Patents

Literature

71results about How to "Reduce dry consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

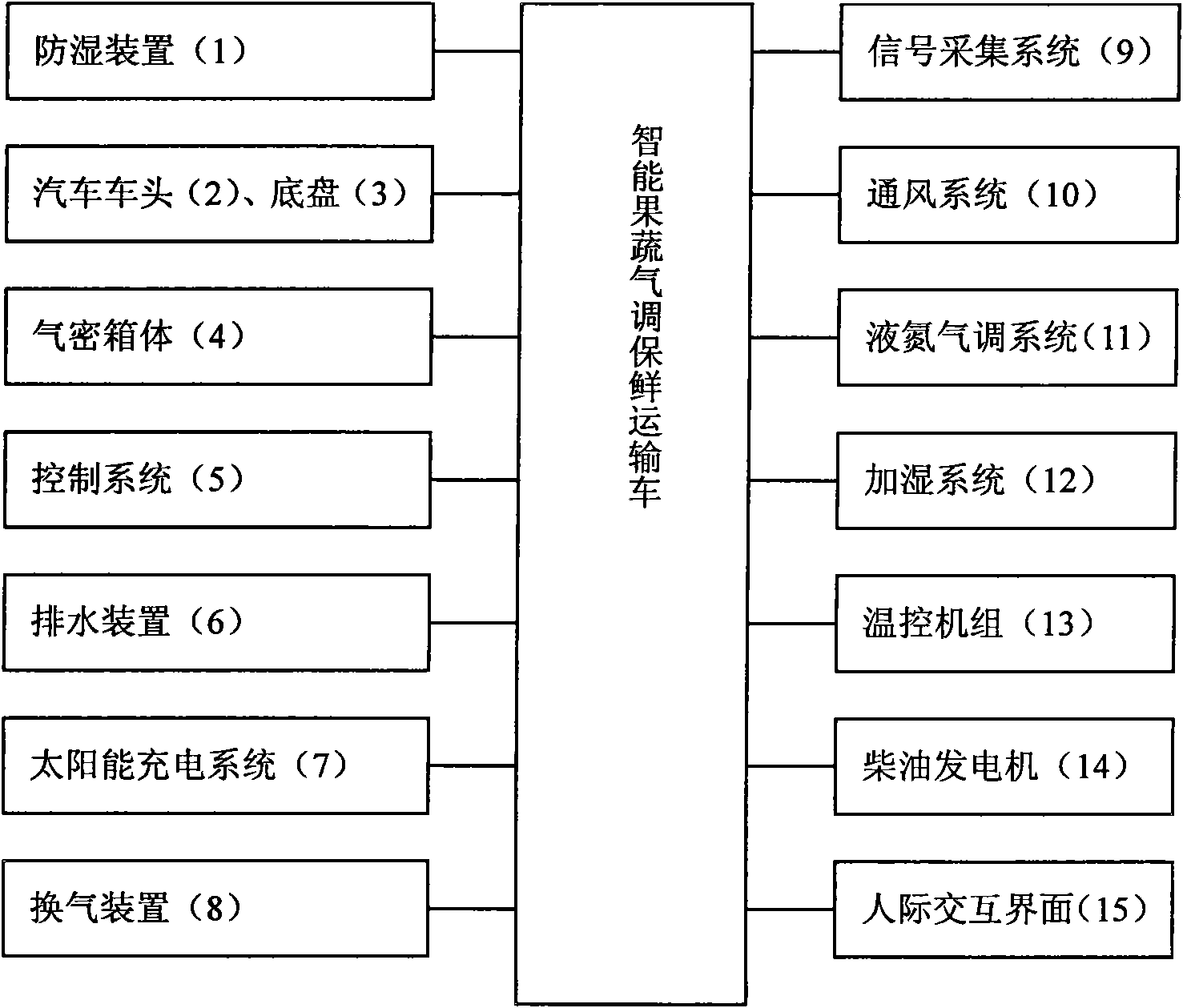

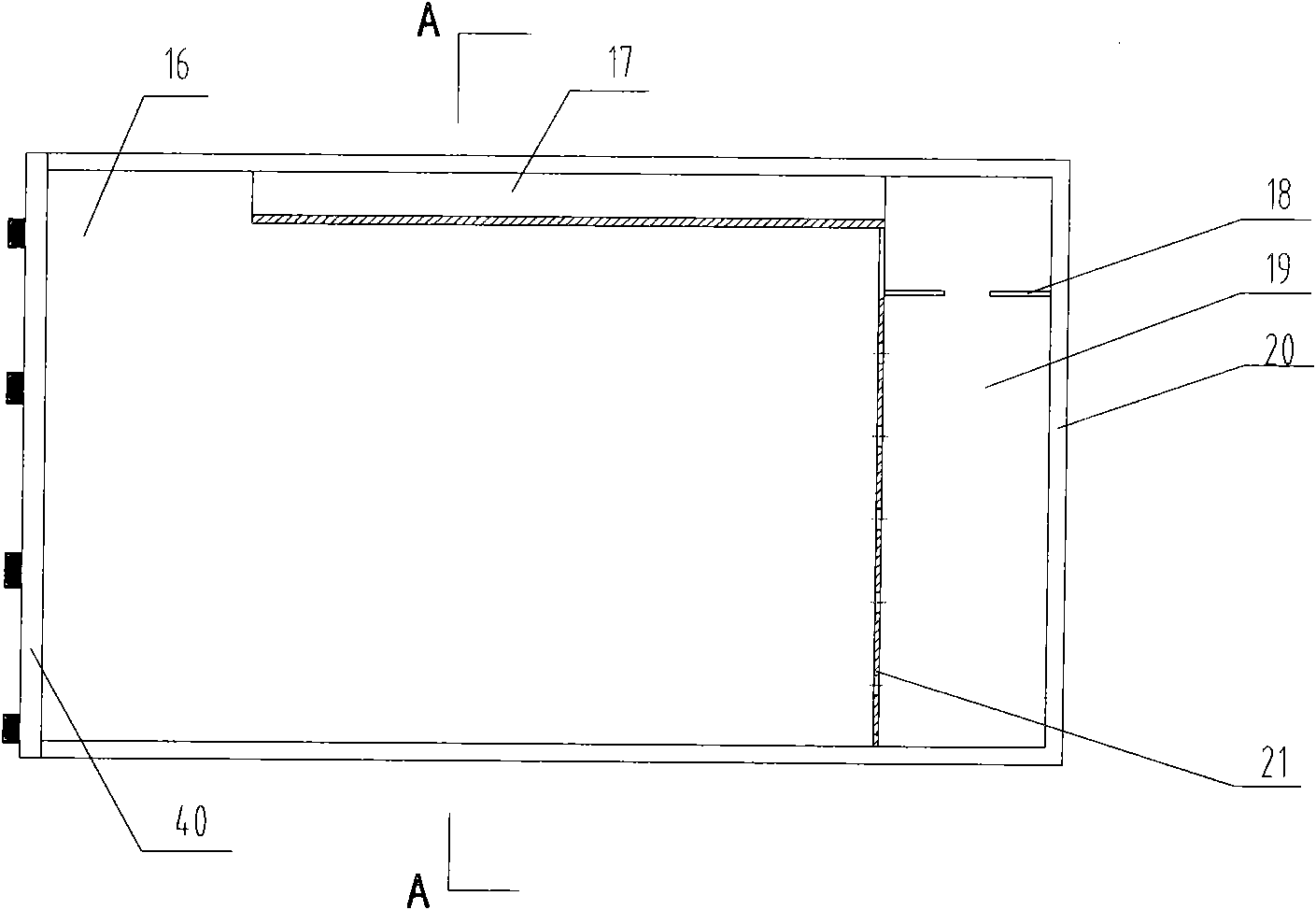

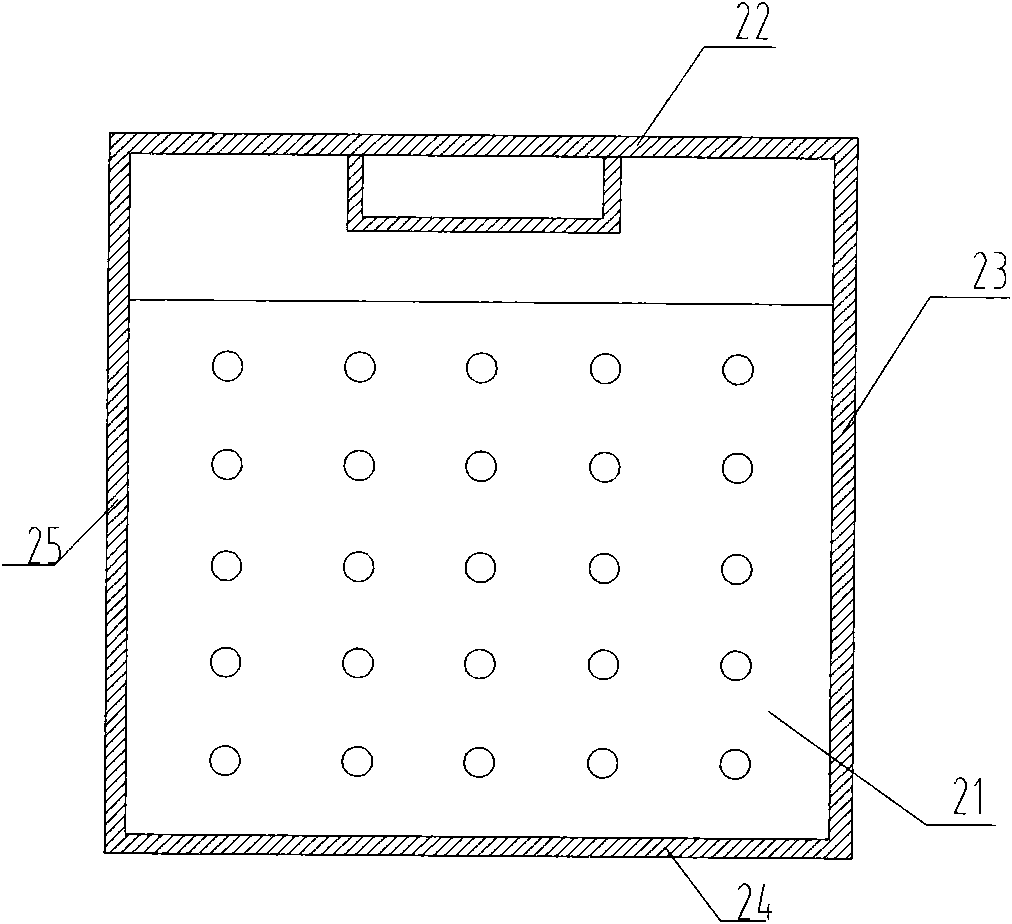

Intelligent fruit and vegetable controlled atmosphere carrier vehicle and implementing method thereof

InactiveCN101961990AAccurate and uniform regulationImprove preservation qualityAir-treating devicesFruit and vegetables preservationTemperature controlControl system

The invention discloses an intelligent fruit and vegetable controlled atmosphere carrier vehicle, which comprises a headstock, a chassis, an airtight box and a human-computer interaction interface, and also comprises a control system, an air exchange device, a signal acquisition system, a ventilation system, a liquid nitrogen controlled atmosphere system, a humidifying system, a solar charging system, a temperature control unit, a diesel generator and a dampproof device, wherein the chassis is respectively connected with the headstock and the airtight box; the control system is respectively connected with the human-computer interaction interface, the air exchange device, the signal acquisition system, the ventilation system, the liquid nitrogen controlled atmosphere system, a humidifying system, the temperature control unit and the diesel generator; and the diesel generator is respectively connected with the control system, the ventilation system, the humidifying system, and the temperature control unit. The invention also discloses a method for implementing the carrier vehicle. The intelligent fruit and vegetable controlled atmosphere carrier vehicle and the method have the advantages of making the fruit and vegetable fresh-keeping environment more uniform, improving the quality of the fruit and vegetables, prolonging the fruit and vegetable fresh-keeping period and the like.

