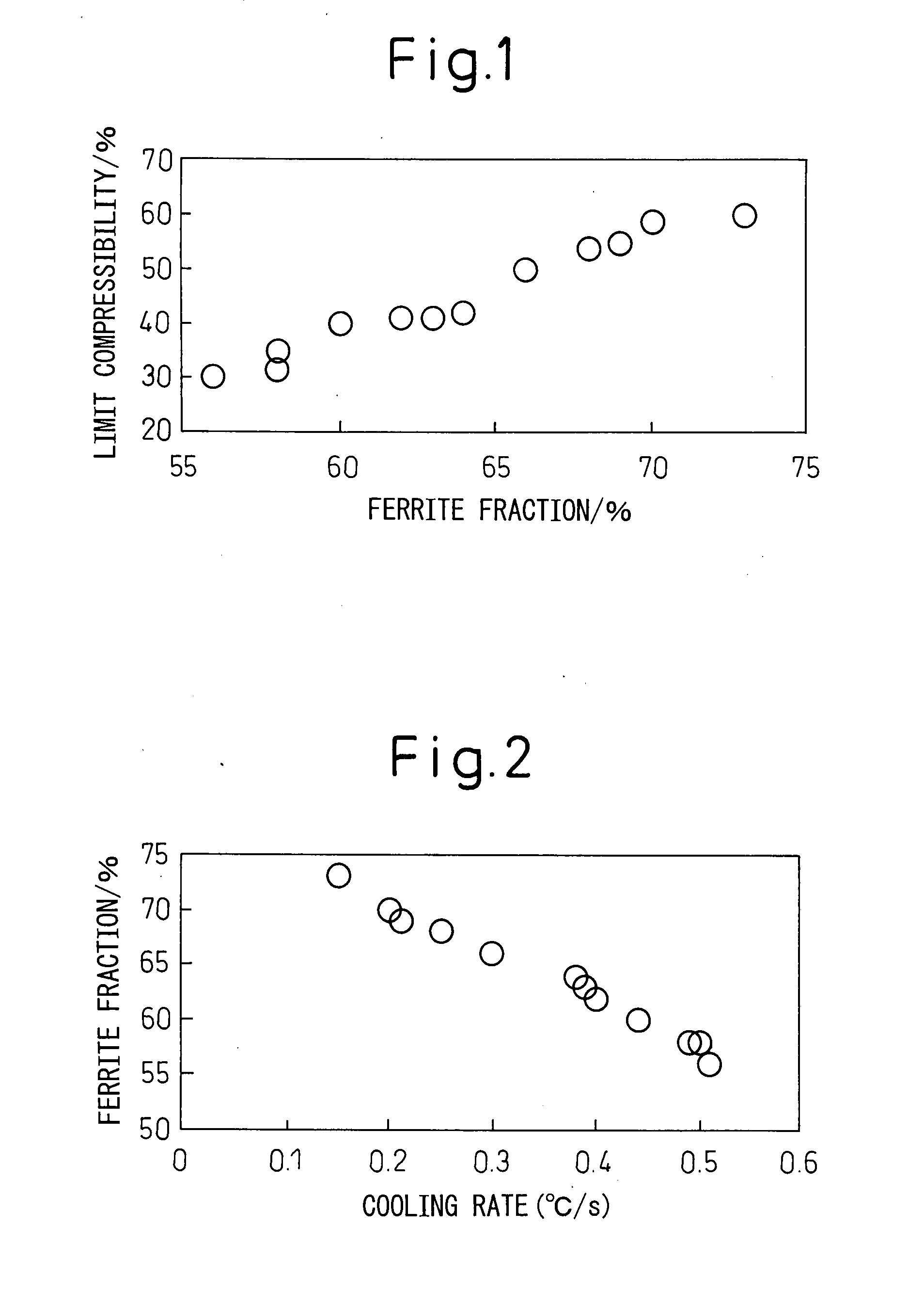

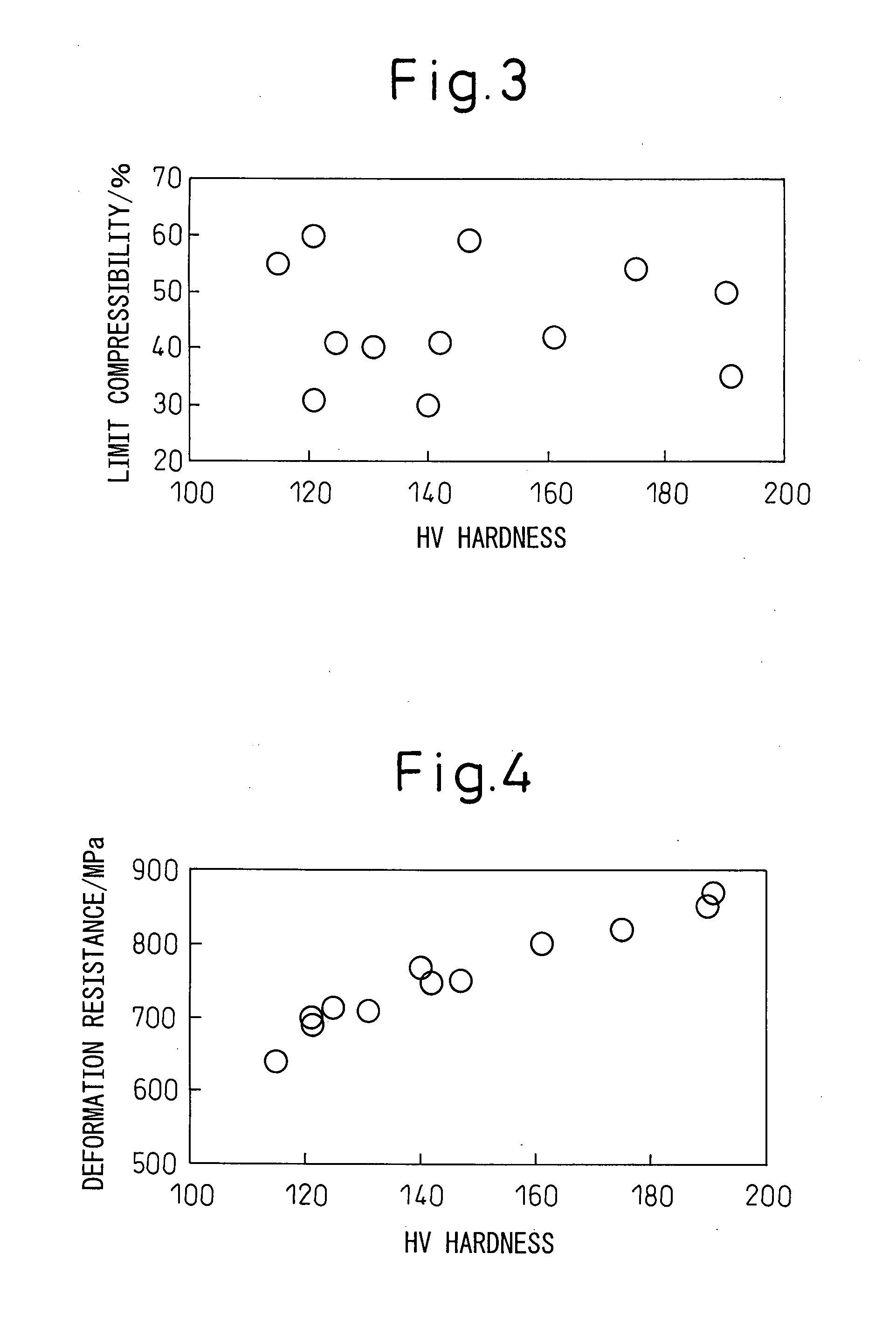

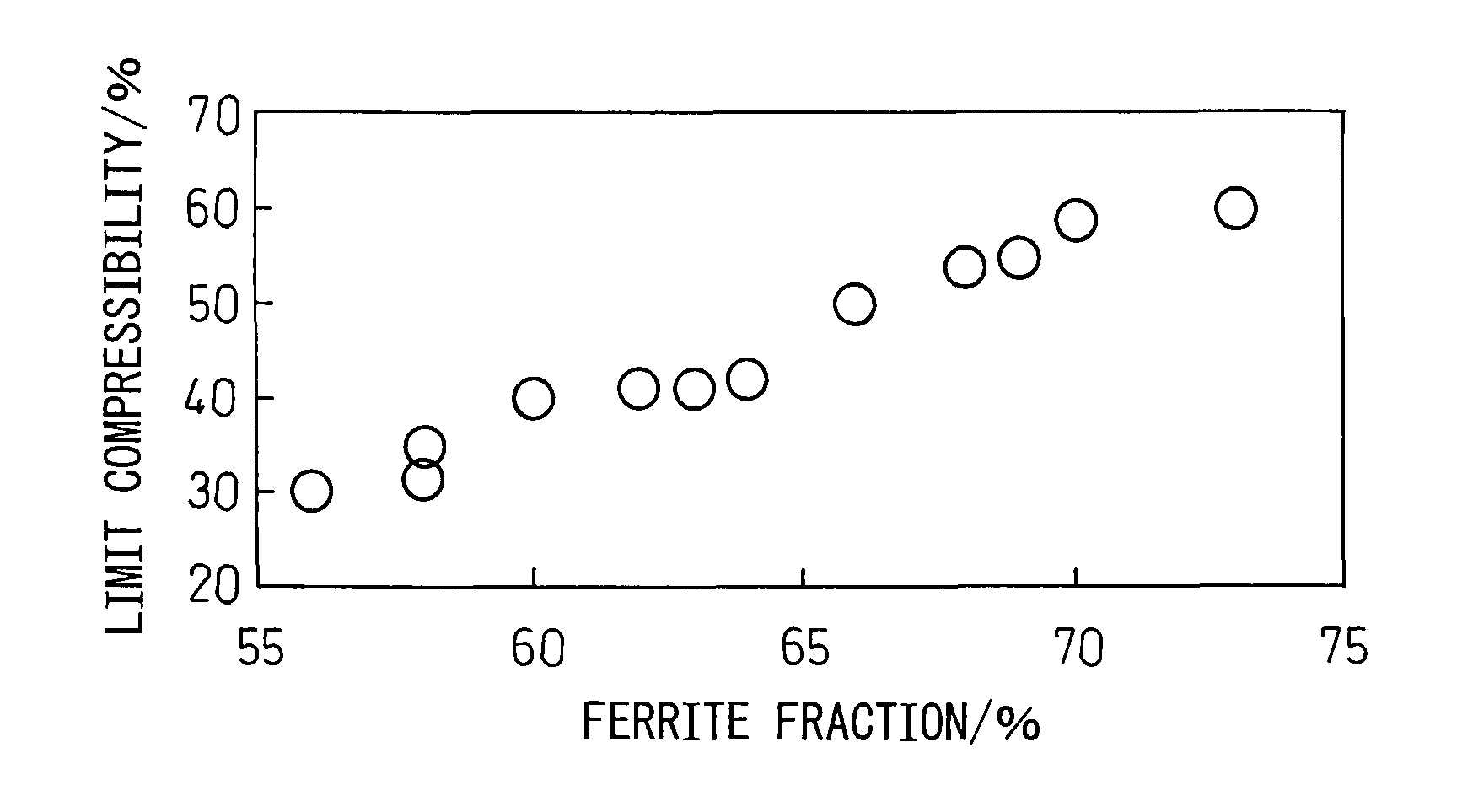

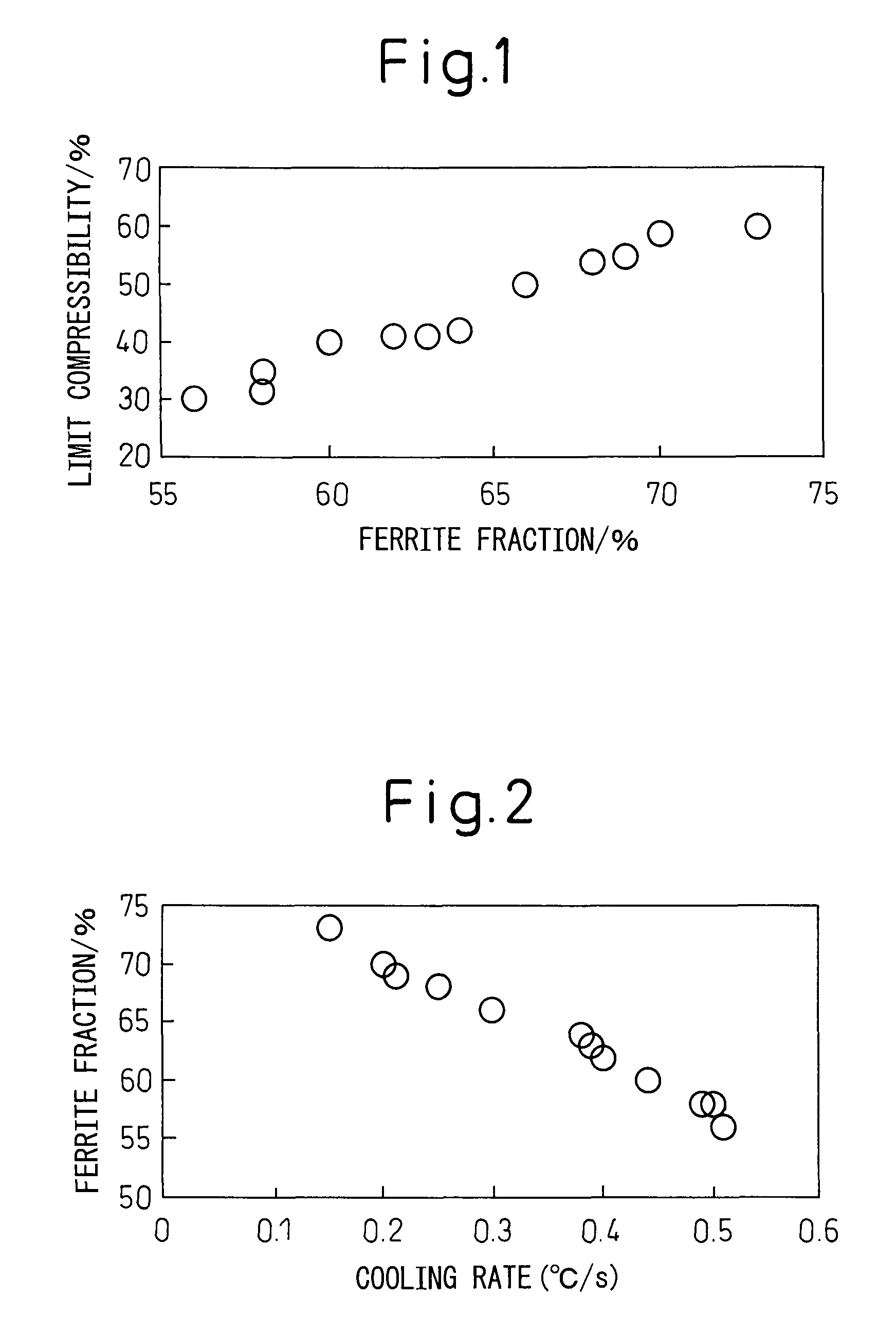

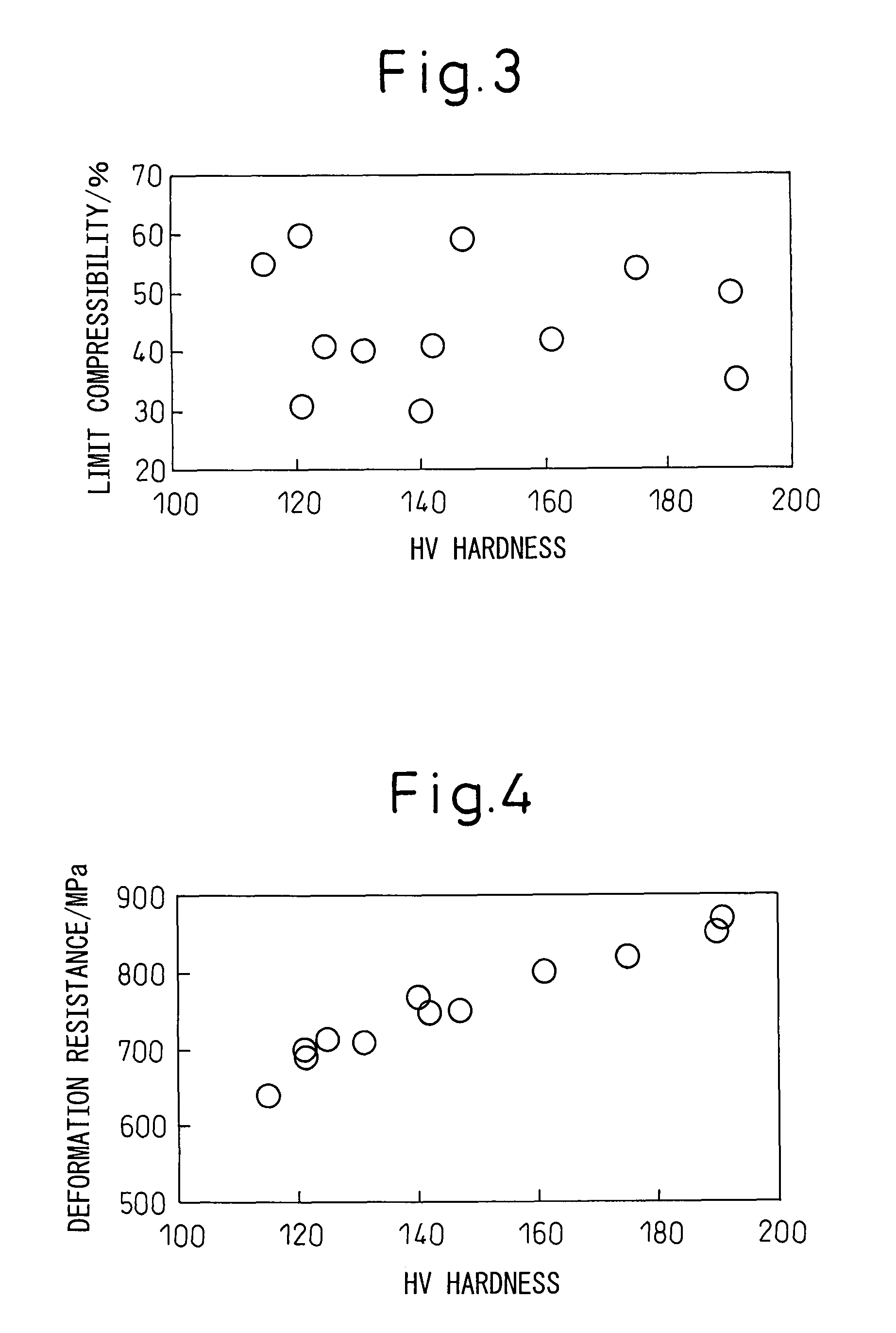

Case-hardening steel excellent in cold forgeability and low carburization distortion property

This invention provides a case-hardening steel excellent in cold forgeability and low carburization distortion property that exhibits low deformation resistance and high limit compressibility when cold, namely, a case-hardening steel excellent in cold forgeability and low carburization distortion property comprising, in mass %, C: 0.07% to 0.3%, Si: 0.01% to 0.15%, Mn: 0.1% to 0.7%, P: 0.03% or less, S: 0.002% to 0.10%, Al: 0.01% to 0.08%, Cr: 0.7% to 1.5%, Ti: 0.01% to 0.15%, B: 0.0005% to 0.005%, N: 0.008% or less, and the balance of Fe and unavoidable impurities, and having a metallographic structure comprising 65% or greater of ferrite and 15% or less of bainite.

