Control method and system for auxiliary gear engaging of wet-type double-clutch synchronizer and automobile

A wet dual clutch and control method technology, applied in the field of clutches, can solve problems such as easy generation of noise, and achieve the effects of reducing gear shifting noise and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

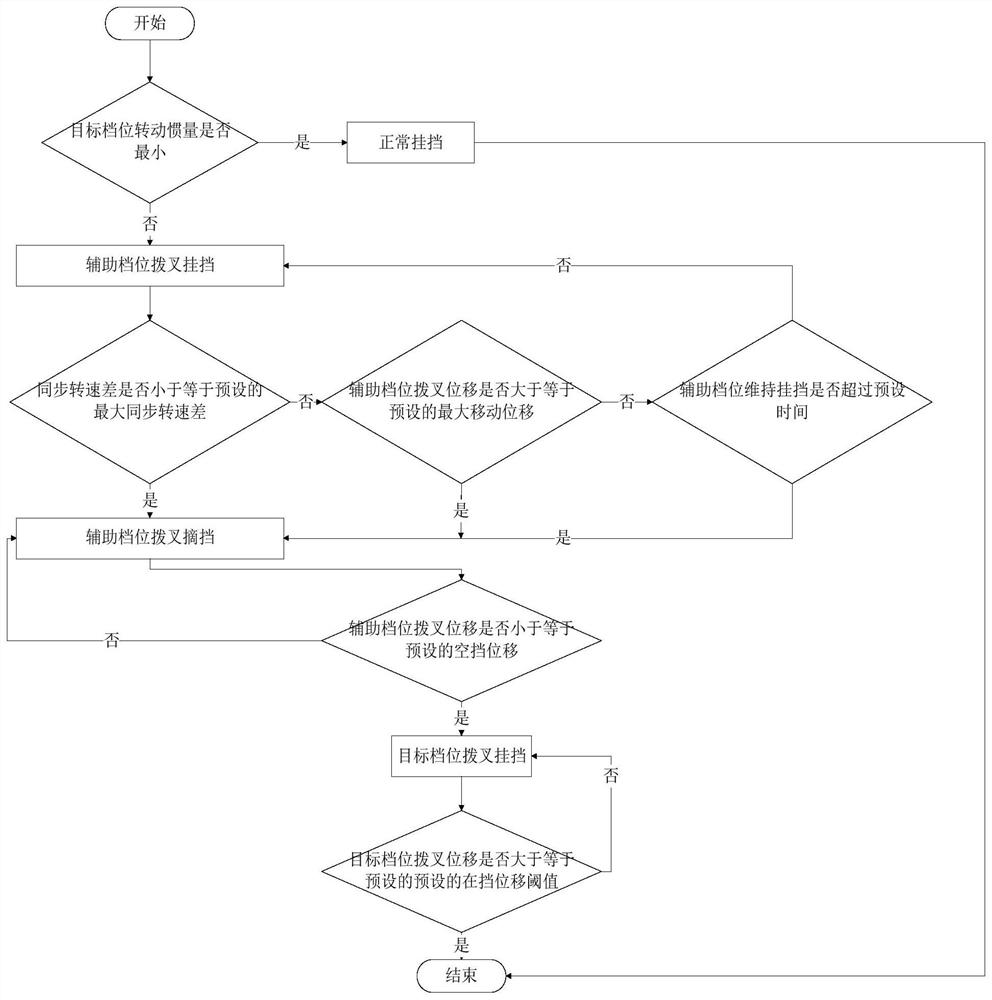

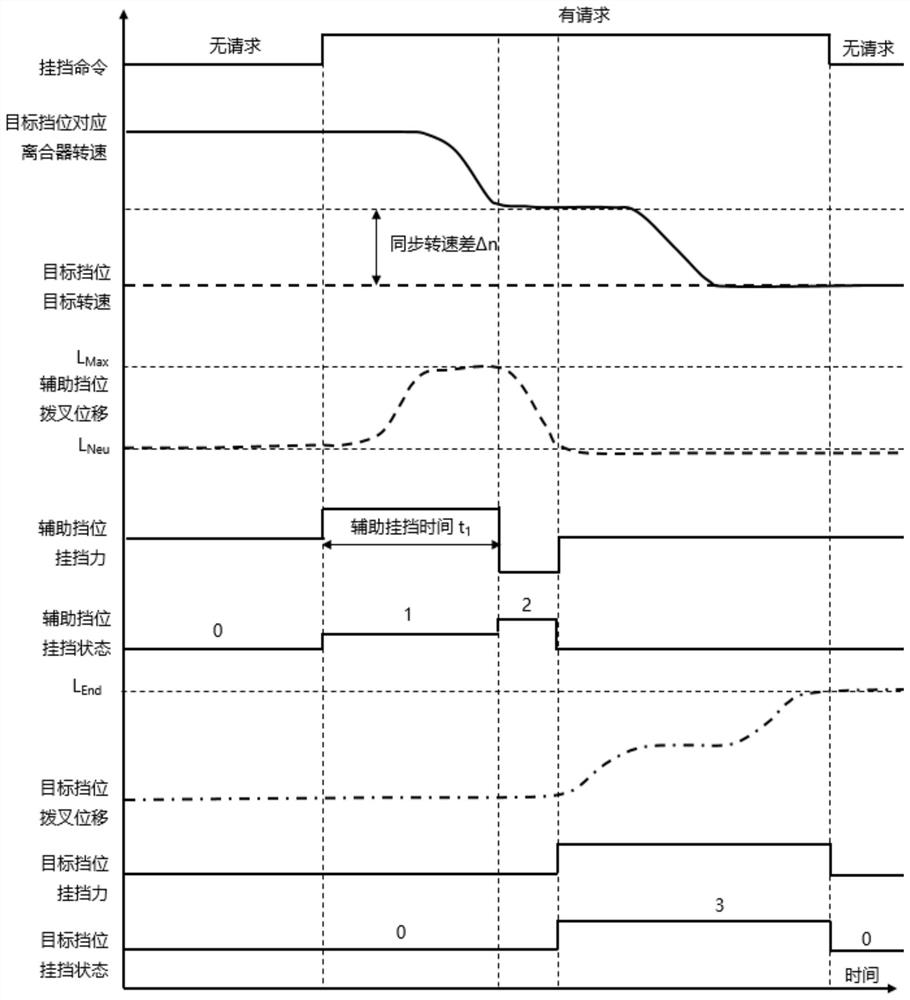

[0031] This embodiment proposes a control method for auxiliary gear shifting of a wet dual-clutch synchronizer, such as figure 1 and figure 2 As shown, the method is specifically as follows: before the method is implemented, the odd-numbered shaft clutch speed n is collected by the electronic control unit 1 , even-numbered shaft clutch speed n 2 , 1st gear shift fork displacement L 1 , 2-gear fork displacement L 2 , 3-speed fork displacement L 3 , 4-speed fork displacement L 4 , 5-speed fork displacement L 5 , 6-speed fork displacement L 6 , 7-speed fork displacement L 7 , R shift fork displacement L R , 1st gear moment of inertia J 1 , 2nd gear moment of inertia J 2 , 3rd gear moment of inertia J 3 , 4th gear moment of inertia J 4 , 5th gear moment of inertia J 5 , 6th gear moment of inertia J 6 , 7th gear moment of inertia J 7 , R gear moment of inertia J R , 1st gear ratio g 1 , 2nd gear ratio g 2 , 3rd gear ratio g 3 , 4th gear ratio g 4 , 5th gear rat...