Owner:SOUTH CHINA AGRI UNIV

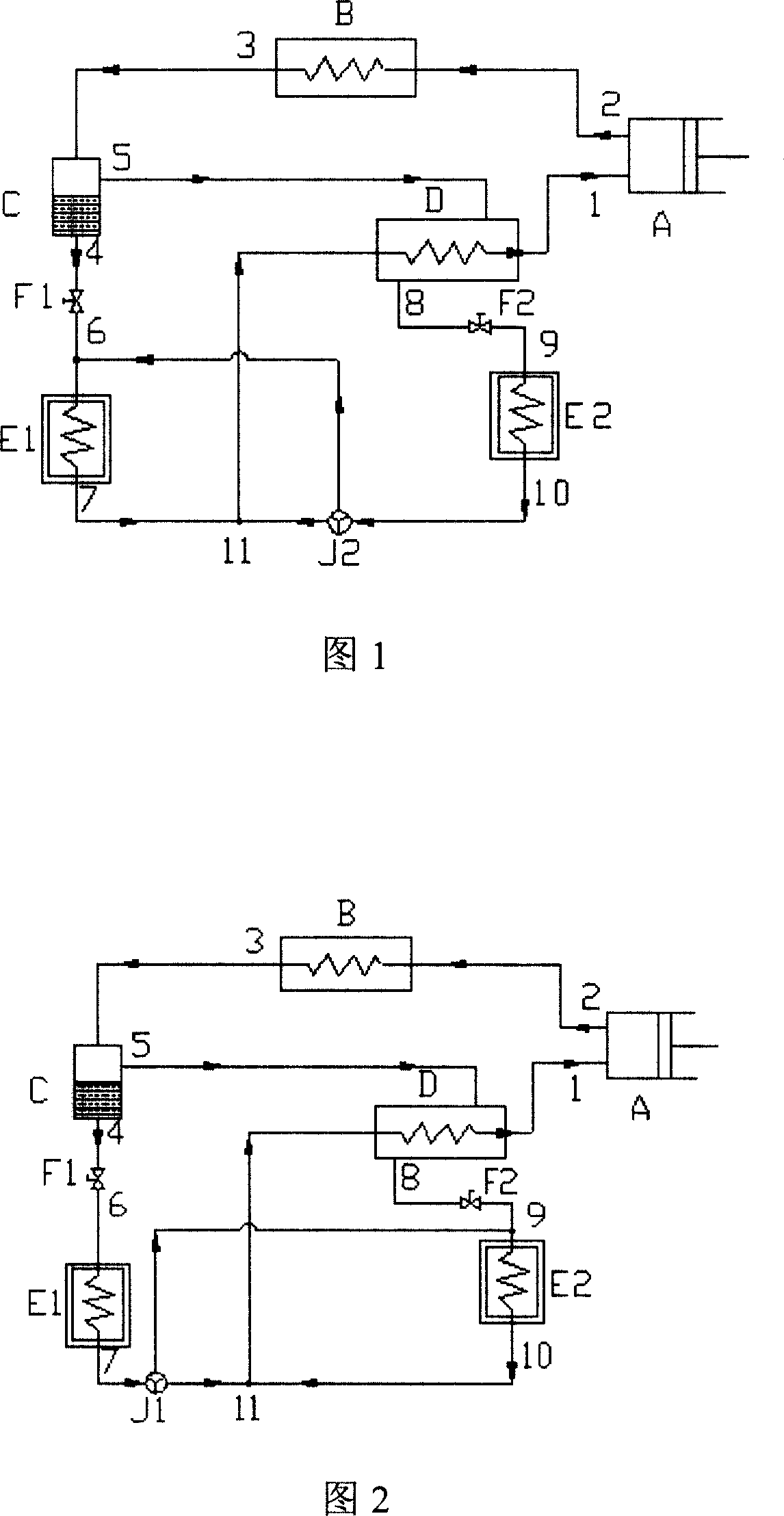

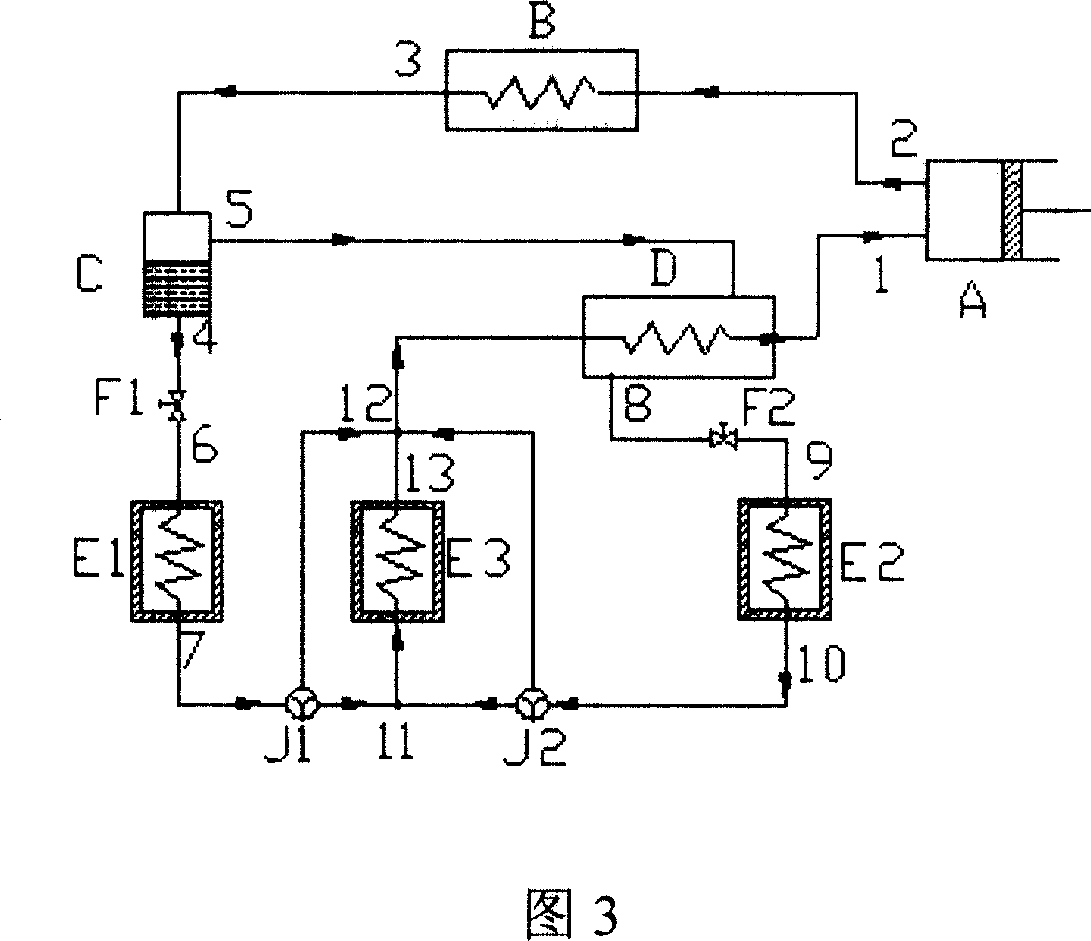

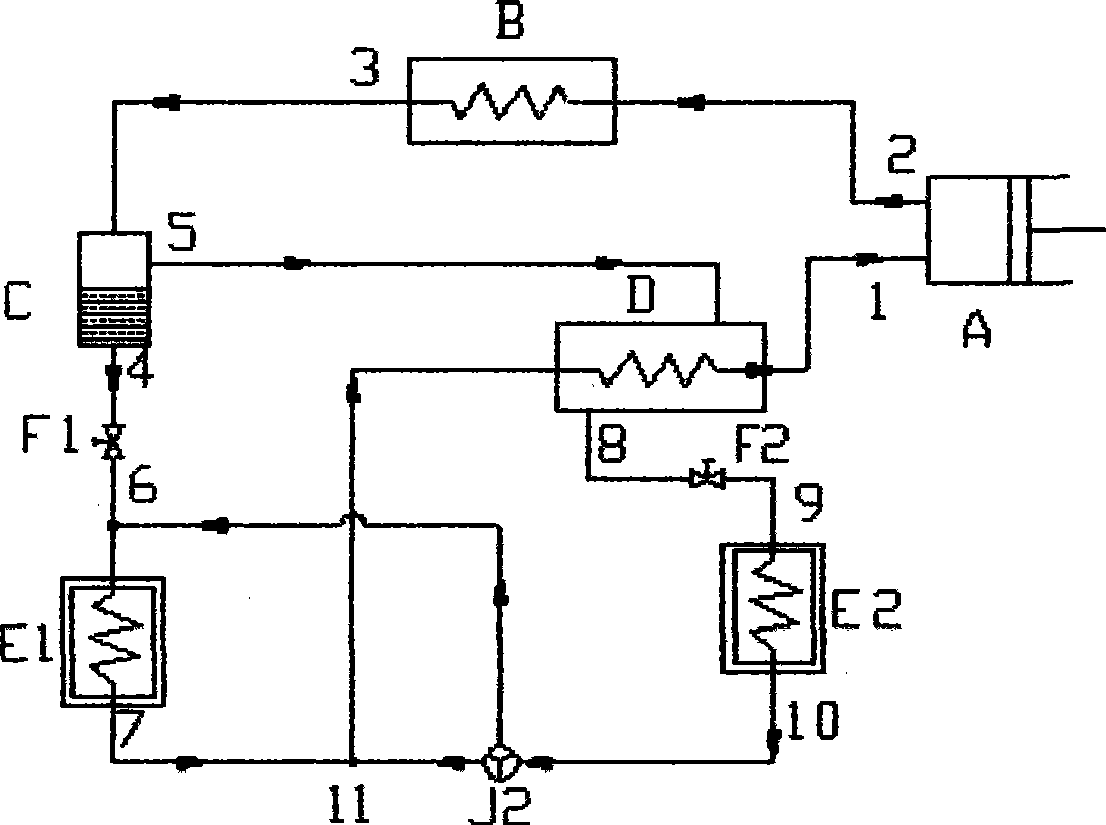

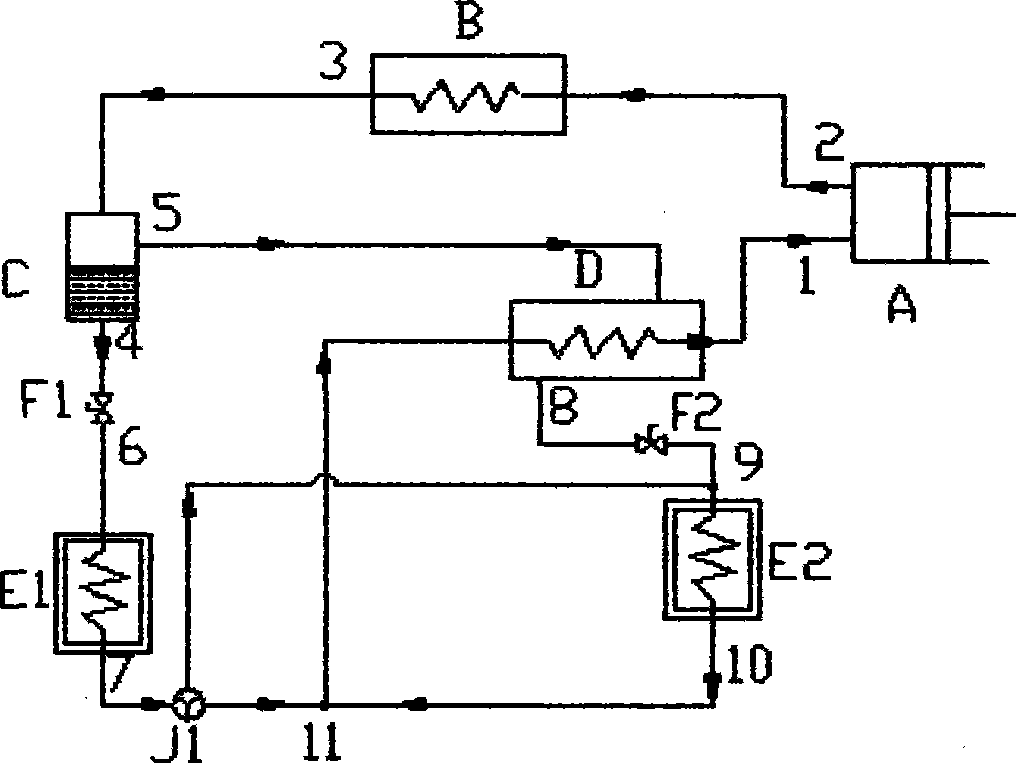

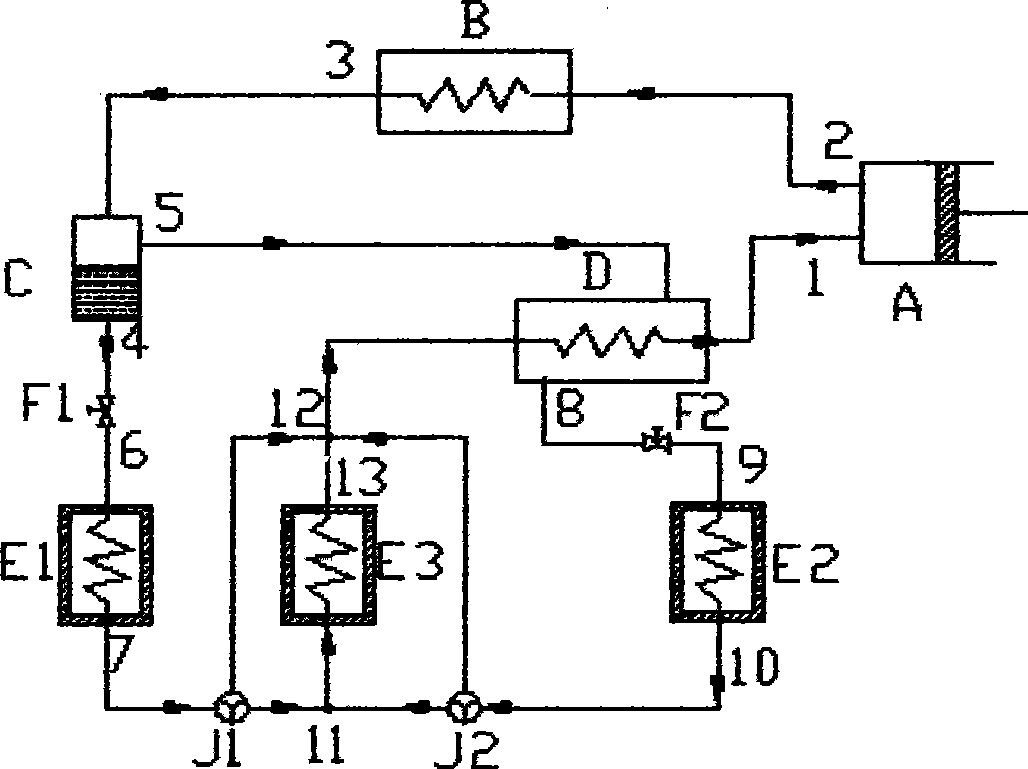

Method for making multi-temperature refrigerator with variable vapourating temperature

InactiveCN101025312AExcellent heat transfer temperature differenceReduce dry consumptionCompression machines with cascade operationVapor–liquid separatorBoiling point

The invention discloses a method to prepare a multi-temperature refrigerator with variable evaporating temperature. It adopts single compressor, condenser, gas-liquid separator, condensation vaporizer, throttle valve, vaporizer and three-channel flow distributing valve as components. The refrigerating medium is polyatomic unazeotropic mixed refrigerating medium. Based on the existed self-overlapping cycle, add a vaporizer used for high-temperature or change-temperature chambers and one or two three-channel flow distributing valves. According to the property of polyatomic unazeotropic mixed substance, adjust the component of mixed refrigerating medium in vaporizer to provide two or three different evaporating temperatures under the same evaporating pressure. One of the evaporating temperatures is adjustable on requirements of users. Applicable polyatomic unazeotropic mixed refrigerating medium is composed of low-boiling and high-boiling substance and selects one or more from them as component refrigerating medium. The method has merits of convenient control and energy-saving operation.

Owner:XI AN JIAOTONG UNIV

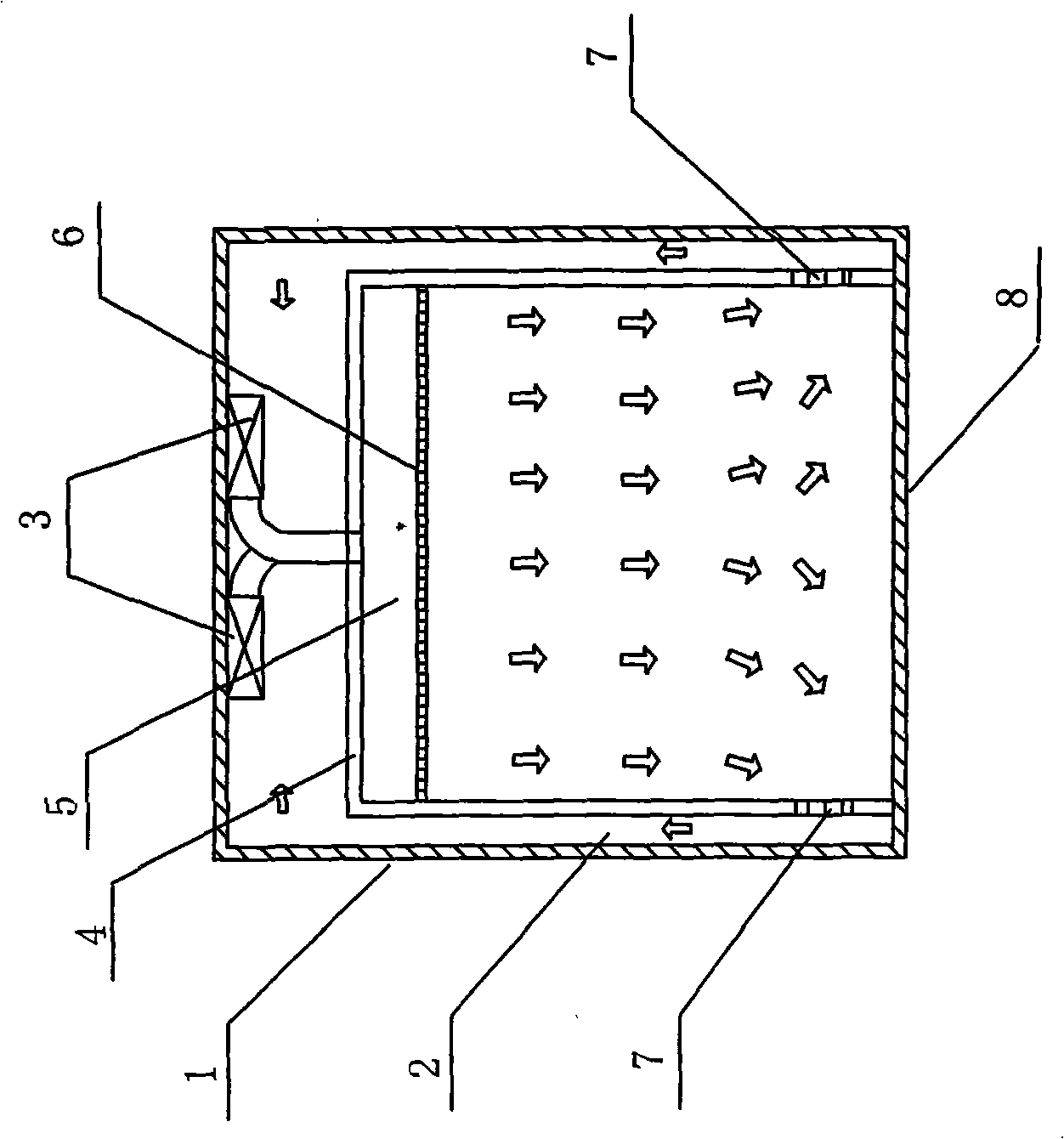

Ice-temperature vault

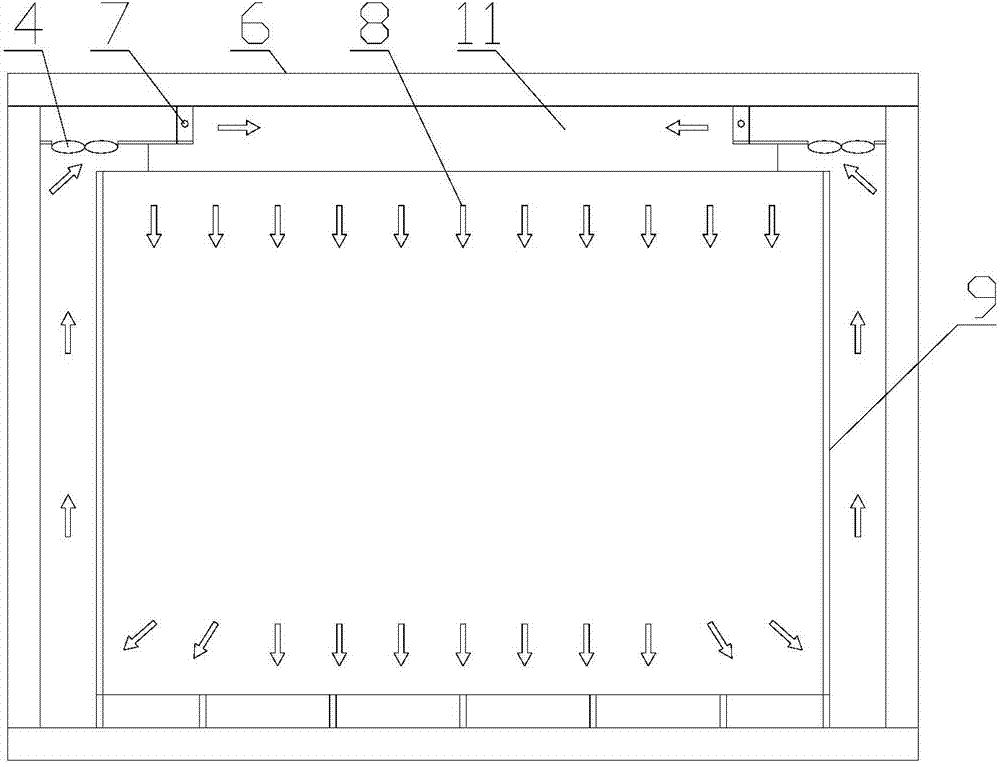

InactiveCN101551189AImprove stabilityReduce dry consumptionStationary refrigeration devicesCompression machines with several evaporatorsEngineeringWind speed