Owner:NIPPON STEEL CORP

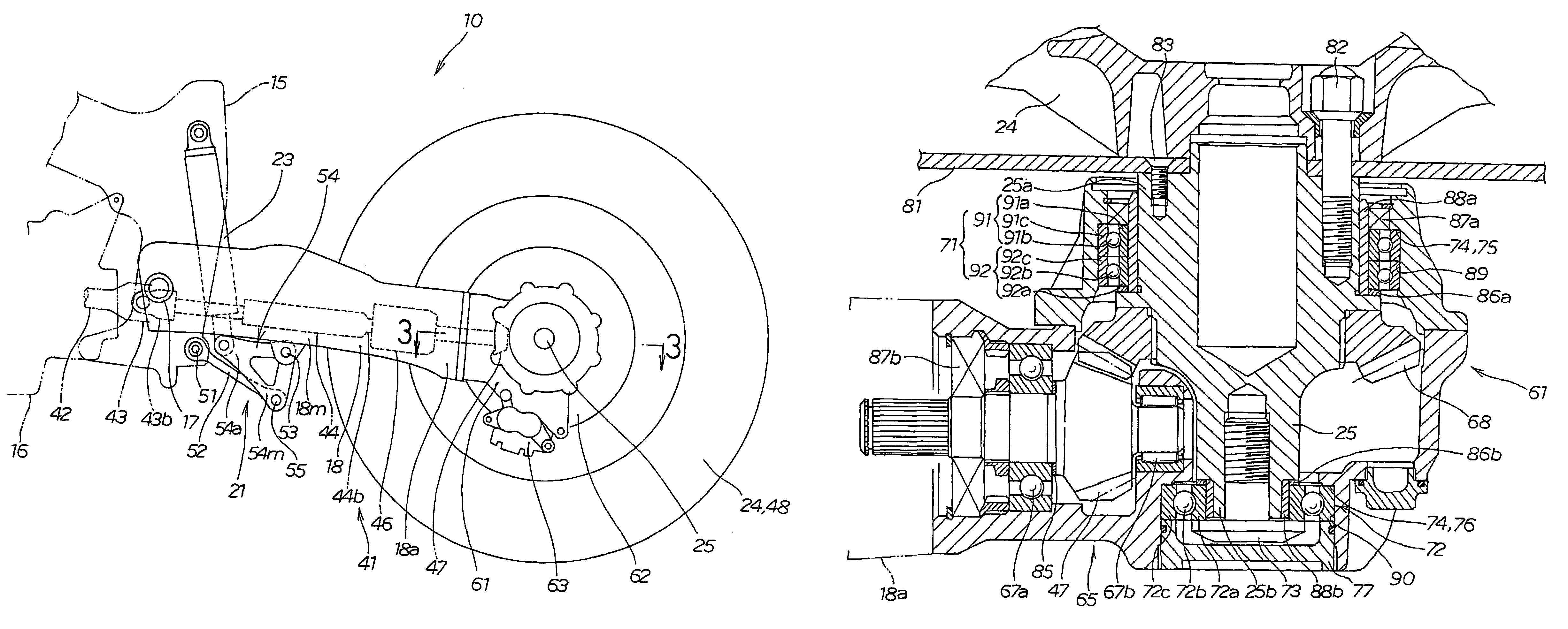

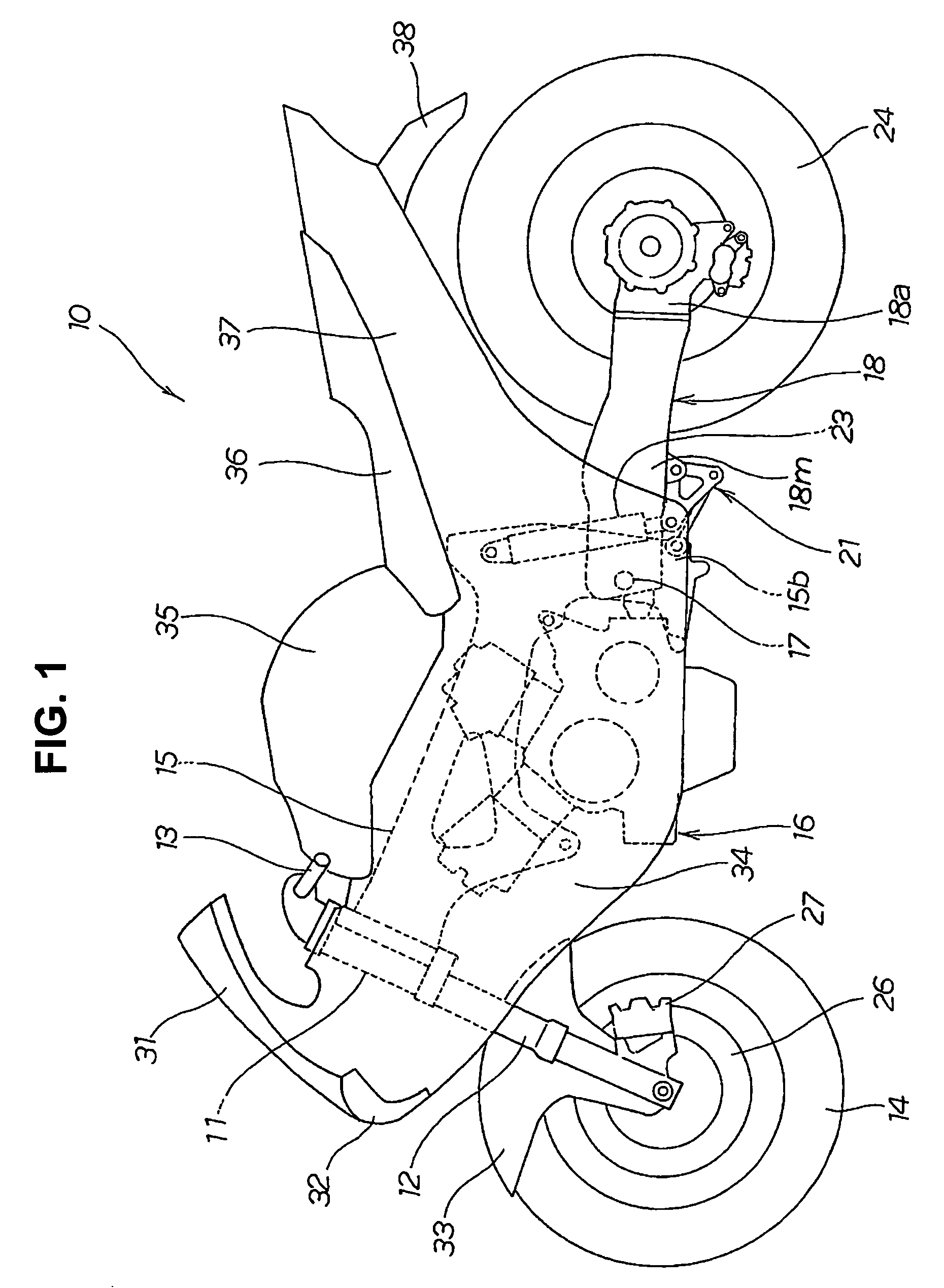

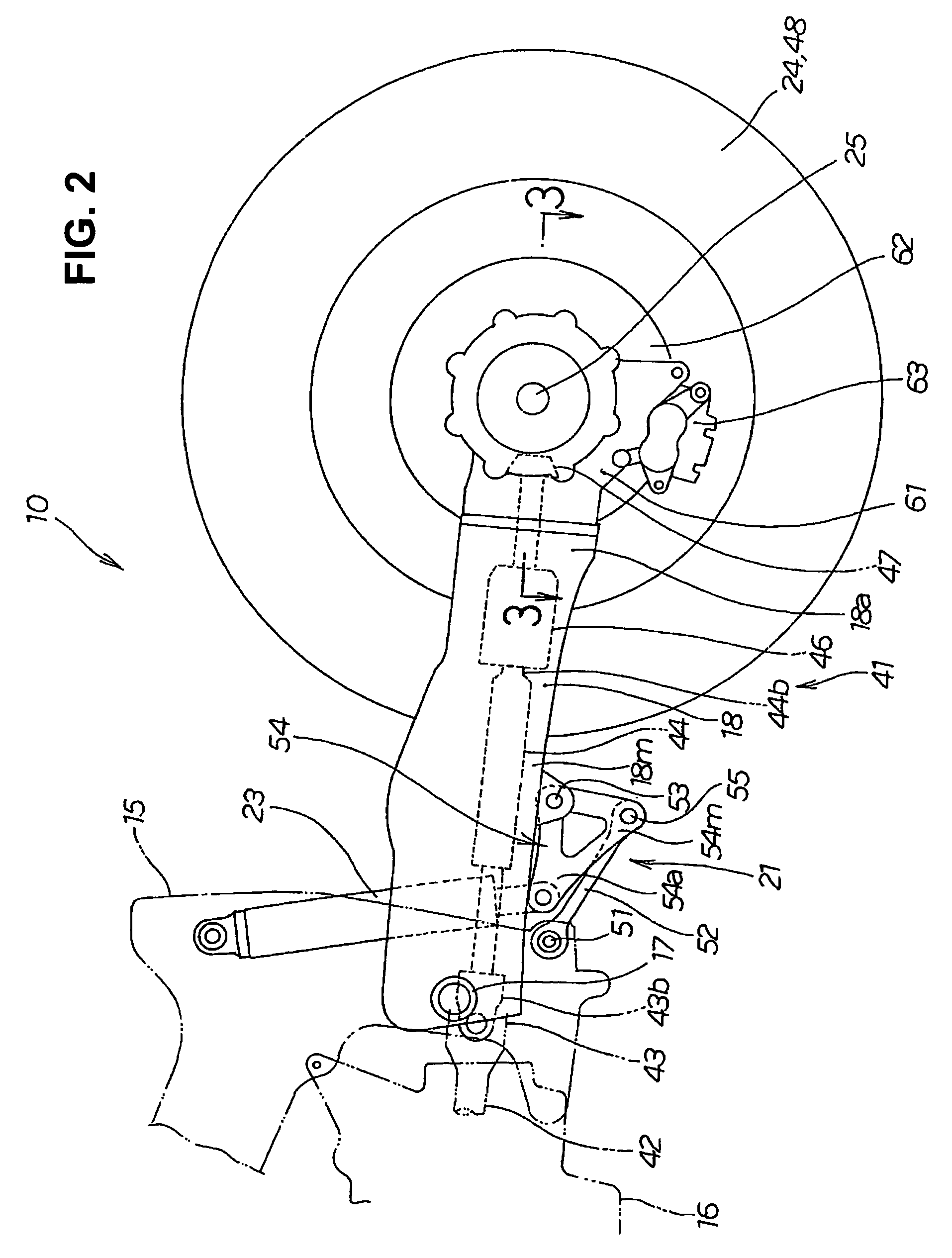

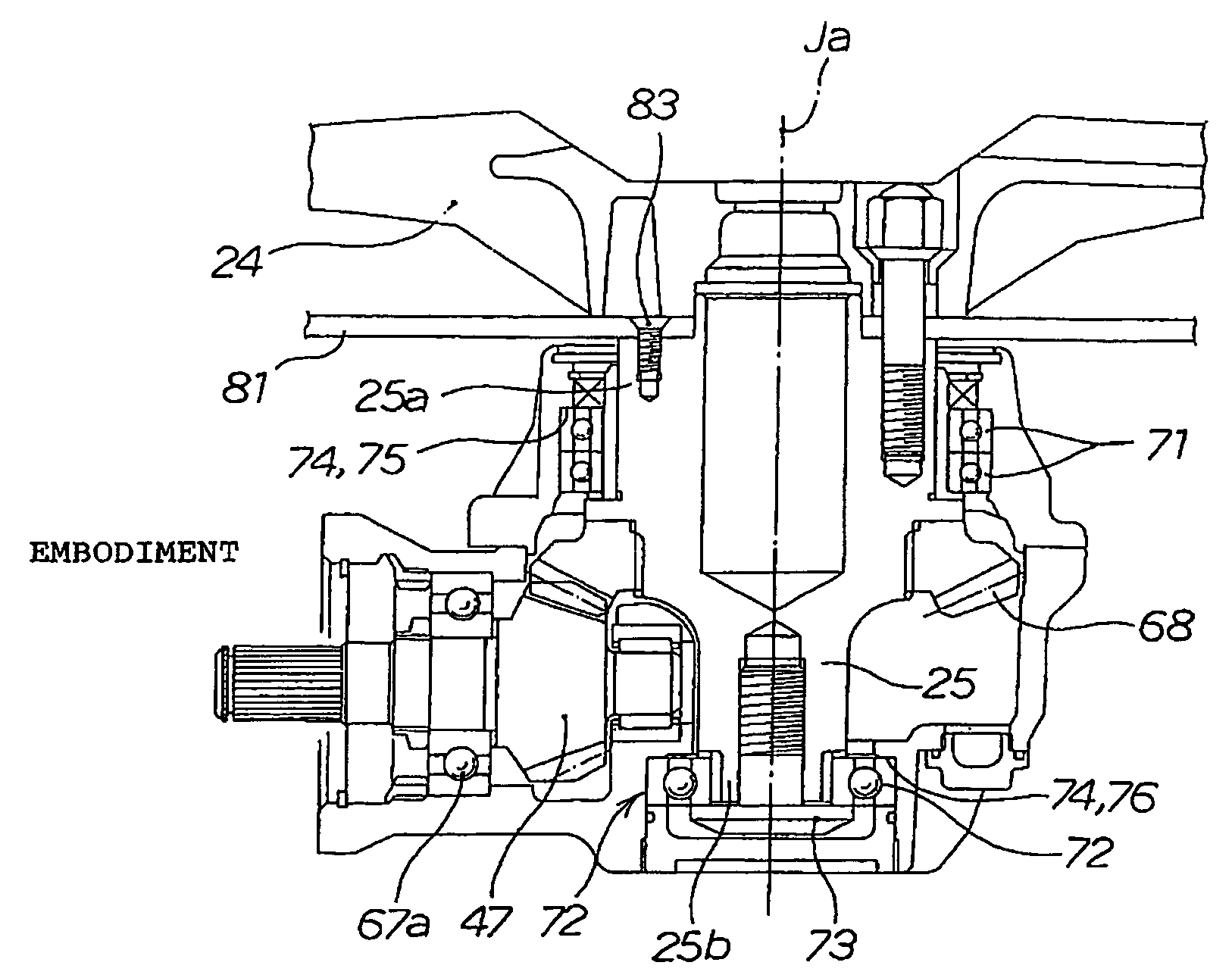

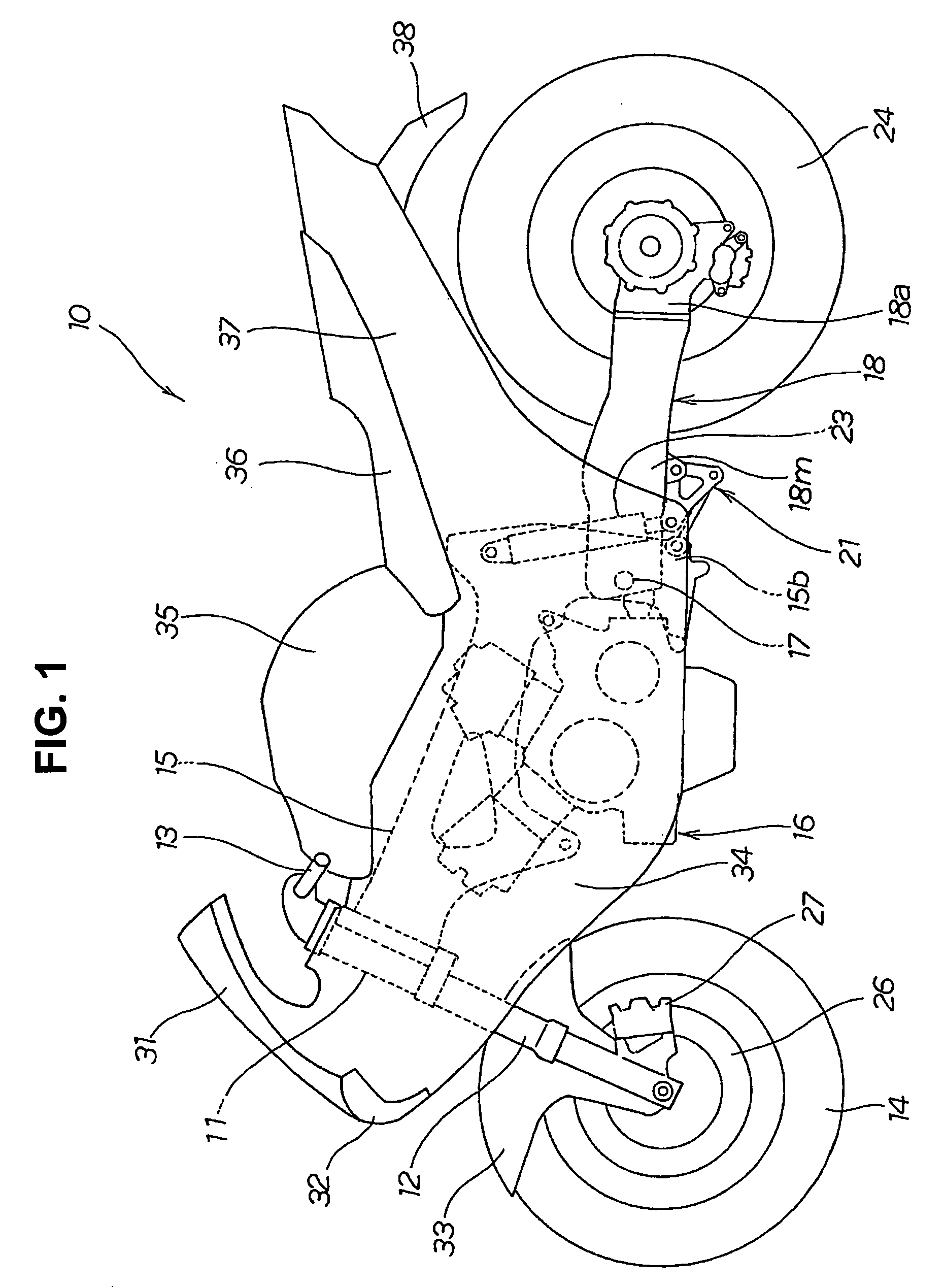

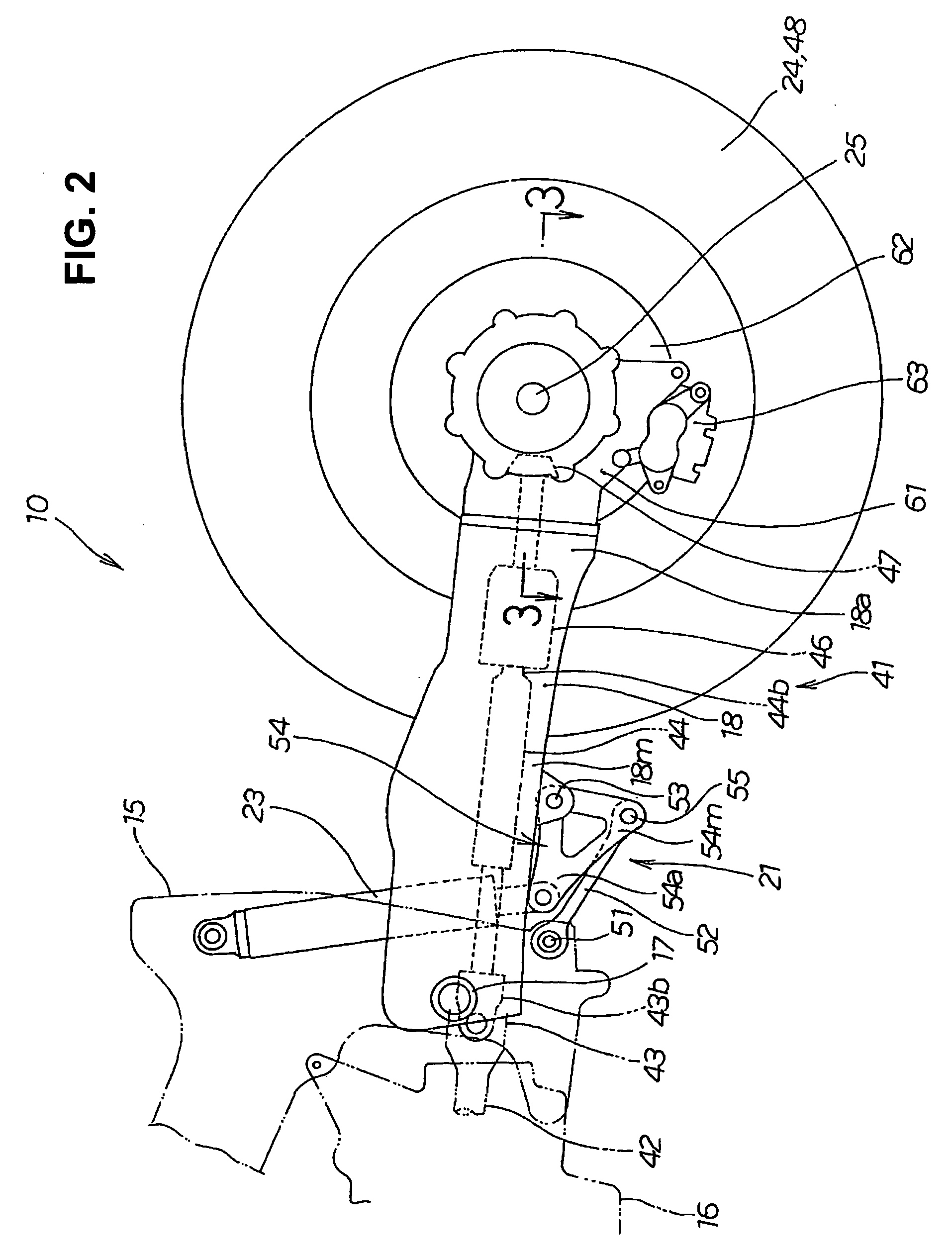

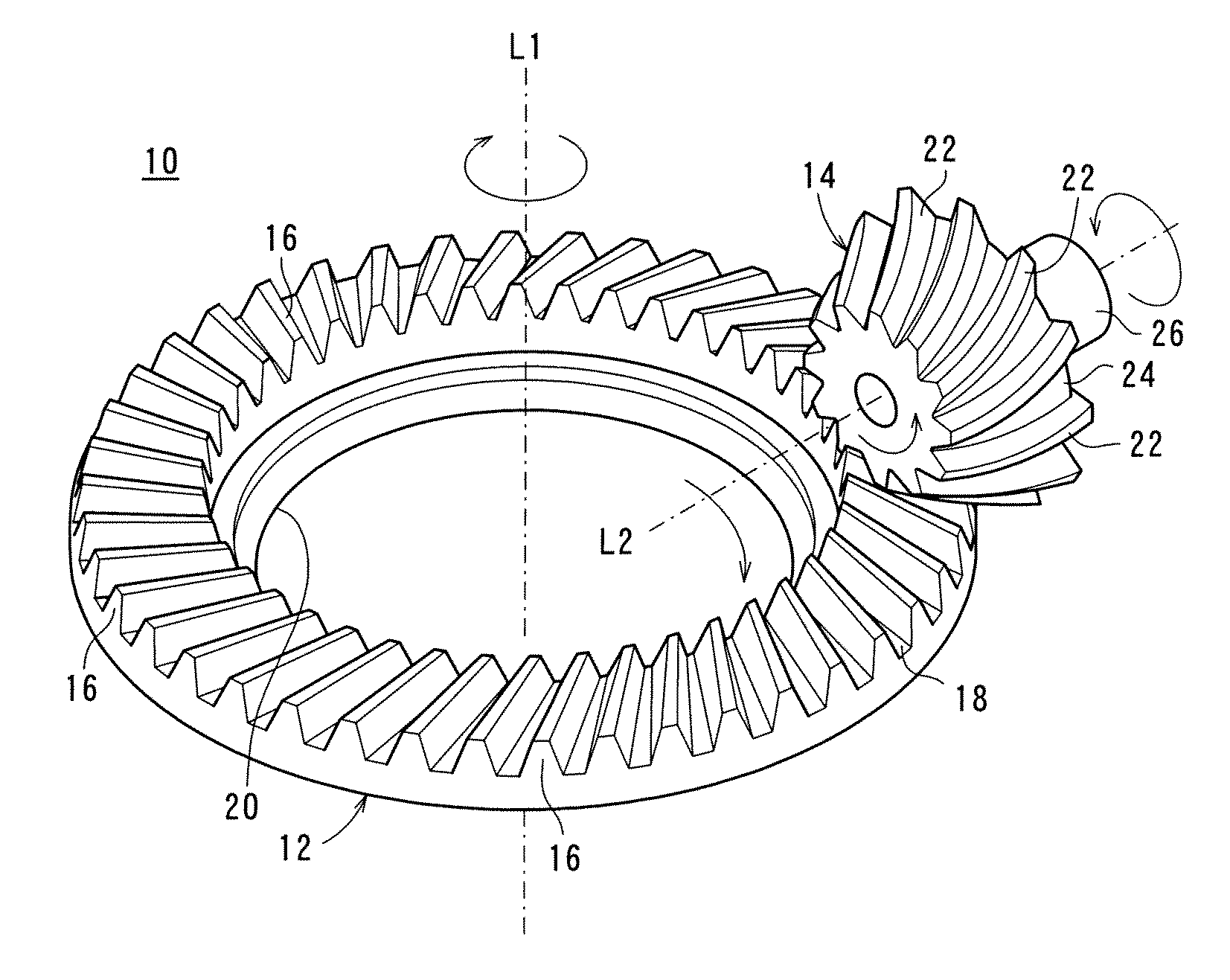

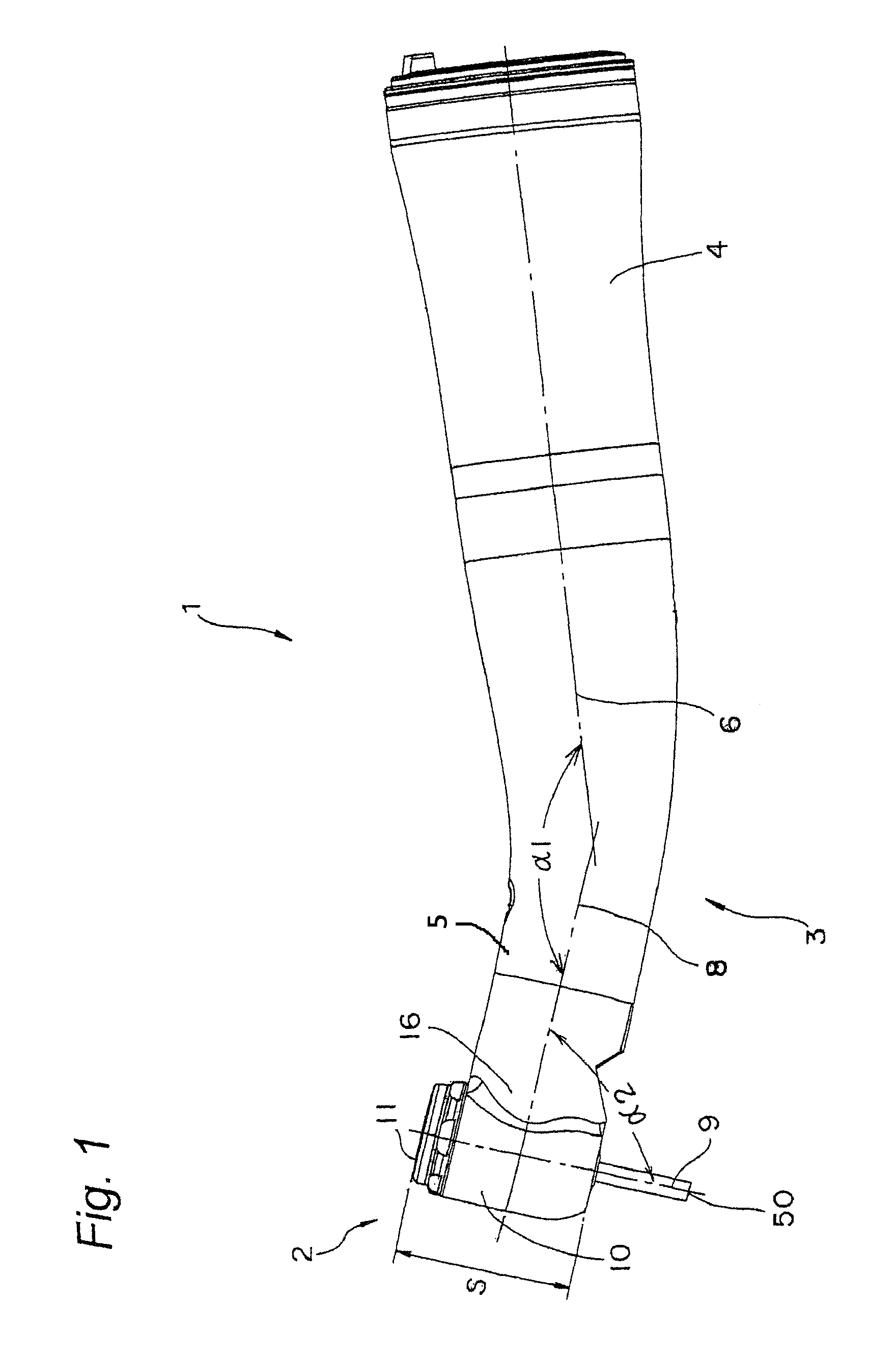

Final gear transmission mechanism for a motorcycle, and motorcycle incorporating same

A motorcycle includes a swing arm, a rear wheel mounted on a leading end of the swing arm, a drive shaft disposed in the swing arm, and a final gear transmission mechanism interposed between the drive shaft and the rear wheel. The final gear transmission mechanism includes a gear case mounted on the leading end of the swing arm for supporting a rear axle; a first end bearing and a second end bearing for supporting a first end and a second end of the rear axle, respectively, a ring gear mounted on the rear axle for transmitting the rotary drive force of an engine to the rear axle; a holding portion for holding the first end of the rear axle in the axial direction of the rear axle; and a fastening member for fastening the second end bearing to the second end of the rear axle.

