Integrated advanced wastewater treatment device and process

A technology for advanced treatment and sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of small reserved space and high water head requirements, and reach the water head The loss is small, the amount of dosing is saved, and it is beneficial to the effect of subsequent precipitation and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

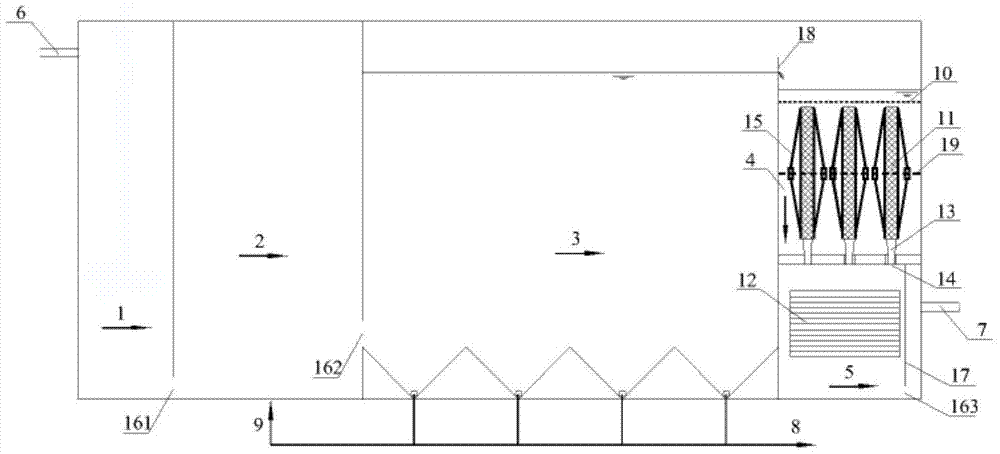

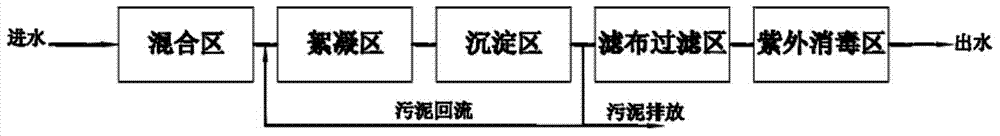

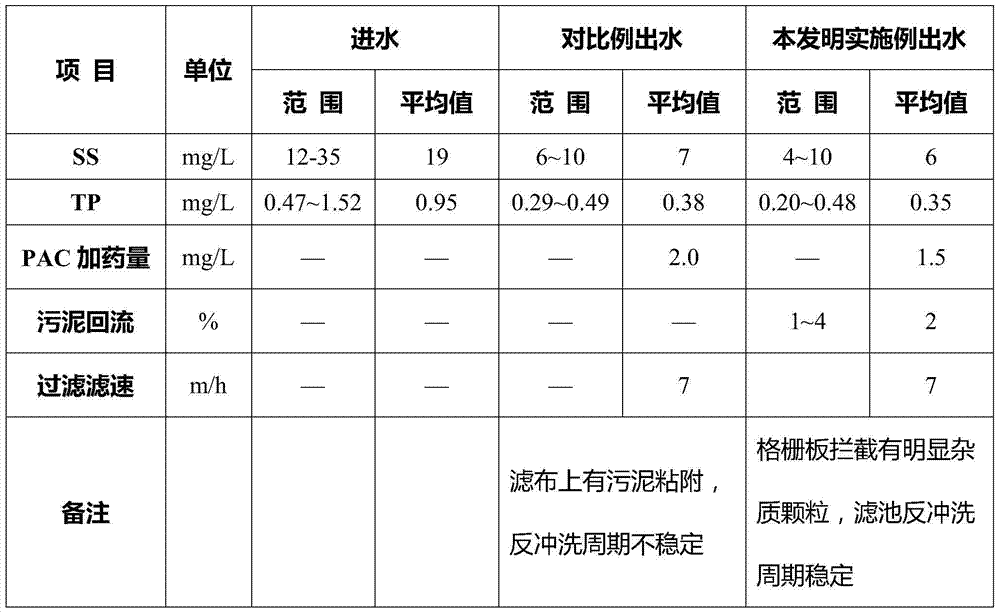

[0033] Integrated sewage advanced treatment device, such as figure 1 As shown, the device includes a mixing zone 1, a flocculation zone 2, a sedimentation zone 3, a filter cloth filtration zone 4 and a disinfection zone 5, wherein a water inlet pipe 6 is provided on one side of the mixing zone 1, and the mixing zone 1 passes through the first water hole 161 communicates with the flocculation area 2, and the flocculation area 2 communicates with the sedimentation area 3 through the second water hole 162, and the upper part of the other side of the sedimentation area 3 is provided with an outlet weir 18, and a filter cloth filter area 4 is provided under the outlet weir 18, A slot-type filter element 11 is arranged in the filter cloth filter area 4, a grid plate 10 is provided at the front end of the filter cloth filter area 4, a water collection tank 13 is provided at the rear end of the filter cloth filter area 4, and a mesh 14 is provided at the bottom of the water collection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com