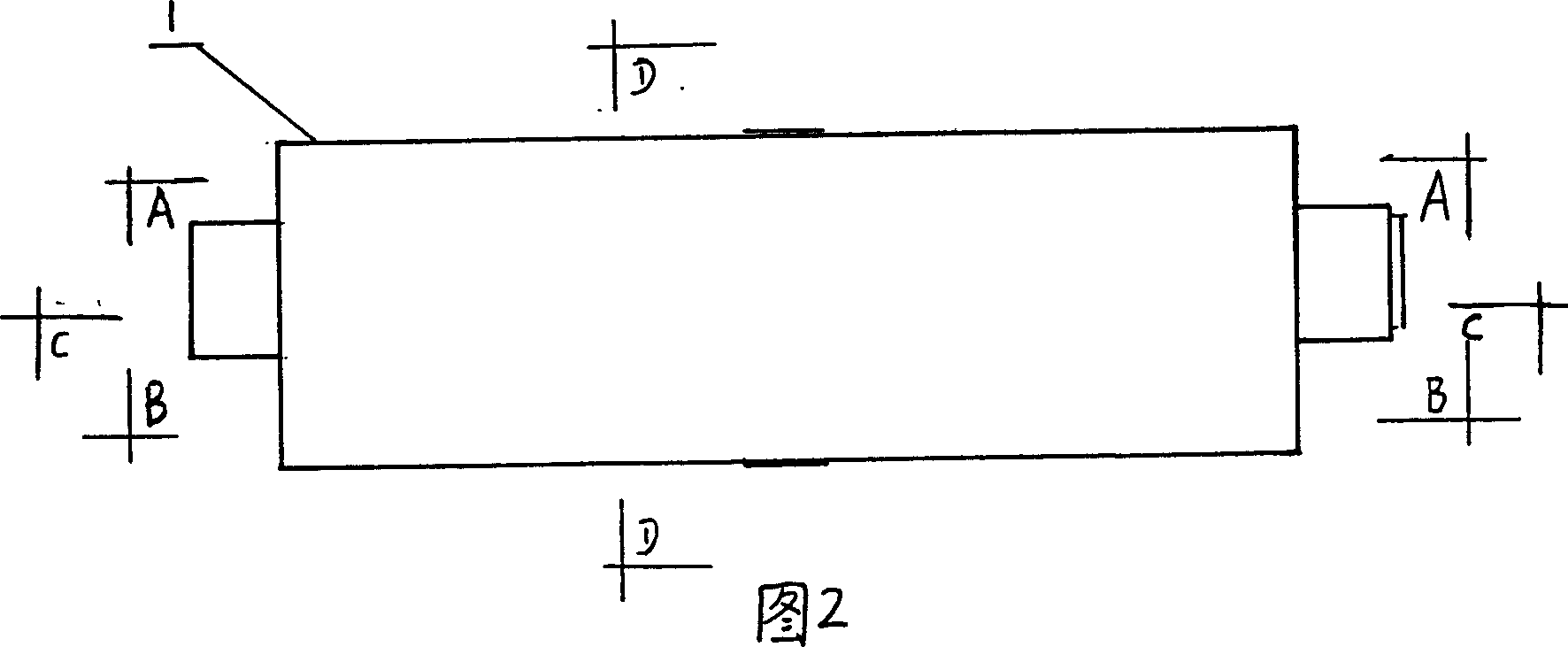

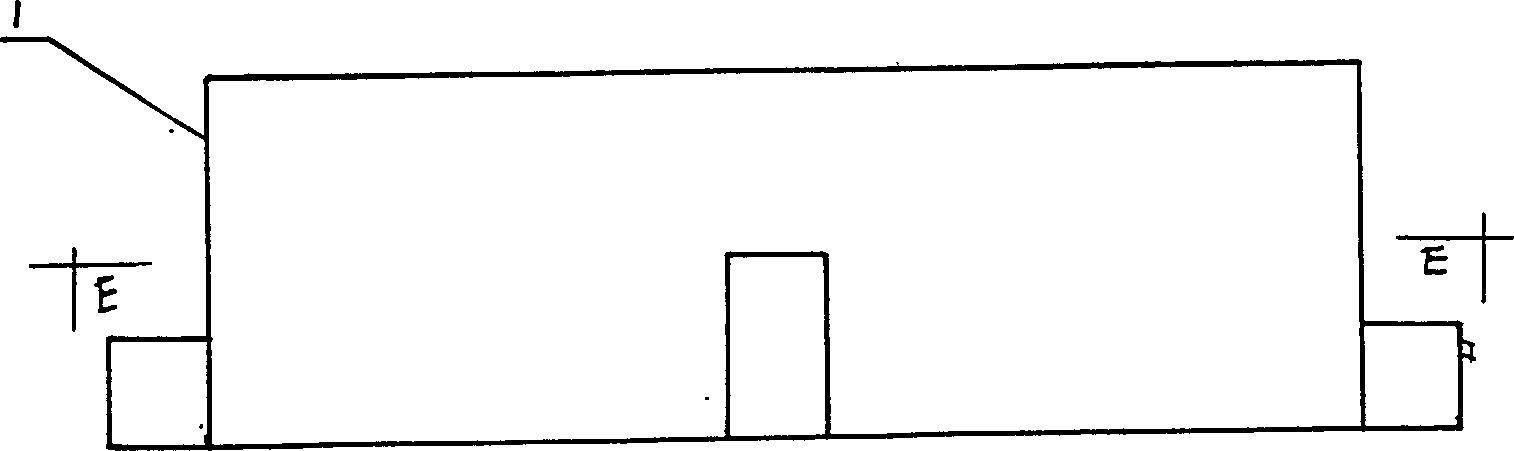

The present invention discloses an ice-temperature vault. The aim of the invention is to provide an ice-temperature vault which has the advantages of high-precision control, uniform wind speed field in the vault, uniform temperature field in the vault, and satisfaction to the requirement of ice-temperature storage. The vault body comprises a base layer heat insulation layer, an outer heat insulation vault body and an inner non-heat-insulation vault body which are connected with the base layer heat insulation layer. An air interlayer is provided between the inner non-heat-insulation vault body and the outer heat insulation vault body. A plurality of air coolers which are connected in parallel for alternately operating or defrosting are installed in the air interlayer at the top part of outer vault body. A top air supply aperture plate is provided in the inner vault body. A static pressure box layer is formed between the top air supply aperture plate and the inner non-heat-insulation vault body. The periphery at the base part of inner non-heat-insulation vault body is provided with a plurality of return air grilles. A temperature sensor is respectively installed at the lower part of static pressure box layer and at the return air grilles. The temperature in the ice-temperature vault is stable. The speed field and temperature field are extraordinarily uniform. The defrosting does not affect the temperature in the vault. The ice-temperature vault has high control precision. The temperature fluctuation of hollow vault does not exceed + / - 0.3 DEG C.

Owner:TIANJIN UNIV OF COMMERCE

Shellfish film preservative

InactiveCN102578681AReduce pollutionInhibit growthClimate change adaptationFood preservationVitamin CPolyphenol

The invention provides a shellfish film preservation method, relates to a shellfish film preservative, and belongs to the technical field of food processing. The preservation, by proportion, comprises 1.0-2.0% of chitosan, 0.02% of nisin, 0.2-0.5% of vitamin C, 0.6-1% of edible acetic acid and 0.02-0.06% of tea polyphenol; or 1.0-2.0% of sodium alginate; or 1.0-2.0% of sodium alginate, 0.02% of nisin and 0.2-0.5% of vitamin C; or 1.0-2.0% of sodium alginate, 0.05% of lysozyme, 0.2-0.5% of vitamin C and 6-8% of glycine and the balance water. The method includes subjecting shellfish to conditioning for twenty-four hours, washing, shelling and taking out meat, immersing the meat into the preservative for about two minutes, draining, performing vacuum package, and preserving the meat at the temperature of 20 DEG C below zero. The shellfish film preservative has the advantages that a thin-film formed on the surface of the shellfish meat is capable of blocking the growth of microorganism, reducing the speed of oxidative deterioration, and the like.

Owner:HEBEI AGRICULTURAL UNIV.

Production method for multi-temperature refrigerating machine with variable evaporating temperature

InactiveCN101430144AExcellent heat transfer temperature differenceReduce dry consumptionChemical industryCompression machines with several evaporatorsVapor–liquid separatorBoiling point

The invention discloses a preparation method of a multi-stage temperature refrigerating machine with changeable evaporating temperature. The multi-stage temperature refrigerating machine comprises such parts as a single compressor, a condenser, a gas-liquid separator, a condensation evaporator, a throttle valve, an evaporator and a three-way flow distributing valve, and the used refrigerant is a multi-component non-azeotropic mixed refrigerant; on the basis of an original auto cascade cycle, the multi-stage temperature refrigerating machine is additionally provided with the evaporator used in a high temperature chamber or a variable temperature chamber, one or two three-way flow distributing valves; the refrigerating machine adjusts the components of the mixed refrigerant which is carried into the evaporator by the characteristic of the multi-component non-azeotropic mixed working substance to provide two stages or three stages of different evaporating temperatures under the same evaporating pressure, wherein, one stage of the evaporating temperature can be adjusted according to the user requirement. The suitable multi-component non-azeotropic mixed refrigerant consists of a low-boiling point working substance and a high-boiling point working substance, and the component refrigerant of the non-azeotropic mixed working substance is selected from one or more than one of the high-boiling point working substance and the low-boiling point working substance. The multi-stage temperature refrigerating machine has the characteristics of convenient control and energy-saving operation.

Owner:XI AN JIAOTONG UNIV

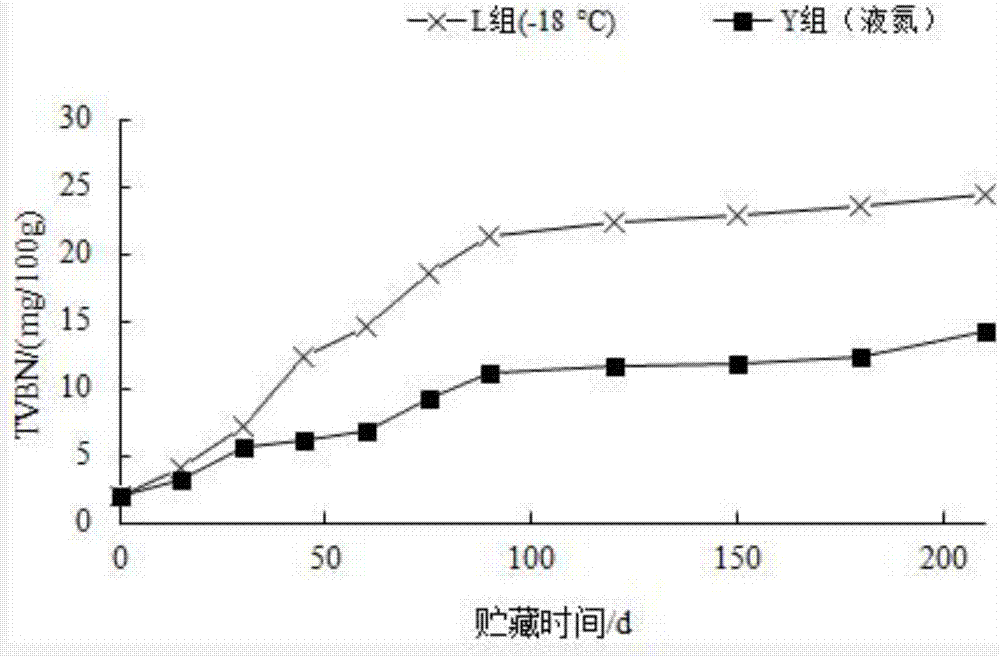

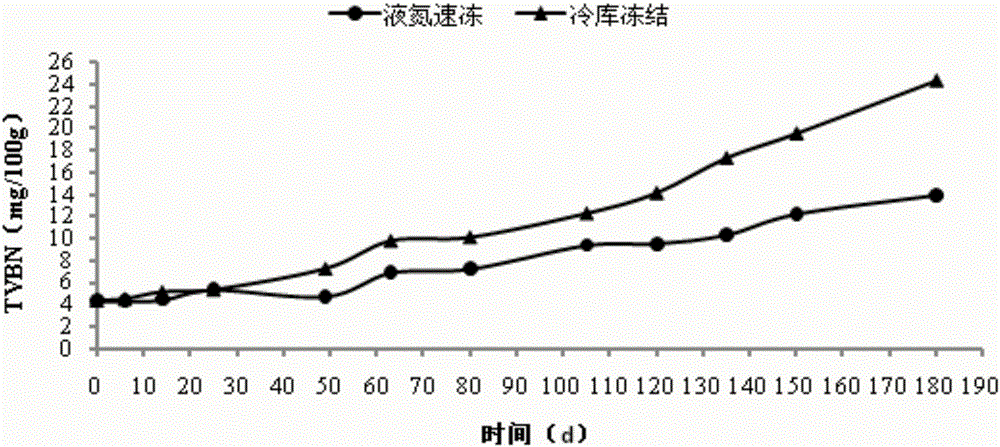

Method for ultralow-temperature deep cooling rapid freezing preservation of little yellow croaker

InactiveCN107258882AIntegrity guaranteedReduce dry consumptionMeat/fish preservation by freezing/coolingNatural extract food ingredientsFlavorLiquid nitrogen

The invention relates to the technical field of food processing storage, and discloses a method for the ultralow-temperature deep cooling rapid freezing preservation of a little yellow croaker. One set of integral technology for the ultralow-temperature liquid-nitrogen deep cooling rapid freezing preservation of the little yellow croaker is formed through working procedures including cleaning, leaching, freeze prevention, vacuum packaging, pre-cooling, multi-stage quick freezing, packaging and the like in sequence. A product which is subjected to deep cooling processing by the method forms a small crystal, the integrity of a product cell is ensured, the original color and luster, freshness and flavor of the product can be kept, the shelf life of the product is greatly prolonged, a refreshment degree is good, perennial supply demands can be met, and the method has a good application value.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

