Graphite bubble-cap tower for purifying wet-process phosphoric acid by solvent extraction method

A wet-process phosphoric acid and extraction technology, which is applied in solvent extraction, liquid solution solvent extraction, inorganic chemistry, etc., can solve the problems of increasing production costs and safety risks, destroying the stability of process operation, and malfunctioning of bubble towers. Achieve the effects of improving the utilization rate of the tray, improving the start-up efficiency, and reducing the high-frequency risk of damage and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

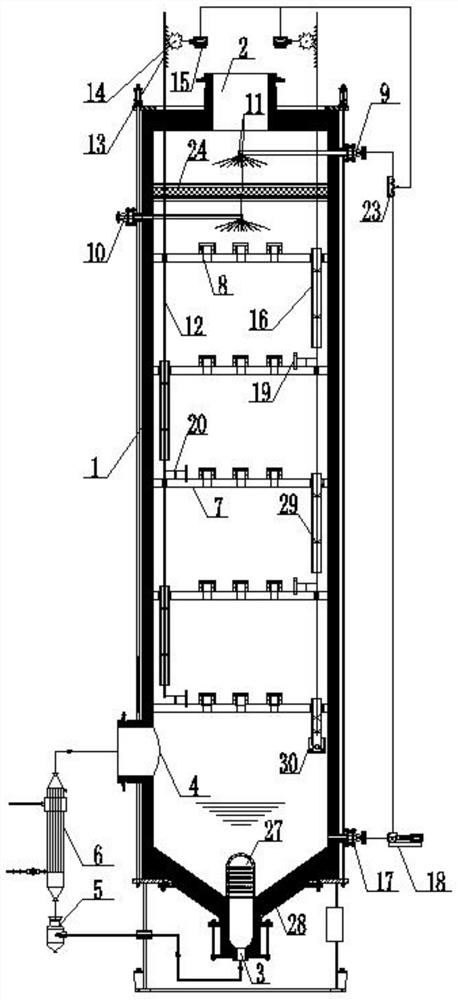

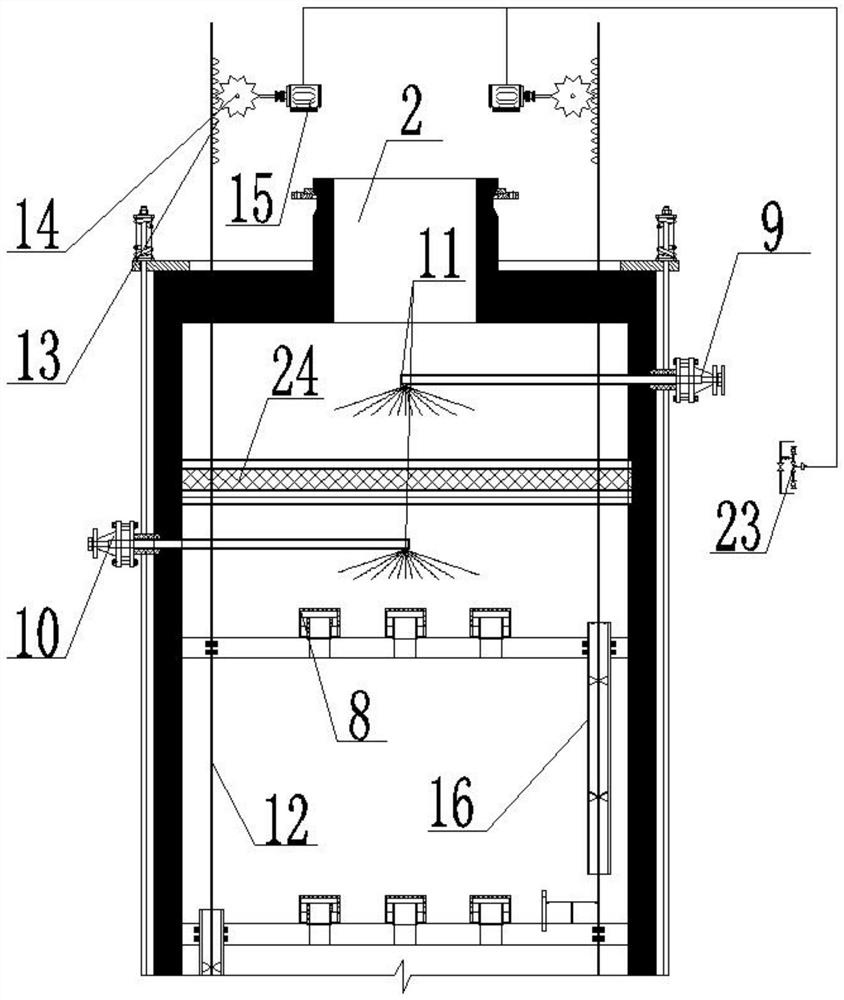

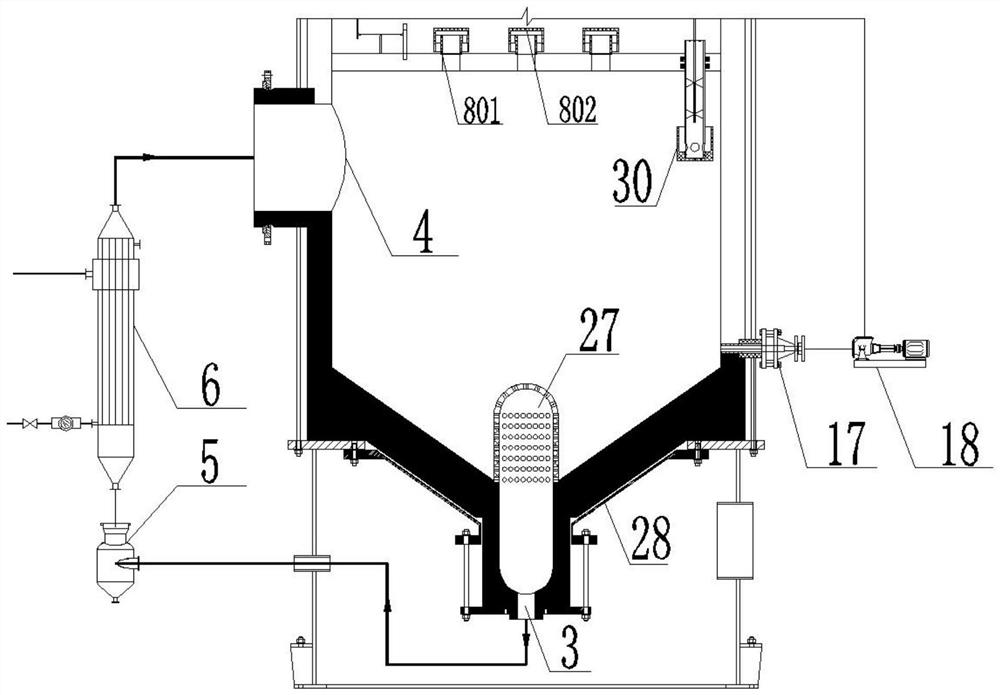

[0044] Embodiments of the present invention: a graphite bubble tower used for solvent extraction to purify wet-process phosphoric acid, as attached Figure 1-13 As shown, a graphite tower body 1 is included, the top of the graphite tower body 1 is a gas material outlet 2, and the bottom end is a liquid material outlet 3, the side of the lower end of the graphite tower body 1 is respectively provided with a material vapor-liquid mixture inlet 4, and the gas material outlet 2 and The inlets 4 of the material vapor-liquid mixture are connected through a reboiler 6. The inside of the graphite tower body 1 is provided with multi-layer trays 7 evenly spaced horizontally from top to bottom, and the surface of each tray 7 is densely covered with graphite bubble caps 8. A plurality of cleaning solution inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com