Owner:HONDA MOTOR CO LTD

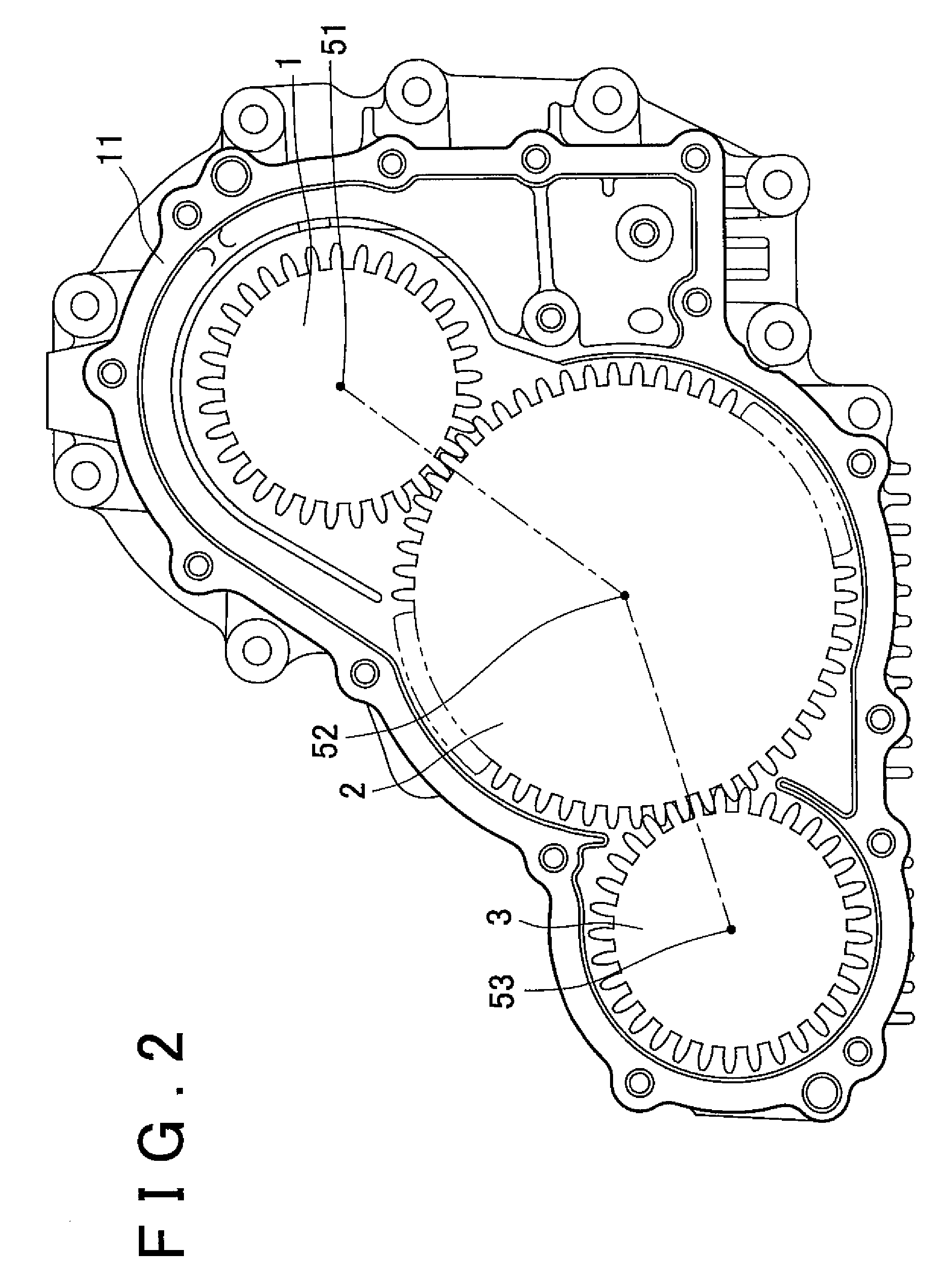

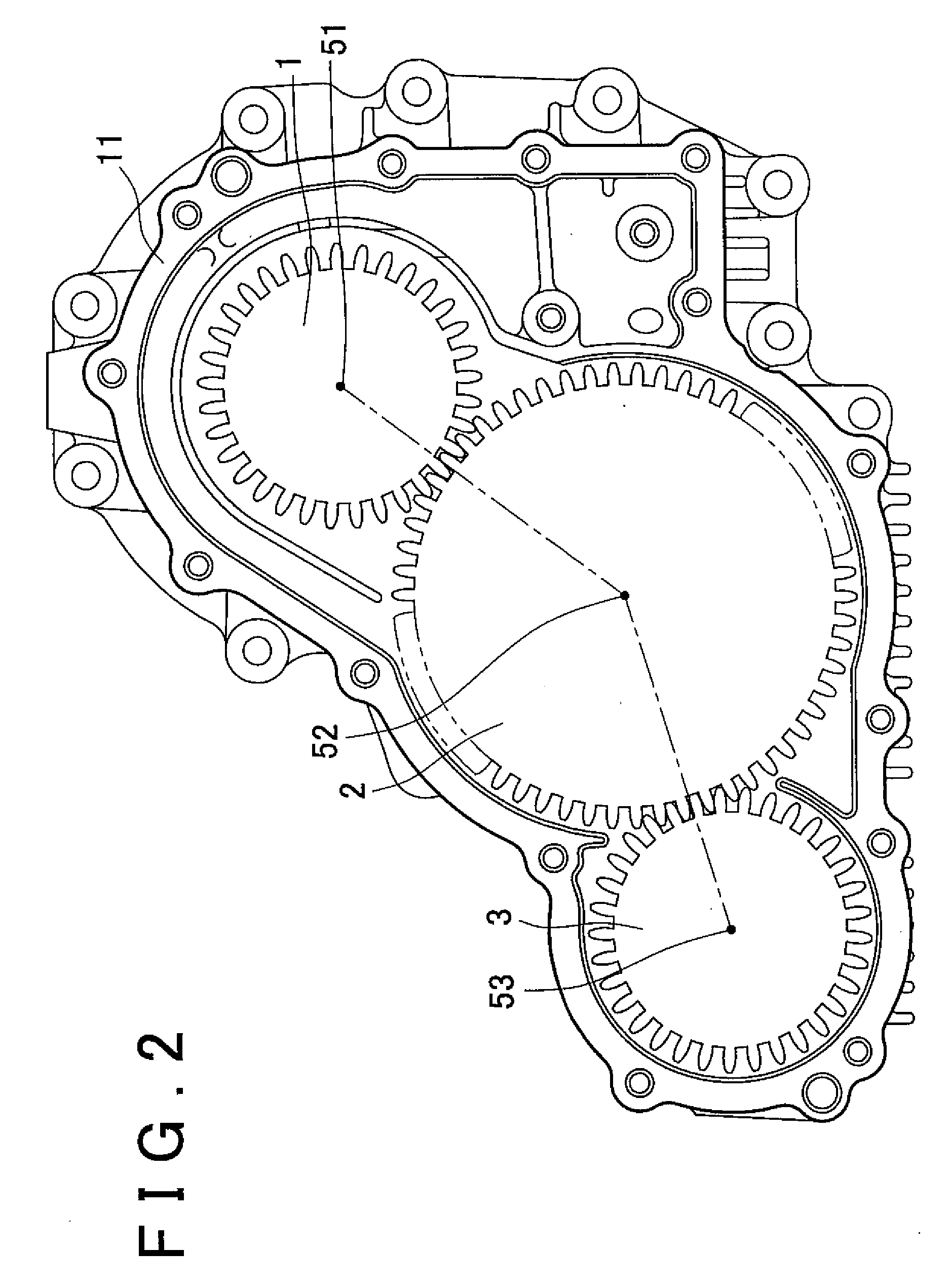

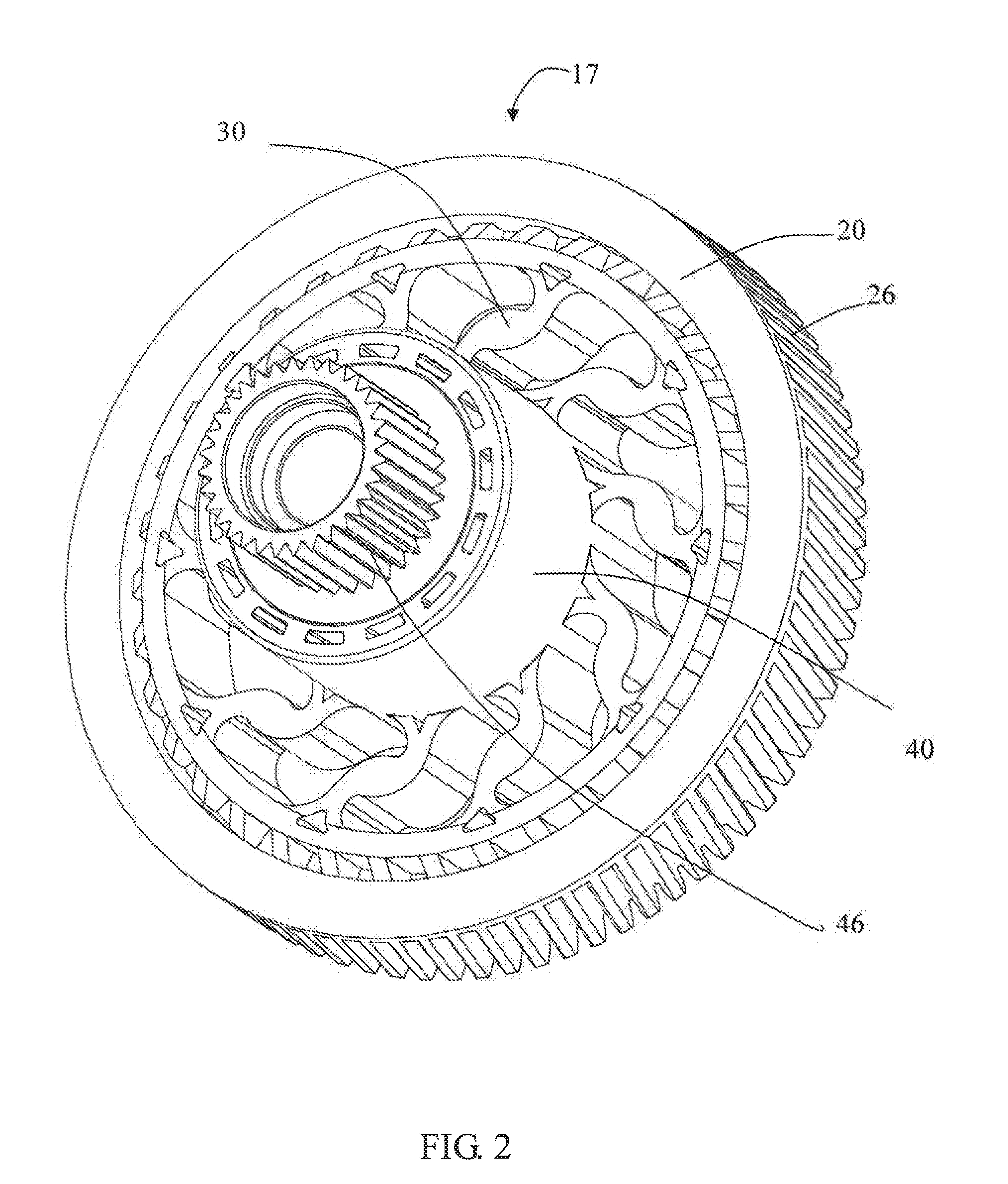

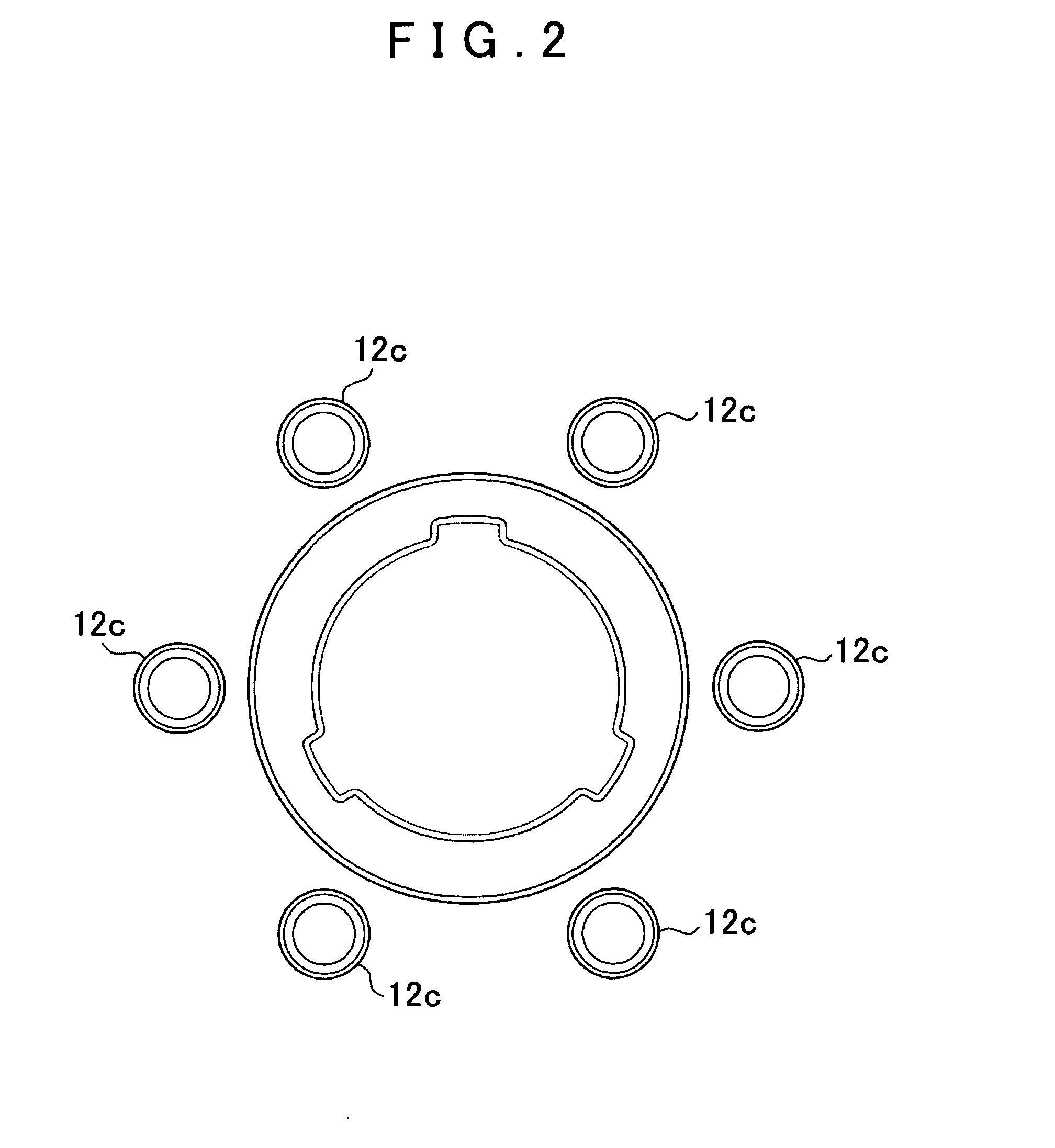

Planetary gear unit

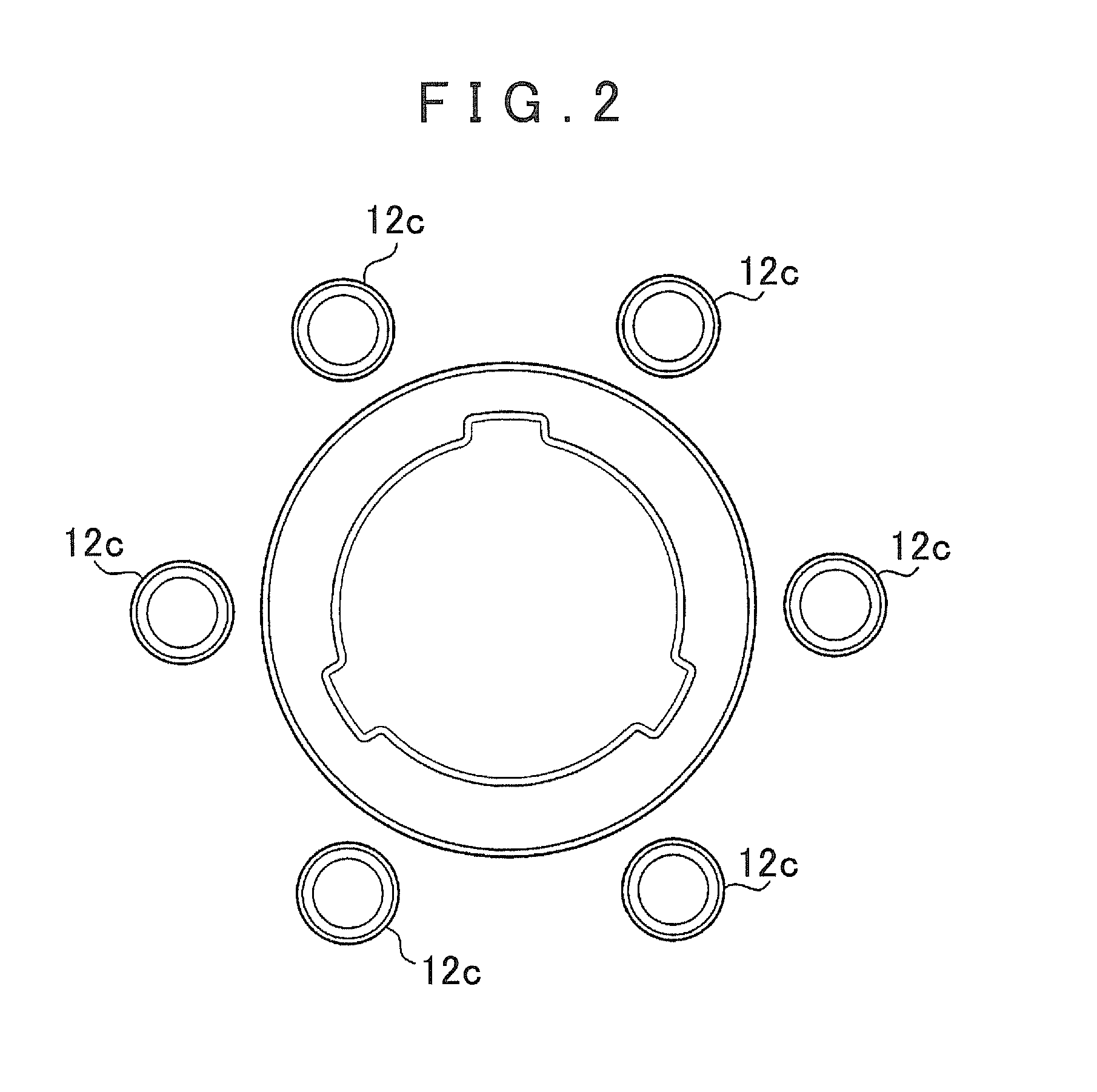

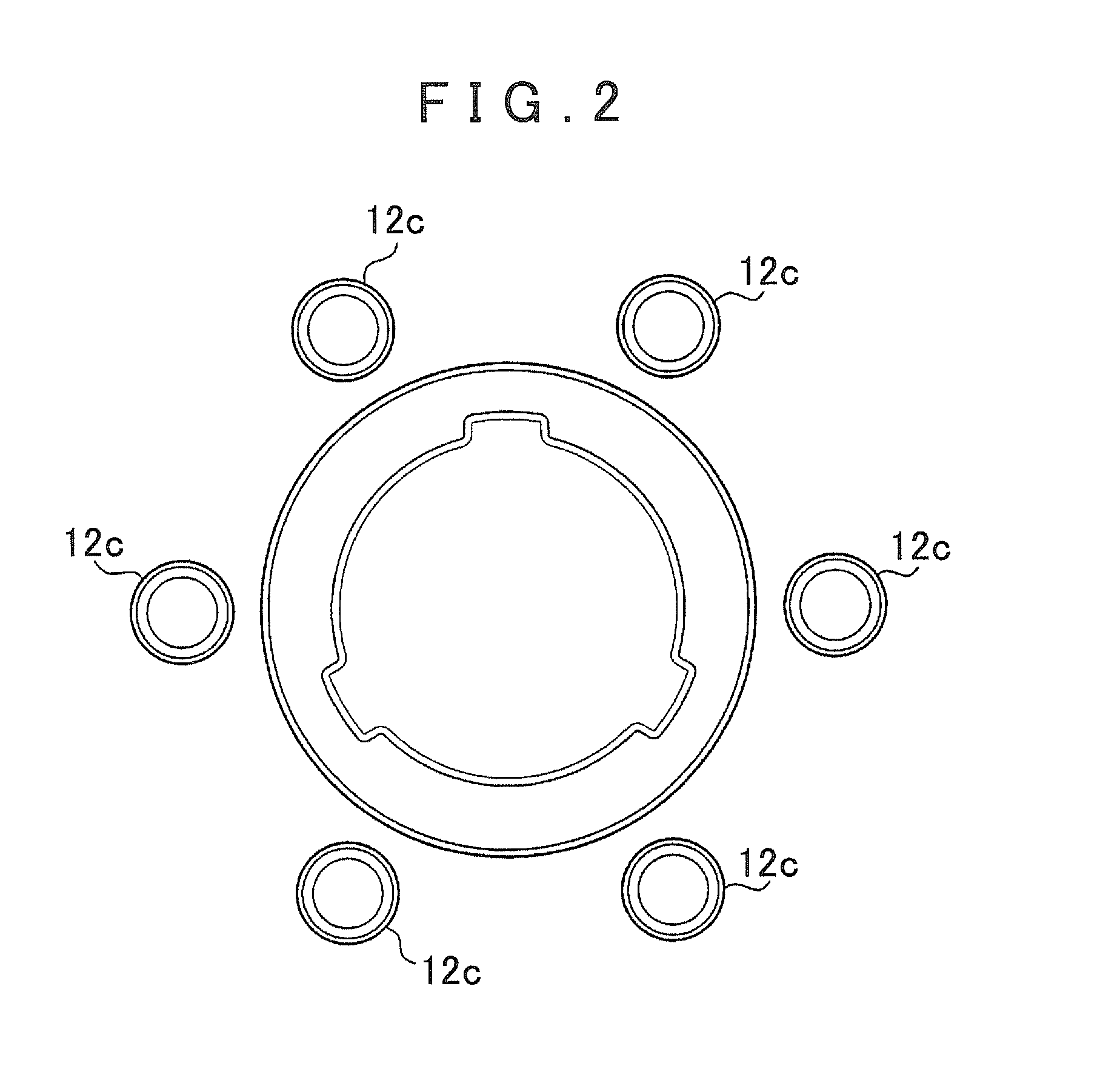

ActiveUS20130072345A1Improve machining accuracyReduce gear noiseGearboxesGearing detailsFlangePlanet

A planetary gear unit inside a case includes coaxial sun and ring gears, a planetary pinion gear that meshes with the sun and ring gears, and a carrier that holds the planetary pinion gear, the ring gear being fixed with respect to the case, and a flange disposed inward of the ring gear. The ring gear is fixed to a case wall, via the flange, the wall extending radially inward, and the flange being prevented from rotating with respect to the wall by a rotation prevention mechanism. The rotation prevention mechanism includes a plurality of case holes on the same circle in the wall, flange holes in the flange at positions corresponding to the case holes, and rotation prevention members fitted into the case and flange holes to prevent rotation of the flange with respect to the wall with the flange relatively movable axially with respect to the wall.

Owner:AISIN AW CO LTD +1

Final gear transmission mechanism for a motorcycle, and motorcycle incorporating same

InactiveUS20090236168A1Reduce gear noiseControl mechanismBraking element arrangementsDrive shaftEngineering

A motorcycle includes a swing arm, a rear wheel mounted on a leading end of the swing arm, a drive shaft disposed in the swing arm, and a final gear transmission mechanism interposed between the drive shaft and the rear wheel. The final gear transmission mechanism includes a gear case mounted on the leading end of the swing arm for supporting a rear axle; a first end bearing and a second end bearing for supporting a first end and a second end of the rear axle, respectively, a ring gear mounted on the rear axle for transmitting the rotary drive force of an engine to the rear axle; a holding portion for holding the first end of the rear axle in the axial direction of the rear axle; and a fastening member for fastening the second end bearing to the second end of the rear axle.