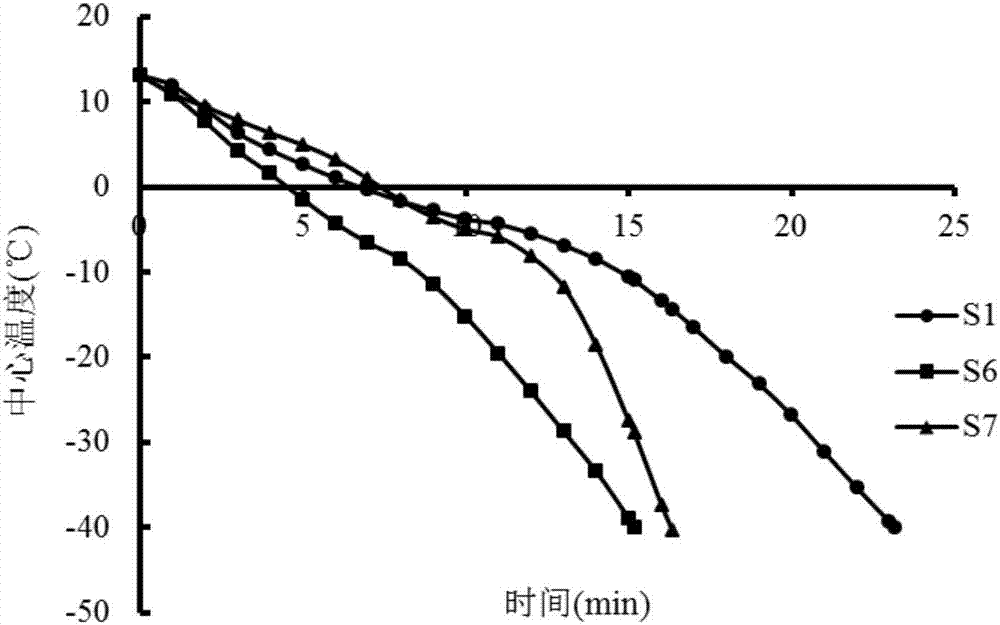

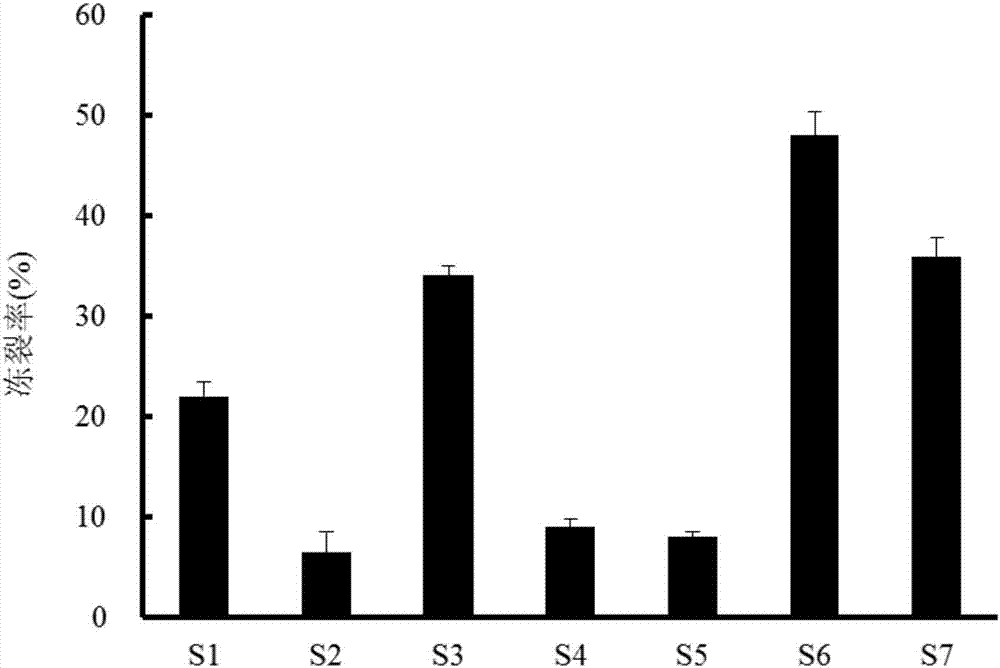

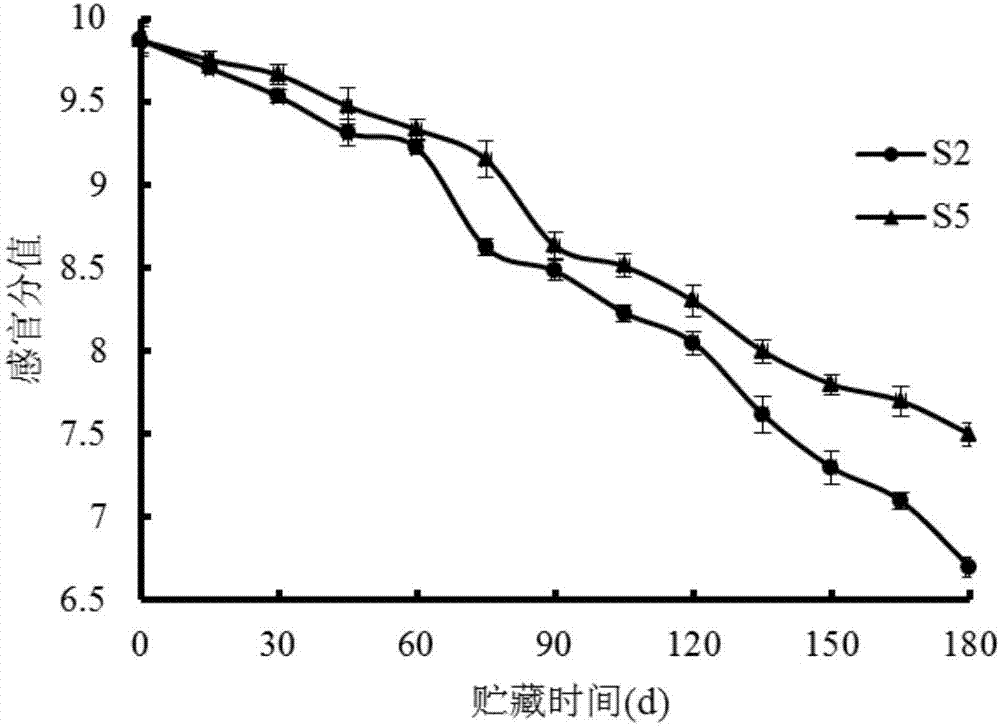

Ultra-low-temperature liquid-nitrogen deep-cooling quick-freezing method of portunus trituberculatus

InactiveCN106973975AIntegrity guaranteedNot brittleFood freezingFood ingredient as thickening agentQuick FreezeCrack resistance

The invention relates to food processing and storage technologies, and discloses an ultra-low-temperature liquid-nitrogen deep-cooling quick-freezing method of portunus trituberculatus. The ultra-low-temperature liquid-nitrogen deep-cooling quick-freezing method of the portunus trituberculatus comprises the following steps: (1), carrying out washing; (2), carrying out soaking, namely soaking the portunus trituberculatus in a low-temperature protective agent solution; (3), carrying out quick freezing, namely carrying out liquid-nitrogen quick-freezing treatment on the soaked portunus trituberculatus, wherein the liquid-nitrogen quick-freezing treatment is carried out in three stages; (4), carrying out ice-glazing; (5), carrying out vacuum packaging; and (6), carrying out cryopreservation. A three-stage gradual cooling process is adopted in the ultra-low-temperature liquid-nitrogen deep-cooling quick-freezing method of the portunus trituberculatus so as to ensure a small amount of ice crystal formation and low drying loss of the portunus trituberculatus after the deep-cooling quick-freezing treatment. The portunus trituberculatus treated by the ultra-low-temperature liquid-nitrogen deep-cooling quick-freezing method has relatively good low-temperature cracking resistance performance, and wholeness of product cells are preserved; moreover, original color, luster, freshness and flavor of the portunus trituberculatus are preserved, shelf life of the portunus trituberculatus is greatly prolonged, and freshness grade of the portunus trituberculatus is good. In addition, shell of the portunus trituberculatus after the deep-cooling quick-freezing treatment is not liable to crack.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

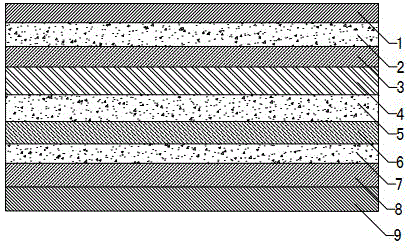

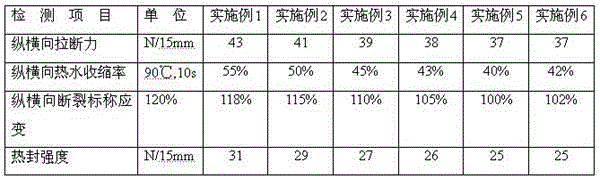

Multilayer improved thermal shrinkage preservative film/bag and base material composition thereof

ActiveCN104608451ALow costReduce wasteSynthetic resin layered productsWater vaporPolyethylene glycol

The invention relates to a multilayer improved thermal shrinkage preservative film / bag and a base material composition thereof, belonging to the technical field of preservative films. The multilayer improved thermal shrinkage preservative film / bag is characterized in that according to the formula, the base material composition comprises the following materials in percentage by weight: 60%-90% of ethanediol modified polyethylene glycol terephthalate copolymers, 5%-20% of ethylene acrylic acid copolymers or maleic anhydride graft polymers and 5%-20% of a soft improver; the preservative film is prepared by adopting the base material composition of the multilayer improved thermal shrinkage preservative film as a resin-based functional layer (4), and at least one functional layer and at least one adhesive layer are co-extruded on the upper surface and the lower surface of the resin-based functional layer (4) so as to form a multilayer layered structure. The multilayer improved thermal shrinkage preservative film / bag disclosed by the invention contains no chloride, is free of crosslinking and has excellent puncture resistance and oxygen and water vapor obstruction property.

Owner:轩福君

Freshwater fish body fresh preservation agent, and preparation method and fresh preservation method thereof

ActiveCN102187891AWide variety of sourcesLow priceMeat/fish preservation using chemicalsWater contentFlavor

The invention discloses a freshwater fish body fresh preservation agent made from scale zymolyte and a preparation method and a fresh preservation method thereof, belonging to the technical field of aquatic product fresh preservation. The freshwater fish body fresh preservation agent is made from scales on fish bodies; the scales releases protein enzymolysis liquid under the enzymolysis effect ofpepsase; and a plasticizer glycerol is added to the protein enzymolysis liquid to obtain the freshwater fish body fresh preservation agent. According to the invention, after the scale collagen proteolysis liquid in the fresh preservation agent permeates into a freshwater fish body, a film can be formed on the surface of the fish body to play the role in reducing bacterial contamination, resistingthe microorganism growth, weakening air oxidation, slowing fat oxidation rate and reducing the weight loss of the fish body. Compared with the common cold storage method, the freshwater fish body fresh preservation agent can well maintain the freshness, the water content and the flavor of the fish body, achieve better fresh preservation effect, reduce the weight loss of the fish body in the storage process and prolong the shelf life of the fish body.

Owner:CHINA AGRI UNIV

Protective agent composition for liquid nitrogen cryogenic quick-freezing of camarons

The invention relates to the technical field of food processing and storage and discloses a protective agent composition for liquid nitrogen cryogenic quick-freezing of camarons. The protective agent composition comprises a low-temperature protective agent for soaking the camarons before liquid nitrogen quick-freezing, and an ice glazing agent for soaking the camarons after liquid nitrogen quick-freezing. The low-temperature protective agent comprises sodium polyphosphate, sodium erythorbate, sodium citrate, sorbitol, bletilla extracts and water. The ice glaze agent comprises trehalose, sodium alginate, bletilla extracts and ice water. The protective agent composition comprises the low-temperature protective agent and the ice glaze agent and is matched with the liquid nitrogen cryogenic quick-freezing method, ice crystals formed by products subjected to cryogenic quick-freezing are small, the drying loss is low, the integrity of product cells is guaranteed, the original color, freshness and flavor can be maintained, the shelf life of the products is greatly prolonged, and the freshness preservation degree is high.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

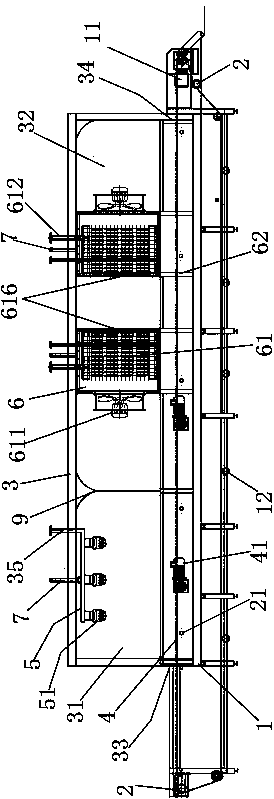

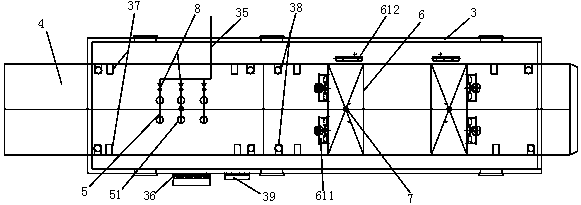

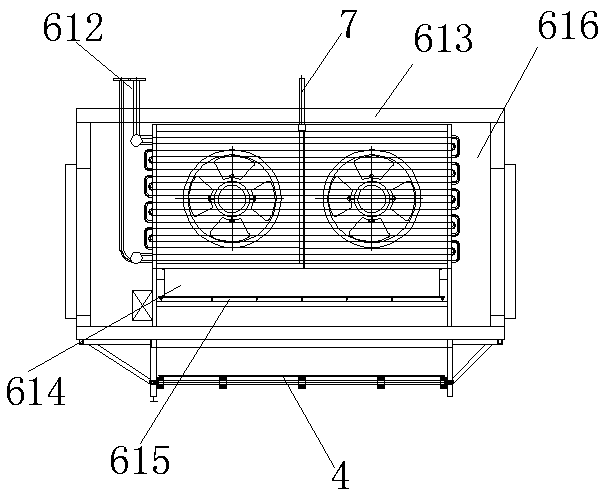

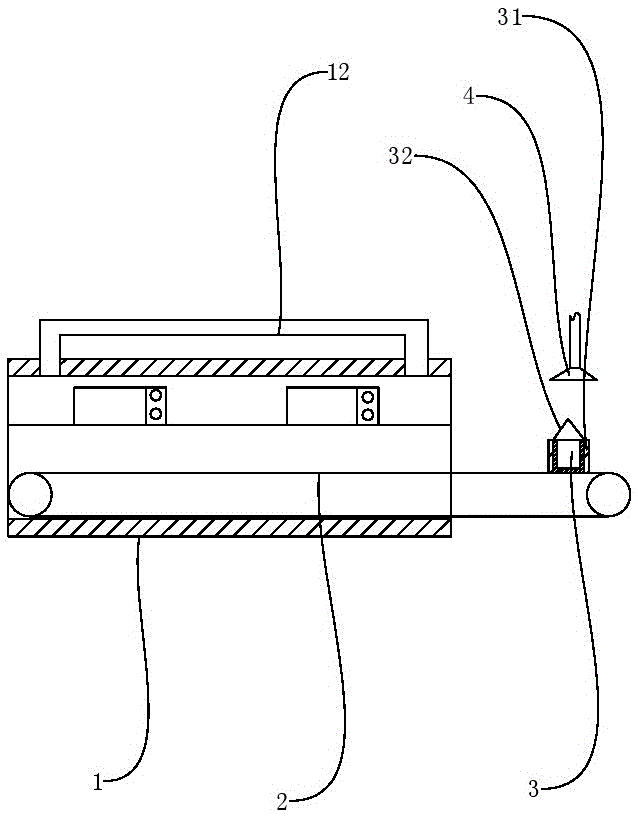

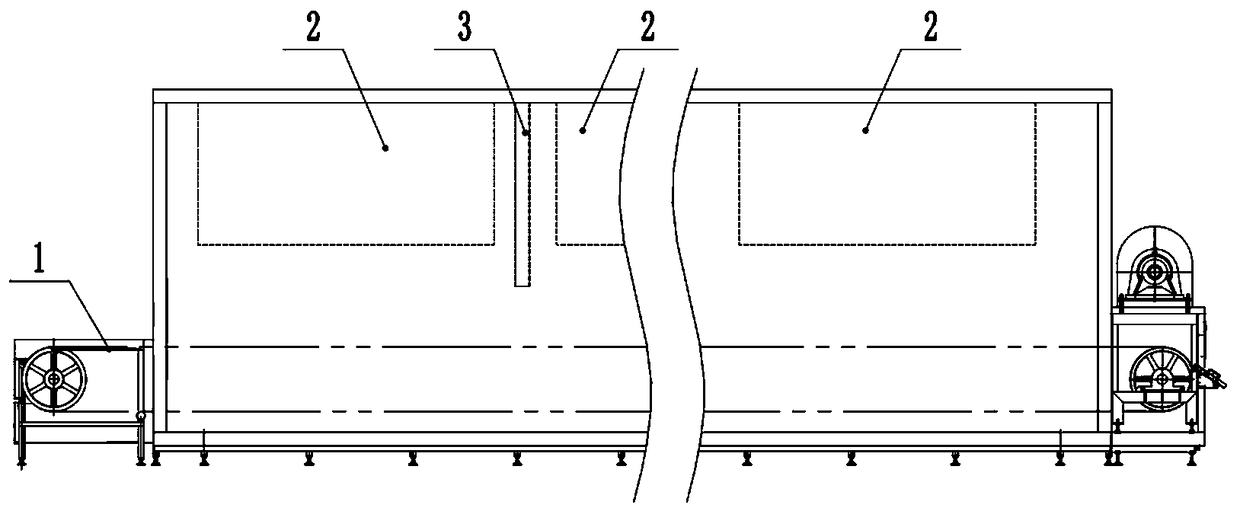

Quick-freezing fresh-keeping method and tunnel-type fresh-keeping quick-freezing machine

PendingCN109990543AFreeze fast and keep freshGood fresh-keeping effectLighting and heating apparatusStationary refrigeration devicesQuick FreezeEngineering