Embodiment 2

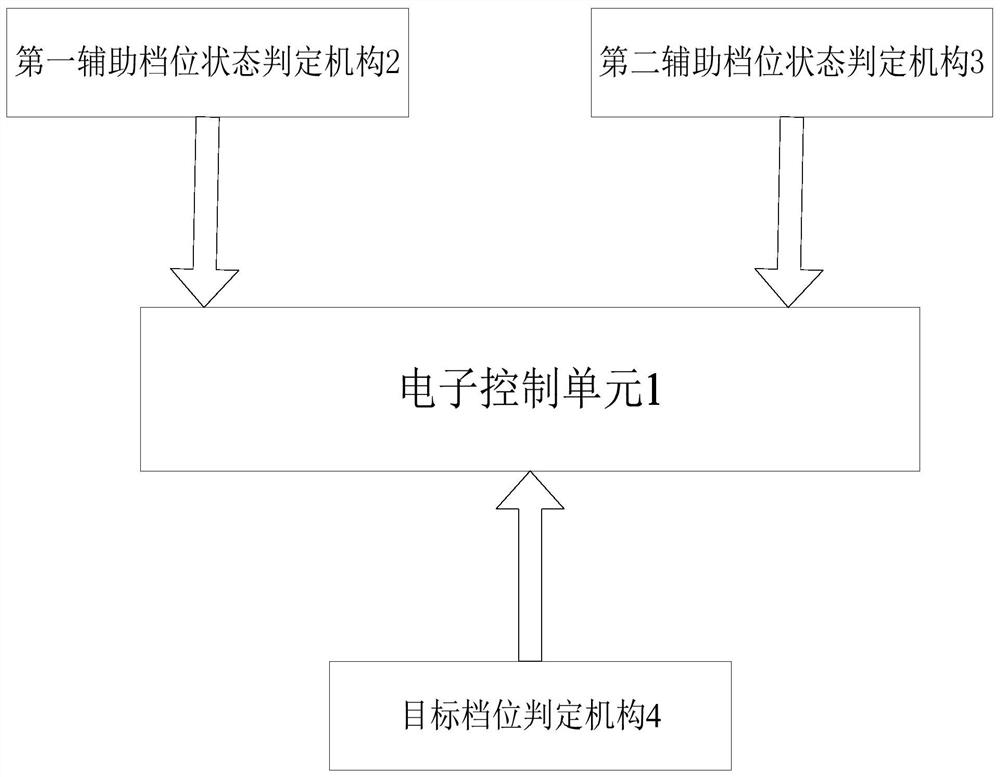

[0039] This embodiment proposes a control system for auxiliary gear shifting of a wet dual-clutch synchronizer, based on the control method for auxiliary shifting of a wet dual-clutch synchronizer described in Embodiment 1, as figure 2 shown.

[0040] It includes an electronic control unit 1 , a first auxiliary gear state determination mechanism 2 , a second auxiliary gear state determination mechanism 3 and a target gear determination mechanism 4 .

[0041] The first auxiliary gear state determination mechanism 2 is configured to determine whether the auxiliary gear changes from the in-gear state to the out-of-gear state. If so, the electronic control unit 1 controls the auxiliary gear to enter the off-gear state; if not, it determines whether the displacement of the fork of the auxiliary gear is greater than or equal to the preset maximum displacement; If not, it is determined whether the time for the auxiliary gear fork to maintain the in-gear state is greater than or equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com