Owner:HONDA MOTOR CO LTD

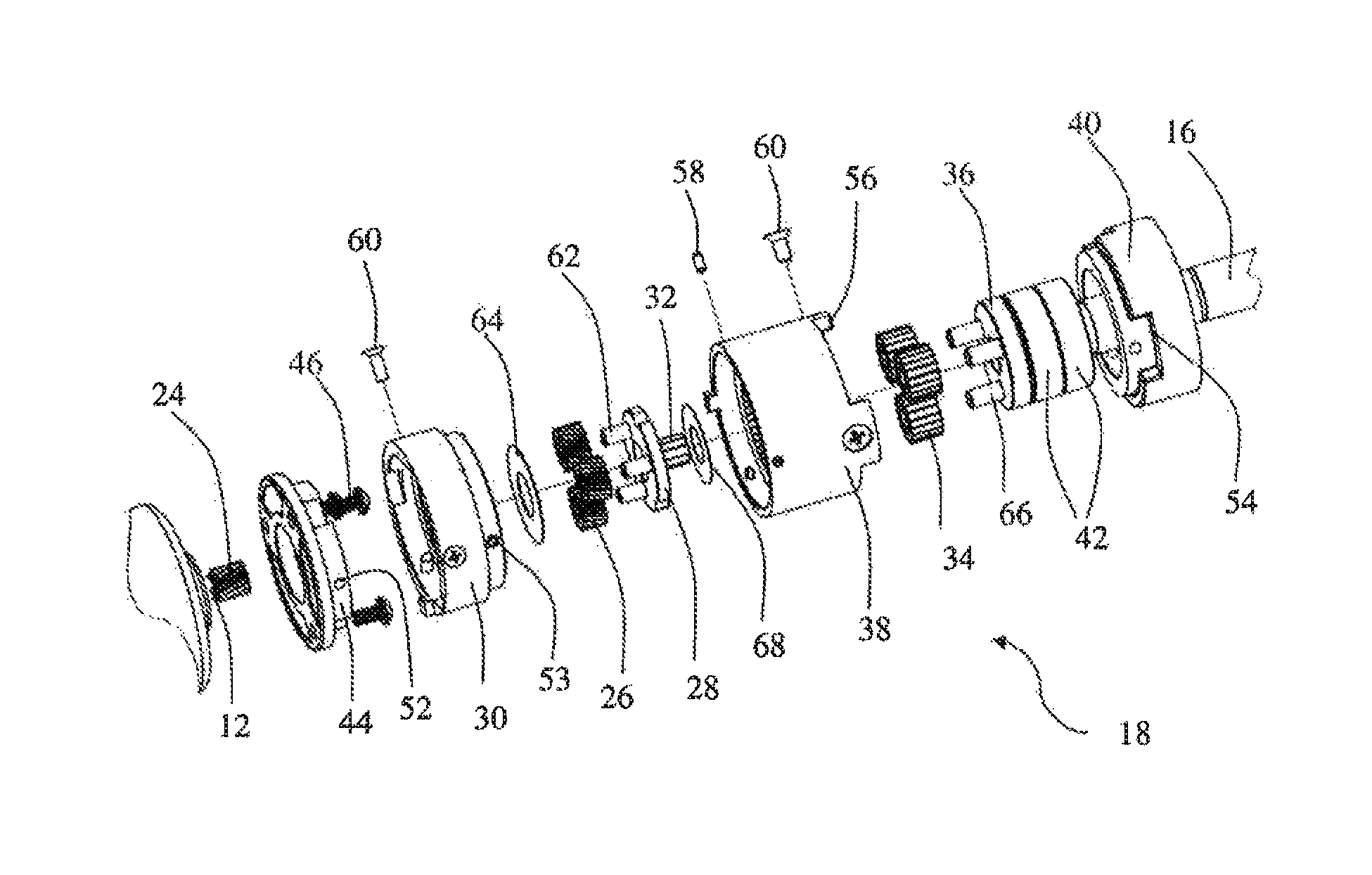

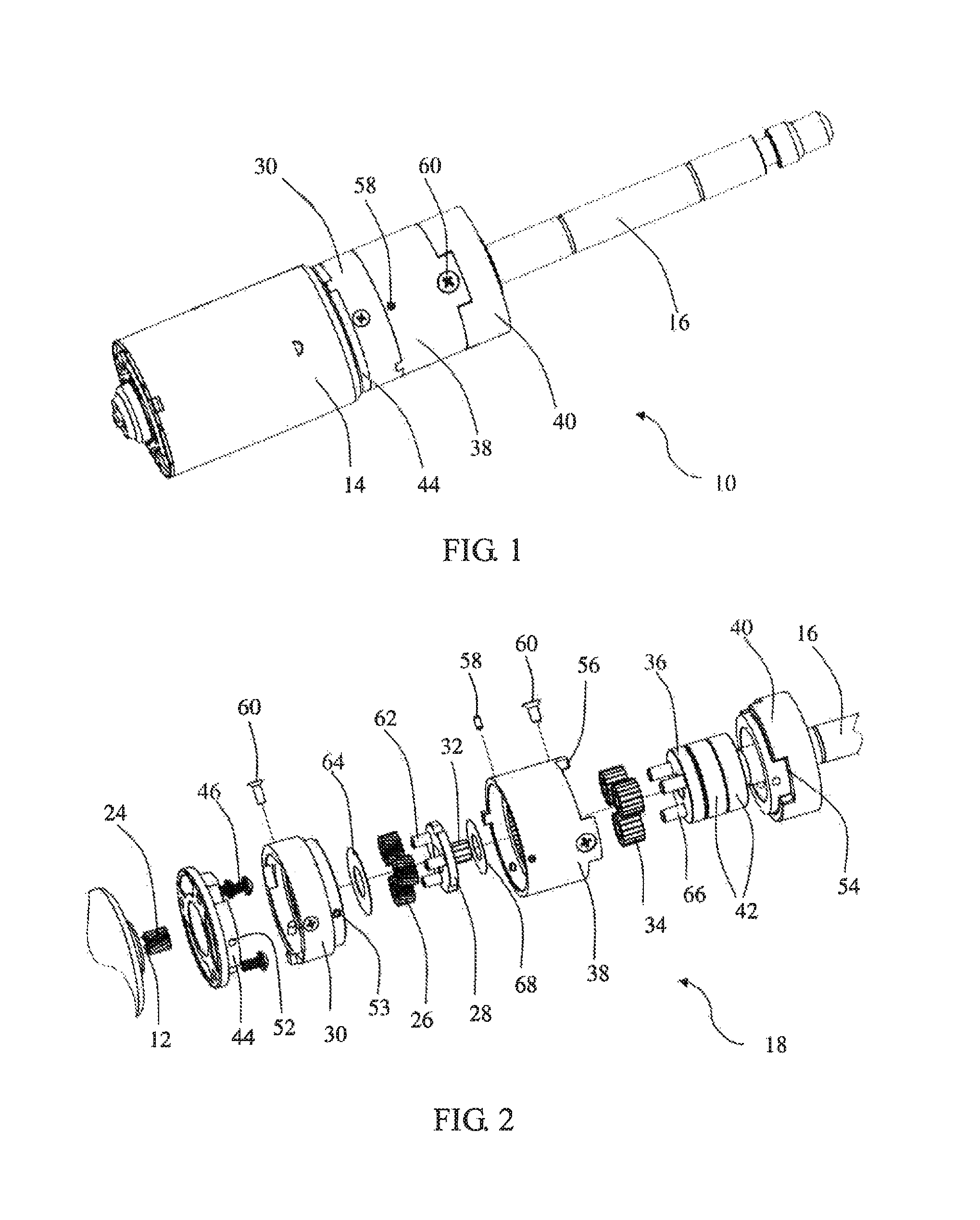

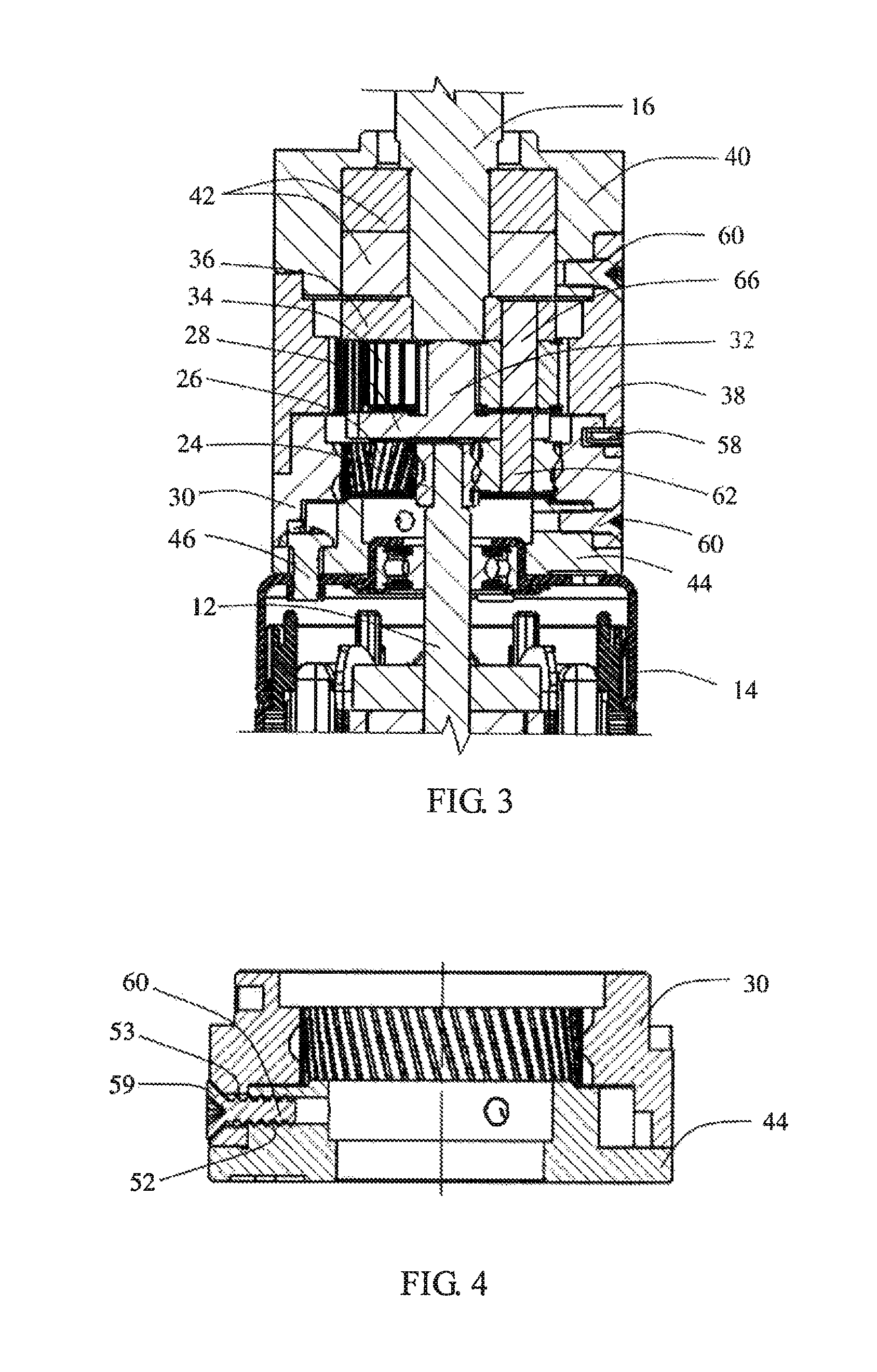

Electric cart with gear motor

InactiveUS9115790B2Reduce noiseReduce gear noiseToothed gearingsDifferential gearingsElectricityElectric machinery

Owner:JOHNSON ELECTRIC SA

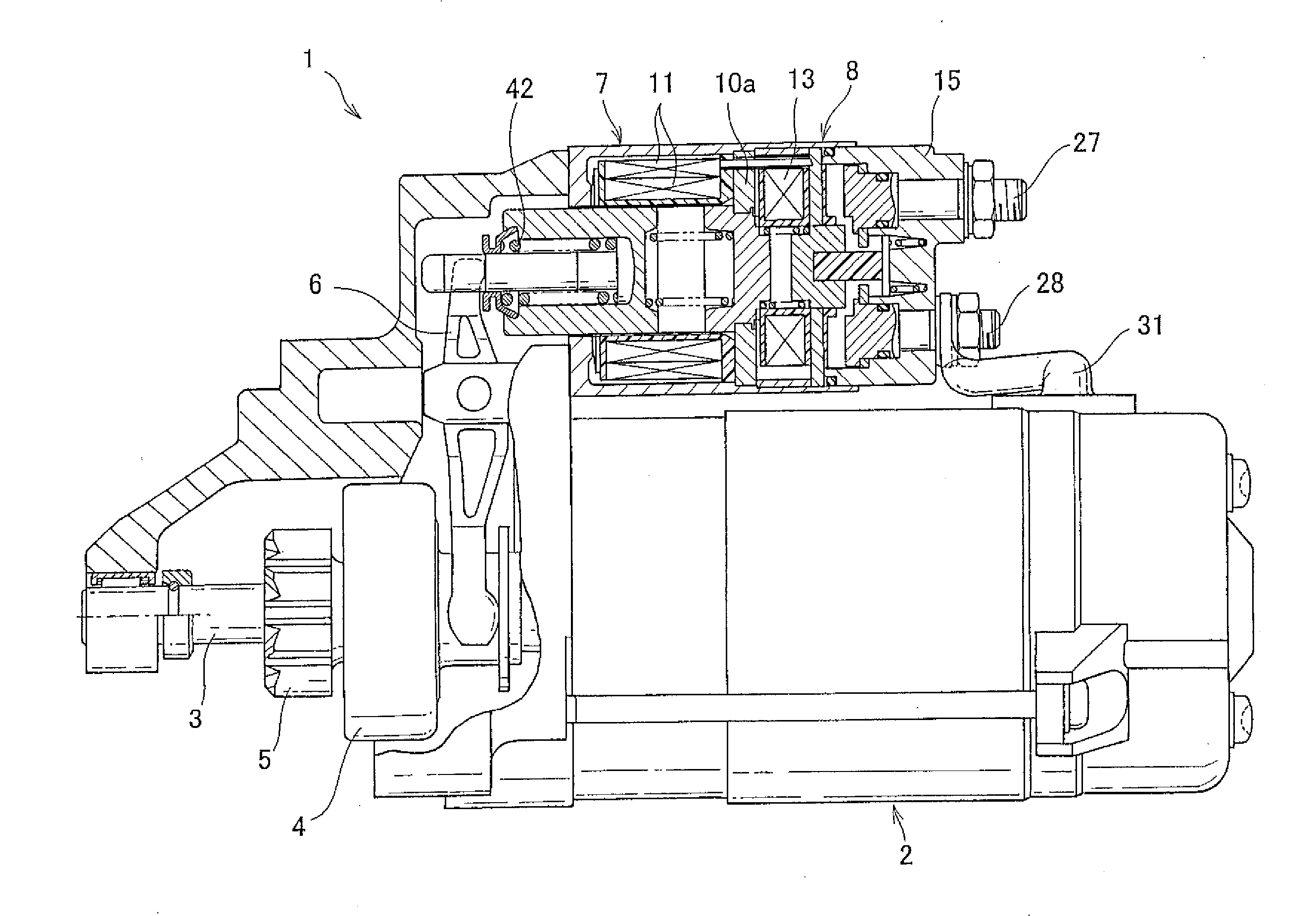

Starting Device for Engines

ActiveUS20120119497A1Reduce crash noiseImprove wear resistancePower operated startersElectrical controlEngineeringMotor circuit