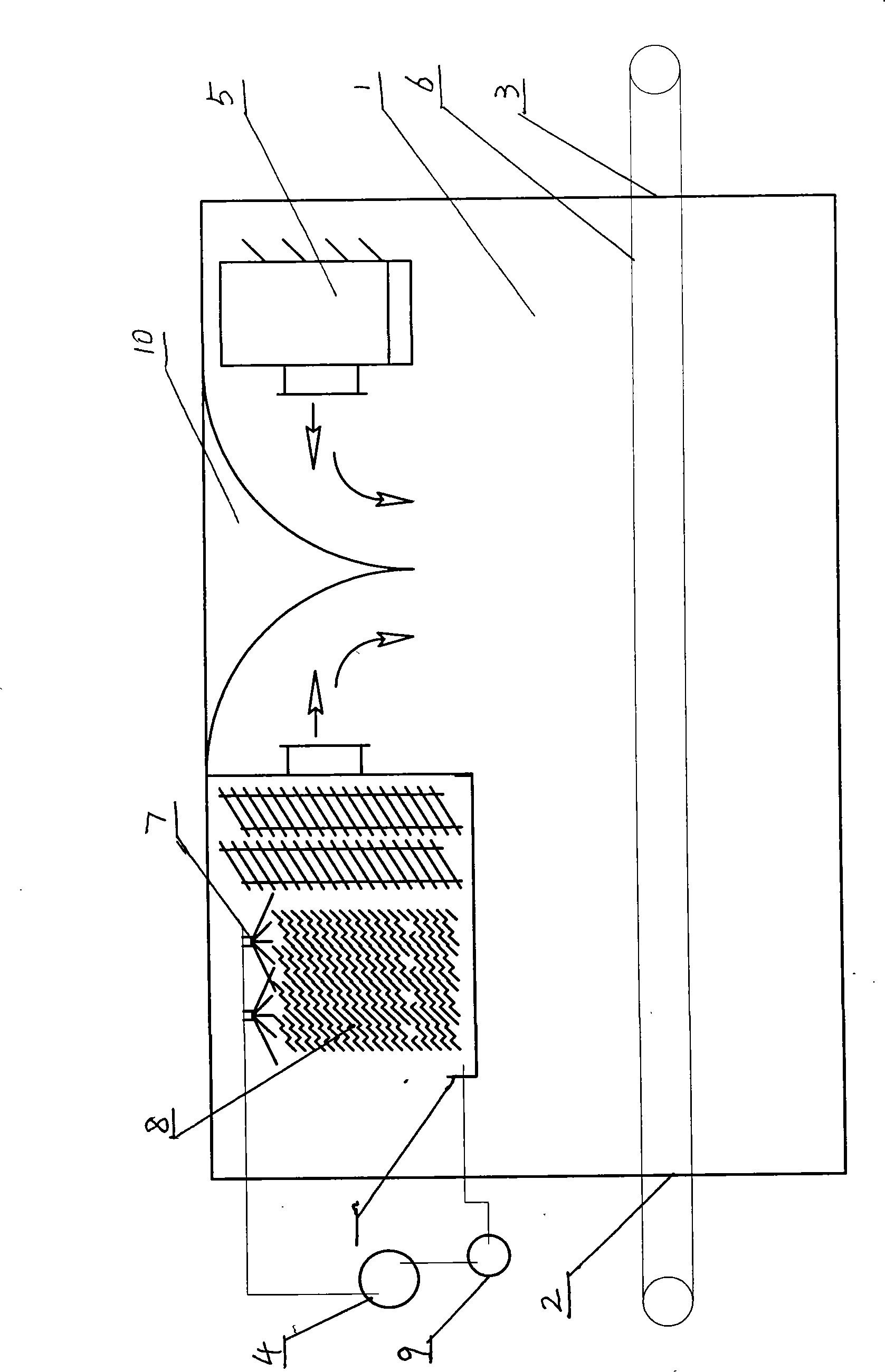

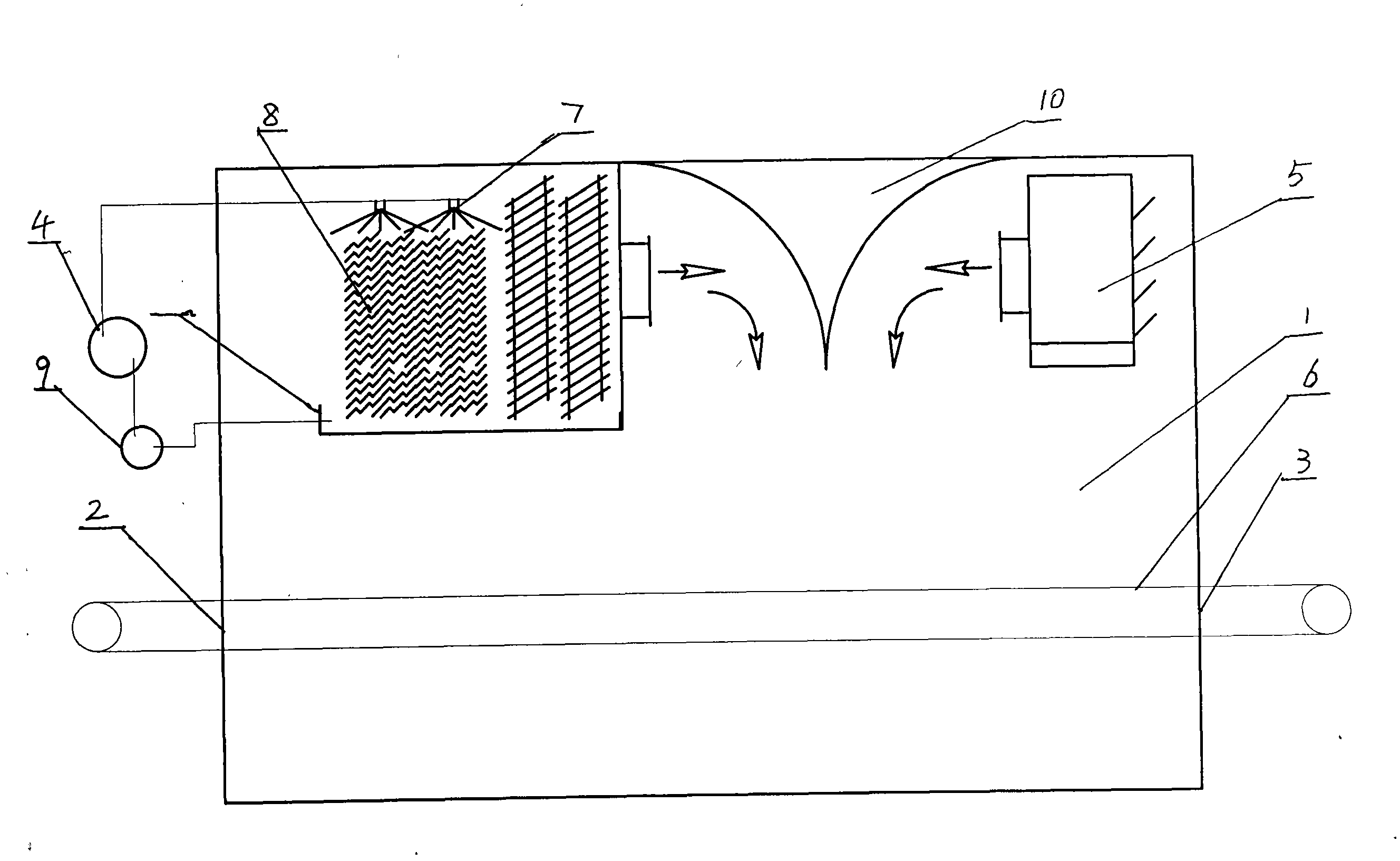

The invention discloses a quick-freezing fresh-keeping method and a tunnel-type fresh-keeping quick-freezing machine. The tunnel-type fresh-keeping quick-freezing machine comprises a fixing frame, a transmission roller shaft and a storehouse body, wherein the storehouse body is provided with a transmission mesh belt; the storehouse body is arranged on the fixing frame; a fresh-locking chamber anda freezing chamber are arranged in the storehouse body; the fresh-locking chamber and the freezing chamber are mutually connected; a liquid nitrogen spraying device is arranged in the fresh-locking chamber; a plurality of atomizing spray heads are arranged on the liquid nitrogen spraying device; an air cooling device is arranged in the freezing chamber; the storehouse body is provided with a regulating and controlling system electrically connected with the liquid nitrogen spraying device and the air cooling device; and the two ends of the storehouse body are provided with a feeding port and adischarging port. According to the quick-freezing fresh-keeping method and the tunnel-type fresh-keeping quick-freezing machine, the mechanical compression refrigeration and the liquid nitrogen refrigeration are effectively combined, a frost protection layer is formed on the surface of material by spraying liquid nitrogen to protect the moisture of the material from losing so as to ensure the freshness of the material, and then a mechanical compression refrigeration is adopted to carry out deep refrigeration so as to avoid dehydration of the surface of the material due to direct air cooling soas to ensure the freshness and taste of the material; and meanwhile, the fresh-locking and fresh-keeping effect are achieved, full-automatic operation is achieved according to set parameters, and energy consumption is reduced.

Owner:广州鲜之源生态冷链技术有限公司

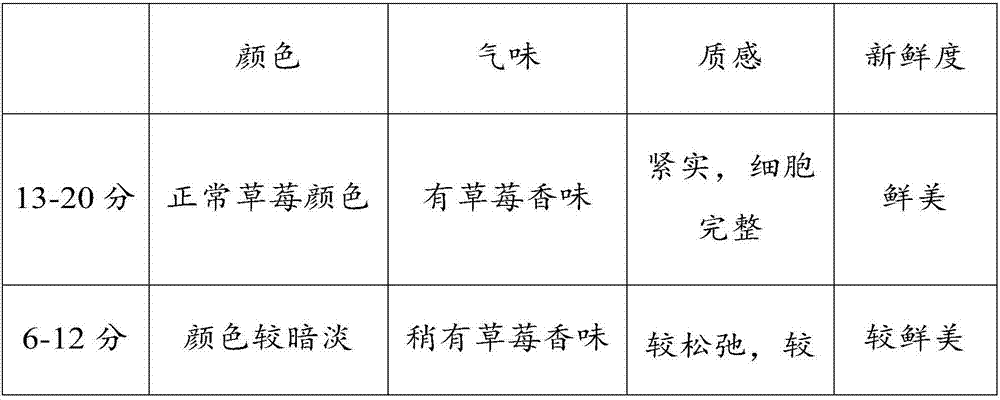

Frozen fruit and vegetable and fruit and vegetable fresh keeping process

InactiveCN107183156AReduce dry consumptionReduce the loss of nutrientsFruits/vegetable preservation by freezing/coolingFood PreserversFruits and vegetables

The invention relates to frozen fruit and vegetable and a fruit and vegetable fresh keeping process, and belongs to the field of food preservation. The fresh keeping process comprises the following steps of putting the fruit and vegetable raw materials into a liquid nitrogen environment with the temperature being -110 to -60 DEG C or a micro frozen liquid environment with the temperature being -40 to -20 DEG C to be quickly frozen for not less than 3min; then, the fruit and vegetable raw materials are put into a warehouse for cold storage or cold chain transportation. The process has the advantages that the process is simple; the operation is convenient and fast; the fresh keeping effect is good; the cost is low. The frozen fruit and vegetable obtained through the process can maintain the raw material mouthfeel; the freshness degree of the raw materials can be maintained for a long time.

