Digital intelligent liquid densitometer, and density detecting method thereof

A technology of density detection and liquid density, which is applied to determine the specific gravity and other directions by using the flow characteristics of the fluid, can solve the problems that the data cannot be detected online in real time, and the specific gravity meter is complicated and hysteresis due to the crystallizer working conditions, so as to achieve online real-time detection, The effect of intelligent detection process and stable liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention provides many applicable inventive concepts that can be embodied in numerous specific contexts. The specific examples described in the following embodiments of the present invention are only used as illustrations of specific embodiments of the present invention, and are not intended to limit the scope of the present invention.

[0065] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0066] This embodiment provides a digital intelligent liquid density meter, which is applied to detect the density of overflow liquid in the reverse flotation cold crystallization process of producing potash fertilizer using salt lake brine resources as raw materials.

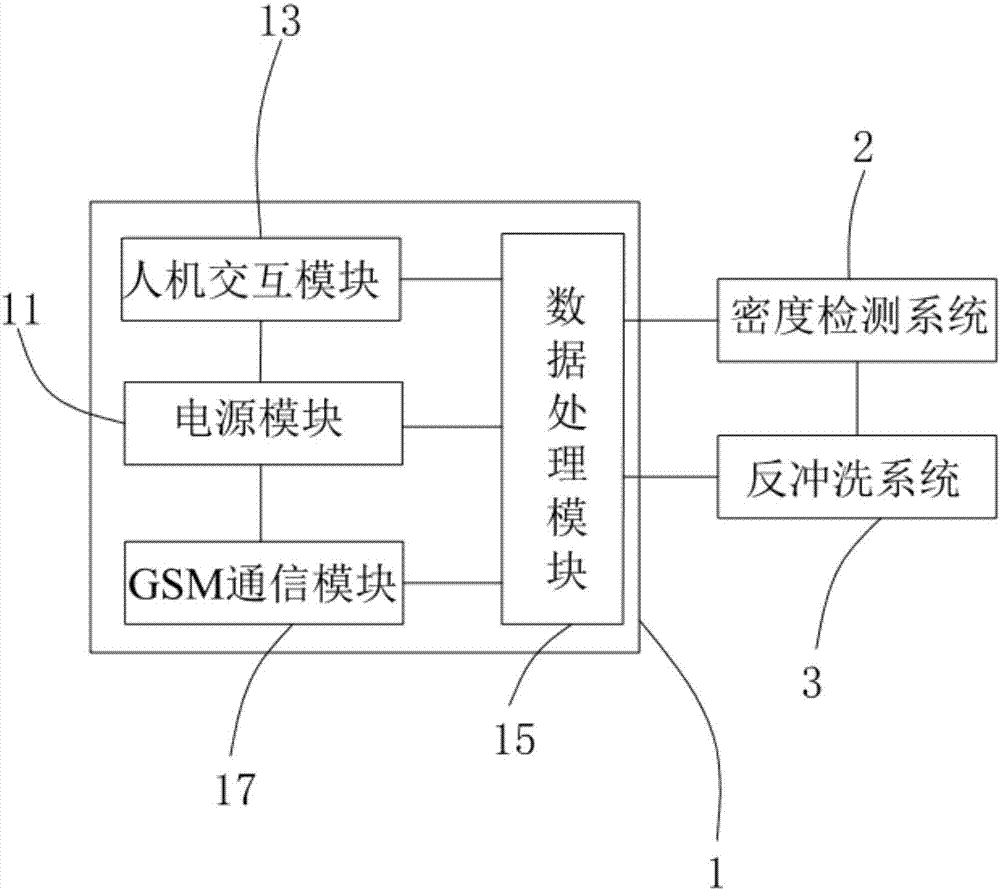

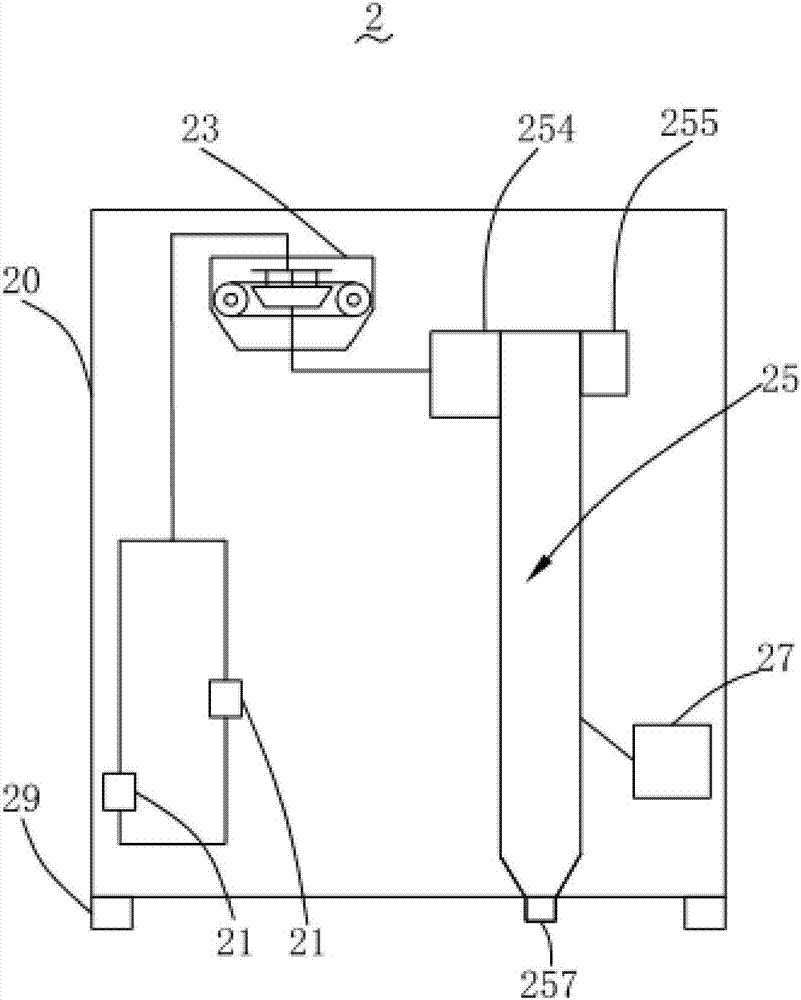

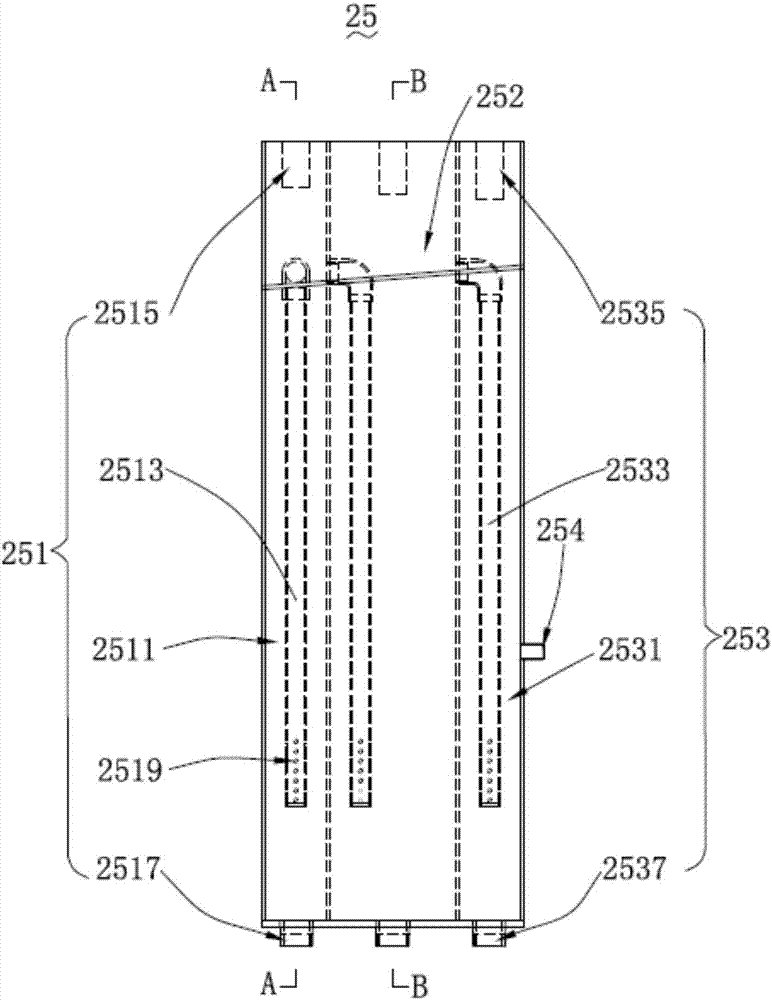

[0067] figure 1 A structural block diagram of a digital intelligent liquid density meter in a preferred embodiment of the present invention is shown. Such as figure 1 As shown, the digital intelligent liquid density meter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com