Owner:DENSO CORP

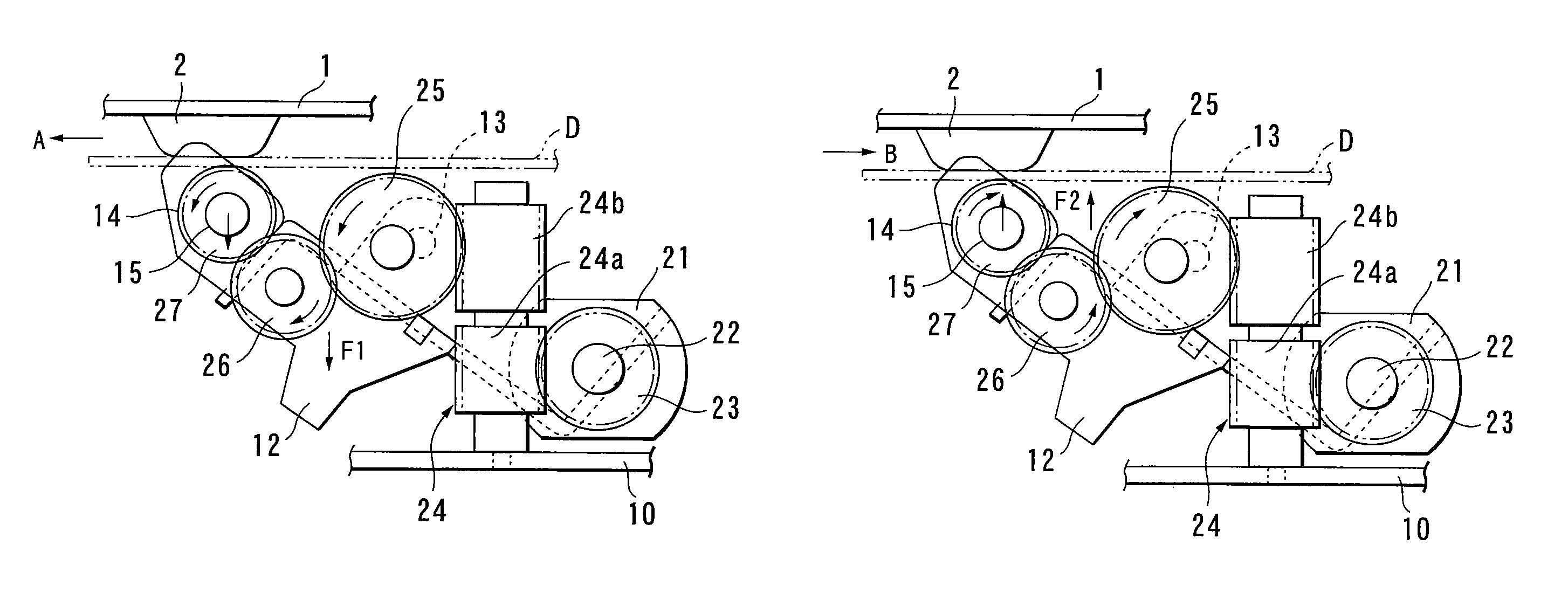

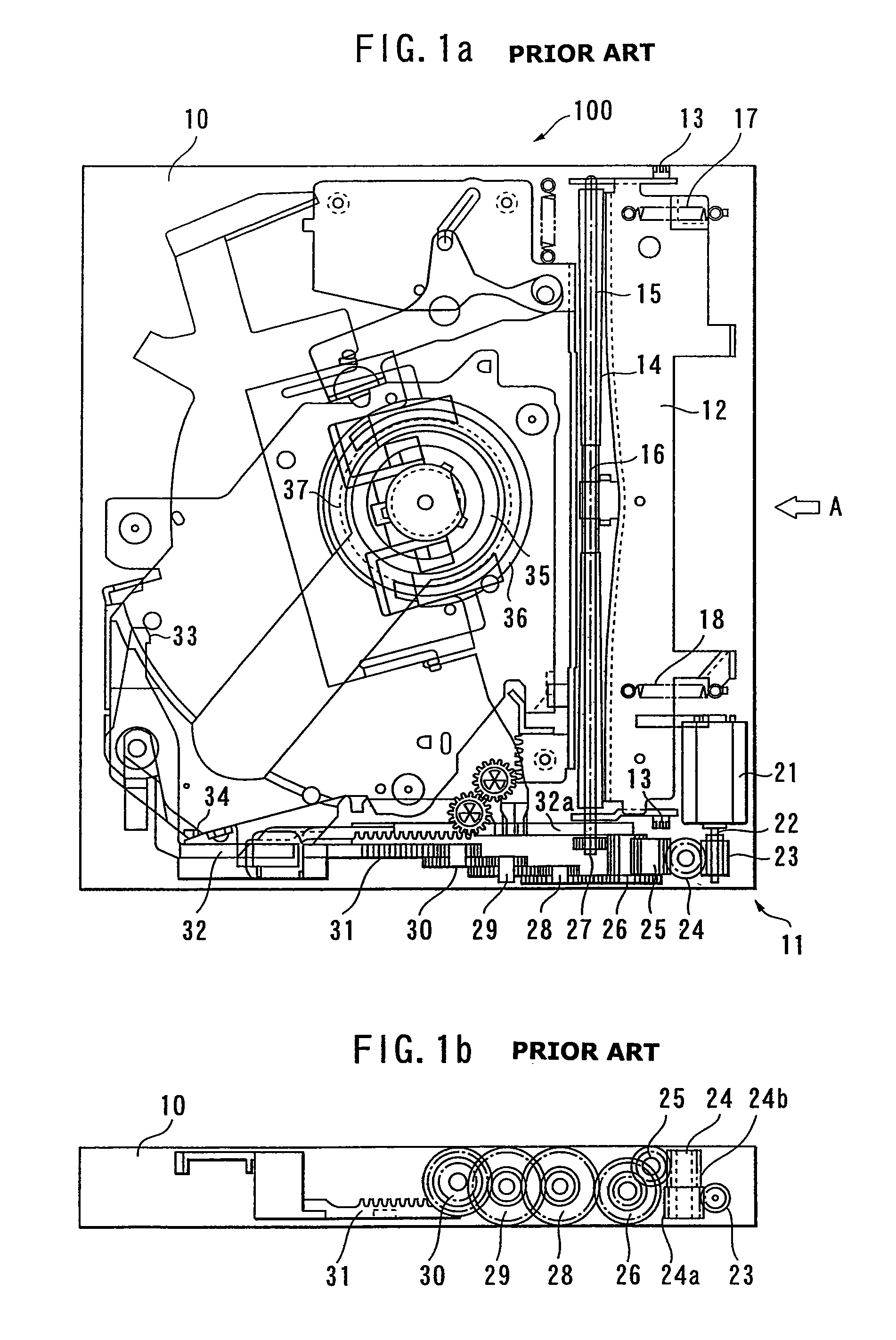

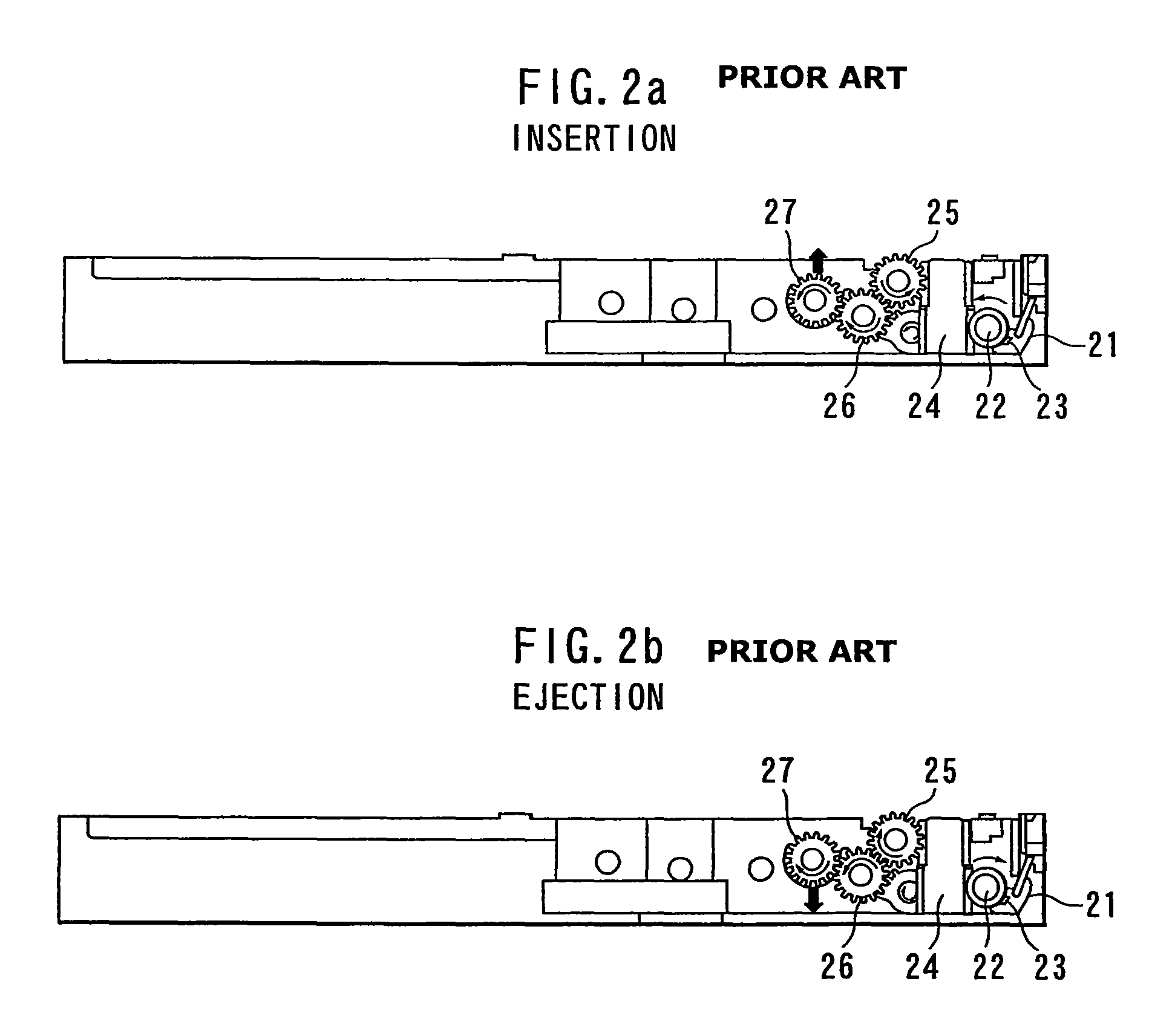

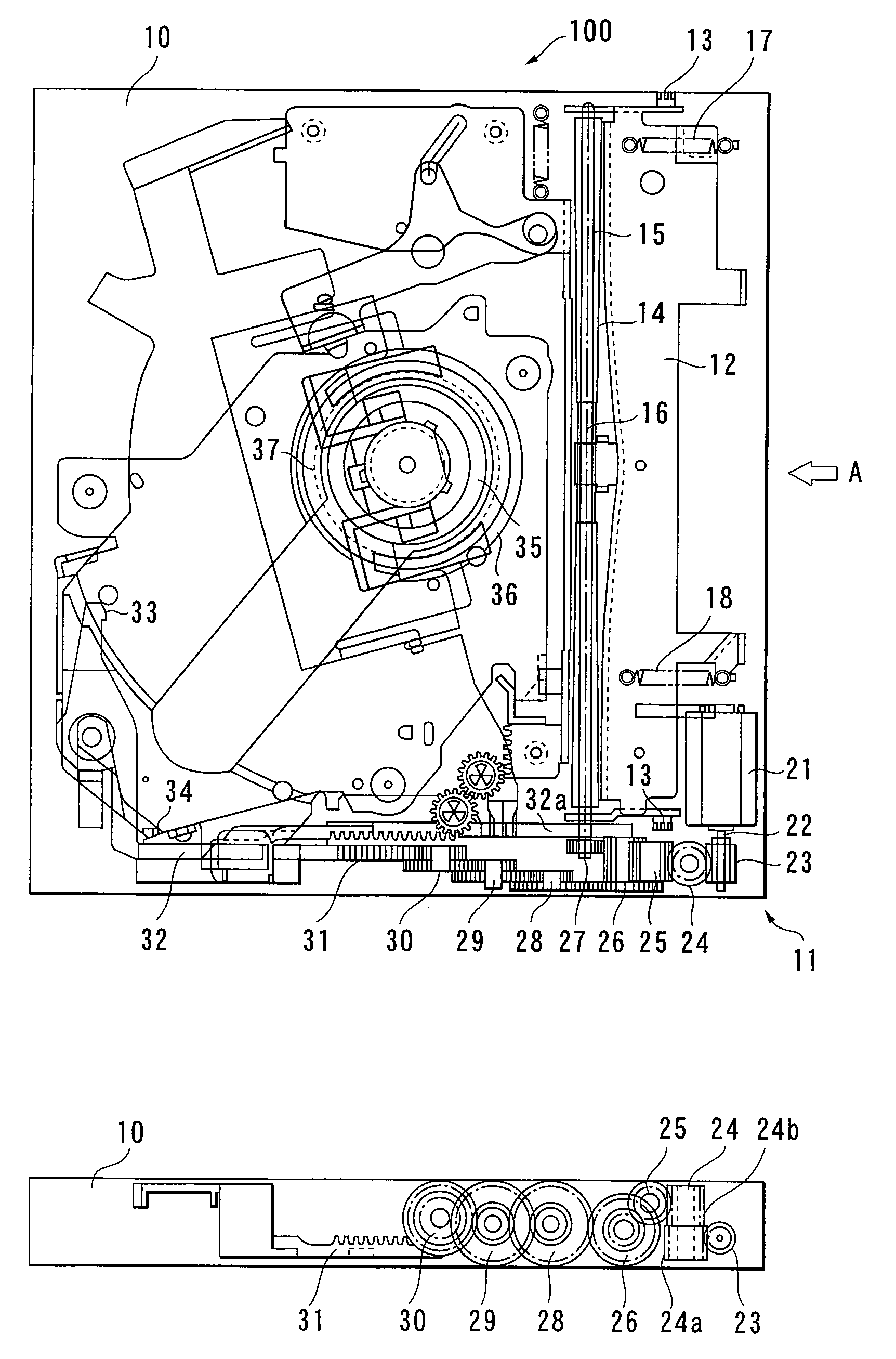

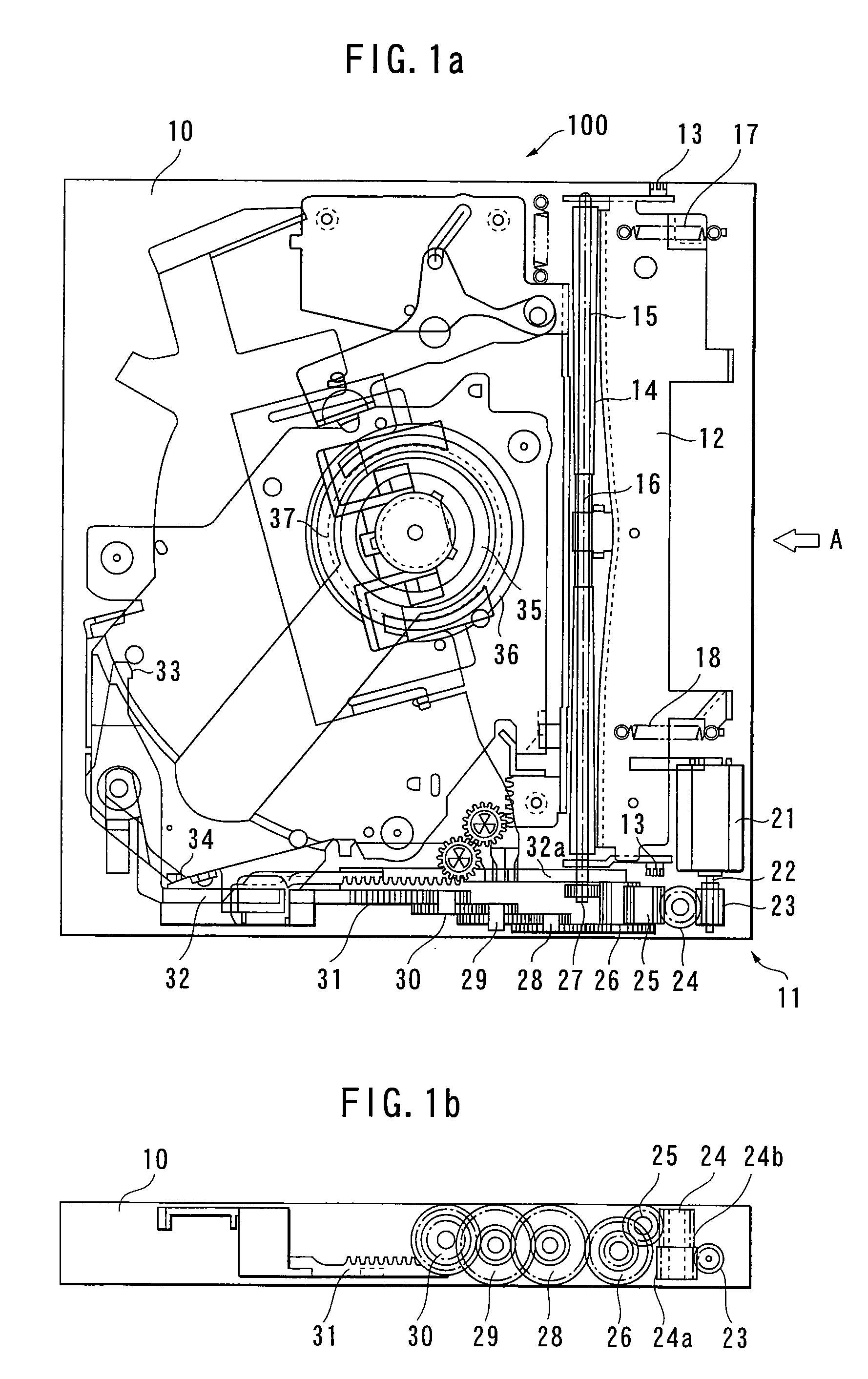

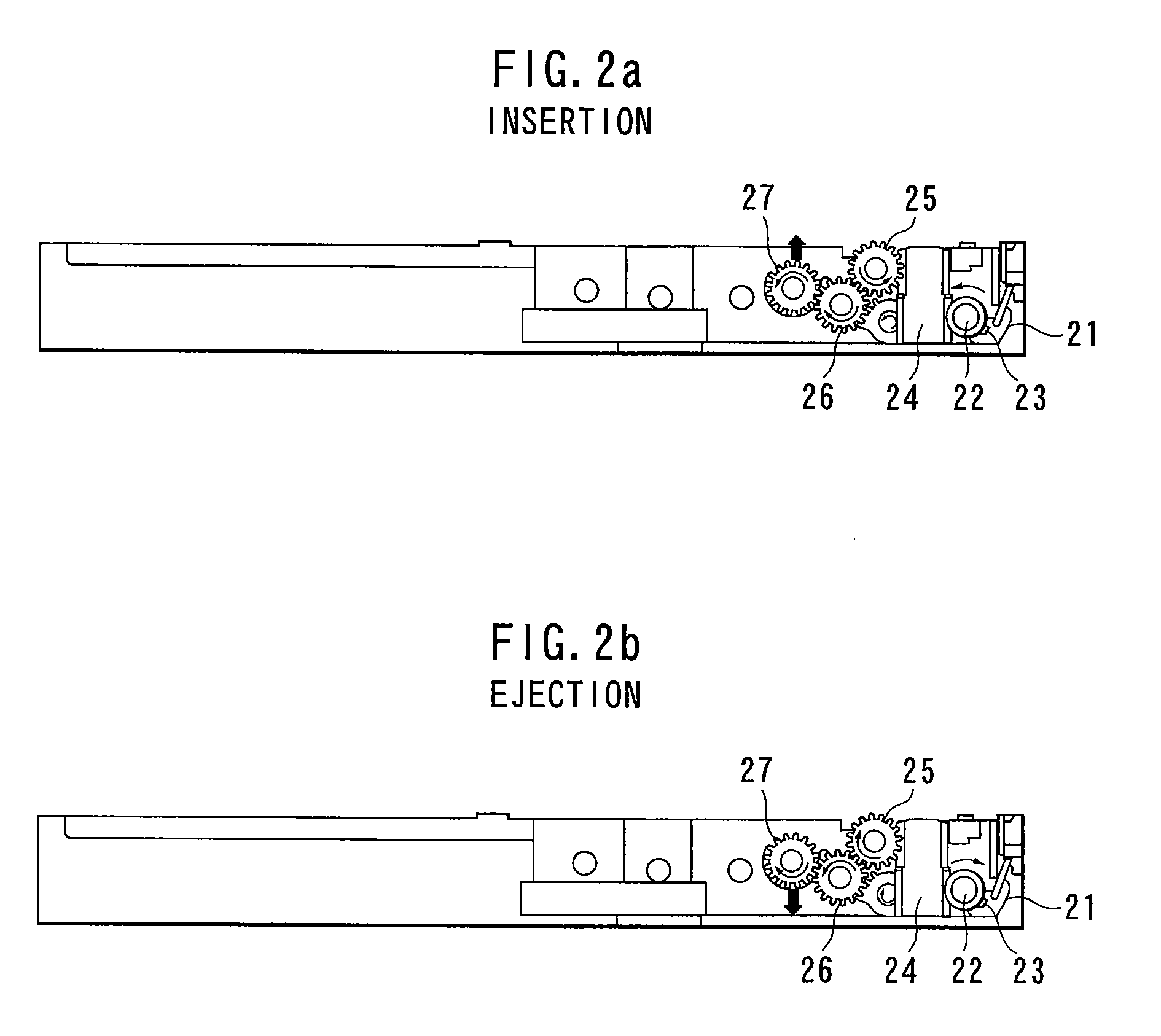

Disk carrying device and optical disk recording/reproducing device

In a disk carrying device including a first idle gear rotatably supported by a lower chassis and a second idle gear for contacting and separating from the first idle gear to perform a rotation operation, the second idle gear and a roller gear meshing therewith are rotatably supported by a feed plate to cause the second idle gear to contact and separate, from below, from the first idle gear rotatably supported by the lower chassis. Because of this configuration, in disk insertion, a downward force F1 acts on the second idle gear and a pushing pressure of the feed roller to a disk D decreases. In disk ejection, an upward force F2 acts on the second idle gear and the pushing pressure of the feed roller to the disk D increases.