Owner:四川鲜能农业科技有限公司

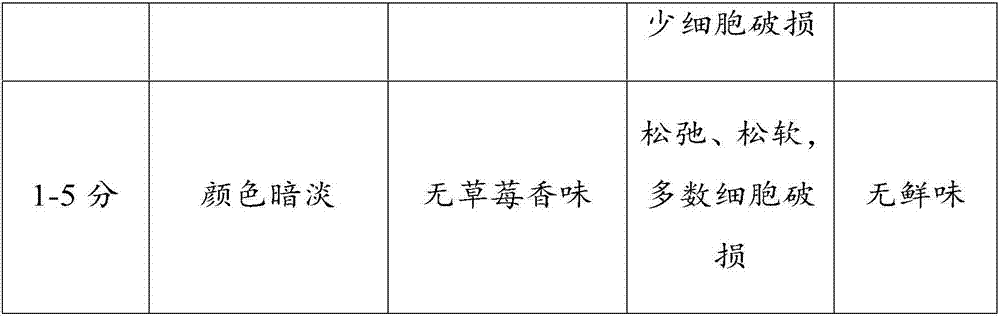

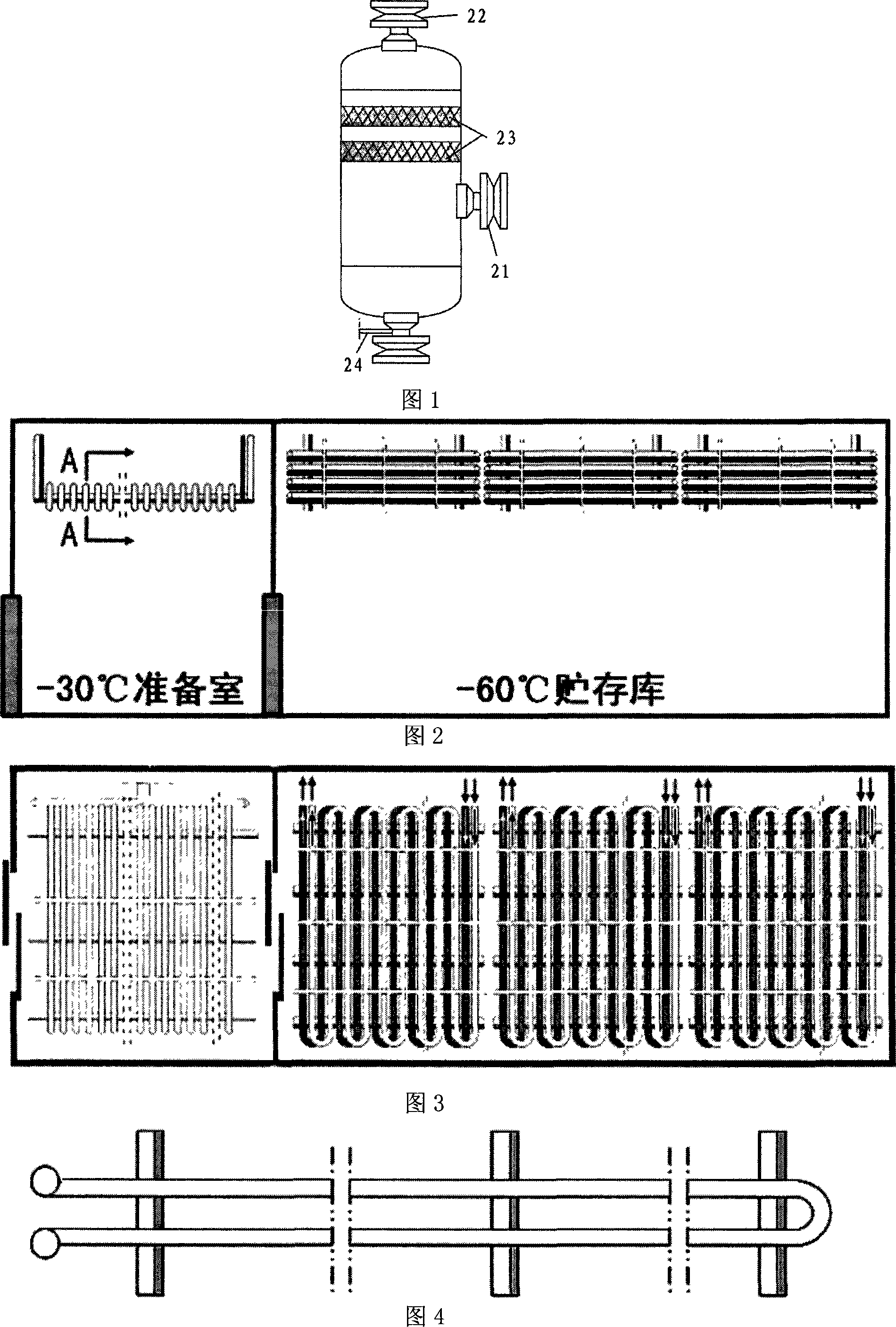

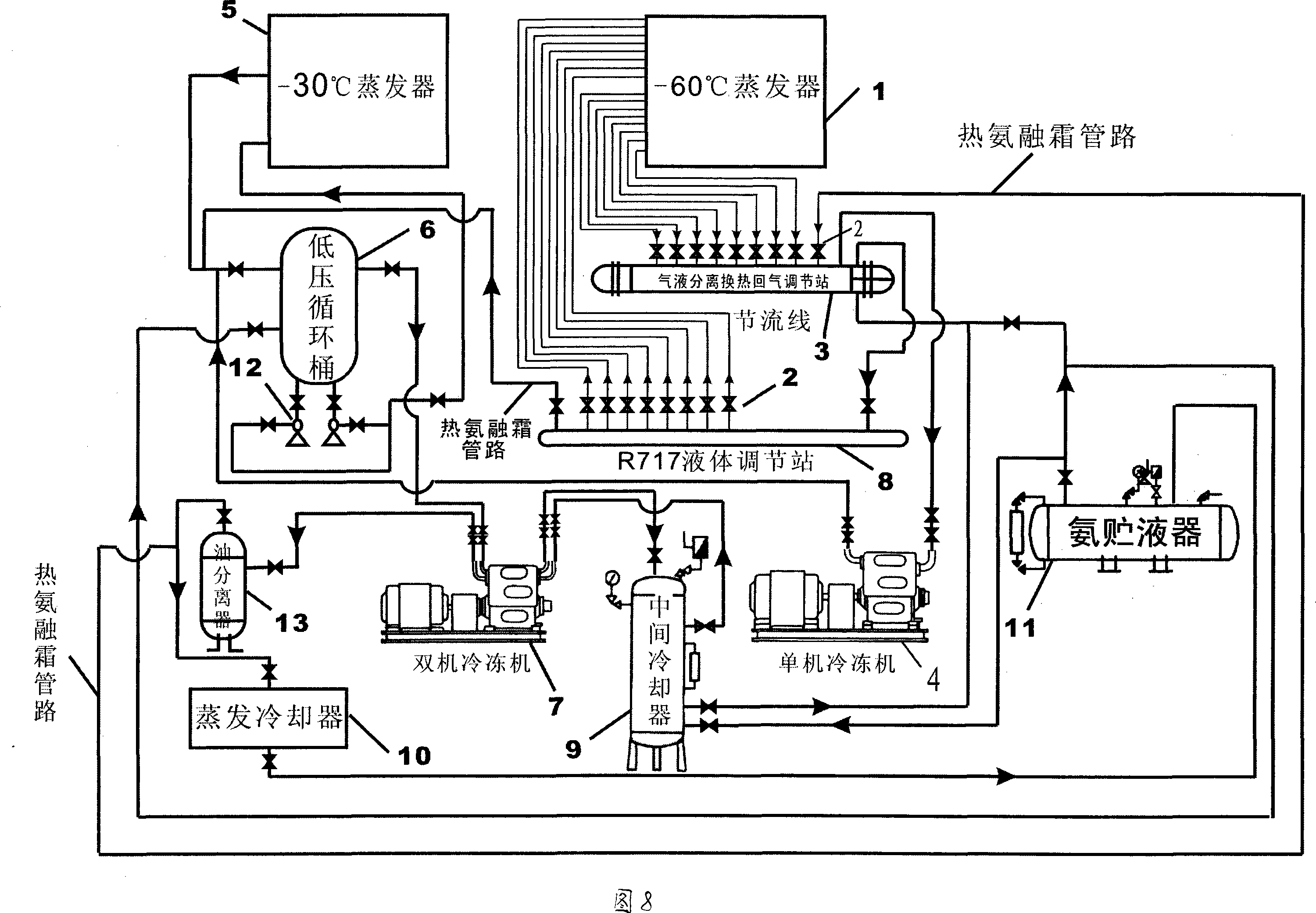

Ultra low temperature cool house

ActiveCN101158530AEasy to operateEasy to makeCompression machinesStationary refrigeration devicesEvaporative coolerProcess engineering

The invention relates to an ultra low temperature cold storage warehouse, which belongs to the technical field of the structure of the cold storage warehouse. The invention is characterized in that the ammonia is used as the refrigerants and a low-temperature evaporator, and a middle-low temperature evaporator are arranged in the preparatory room and the reservoir pool; the low-temperature evaporator is communicated with an air-liquid separating heat exchange air return regulating station, a freezer with a single engine and a low-pressure circulation barrel through an air return regulating station for ammonia, and the liquid of the low-pressure circulation barrel is communicated with the middle-low temperature evaporator and communicated back to the low-pressure circulation barrel through a liquid pump; the low-temperature evaporator enters the low-pressure circulation barrel 6 through a regulating station for ammonia liquid and the air-liquid separating heat exchange air return regulating station is connected with the low-temperature evaporator through the regulating station for ammonia liquid; the gas of the low-pressure circulation barrel is communicated with a freezer with double engines, to an intermediate cooler and communicated back to the freezer with double engines, and the gas of the freezer with double engines is communicated with an oil separator; the output end of the oil separator is communicated with an evaporative cooler and the air-liquid separating heat exchange air return regulating station, and the evaporative cooler is communicated to a liquid receiver for ammonia; the liquid receiver for ammonia is communicated with the air-liquid separating heat exchange air return regulating station, the low-temperature circulation barrel and the intermediate cooler.

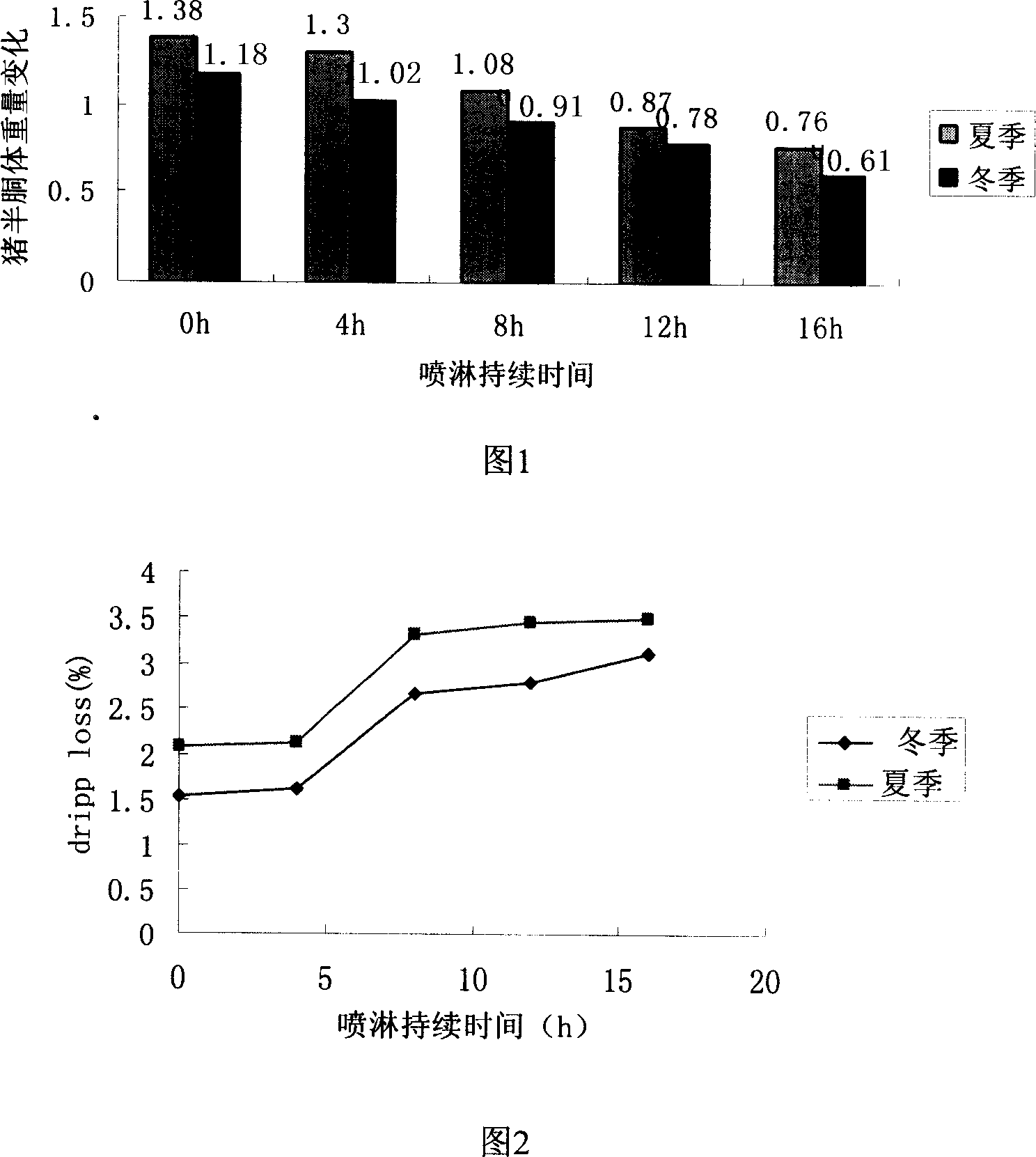

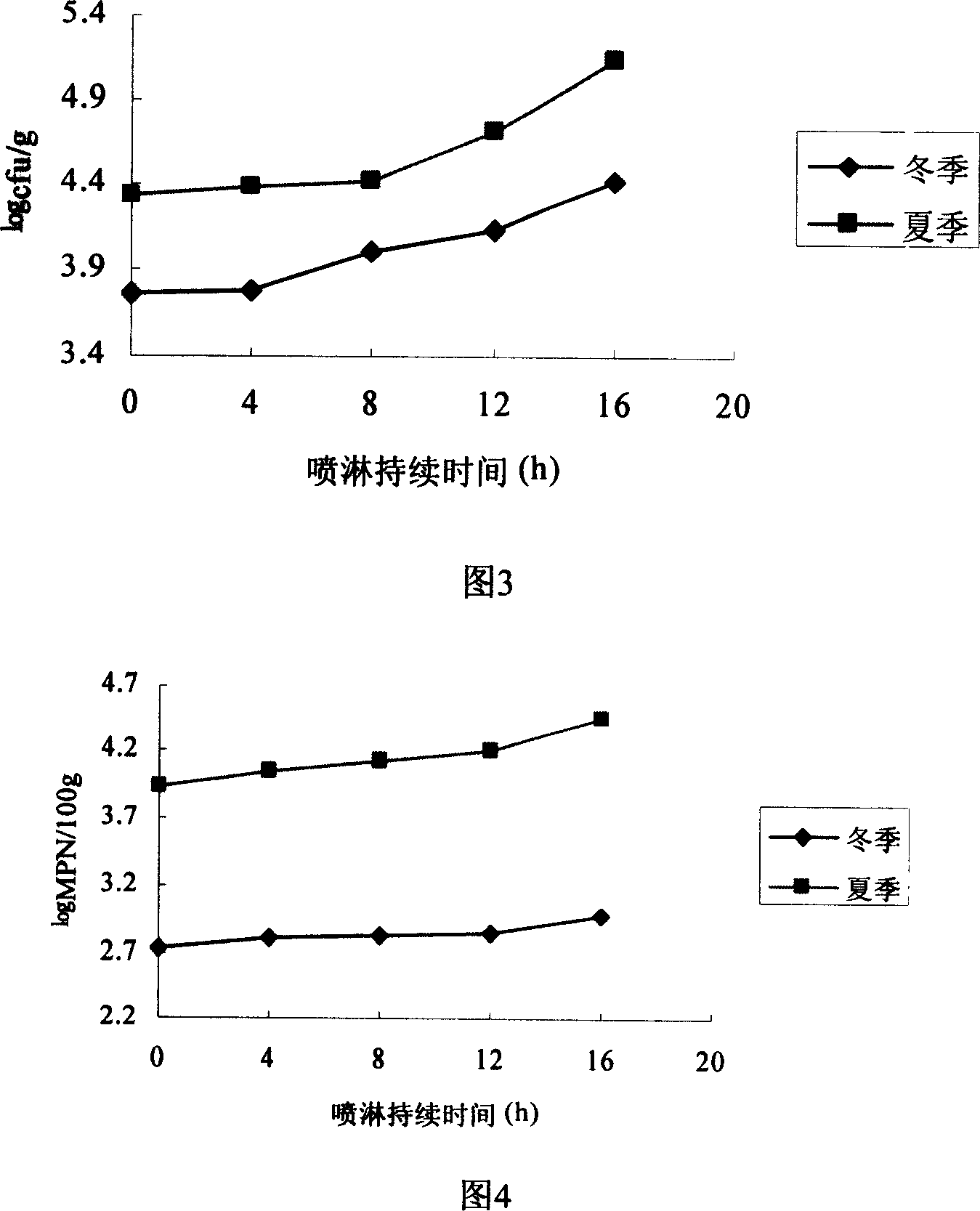

An atomizing spray cooling method for producing cooled meat

ActiveCN101006800AImprove qualityReduce dry consumptionMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsSpray coolingEnergy consumption

The invention relates to the field of meat processing, specifically to a method for producing cooling meat with atomization showering cooling method. The method comprises: interval -showering (showering for 40-60s every 30min-50min) the half naked body with water at 0-5DEG C for 8-12h. The atomization showering cooling method can reduce energy consumption, keep good quality of the naked body, and has broad application perspective.

