Vehicle drive apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

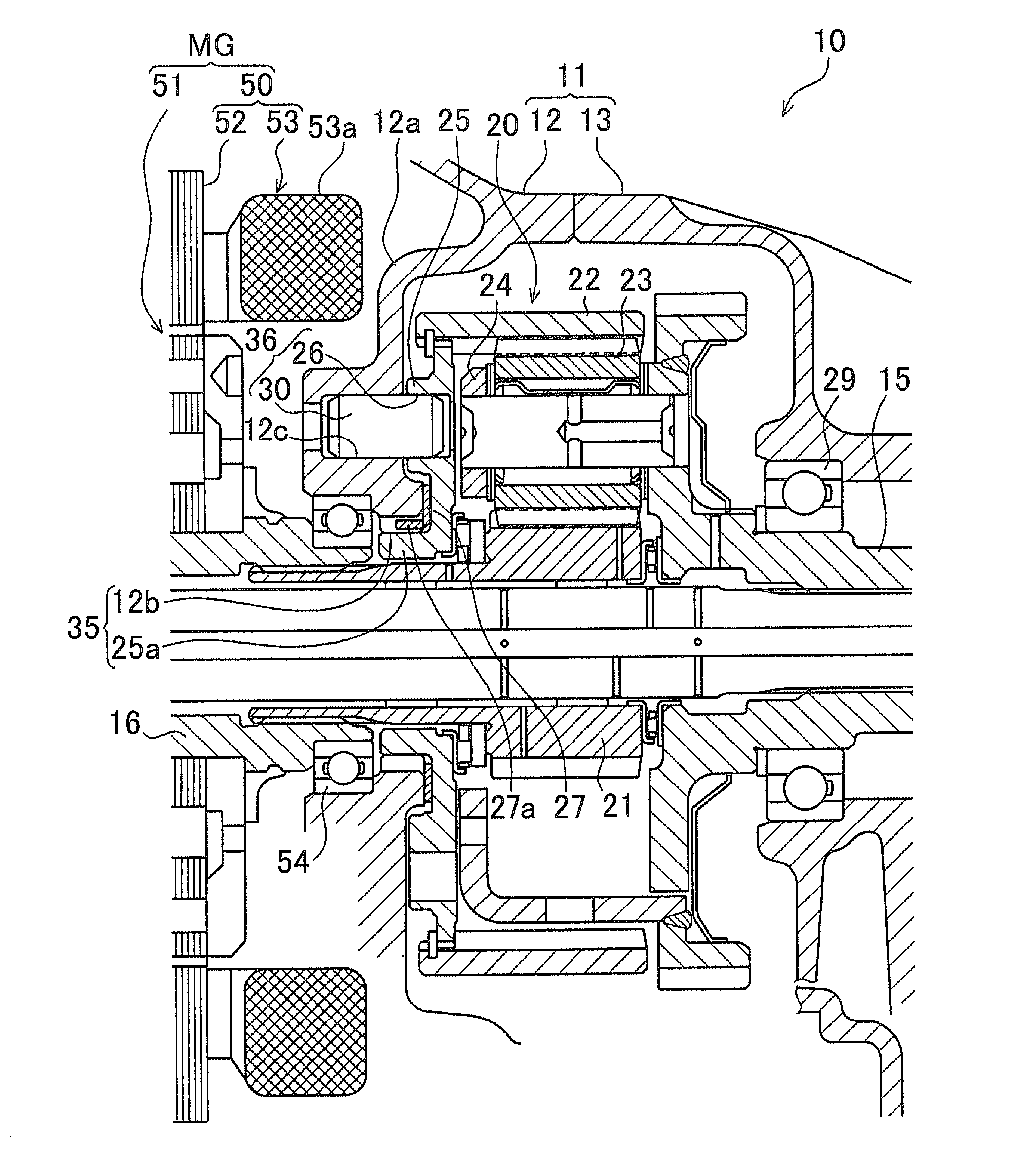

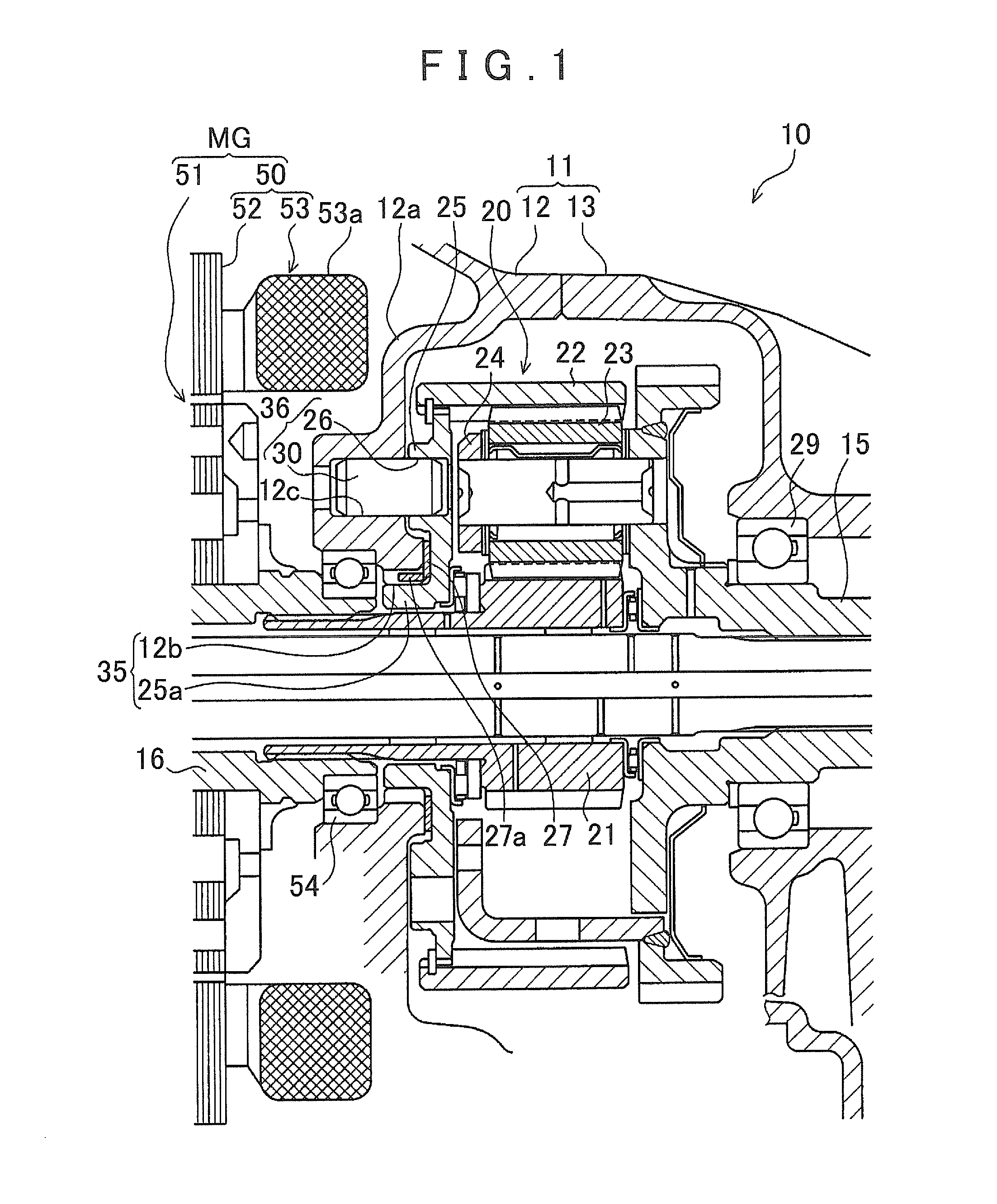

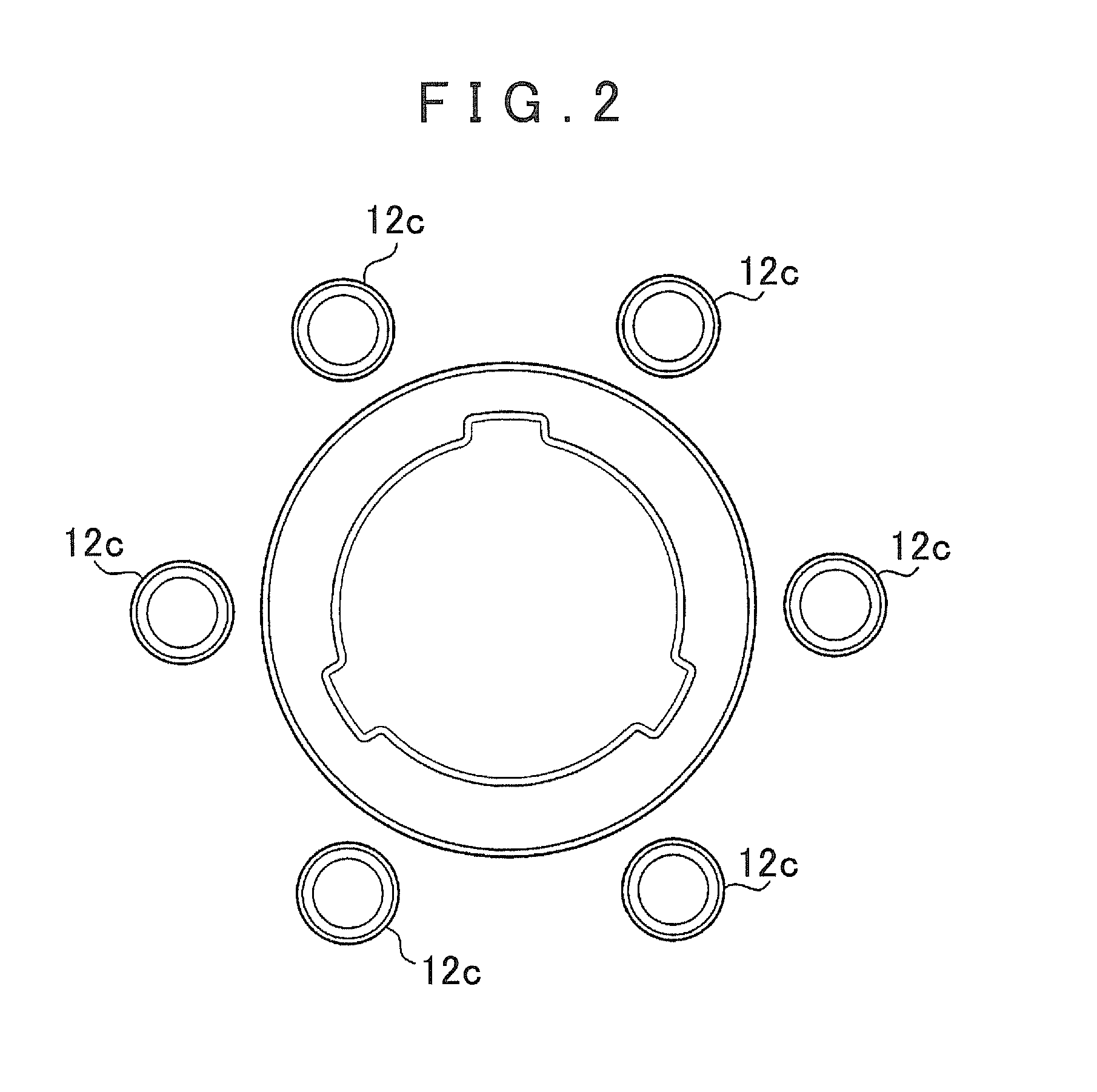

[0040]A vehicle drive apparatus according to a preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings. The embodiment represents a drive apparatus disposed longitudinally in a front-engine rear-drive (FR) hybrid vehicle. The drive apparatus according to the embodiment will be described with reference to FIG. 1. FIG. 1 is a cross-sectional view schematically showing a configuration of a speed reduction mechanism of the drive apparatus according to the embodiment.

[0041]Referring to FIG. 1, a drive apparatus 10 according to the embodiment includes a motor generator MG, a speed reduction mechanism 20 connected to the motor generator MG, and an output shaft 15 connected to the speed reduction mechanism 20. These are accommodated inside a transmission case 11 composed of a main housing 12 and an extension housing 13. The main housing 12 and the extension housing 13 each are formed of a metallic material, such as aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com