Owner:PANASONIC CORP

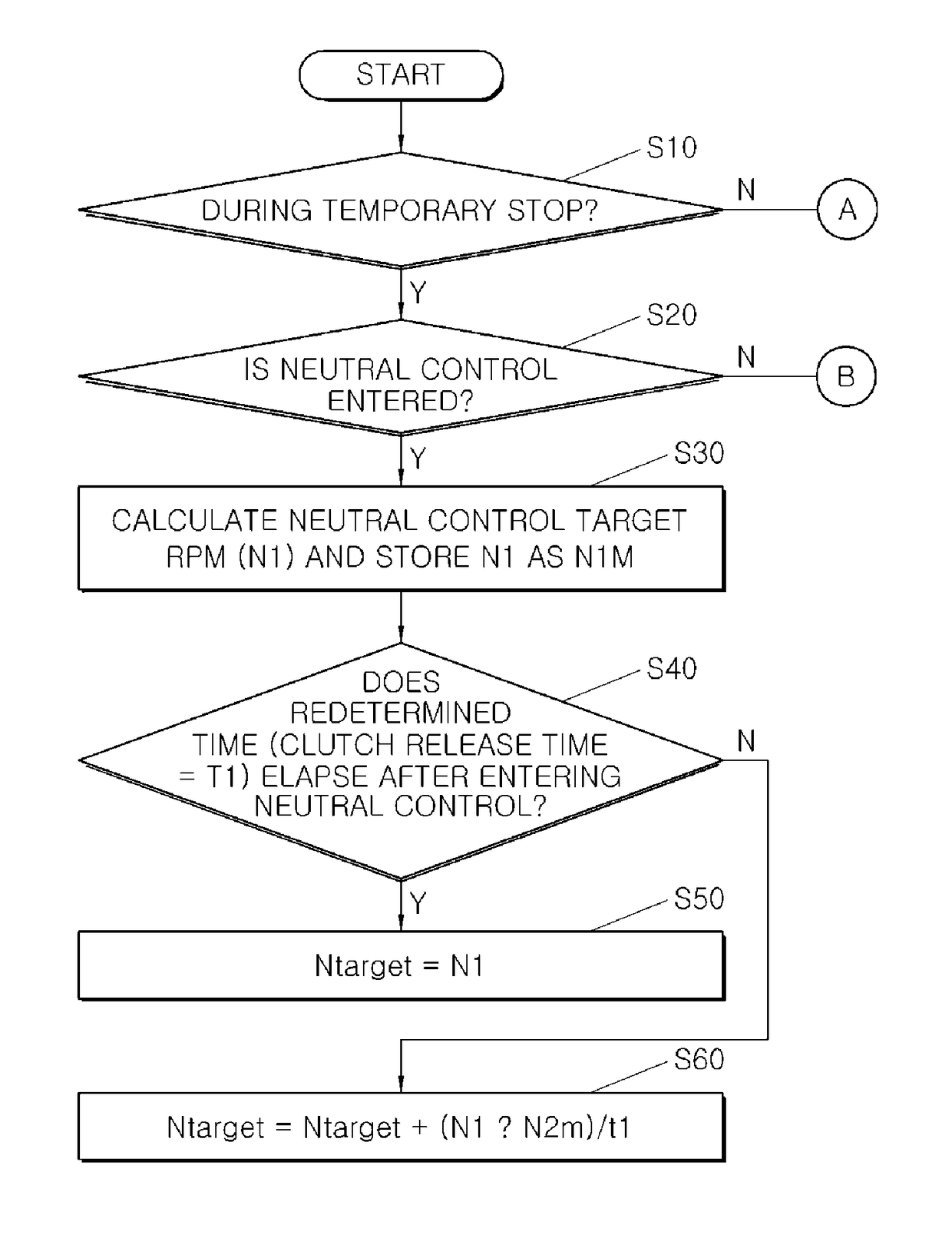

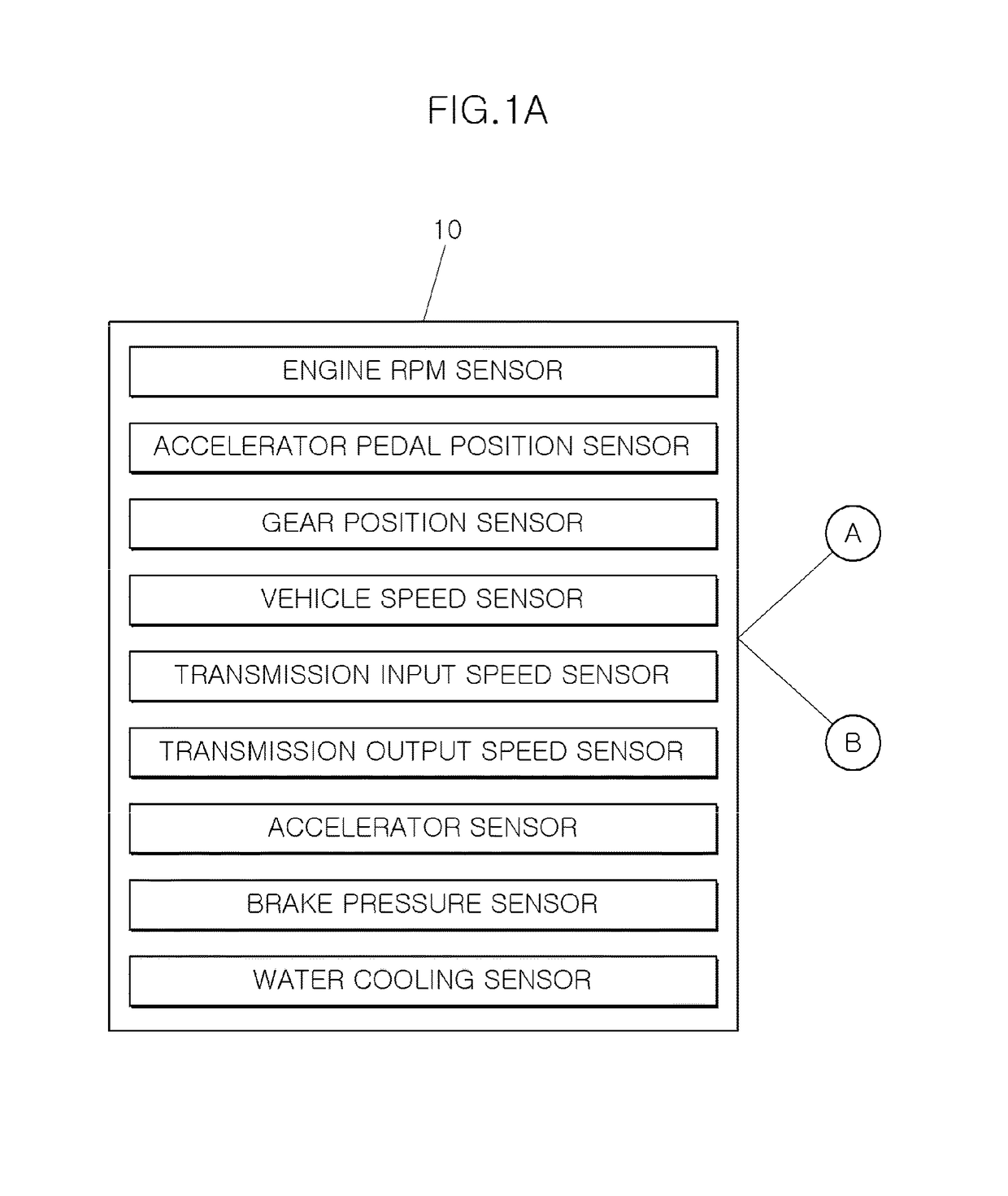

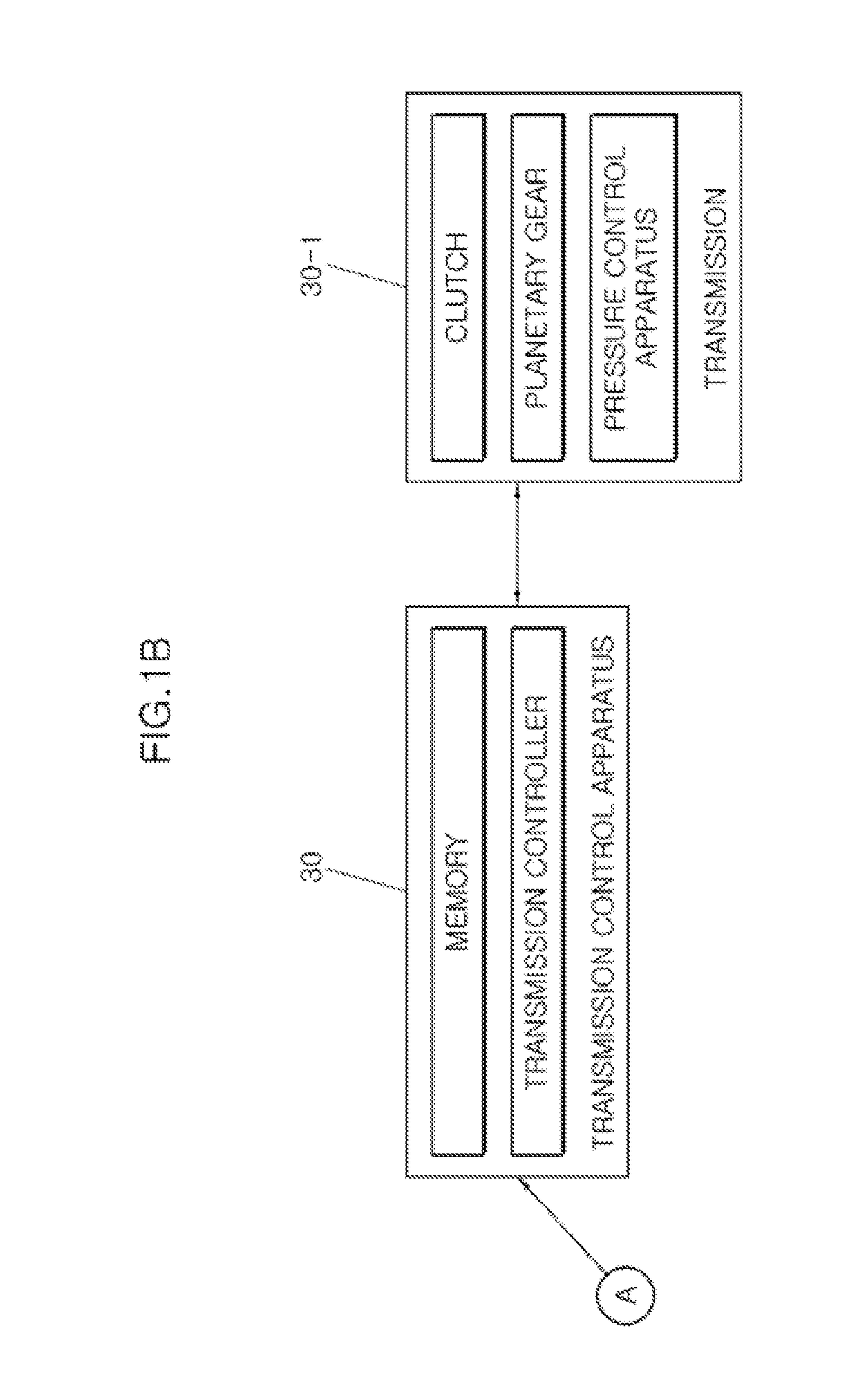

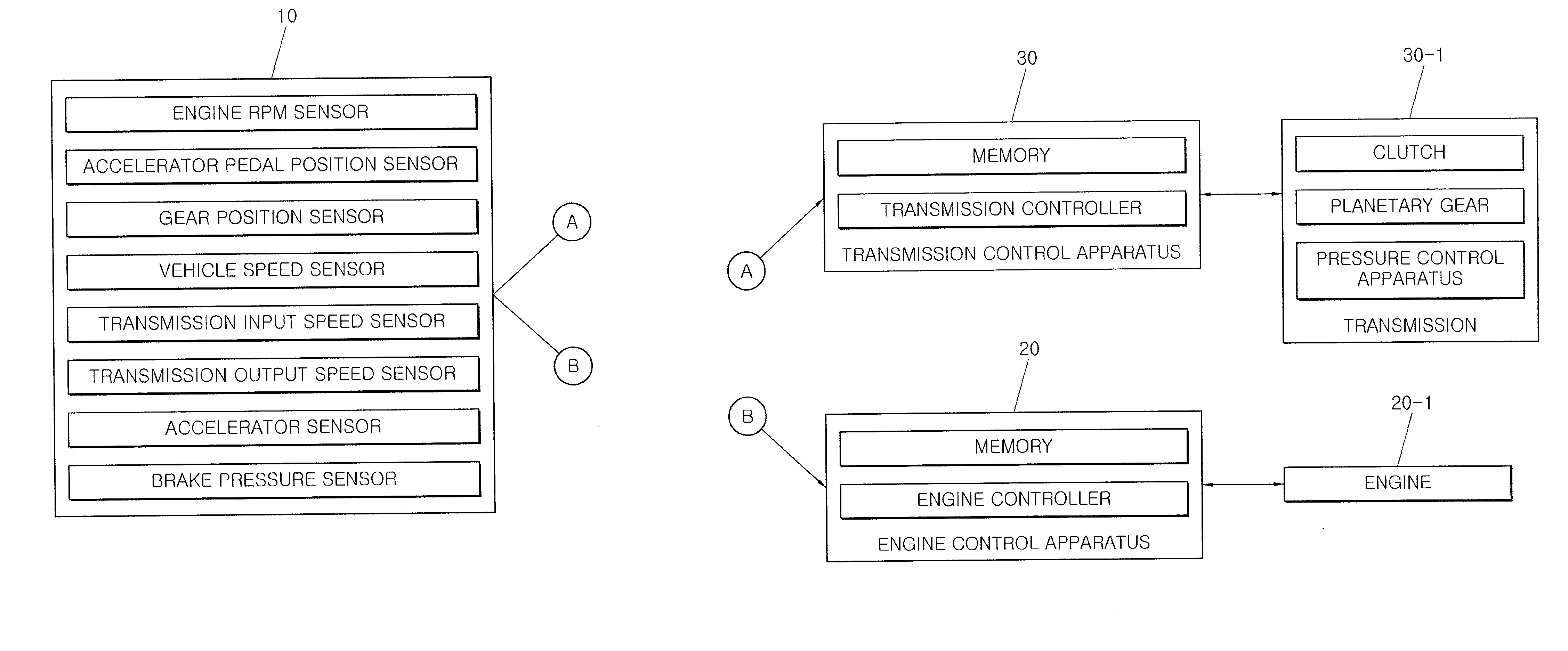

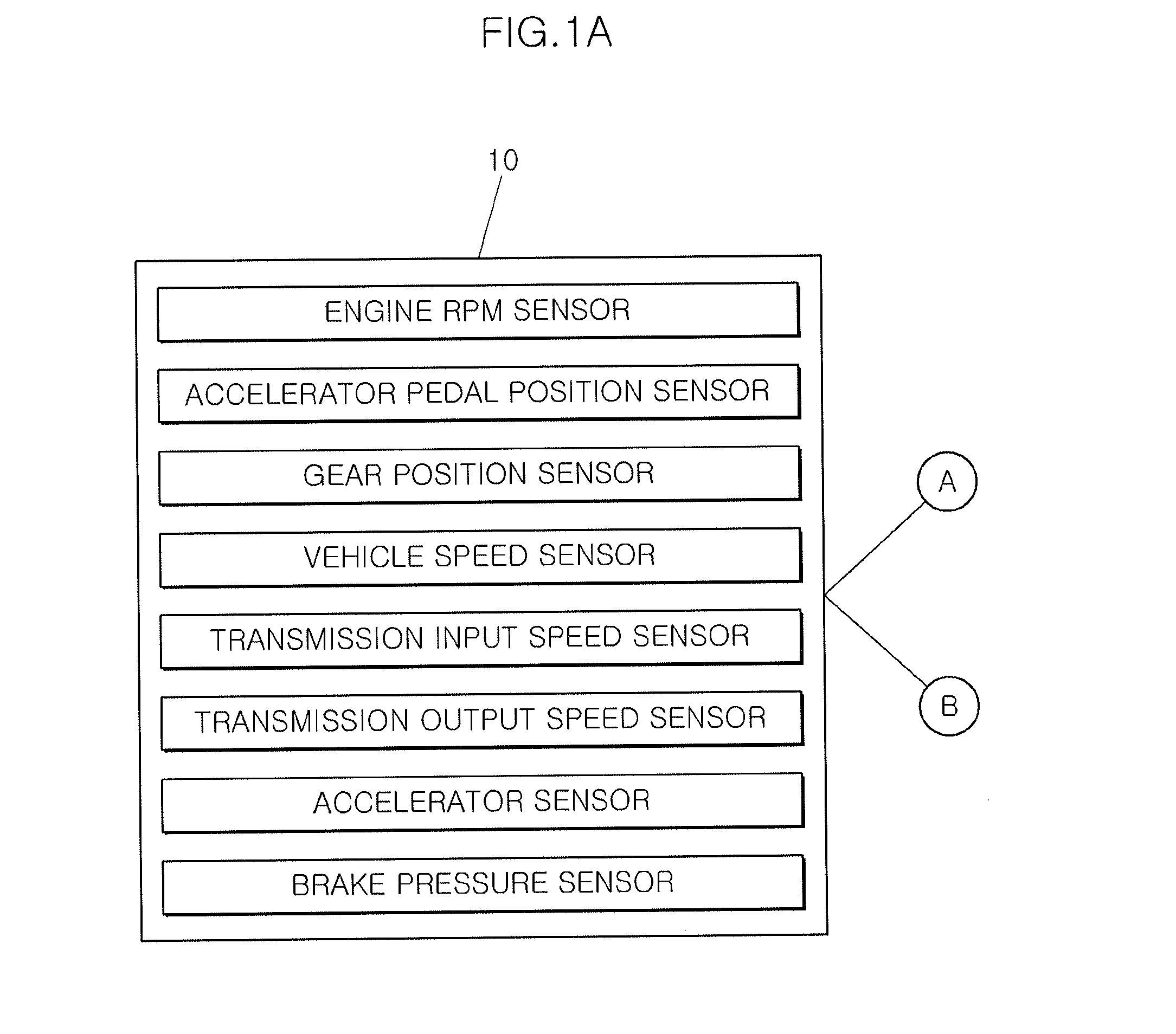

Vehicle and method for improving fuel-efficiency during temporary stop

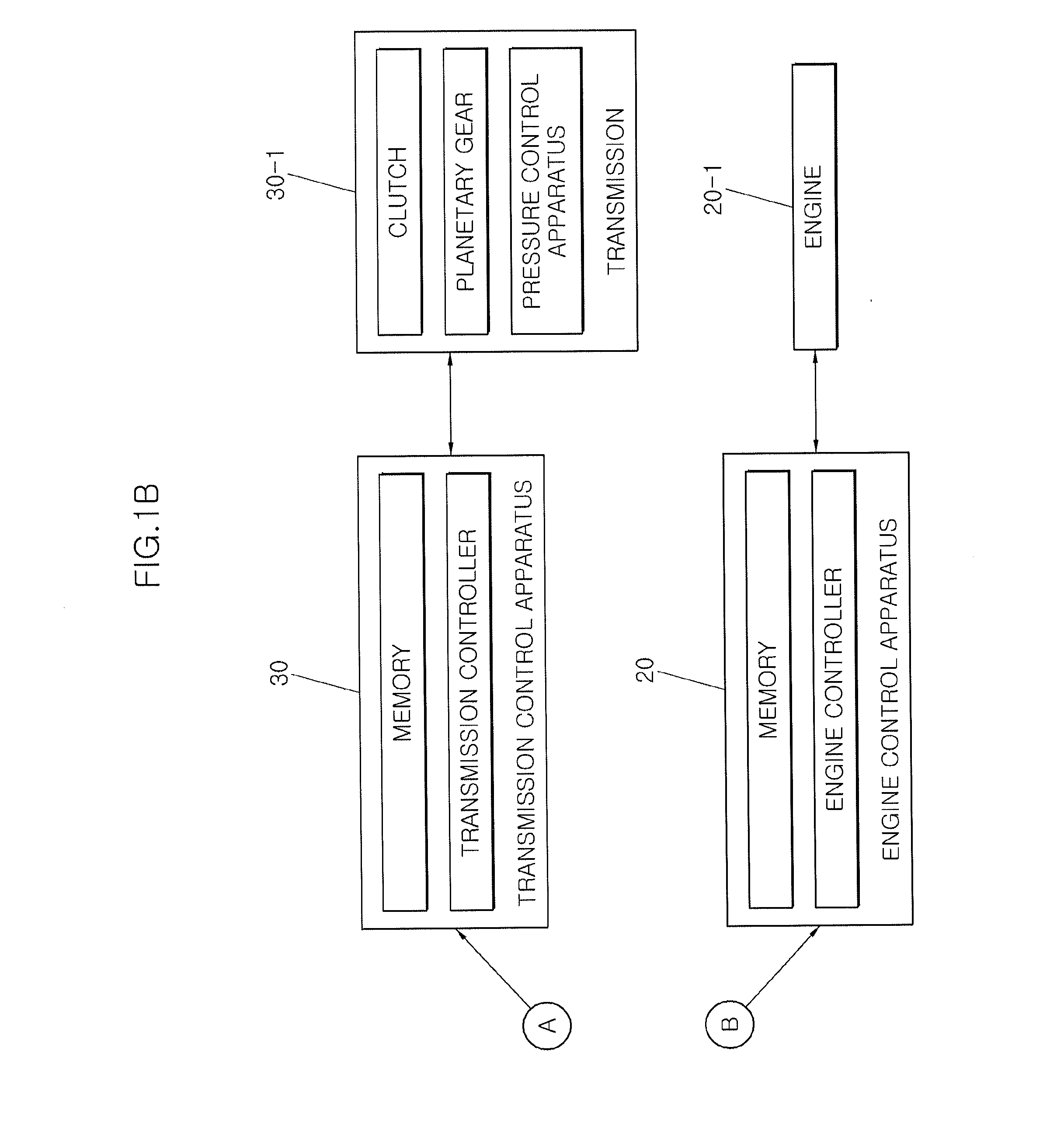

ActiveUS9889840B2Improve fuel efficiencyReduce gear noiseGearing controlEngine controllersControl releaseCoupling

A method for improving fuel-efficiency during a temporary stop may include dividing, by an engine control apparatus, a neutral control condition into a neutral control entry and a neutral control release during a D-stage temporary stop, determining, a neutral control entry D-stage target RPM at a time of the neutral control entry, and a neutral control release D-stage target RPM at a time of the neutral control release, and RPM shifting the neutral control entry D-stage target RPM to a speed gradient conforming to a transmission clutch release time of a transmission control apparatus at a time of a neutral control after the neutral control entry and RPM shifting the neutral control release D-stage target RPM to a speed gradient conforming to a clutch coupling time of a transmission by the transmission control apparatus at a time of a neutral control after the neutral control release.

Owner:HYUNDAI MOTOR CO LTD +1

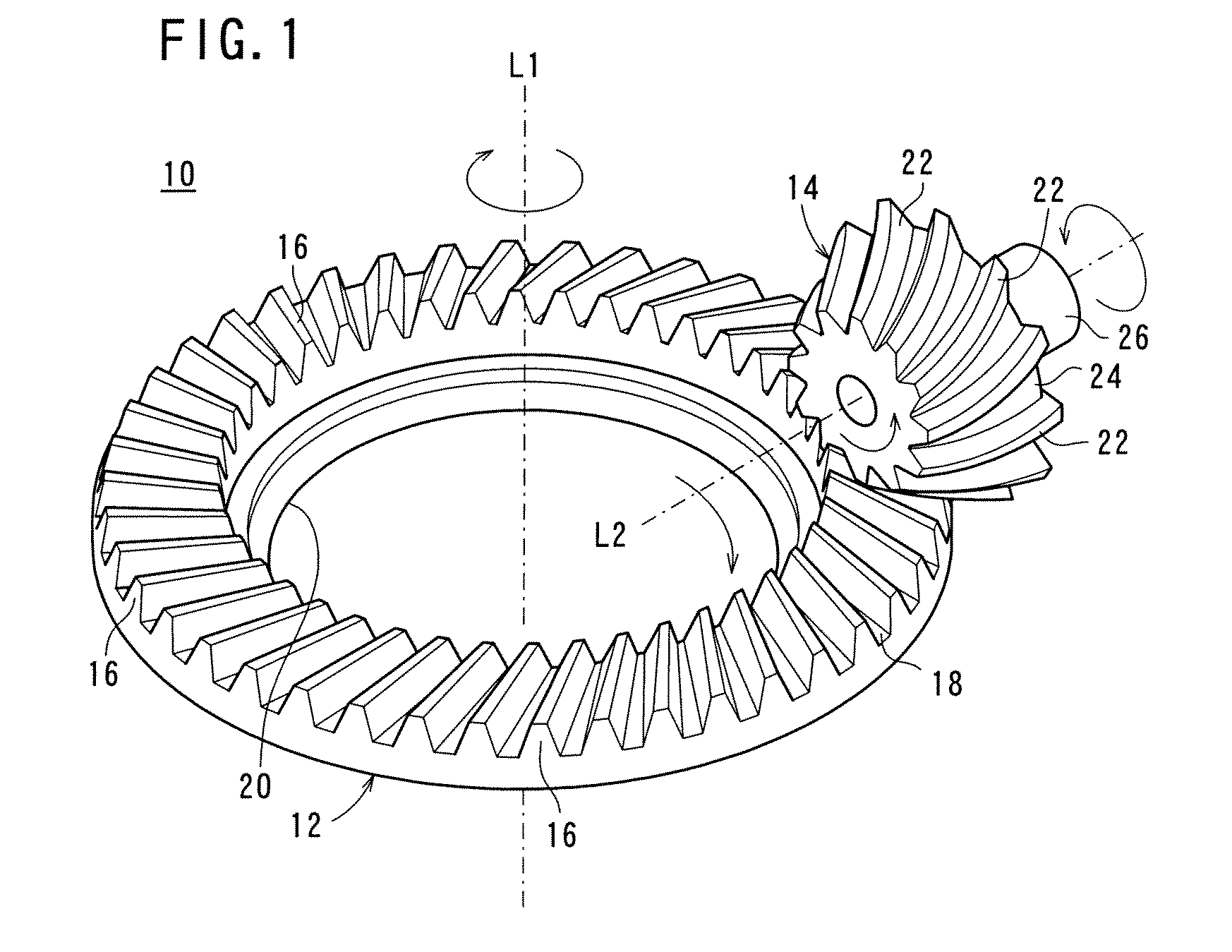

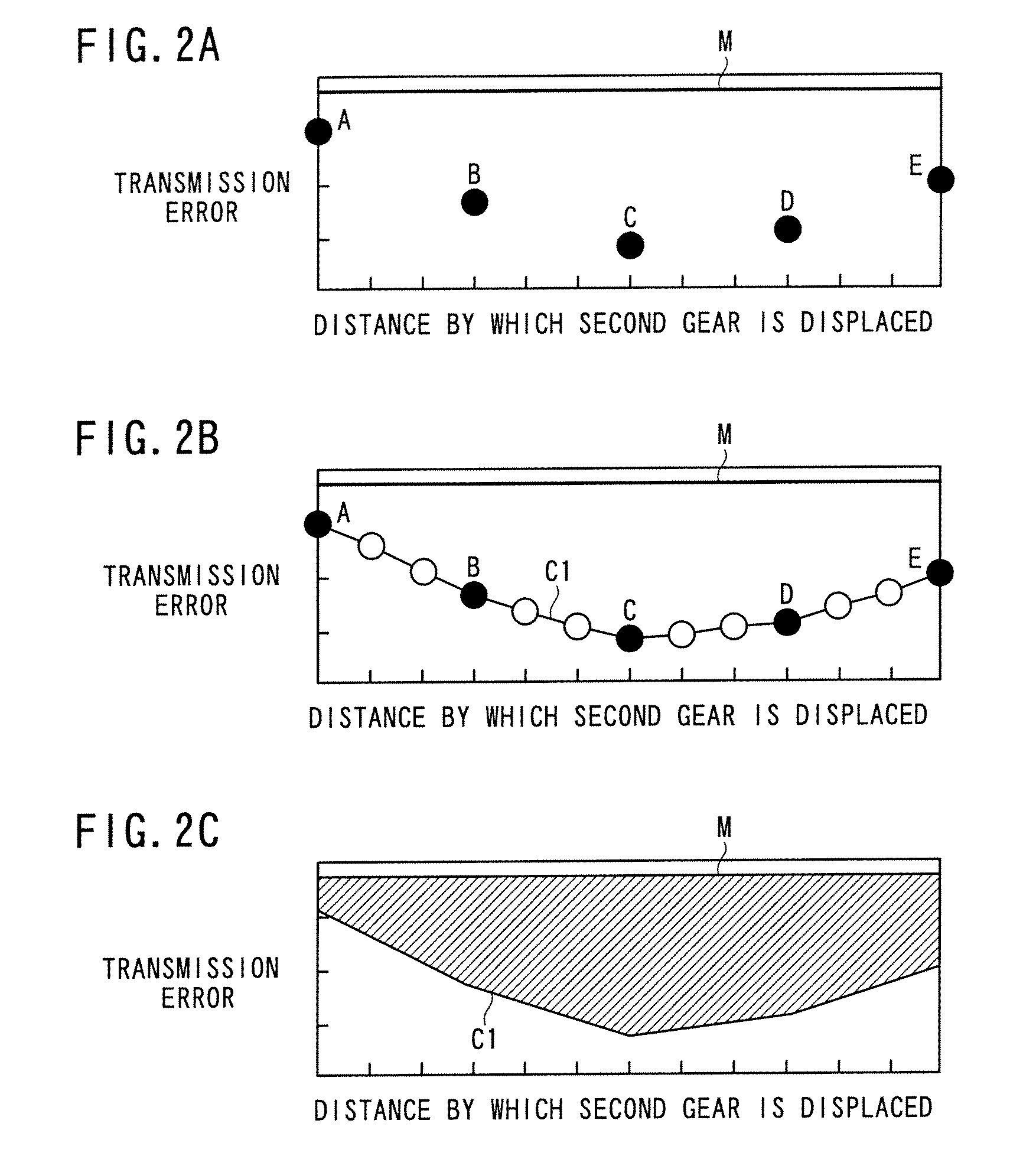

Method for adjusting meshing position of hypoid gear

ActiveUS8813595B2Reduce gear noiseBig errorMachine gearing/transmission testingToothed gearingsGear wheelControl theory

A method for adjusting the meshing position of a hypoid gear having a first gear, and a second gear meshing with the first gear and transmitting the rotary motion thereof in the direction different from the extending direction of the axis of rotation of the first gear. The method for adjusting the meshing position comprises; a) a step for displacing the second gear a plurality of times along the axial direction of rotation while meshing with the first gear, b) a step for measuring the transmission error at each displacement position and plotting the relation of the displacement distance of the second gear and the measured transmission error, c) a step for evaluating the virtual transmission error between the measured transmission errors from the measured transmission error, d) a step for subtracting the measured transmission error and the virtual transmission error from a maximum allowable transmission error to determine the difference, e) a step for determining the area of a part surrounded by the difference and the maximum allowable transmission error by integrating the difference with the displacement distance of the second gear, and f) a step for dividing the part at a predetermined area ratio and setting a point where the division line intersects the displacement distance of the second gear at the meshing position of the second gear.

Owner:HONDA MOTOR CO LTD

Multiple-speed automatic transmission having a two-speed input and a Simpson gearset

ActiveUS20070037658A1Improve design flexibilitySuitable for applicationToothed gearingsTransmission elementsAutomatic transmissionEngineering

A multi-speed automatic transmission includes an input and output, first, second and three planetary gear units, each gear unit including a sun gear, a ring gear, planet pinions meshing with the sun gear and the ring gear, and a carrier rotatably supporting the planet pinions. A first brake alternately holds against rotation and releases the sun gear of the second gear unit and the sun gear of the third gear unit. A second brake alternately holds and releases the carrier of the second gear unit. A first clutch alternately connects and disconnects the carrier of the first gear unit and the ring gear of the third gear unit. A second clutch alternately disconnects and connects the carrier of the first gear unit to the sun gears of the second gear unit and third gear unit. A third clutch alternately releases and connects the input and ring gear of the first gear unit to the carrier of the second gear unit.

Owner:FORD GLOBAL TECH LLC

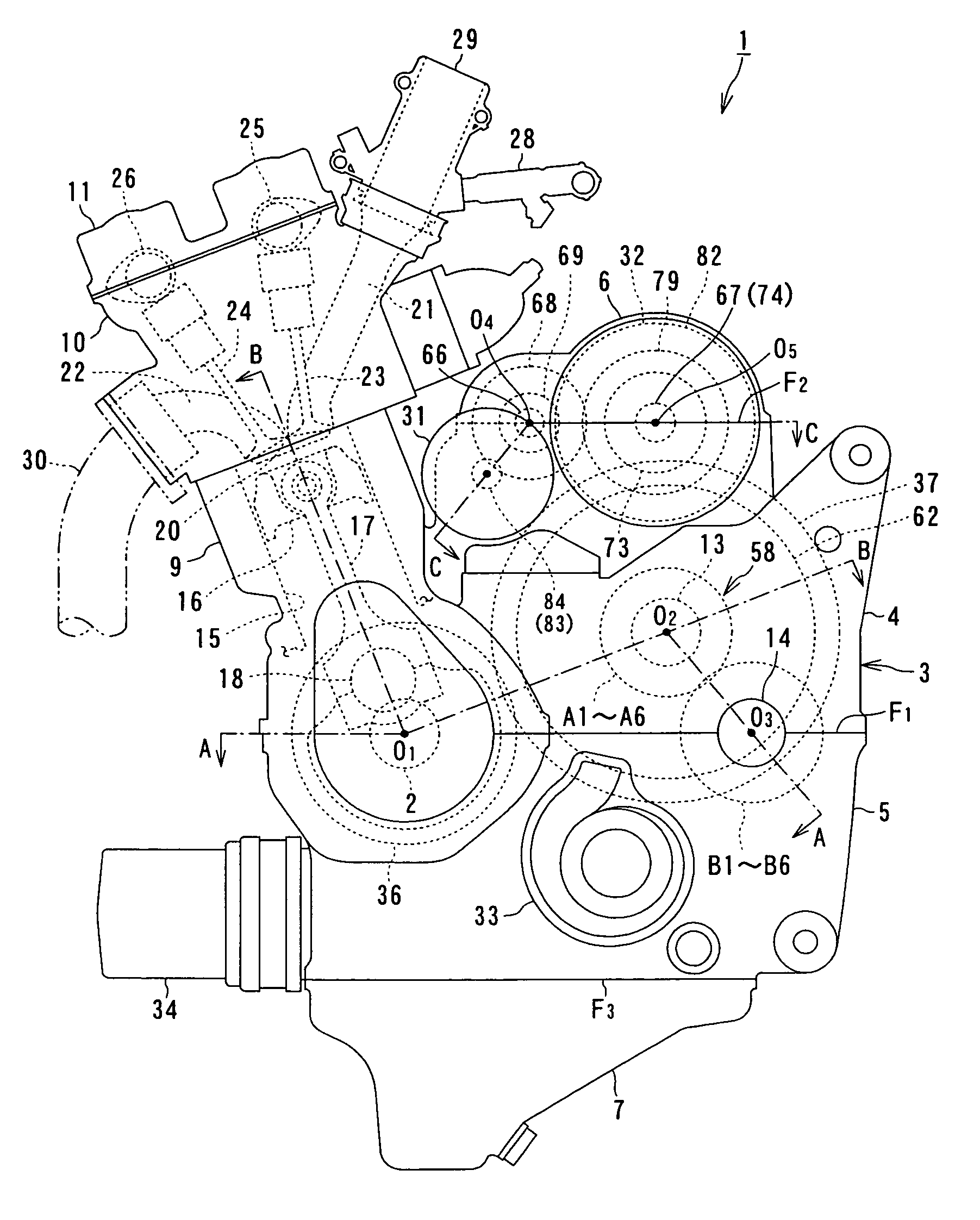

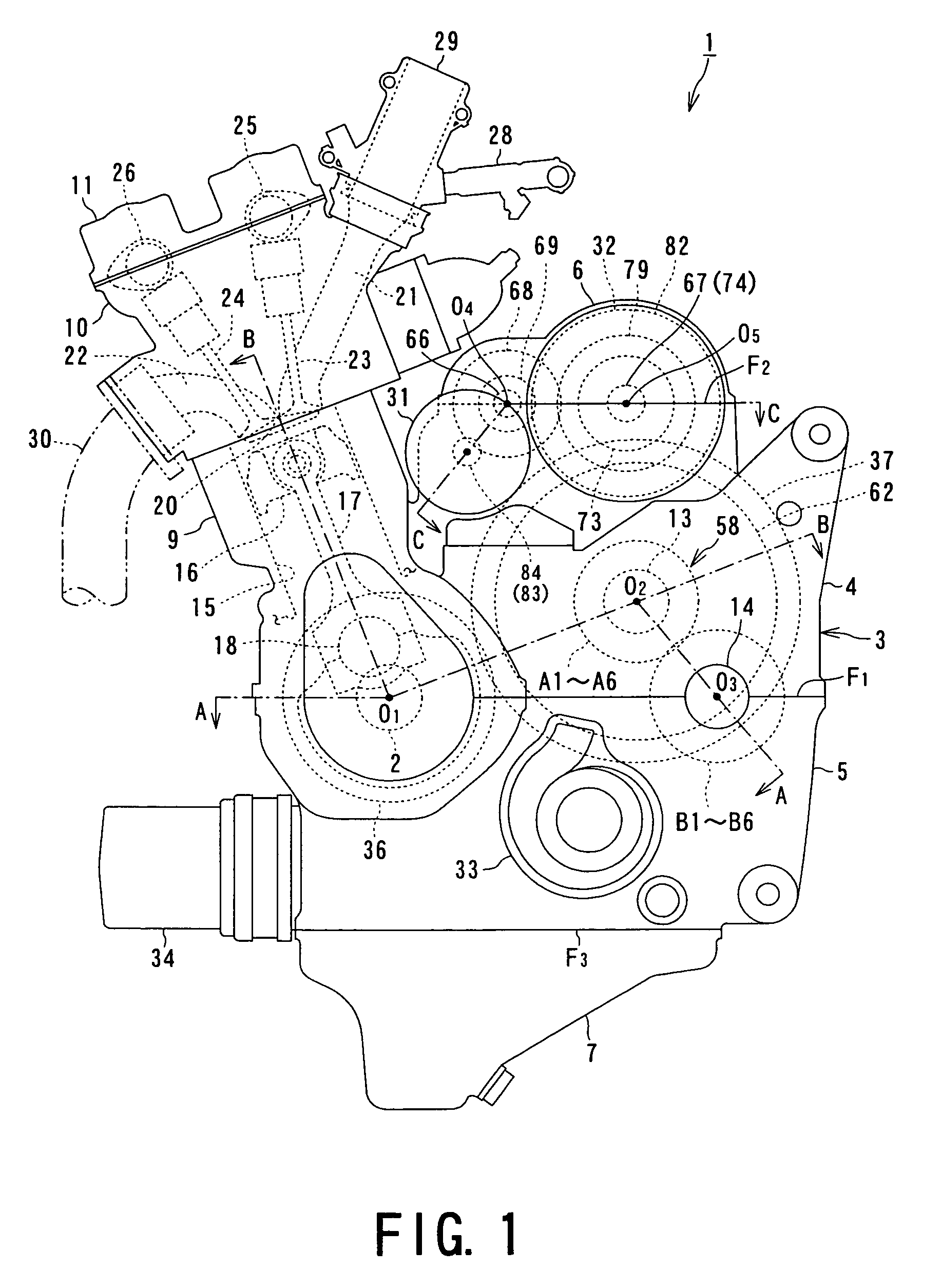

Engine unit of motorcycle

InactiveUS7162989B2Reduce gear noiseIncreased durabilityCasingsMachine framesAccessory driveControl theory

An engine unit for an motorcycle is disclosed in which an accessory drive gear is disposed downstream of primary dampers in the engine power transmission path, and simultaneously upstream of a clutch mechanism in the engine power transmission path. In this engine unit, an accessory, for example, generator, is connected to an intermediate shaft that is parallel to a crank shaft and a counter shaft so as to rotate integrally with the intermediate shaft. An accessory driven gear is meshed with the accessory drive gear, and an accessory damper is disposed between the intermediate shaft and the accessory for absorbing rotational shocks. Furthermore, a starter motor is gear-engaged with the intermediate shaft via a one-way clutch, and the position of this gear engagement is provided between the accessory damper and the accessory driven gear.