Owner:JIANGSU SUSHI MEAT

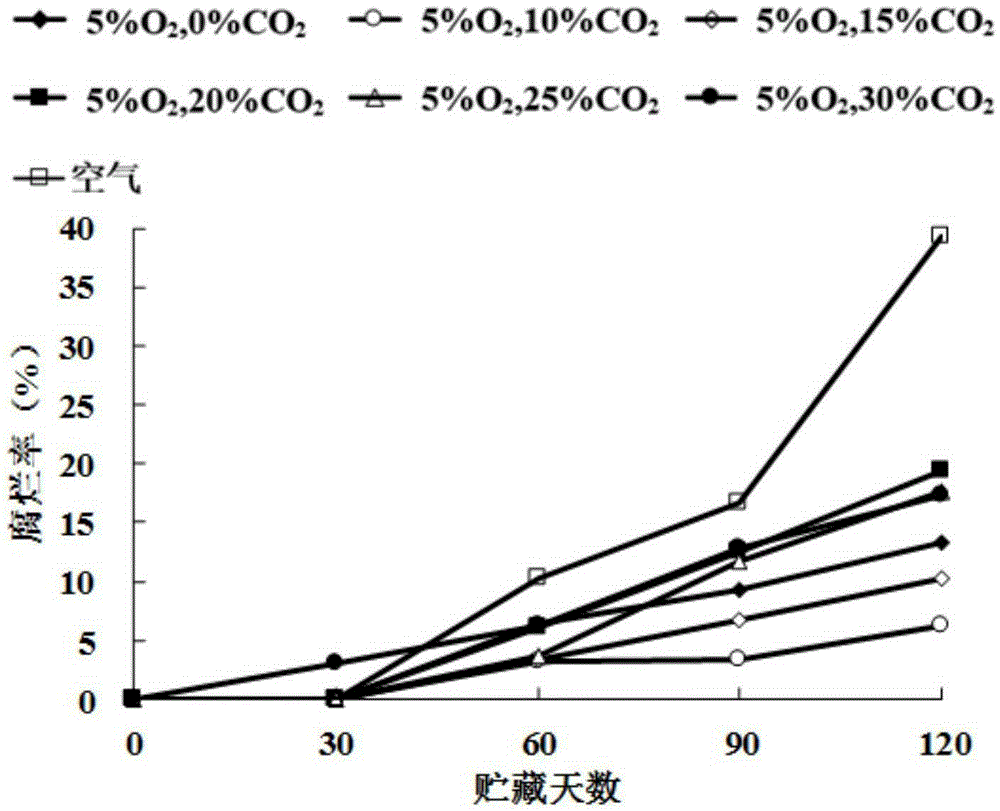

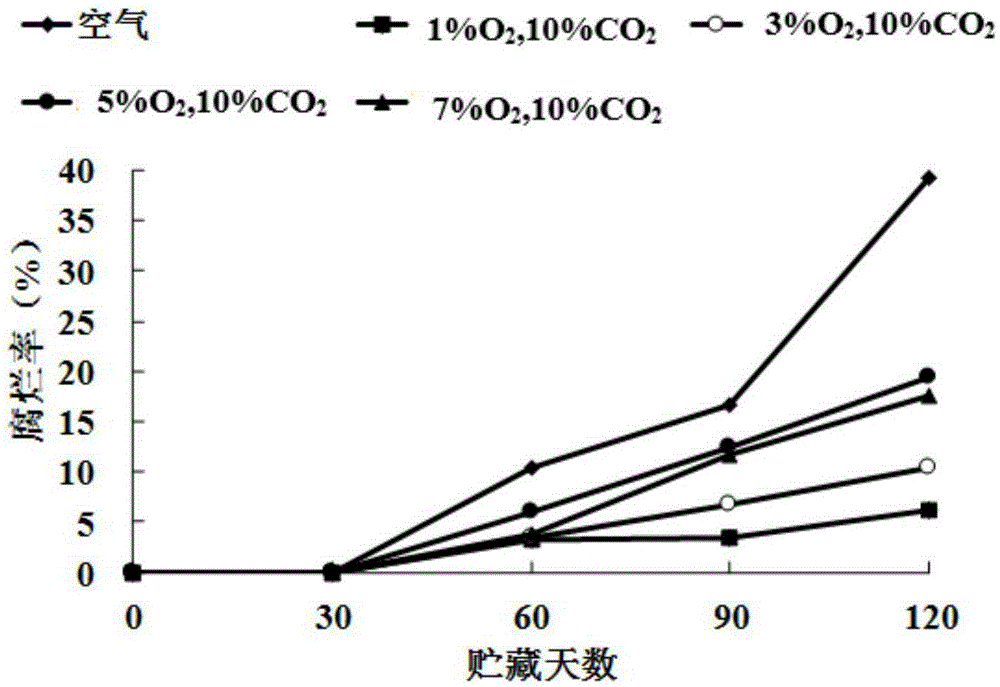

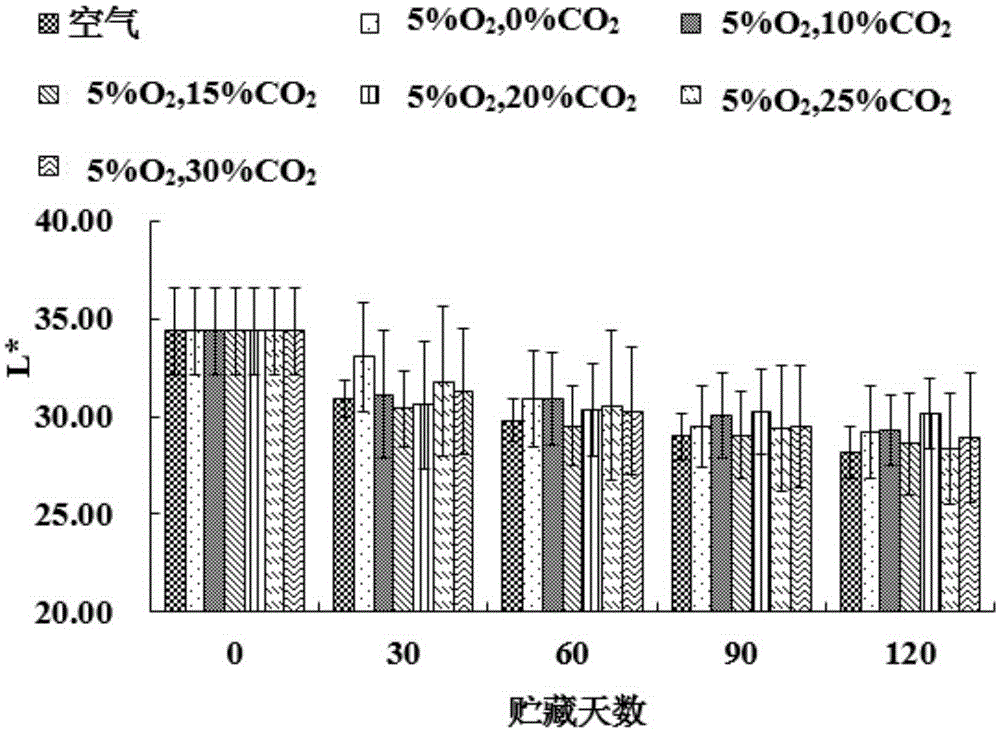

Small-package controlled atmosphere preservation method of sweet cherries

InactiveCN105410162AIncrease breathing intensityInhibition of decayFruit and vegetables preservationNitrogen gasPolypropylene

The invention relates to a small-package controlled atmosphere preservation method of sweet cherries. The small-package controlled atmosphere preservation method comprises the following steps: in the morning of sunny days, picking sweet cherries which have mid-late maturity varieties, have no mechanical loss and rot, and have uniform color and luster; storing at 25 DEG C for 5 days; determining the rot rate, color difference and hardness of the sweet cherries before and after storage; taking the sweet cherry variety with the change of three indexes, which is less than 10%, as a small-package controlled atmosphere preservation variety; in the morning of sunny days, picking the sweet cherries and keeping stems of the sweet cherries; selecting the sweet cherries with uniform color and luster and eliminating the sweet cherries with the mechanical loss and rot; putting the sweet cherries into pre-cooling air drying equipment, washing the sweet cherries with cold water and pre-cooling the sweet cherries to 2-7 DEG C; drying the sweet cherries with air until no water is remained and immediately carrying out the next step; taking 200g of the sweet cherries which are dried with the air and putting the sweet cherries into a polypropylene package box which is internally padded with water absorption paper; packaging the box by using a controlled atmosphere packaging machine, wherein the volume percent of mixed gas in the packaged polypropylene package box is as follows: 3%-7% of O2, 10%-20% of CO2 and the balance of nitrogen gas; and putting the sweet cherries subjected to controlled atmosphere packaging into a refrigeration house at a temperature ranging from -1 DEG C to 1 DEG C and storing.

Owner:LUDONG UNIVERSITY

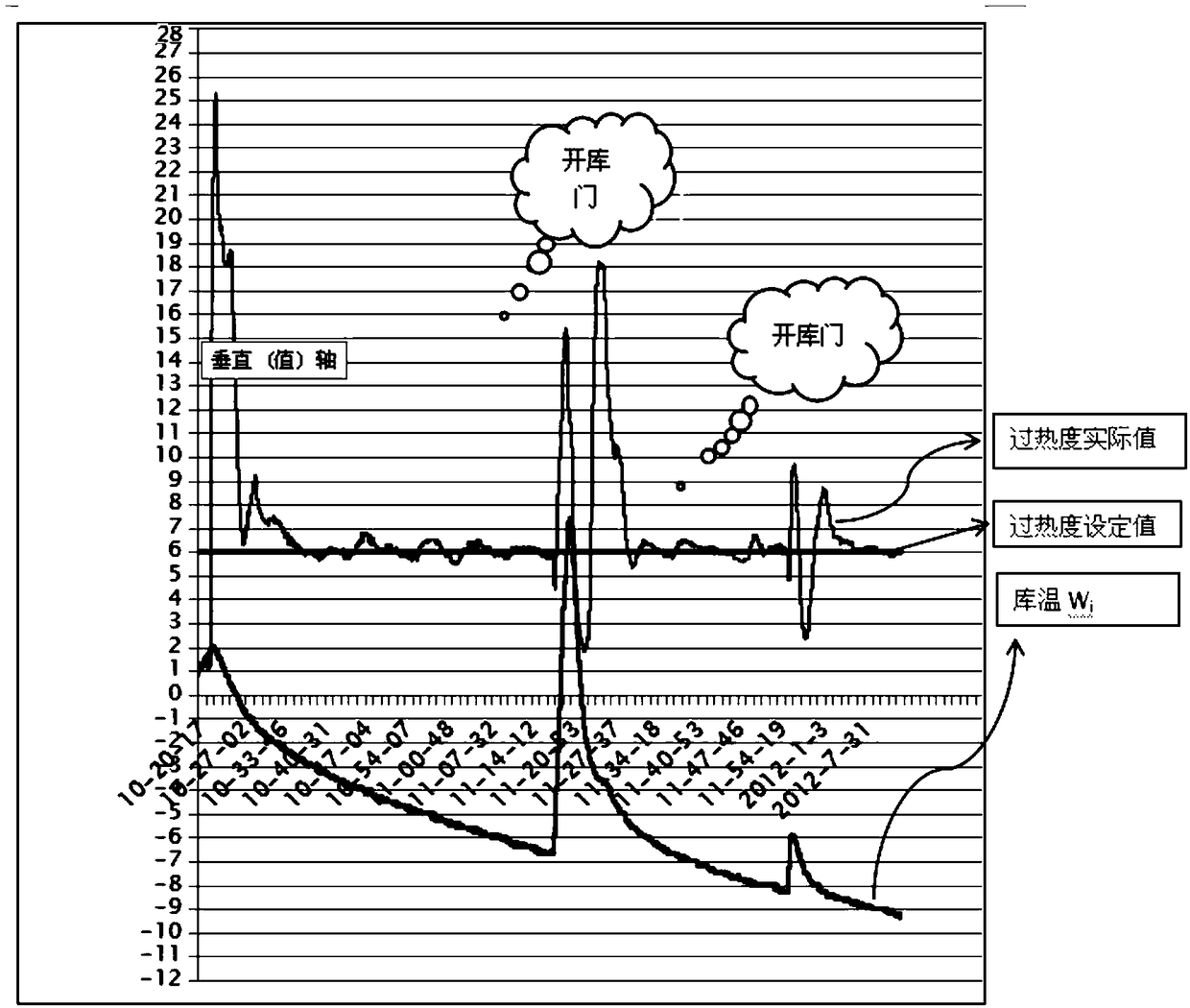

Superheat degree control electronic expansion valve system

ActiveCN108731324ASmall temperature differenceReduce frostingMechanical apparatusEfficient regulation technologiesEngineeringTemperature difference

The invention relates to a superheat degree control electronic expansion valve system. The superheat degree control electronic expansion valve system comprises an electronic expansion valve controller, an evaporator inlet refrigerant temperature sensor, an electronic expansion valve, an evaporator, a temperature sensor, an evaporator outlet refrigerant temperature sensor and a compressor; and thetemperature sensor is used for detecting the air inlet temperature of the evaporator, the evaporator inlet refrigerant temperature sensor is used for detecting the inlet temperature of the evaporatorrefrigerant side, the evaporator outlet refrigerant temperature sensor is used for detecting the outlet temperature of the evaporator refrigerant side, and the electronic expansion valve controller can set the heat exchange temperature difference of the evaporator and the superheat degree of the evaporator. According to the system, a set of algorithm is arranged in the electronic expansion valve controller, a stepping motor of the electronic expansion valve controller is controlled through the algorithm and the stepping motor is driven to move forwards and backwards through a threaded drivingvalve needle, and therefore a flow area of a valve port is changed.

Owner:XINAN JIANGSU ELECTRIC APPLIANCE CO LTD

Frozen delicacies from land and preservation technology of the delicacies from land

InactiveCN107156277AReduce dry consumptionReduce the loss of nutrientsFruits/vegetable preservation by freezing/coolingFood PreserversCold store

The present invention relates to frozen delicacies from land and a preservation technology of the delicacies from land, and belongs to the field of food preservation. The preservation technology comprises the following steps: raw materials of the delicacies from land are placed in a liquid nitrogen environment at -120 DEG C to -60 DEG C or a micro-freezing liquid environment at -40 DEG C to -25 DEG C to be quick-frozen for 5 min or longer, then the quick frozen delicacies from land are sent into a storage to be cold stored, and the cold stored delicacies from land are subjected to a cold chain transportation. The raw materials of the delicacies from land comprise bamboo shoots and edible fungi. The technological process is simple, easy to operate, excellent in preservation effects and low in costs. The obtained delicacies from land by the above technology are good in mouthfeel, and small in dry consumption rate, and can keep freshness of the raw materials for a long time.

