Hydraulic design method of half-spiral water-sucking chamber for pump

A technology of hydraulic design and water absorption chamber, which is applied in the direction of pumps, pump components, mechanical equipment, etc., and can solve problems such as dependence on experience, eddy loss, and inability to meet the requirements of anti-cavitation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

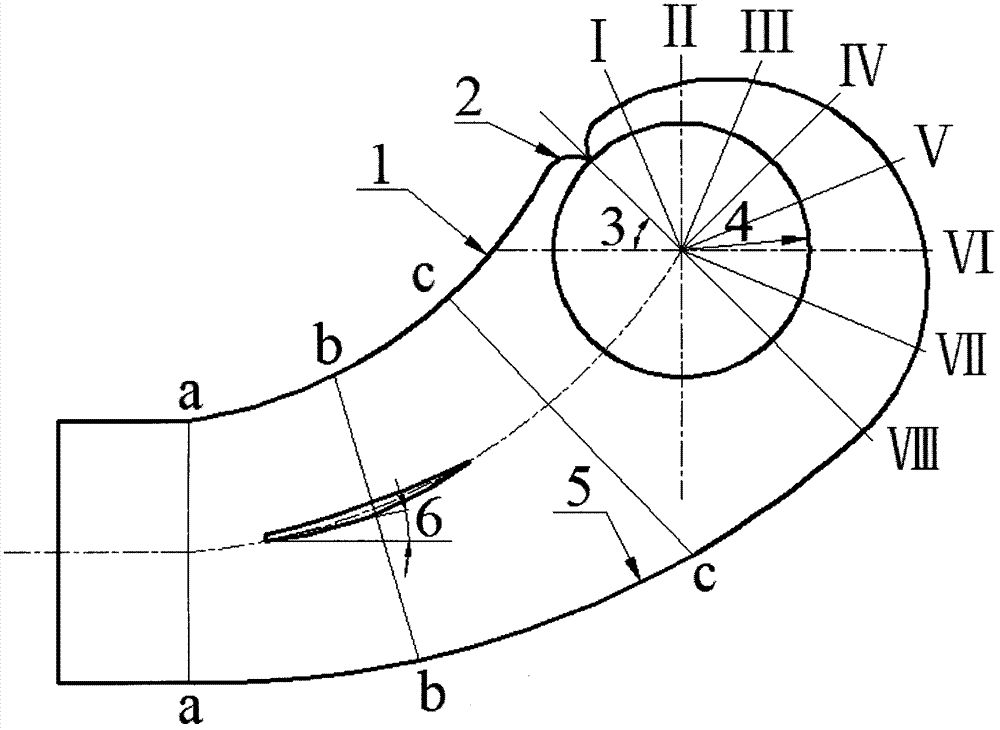

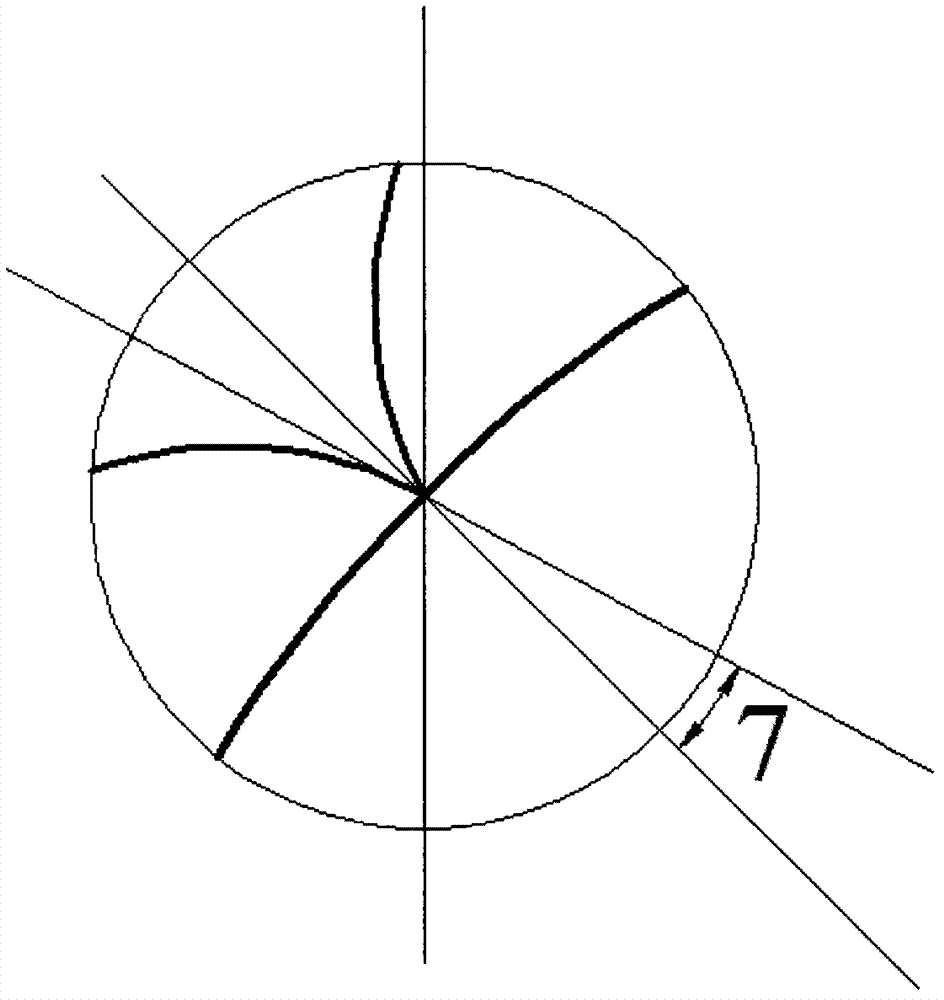

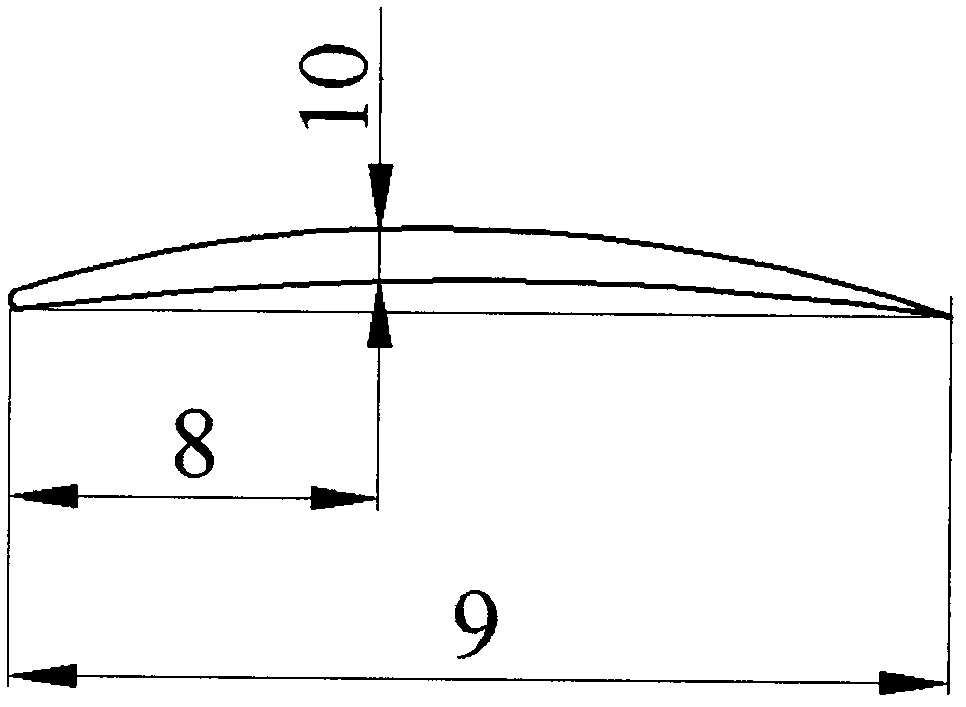

[0126] figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The shape of the water-absorbing chamber of this embodiment is jointly determined, which is a semi-spiral water-absorbing chamber. The present invention utilizes the following parameters to determine the shape of the water-absorbing chamber, mainly including: tongue-separating angle α (3), tongue-separating angle γ (7), and the upper radius R of the suction chamber 1 (1), the radius of the entrance and exit of the septum r 1 (2), base circle radius R 2 (4), the radius R of the lower side of the suction chamber 3 (5). . There is a partition behind the inlet of the water absorption chamber, which is determined by the following parameters: the length of the partition l (9), the angle between the partitions θ (6), and the thickness of the partition δ (10). The inlet section of the water absorption chamber has three transition section shapes, which are determined by the following parameters: the radius of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com