Owner:SUZUKI MOTOR CORP

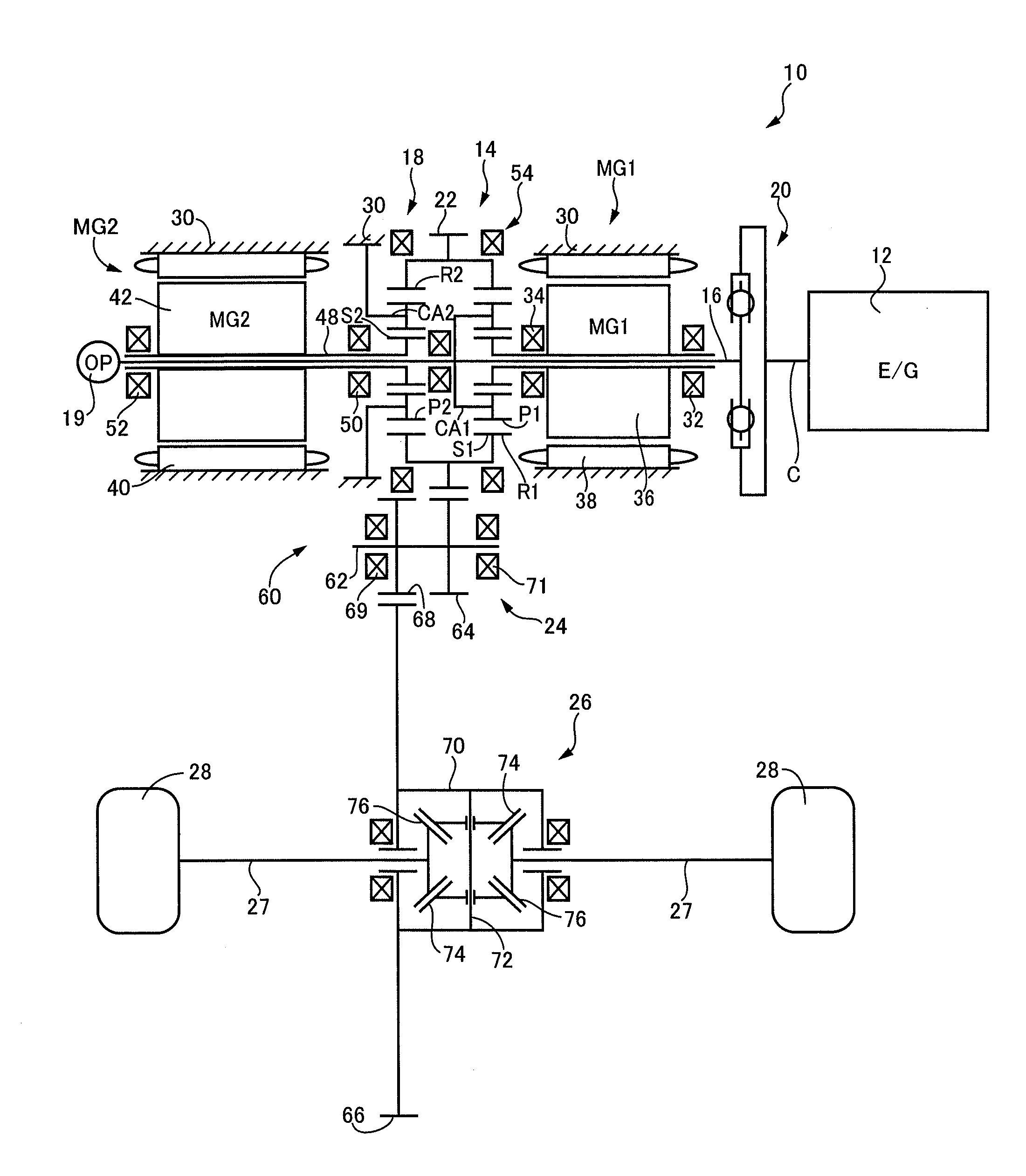

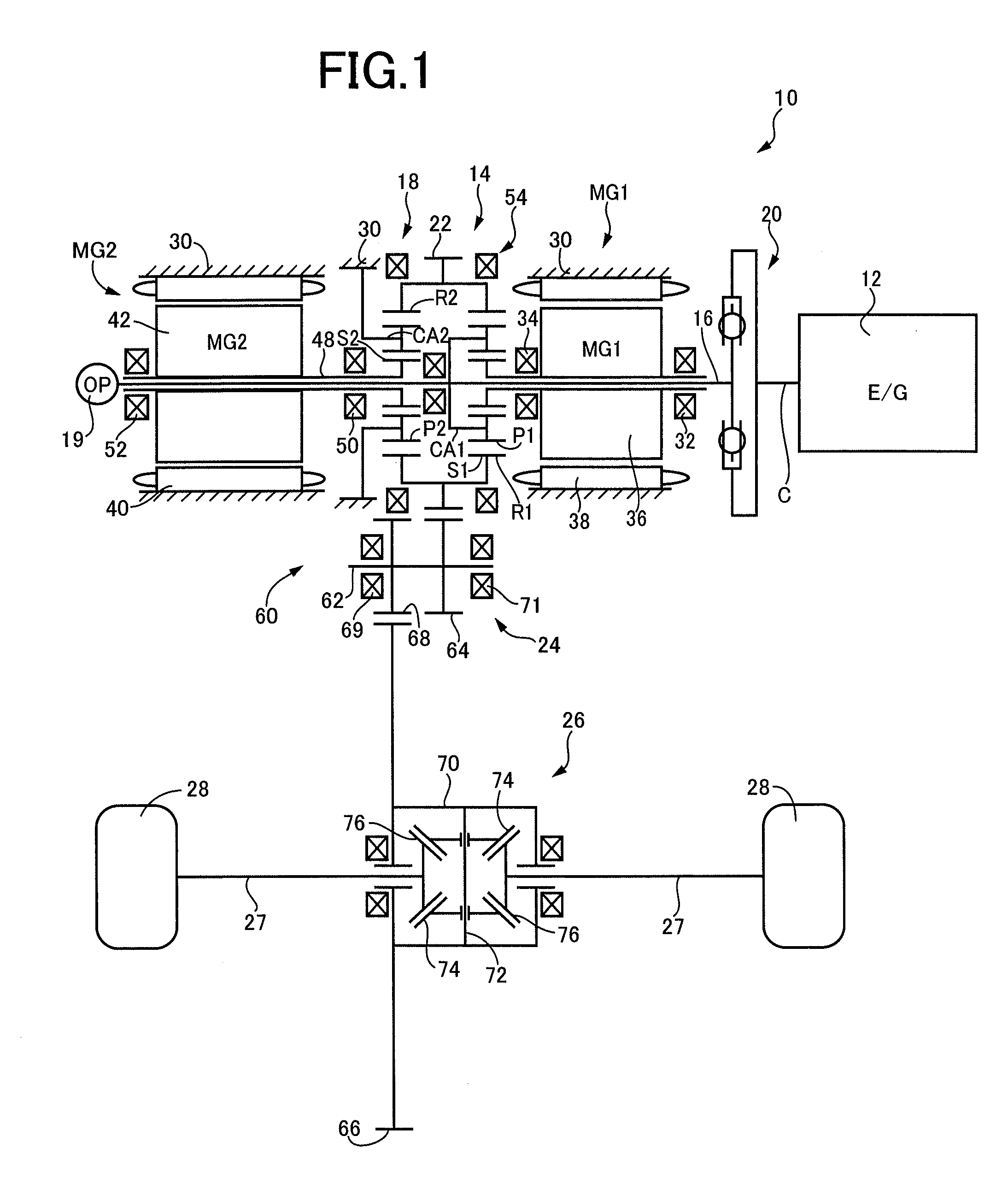

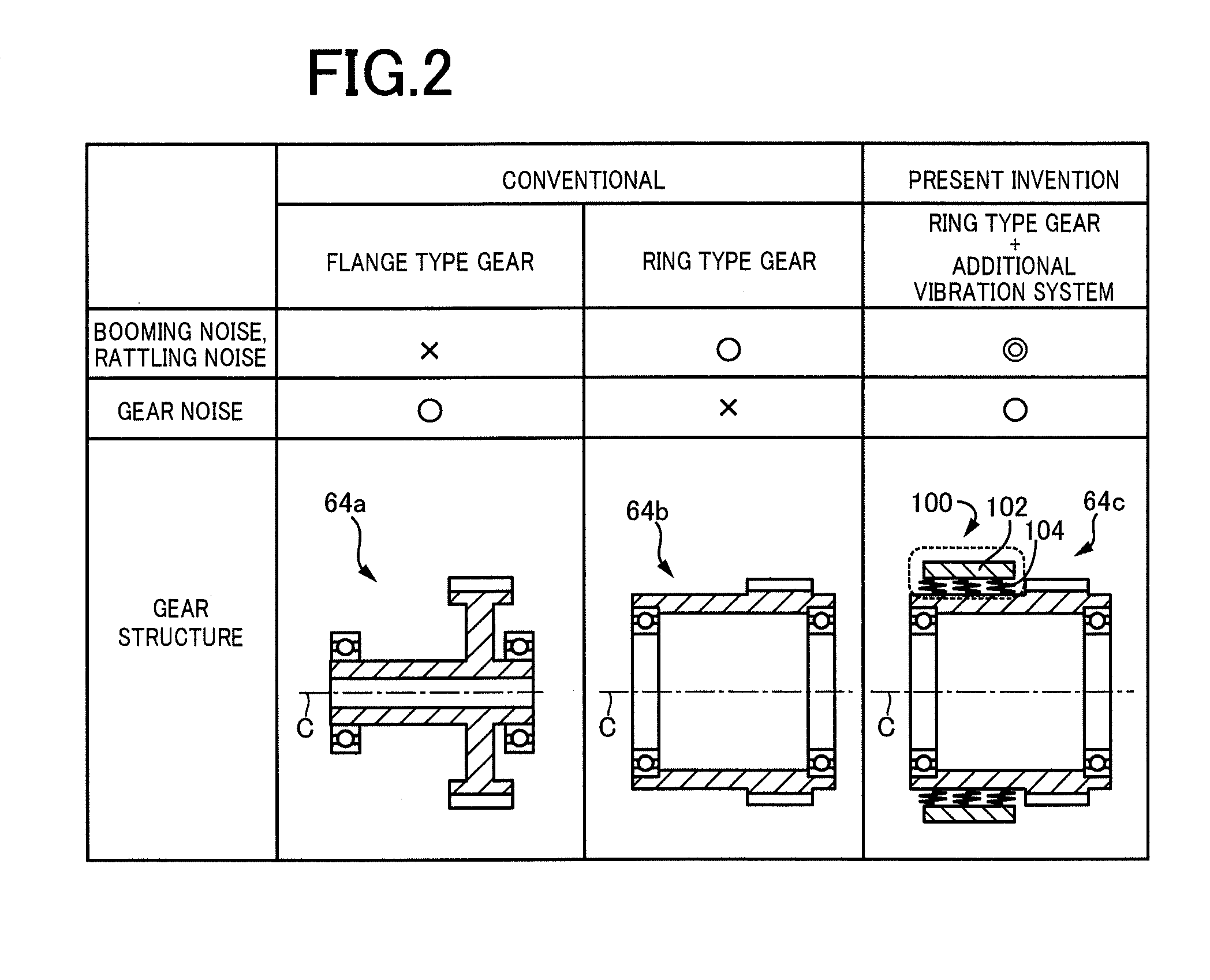

Meshed gear for vehicle

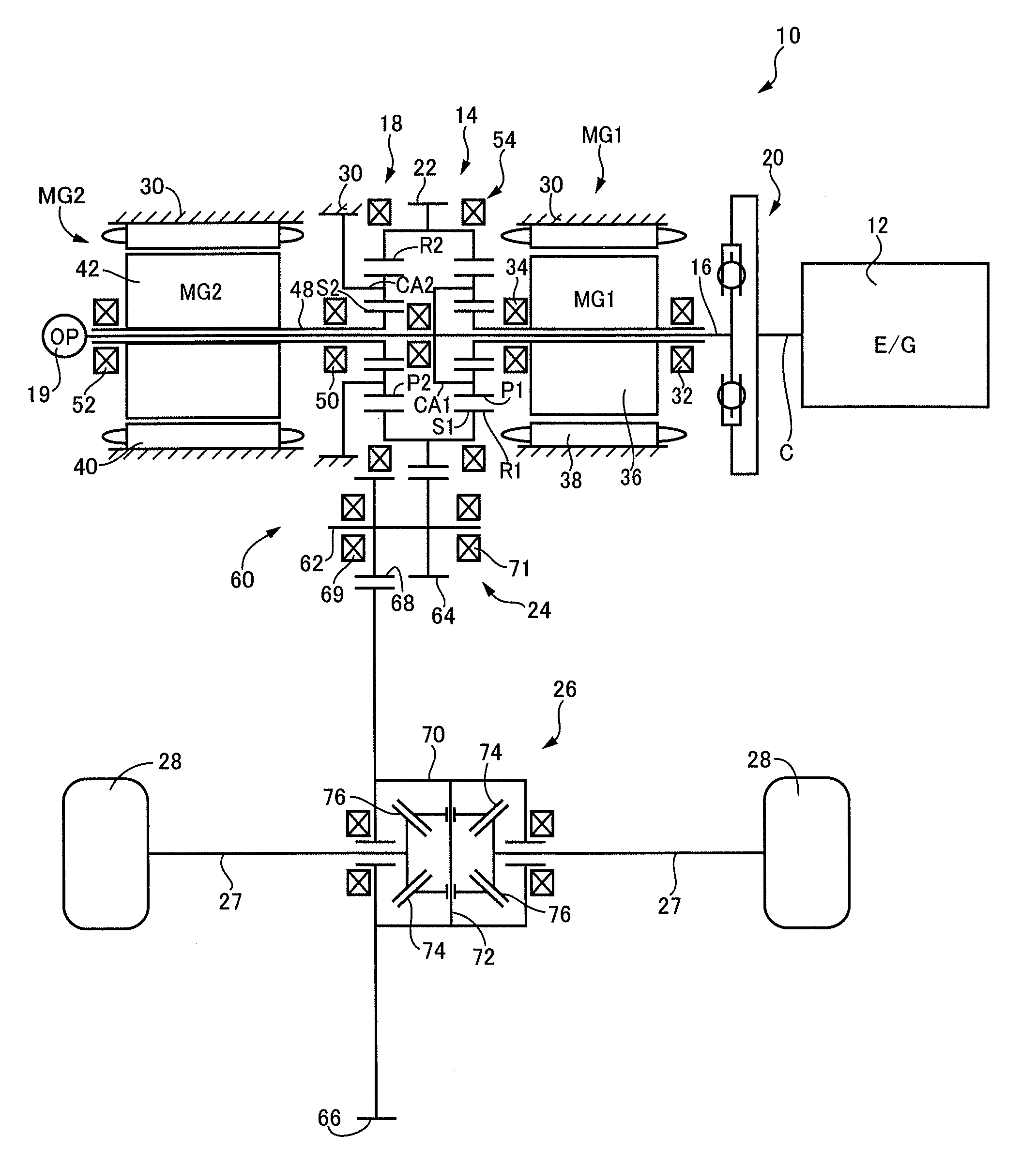

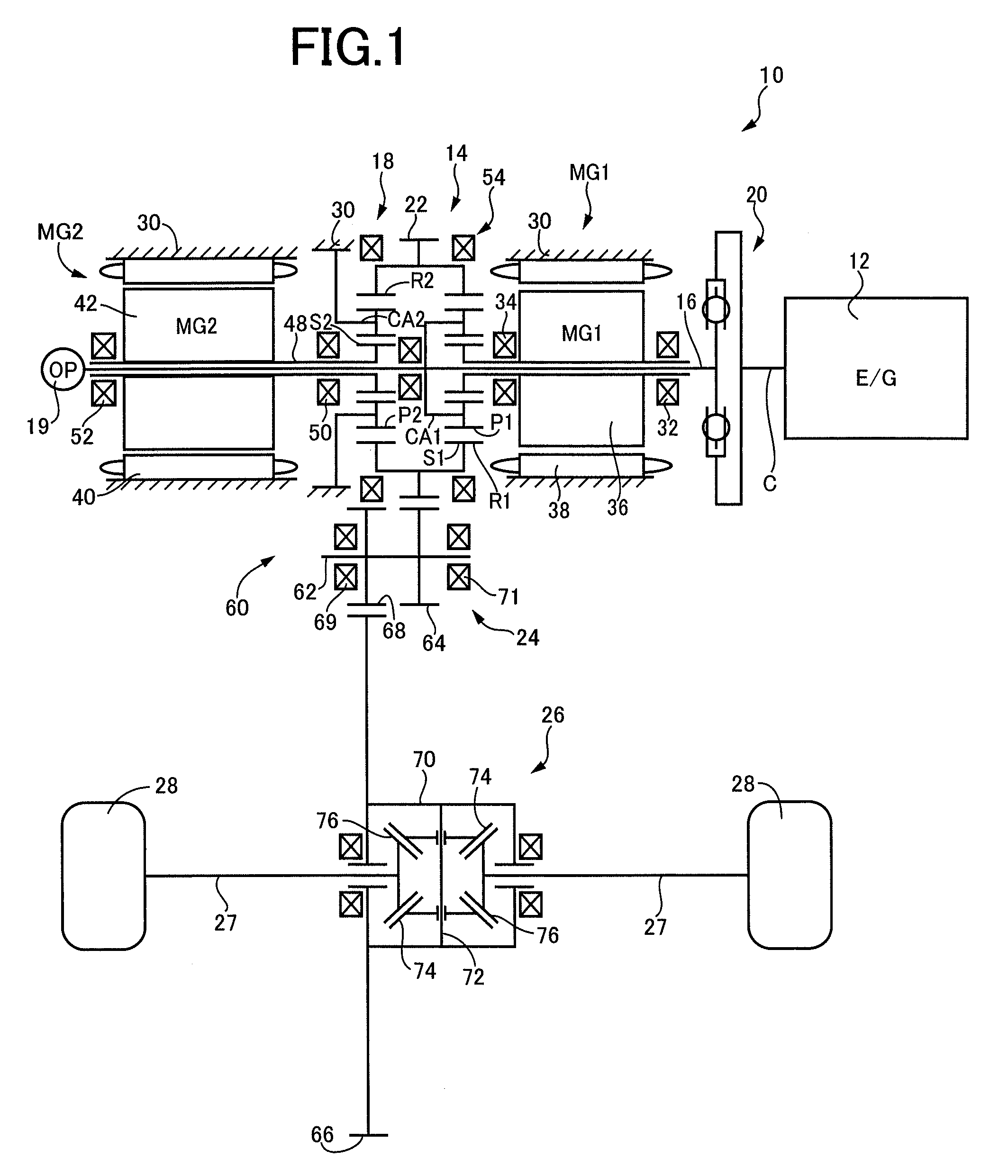

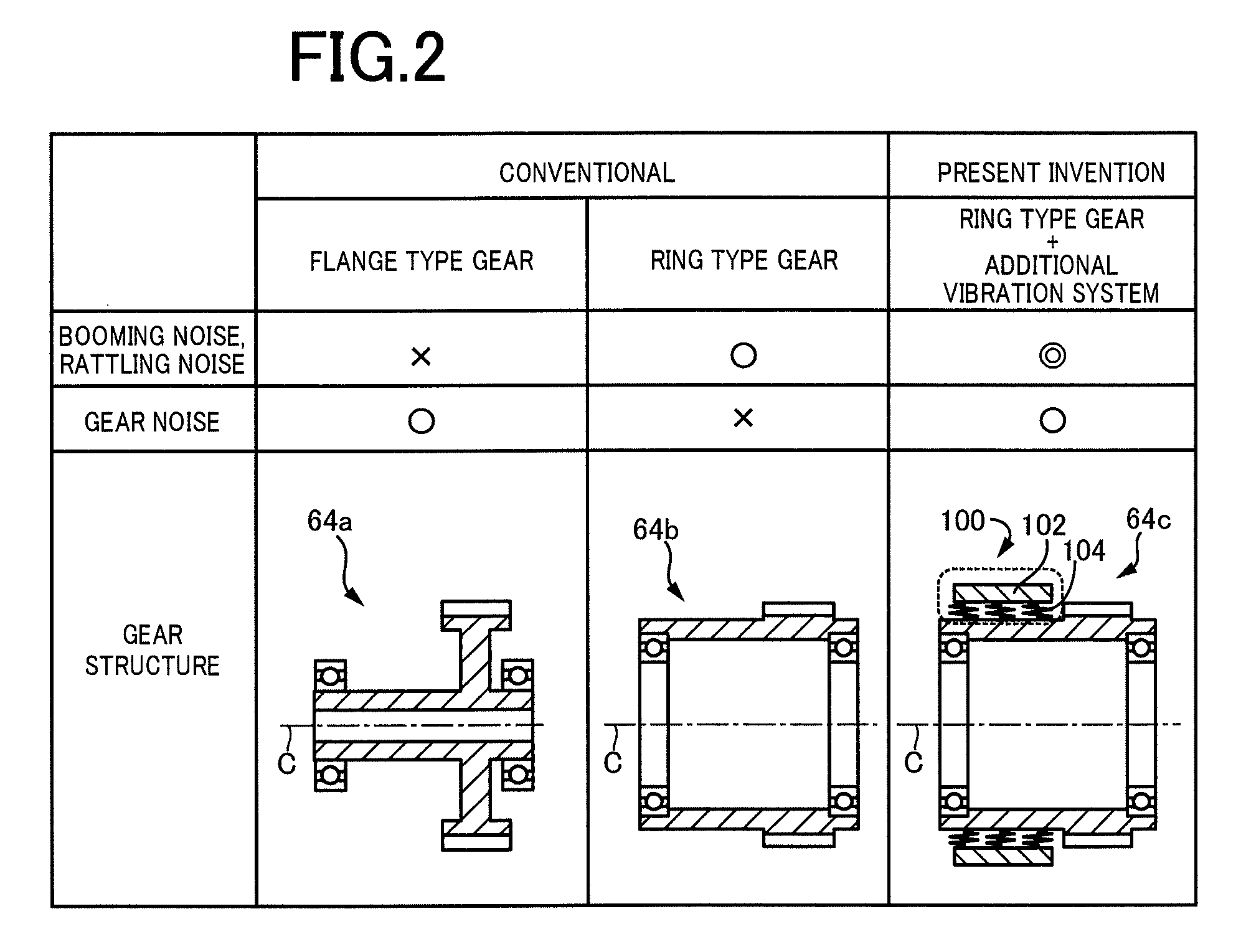

ActiveUS20140013885A1Reduce noiseReduce gear noiseGearboxesGear vibration/noise dampingDrive wheelEngineering

It is provided a meshed gear for a vehicle disposed in a power transmission path between an engine and drive wheels and made up of a pair of gears meshed with each other, at least one gear making up the meshed gear having a ring shape, and the one gear having an outer circumferential portion disposed with an additional vibration system.

Owner:TOYOTA JIDOSHA KK

Case-hardening steel excellent in cold forgeability and low carburization distortion property

Owner:NIPPON STEEL CORP

Vehicular power transmitting system

ActiveUS20180306275A1Reduce noise generateImprove performanceToothed gearingsGearing controlMechanical engineeringEngineering

In a vehicular power transmitting system, a fixing portion of a brake retaining portion receives a reaction force from a reverse drive brake and is located in a portion of a circumference of the brake retaining portion, which is outside a predetermined circumferential portion close to the shifting shaft support portion and is defined by a pair of lines tangent to a circumference of the shifting shaft and parallel to a straight line connecting first and second axes and located on opposite sides of the straight line, as seen in a plane normal to the first axis, where a forward / reverse switching device including the reverse drive brake is disposed on the first axis, and a gear type transmission is disposed on the first axis and the second axis and an outer housing wall and a partition wall radially inwardly extending from the outer housing wall are provided.

Owner:TOYOTA JIDOSHA KK +1

Vehicle and method for improving fuel-efficiency during temporary stop

ActiveUS20160107650A1Reducing planetary gear noiseImprove fuel efficiencyAnalogue computers for vehiclesGearing controlControl releaseCoupling

A method for improving fuel-efficiency during a temporary stop may include dividing, by an engine control apparatus, a neutral control condition into a neutral control entry and a neutral control release during a D-stage temporary stop, determining, a neutral control entry D-stage target RPM at a time of the neutral control entry, and a neutral control release D-stage target RPM at a time of the neutral control release, and RPM shifting the neutral control entry D-stage target RPM to a speed gradient conforming to a transmission clutch release time of a transmission control apparatus at a time of a neutral control after the neutral control entry and RPM shifting the neutral control release D-stage target RPM to a speed gradient conforming to a clutch coupling time of a transmission by the transmission control apparatus at a time of a neutral control after the neutral control release

Owner:HYUNDAI MOTOR CO LTD +1

Meshed gear for vehicle

ActiveUS9212724B2Reduce noiseImprove complianceGear vibration/noise dampingToothed gearingsDrive wheelGear wheel

It is provided a meshed gear for a vehicle disposed in a power transmission path between an engine and drive wheels and made up of a pair of gears meshed with each other, at least one gear making up the meshed gear having a ring shape, and the one gear having an outer circumferential portion disposed with an additional vibration system.

Owner:TOYOTA JIDOSHA KK

Disk carrying device and optical disk recording/reproducing device

ActiveUS20100218205A1Reduce loadSmoothly carry a diskRecord information storageOptical discElectric motor

A disk carrying device and an optical disk recording / reproducing device. The disk carrying device comprises a first idle gear rotatably supported on a lower chassis and a second idle gear rotatingly operated by coming into contact with or separating from the first idle gear. The second idle gear and a roller gear meshed with the second idle gear are rotatably supported on a feed plate, and the second idle gear is brought into contact with or separated from the first idle gear, from the underside, which is rotatably supported on the lower chassis. By this, when a disk is inserted, a downward force F1 acts on the second idle gear, and the pressing force of a feed roller on the disk (D) is decreased and, therefore, the rotating load of a disk carrying motor can be reduced when the carrying of the disk is completed. When the disk is discharged, an upward force F2 acts on the second idle gear and the pressing force of the feed roller on the disk (D) is increased and, therefore, the disk (D) can be smoothly discharged even if the disk (D) is deflected.

Owner:PANASONIC CORP

Vehicle drive apparatus

ActiveUS8888650B2ReliablyReduce gear noiseGear vibration/noise dampingGas pressure propulsion mountingLocking mechanismEngineering

A vehicle drive apparatus includes a motor generator, a speed reduction mechanism connected to a rotor shaft of the motor generator, an output shaft connected to the speed reduction mechanism, an intermediate wall separating the motor generator from the speed reduction mechanism, and a bearing that is fixed to the intermediate wall and supports the rotor shaft. The motor generator, intermediate wall, speed reduction mechanism, and output shaft are disposed in this order, and a ring gear of the speed reduction mechanism is fixed. The ring gear is fixed to the intermediate wall via a ring gear flange that is positioned relative and fixed to the intermediate wall by a centering mechanism and a locking mechanism. The centering mechanism is formed by fitting a boss of the ring gear flange and the intermediate wall. The locking mechanism is disposed on an outer peripheral side relative to the centering mechanism.

