Netted rope-combing sedimentation tank

A sedimentation tank and net rope technology, applied in the direction of the settlement tank, etc., can solve the problems of increasing head loss, poor water flow uniformity, and affecting sedimentation efficiency, and achieve the effect of increasing volume utilization coefficient, reducing cost, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

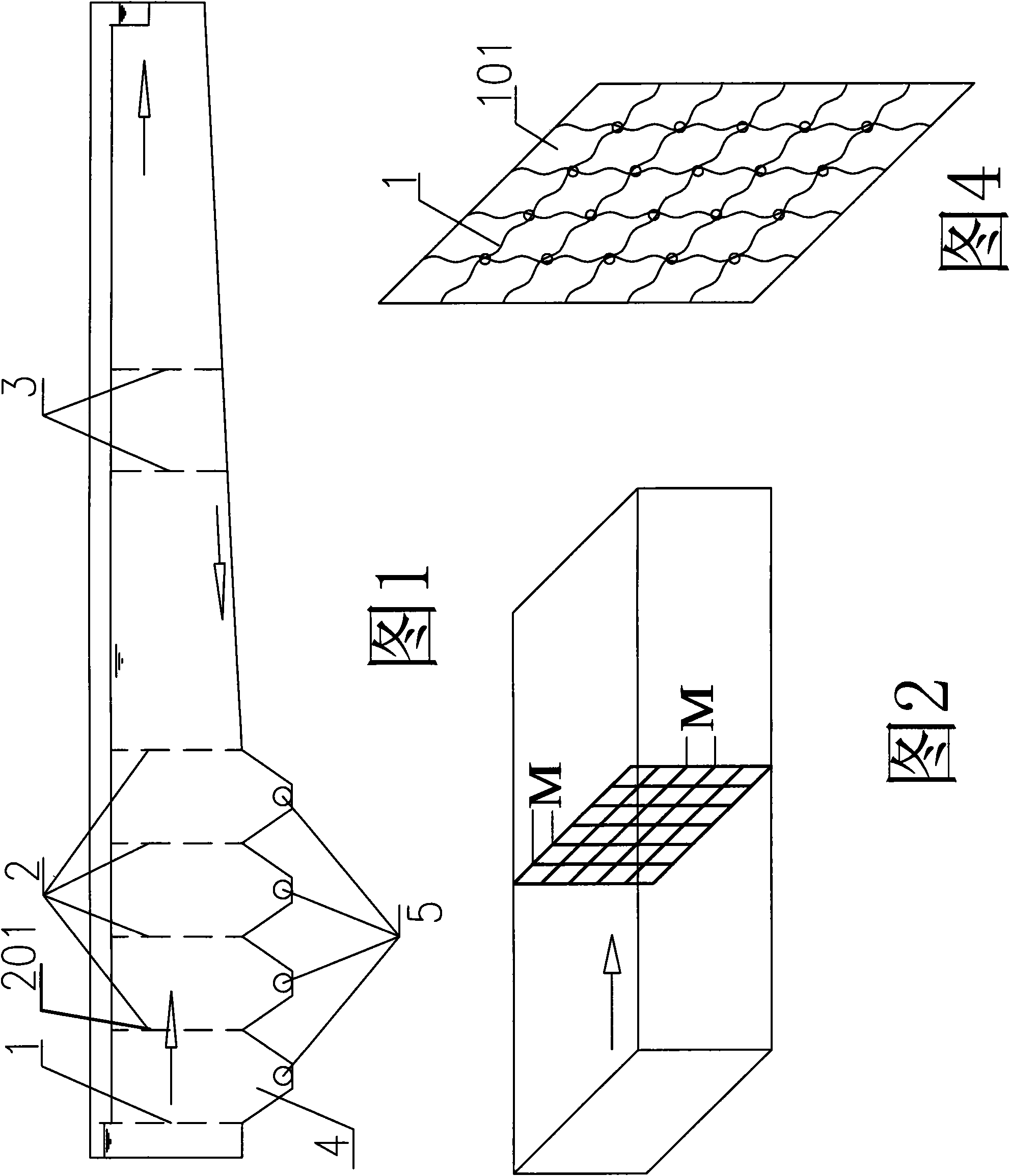

[0051] like figure 1 Shown: a net rope comb flow sedimentation tank, including a sedimentation tank, characterized in that: the water flow inlet section at the front end of the sedimentation tank is provided with an equalizing net rope 1, and the front end of the sedimentation tank is equipped with a N The net rope 2 at the front of the road, the bottom of the sedimentation tank between the net rope 1 and the first net rope 201 at the front of the road, and the bottom of the sedimentation tank between the adjacent net ropes 2 are respectively provided with conical mud collecting buckets 4, A mud discharge pipe 5 is installed at the bottom of each cone-shaped mud collecting bucket 4 .

[0052] Front portion net rope 2 is provided with four roads and can satisfy needs usually.

[0053] In order to prevent the sedimentation particles from jumping up again, 2 middle net ropes 3 are established on the cross-section in the middle of the settling tank.

[0054] see Figure 4 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com