Owner:AISIN AW CO LTD +1

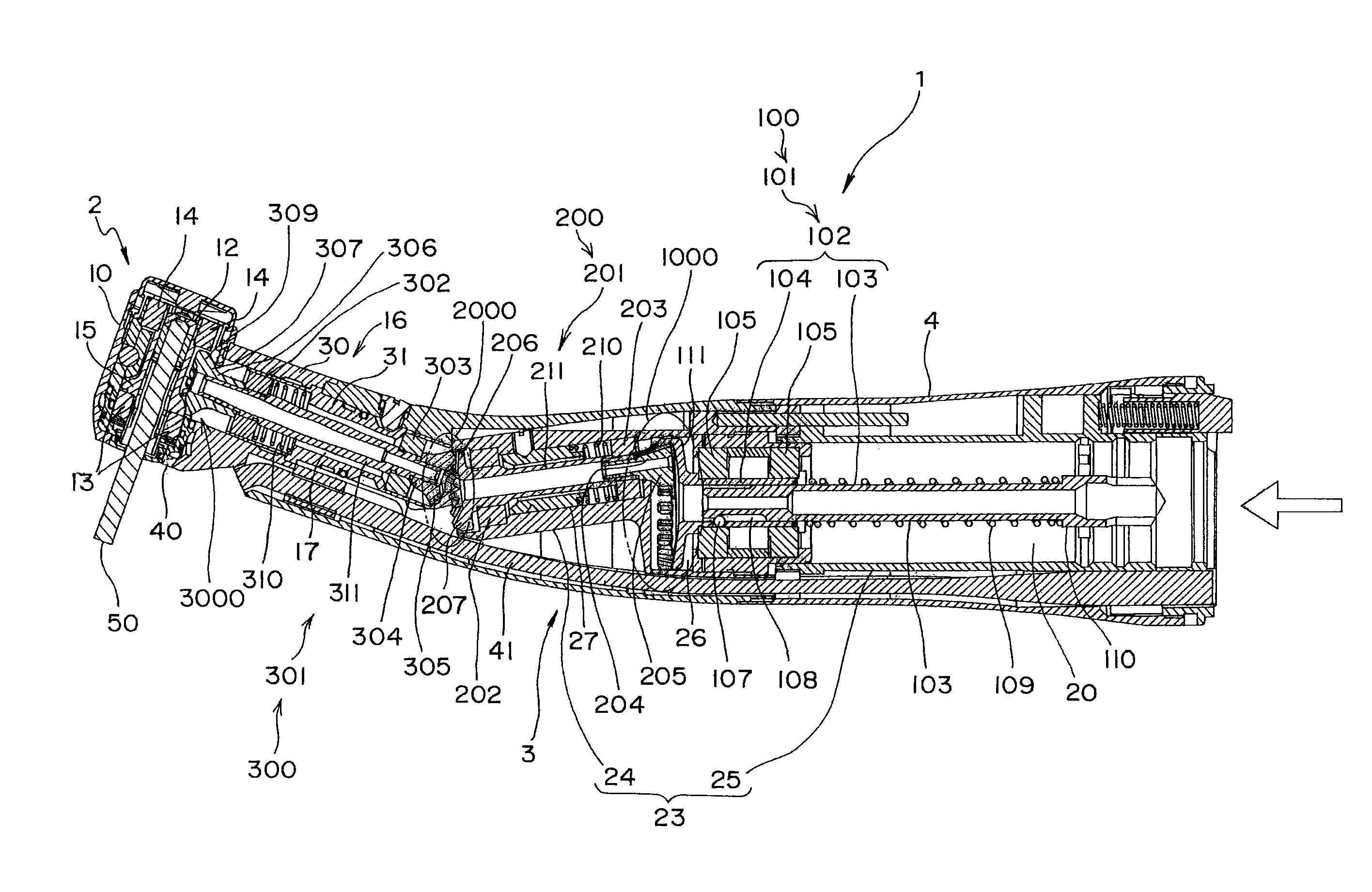

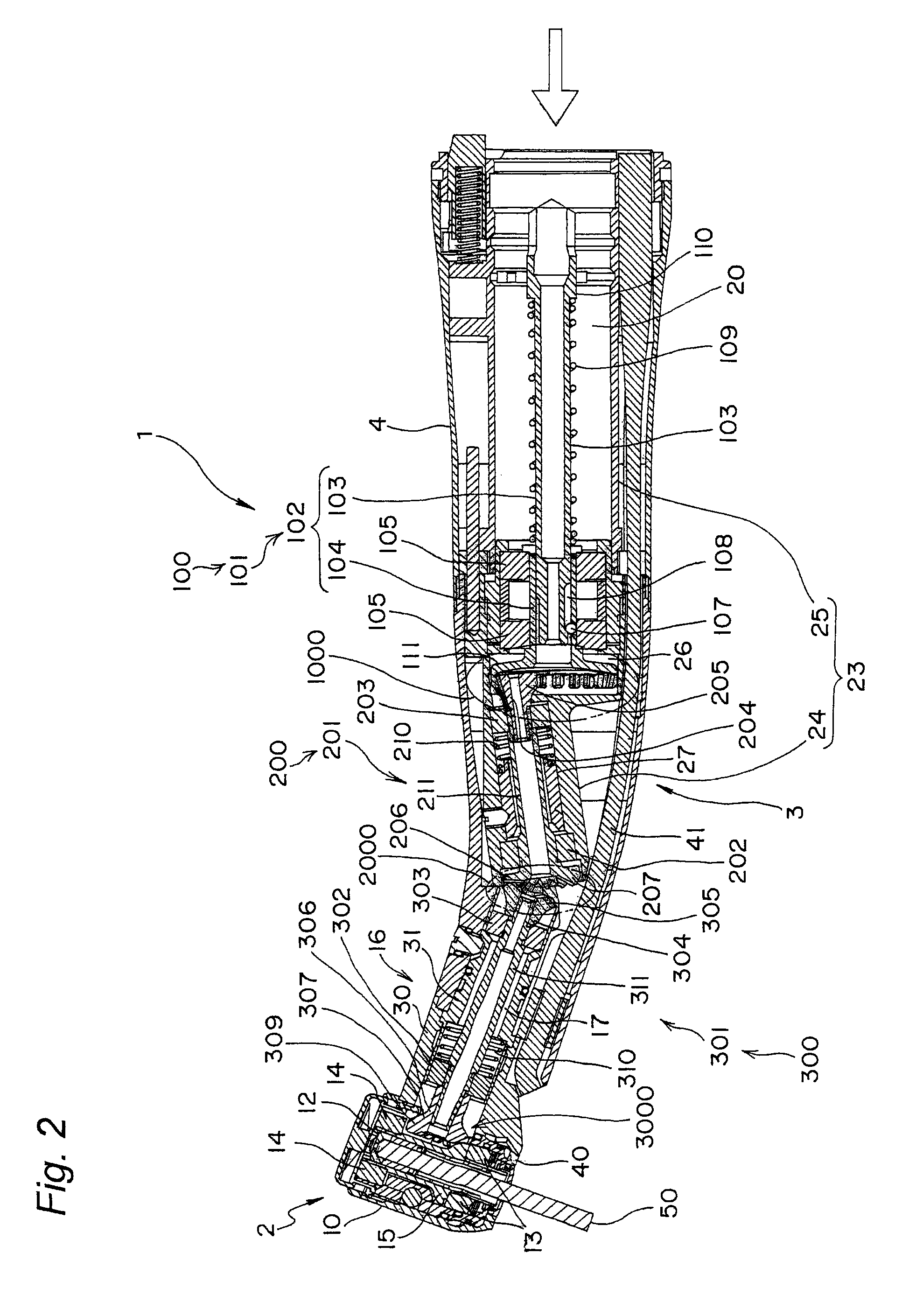

Medical or dental handpiece

ActiveUS9510917B2Increased durabilityHigh strengthMechanical apparatusEndoscopic cutting instrumentsEngineeringMechanical engineering

A medical or dental handpiece has a grip 3. The grip 3 includes first to third rotation shafts 101, 201, and 301. The first and second shafts are connected through a first gear mechanism 1000 and the second and third shafts are connected through a second gear mechanism 2000 so that a rotation is transmitted from the first shaft through the first gear mechanism to the second shaft and then from the second shaft through the second gear mechanism to the third shaft. The first or second gear mechanism has an internal gear secured on shaft and an external gear secured on the other shaft, the internal and the external gears being engaged with each other. The external gear is substantially enclosed within a cylindrical plane 1001, 2001 extending along a peripheral edge of the internal gear.

Owner:MORITA MFG CO LTD

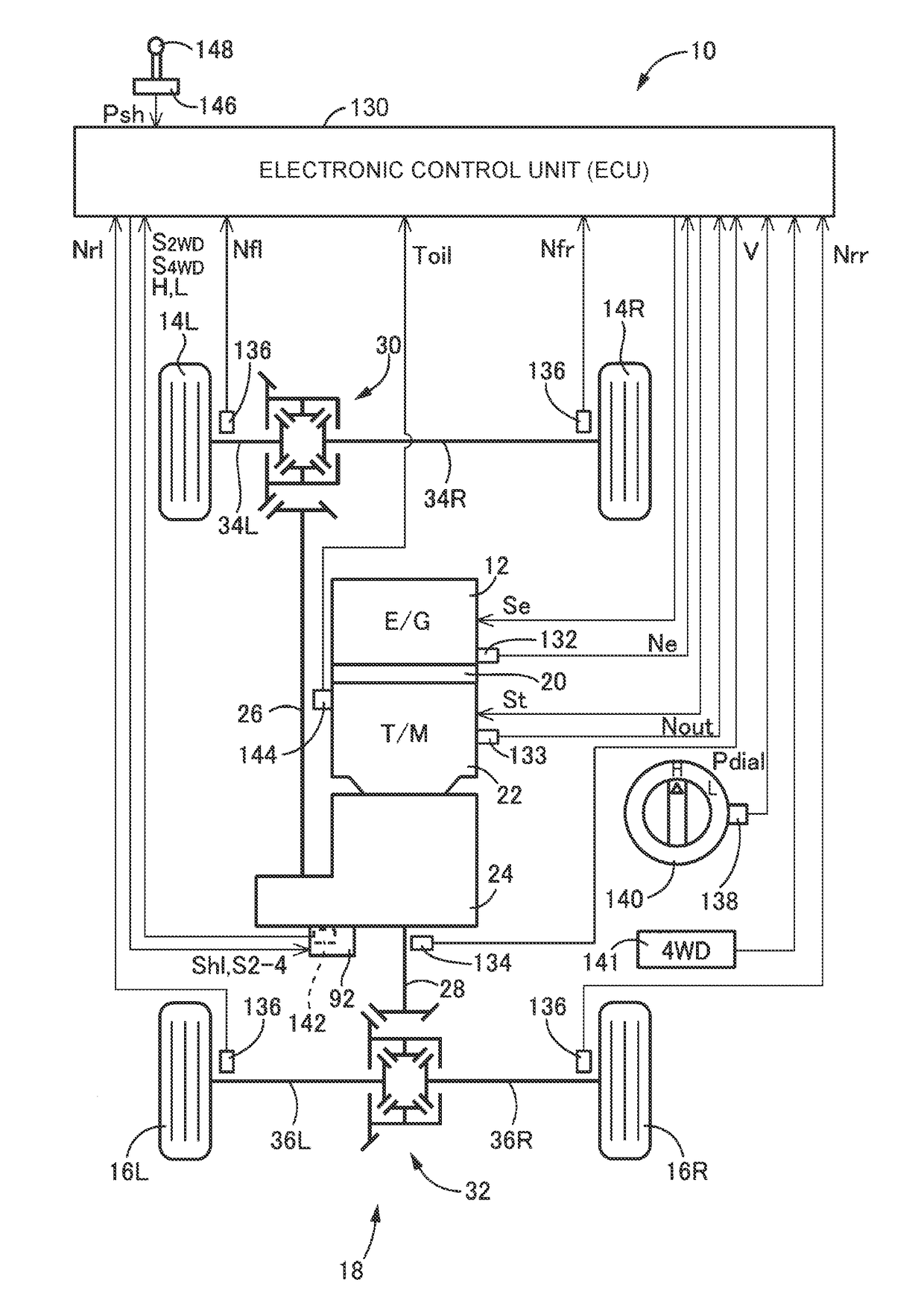

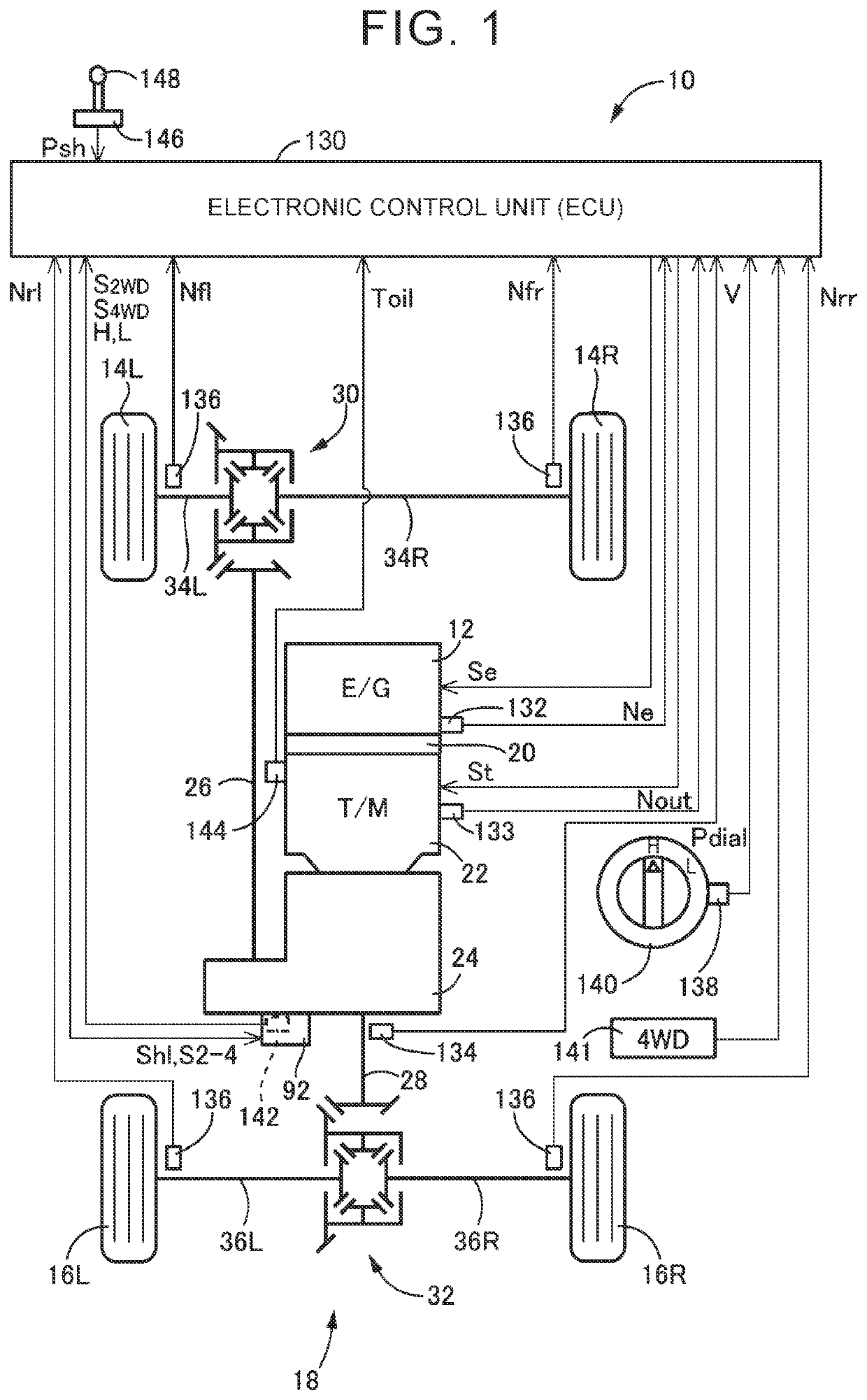

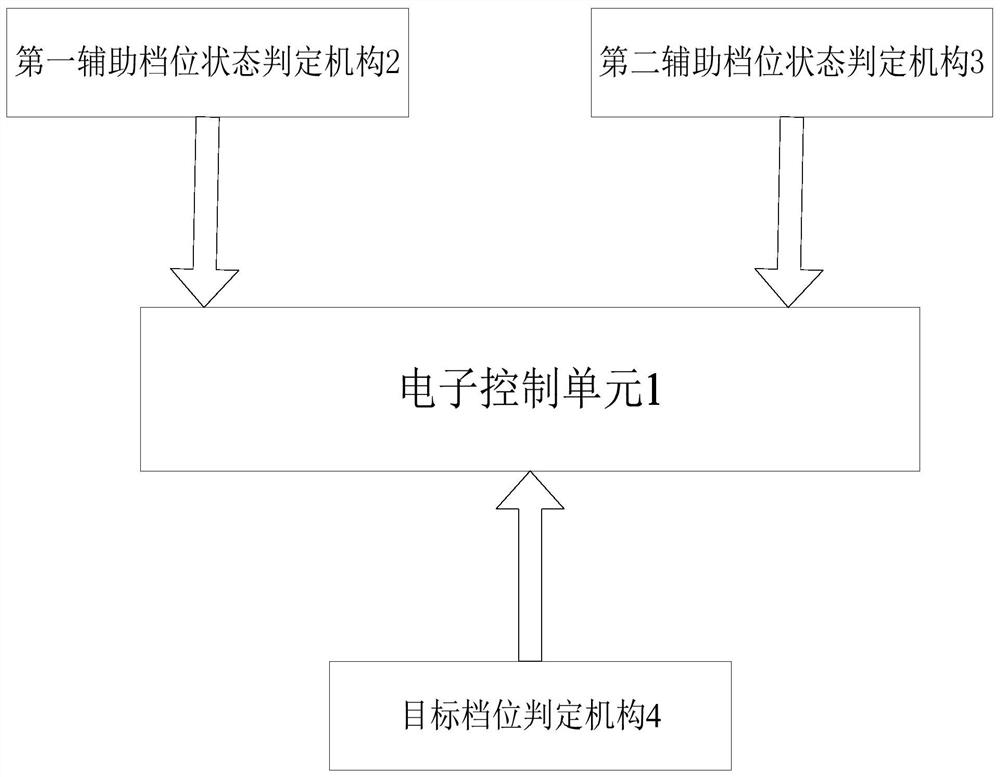

Control Device for Power Transmission Device and Control Method for Vehicle

ActiveUS20180086328A1Reduce speedReduce gear noiseHybrid vehiclesControl devicesLow speedAutomatic transmission

A control device for a power transmission device including an automatic transmission and a sub transmission is provided. The control device includes an electronic control unit. The electronic control unit is configured to perform a rotation speed decrease control in which at least one frictional engagement device is controlled to be an engaged state or a semi-engaged state at a time when switching of gear stage of the sub transmission is started or a time when the switching is started. The electronic control unit is configured to end the rotation speed decrease control during switching of the gear stage. The electronic control unit is configured to switch the sub transmission from the power transmission cutoff state to a state in which one of the high-speed engagement element and the low-speed engagement element is engaged, during disengagement of the at least one frictional engagement device.

Owner:TOYOTA JIDOSHA KK

Control device for power transmission device and control method for vehicle

ActiveUS10501066B2Reduce speedReduce gear noiseHybrid vehiclesControl devicesLow speedAutomatic transmission

A control device for a power transmission device including an automatic transmission and a sub transmission is provided. The control device includes an electronic control unit. The electronic control unit is configured to perform a rotation speed decrease control in which at least one frictional engagement device is controlled to be an engaged state or a semi-engaged state at a time when switching of gear stage of the sub transmission is started or a time when the switching is started. The electronic control unit is configured to end the rotation speed decrease control during switching of the gear stage. The electronic control unit is configured to switch the sub transmission from the power transmission cutoff state to a state in which one of the high-speed engagement element and the low-speed engagement element is engaged, during disengagement of the at least one frictional engagement device.

Owner:TOYOTA JIDOSHA KK

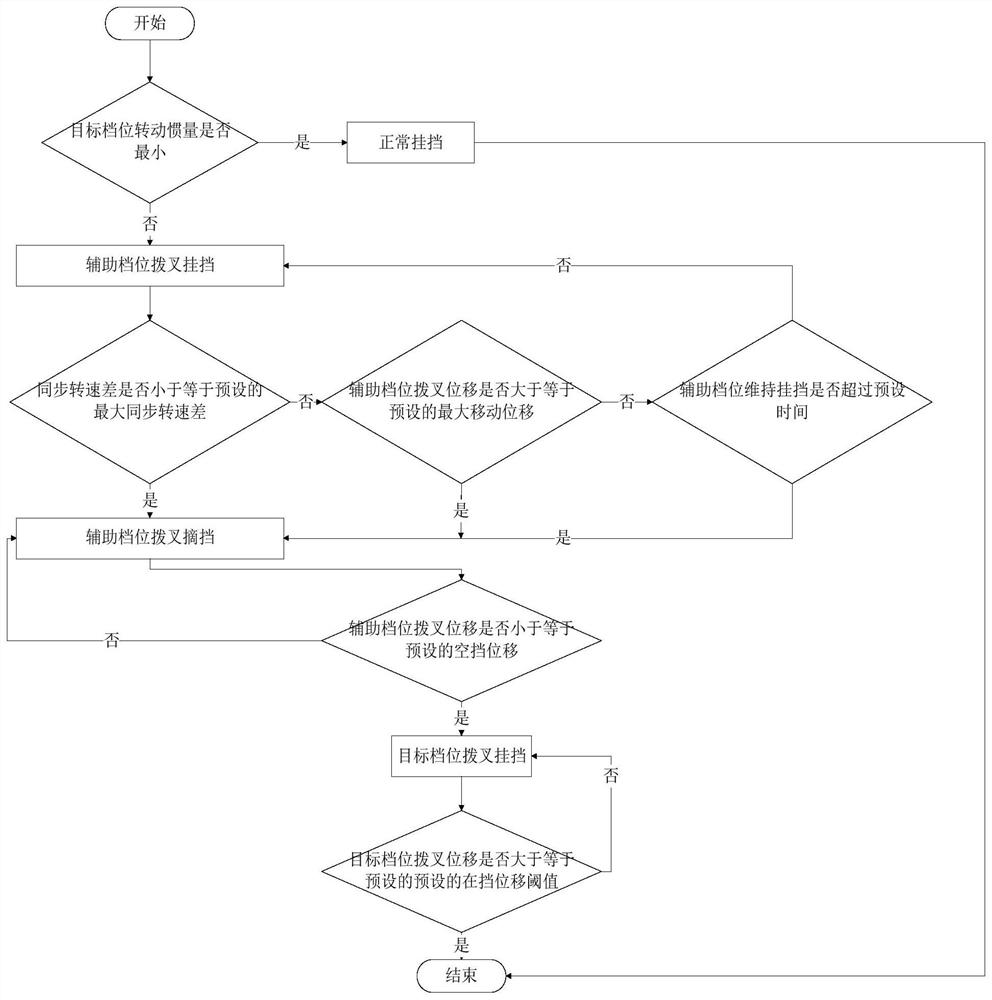

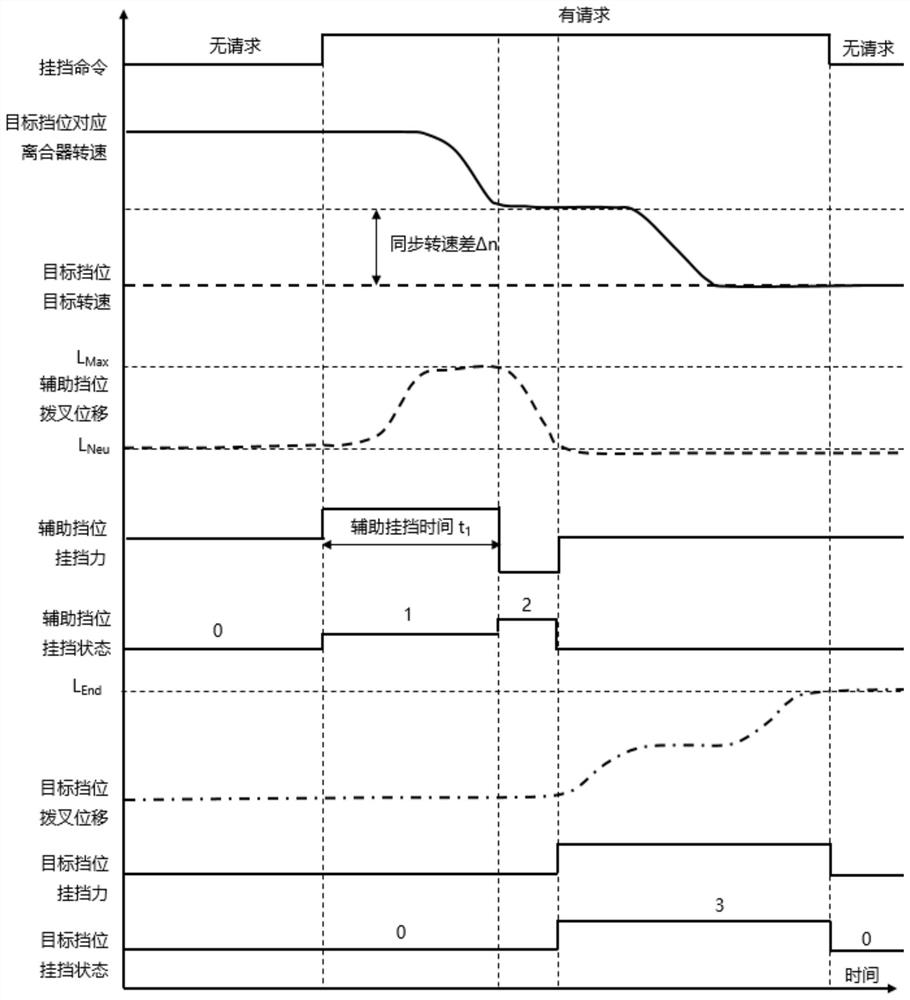

Control method and system for auxiliary gear engaging of wet-type double-clutch synchronizer and automobile

PendingCN114838121AReduce speedImprove comfortRoad transportGearing controlControl theoryRotary inertia

The invention relates to a control method and system for auxiliary gear engaging of a wet-type double-clutch synchronizer and an automobile. The method specifically comprises the steps that S1, rotational inertia of all gears is obtained, whether the rotational inertia of a target gear is minimum or not is judged, if yes, gear engaging is conducted towards the target gear, and the process is ended, and if not, the step S2 is executed; s2, enabling an auxiliary gear shifting fork to enter a gear engaging state; s3, the auxiliary gear is made to enter a gear taking-off state, and an auxiliary gear shifting fork is made to be located in a neutral gear area; and S4, the target gear is made to enter the gear engaging state till the target gear shifting fork moves to the in-gear position till gear engaging of the target gear shifting fork is completed. According to the method, when the low gear is engaged in a static state, the idle high gear can be used for engaging the gear, the rotating speed of the target gear clutch is reduced, and then the low gear is engaged, so that the gear engaging is completed by using small gear engaging force, the gear engaging noise is reduced, and the comfort of the whole vehicle is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com