Owner:四川鲜能农业科技有限公司

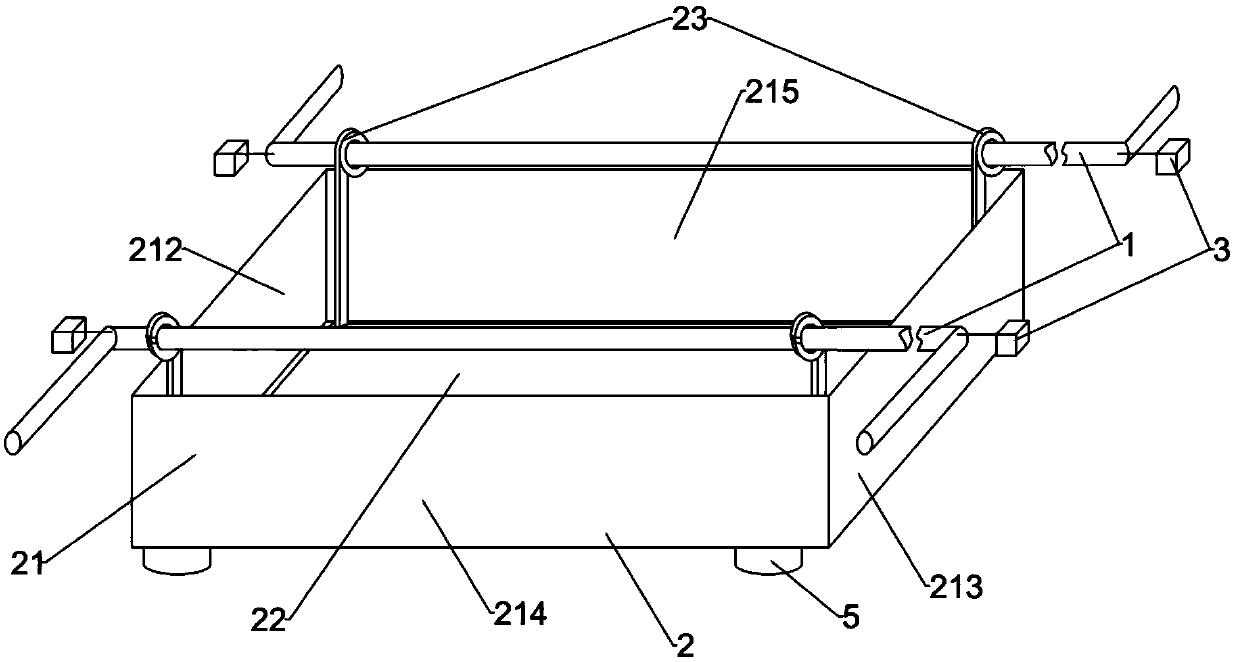

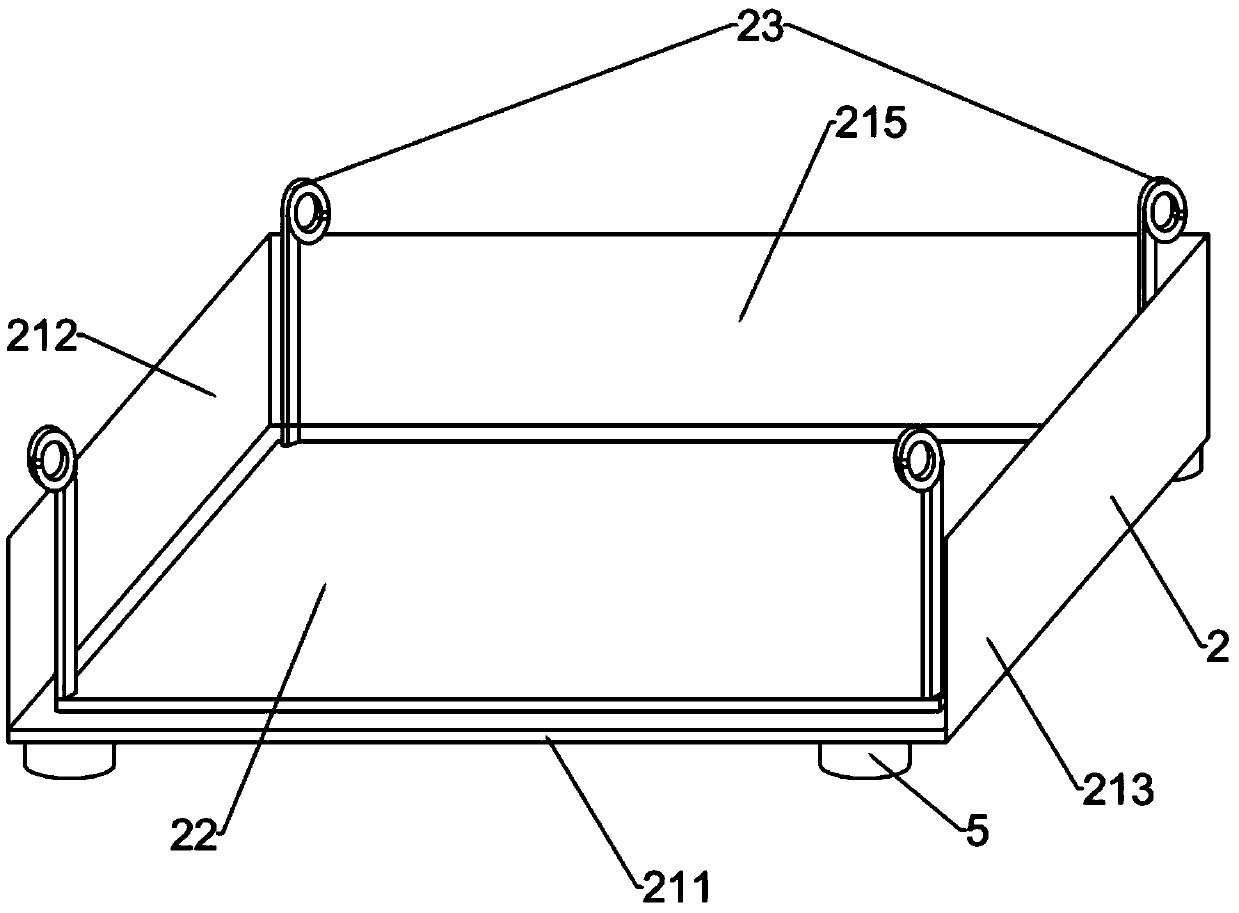

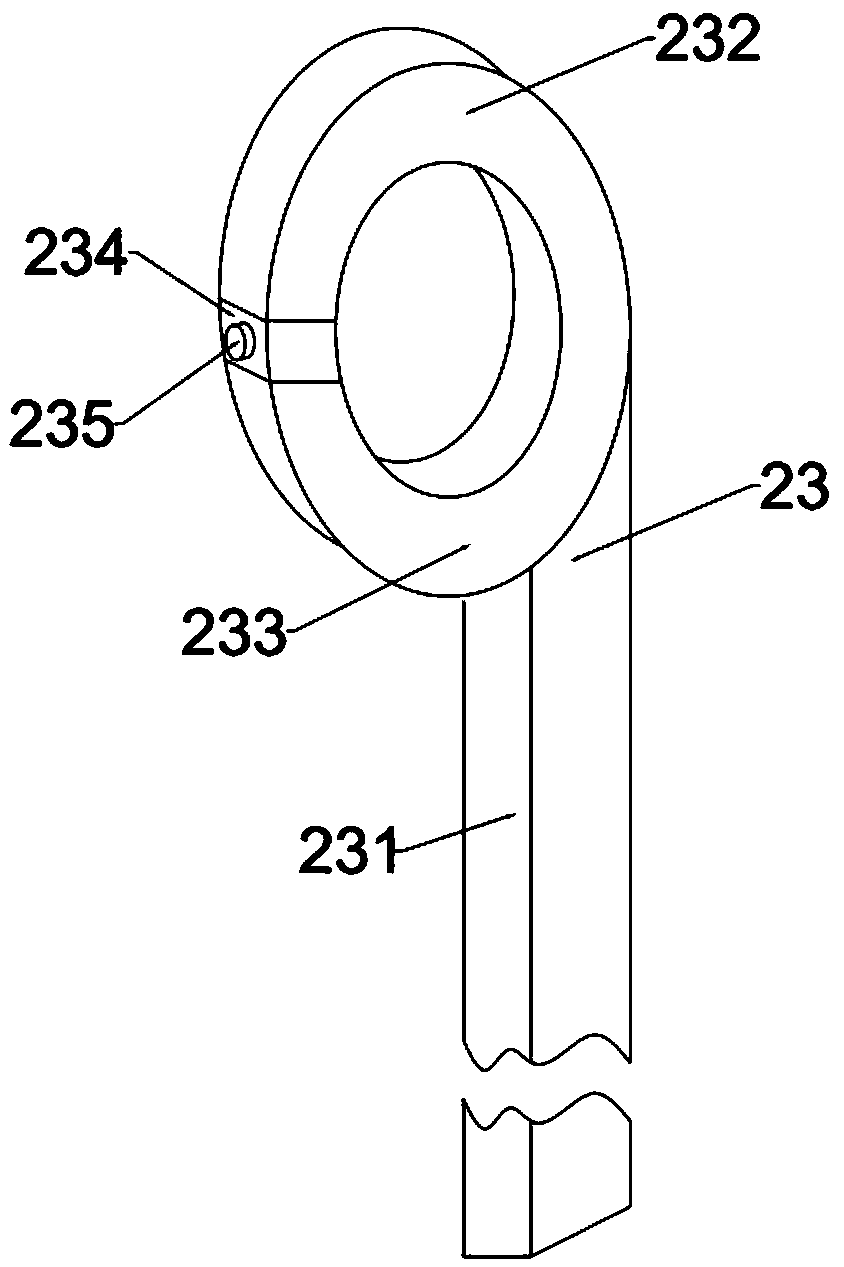

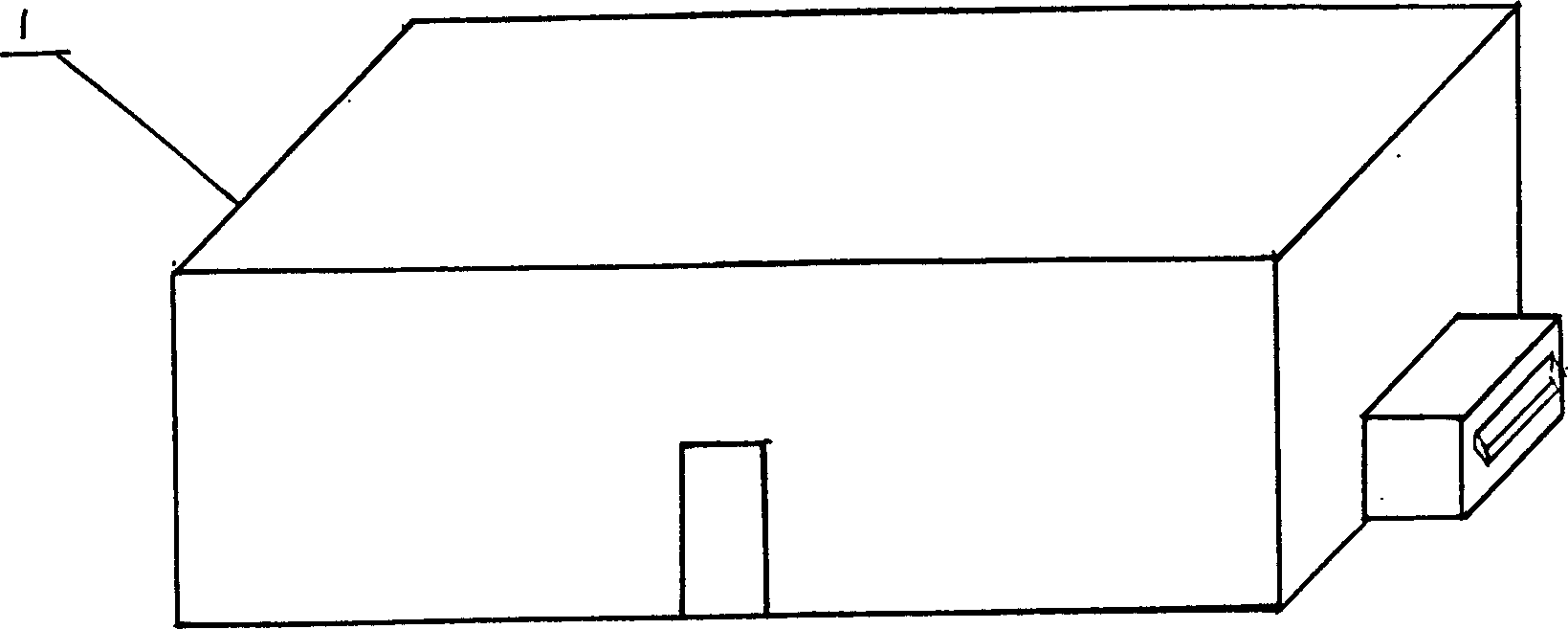

Bombay duck liquid nitrogen ultralow temperature quick-freezing device and quick-freezing fresh-keeping method thereof

InactiveCN109527063AFreeze evenlyGuaranteed qualityMeat/fish preservation by freezing/coolingQuick FreezeElectricity

The invention discloses a bombay duck liquid nitrogen ultralow temperature quick-freezing device and a quick-freezing fresh-keeping method thereof. The device includes a liquid nitrogen quick-freezer,two parallel vibration rods installed on the liquid nitrogen quick-freezer and a plurality of product freezing frames for quick-freezing of products. Each product freezing frame includes a frame body, a placement plate disposed in the frame body, and a plurality of suspension units arranged on the placement plate. Both ends of all the vibration rods are equipped with vibration motors, all the vibration motors are electrically connected to a master controller of the liquid nitrogen quick-freezer. The placement plate is suspended on the two vibration rods through the suspension units. Accordingto the invention, cleaning, soaking, ultra-low temperature quick-freezing, ice plating, vacuum packaging, cryopreservation and other processes are adopted in order to avoid wrinkling and chapping ofthe fish skin, and at the same time the original condition, color and freshness of bombay duck can be maintained. The vibration rods drive the suspension units and the placement plate to vibrate, so that the bombay duck can be frozen more evenly, and the overall freezing quality of bombay duck can be ensured.

Owner:浙江大洋兴和食品有限公司

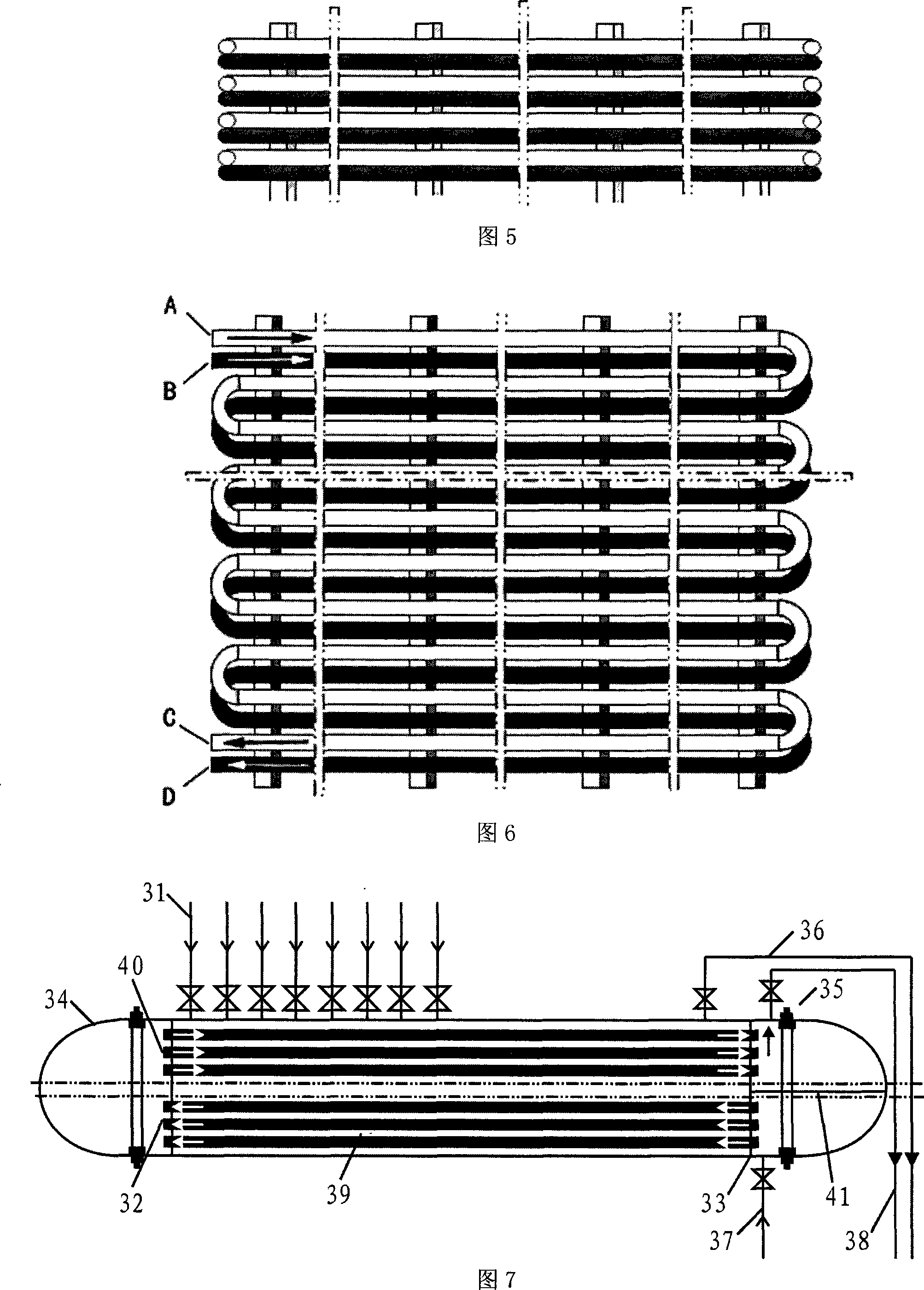

Single-unit foodstuff quick freezing machine

InactiveCN1544865AGuaranteed outputQuality assuranceLighting and heating apparatusStationary refrigeration devicesQuick FreezeFrost

The invention discloses a monomer quick-freezing machine, specially a new food single-freezing machine easy to wash frost, high-efficiency, a little drying loss and saving energy. It mainly includes shell and evaporator, circulating fan, air supply way, air supply chamber, and air return way all in the shell. Its character: the evaporator is composed of several independent evaporator units, each of which has peripheral guard board and made with air supply mouth and air outlet both installed with air doors, respectively, the air supply mouth and air outlet of each evaporator unit are connected with the air supply chamber and air return way, respectively; it has uniform-distributed cold field, low drying consumption, high efficiency, high productivity, etc.

Owner:李永堂

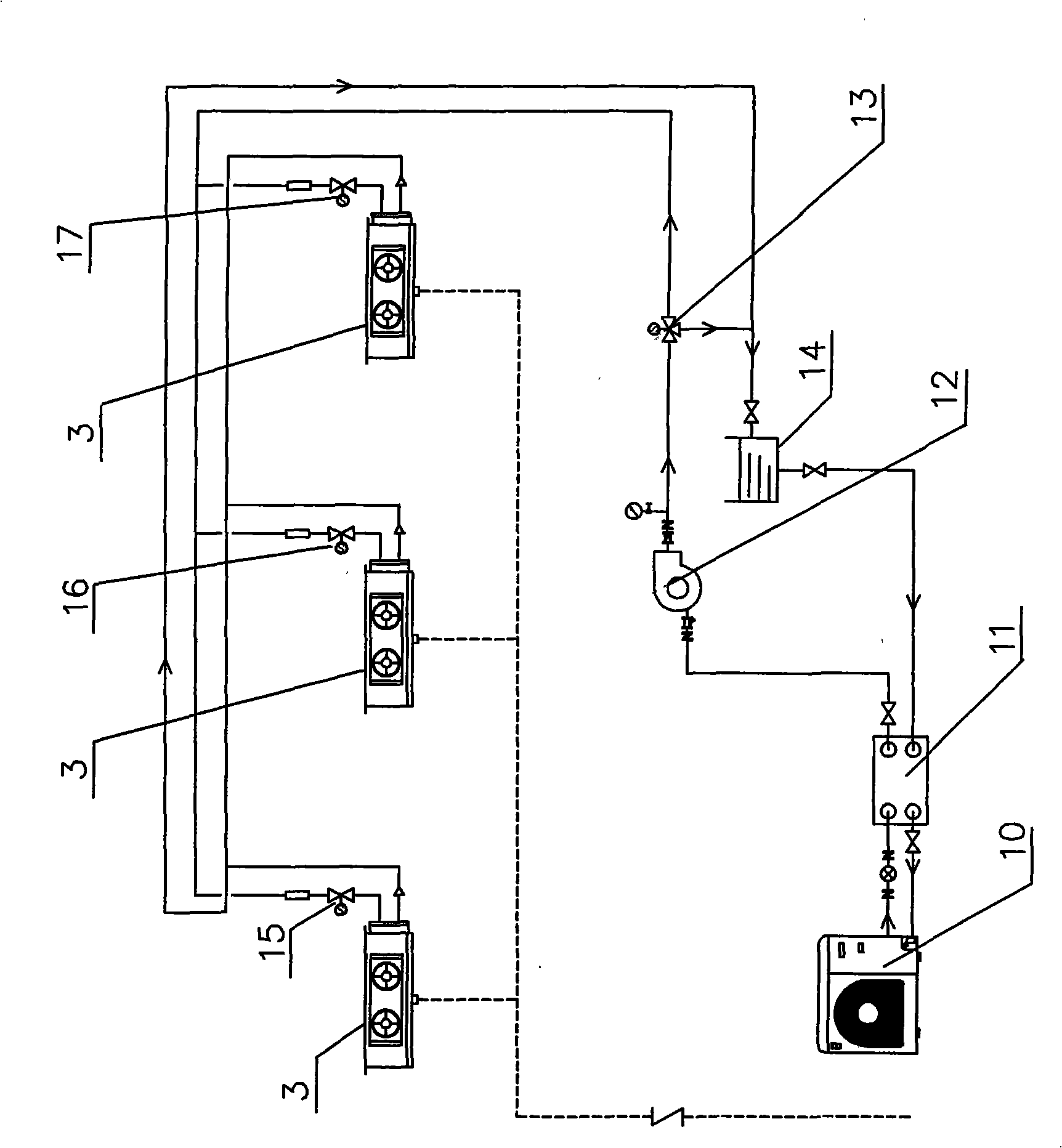

Quick cooling and dehumidifying system for continuous food chilling or quick-freezing process

InactiveCN102613662AReduce moisture contentHumidity content dehumidification effect is obviousFood processingFood preservationElectricityFrost

The invention discloses a quick cooling and dehumidifying system, in particular to a quick cooling and dehumidifying system for a continuous food chilling or quick-freezing process, and belongs to the technical field of food processing. The quick cooling and dehumidifying system comprises a processing room provided with an entrance and an exit, wherein a transmission device for delivering food continuously is arranged between the entrance and the exit. The quick cooling and dehumidifying system is characterized in that a sprinkler is arranged above the transmission device at the entrance of the processing room, a water receiving box is arranged below the sprinkler, and the sprinkler adopts low-temperature water or low-temperature salt water for sprinkling. The quick cooling and dehumidifying system has the advantages that an evaporator has little frost or is not frosted, and the food has little drying loss and good quality; and the quick cooling and dehumidifying system has quick cooling or quick-freezing speed, saves water and electricity, and is time-saving and labor-saving.

Owner:李永堂

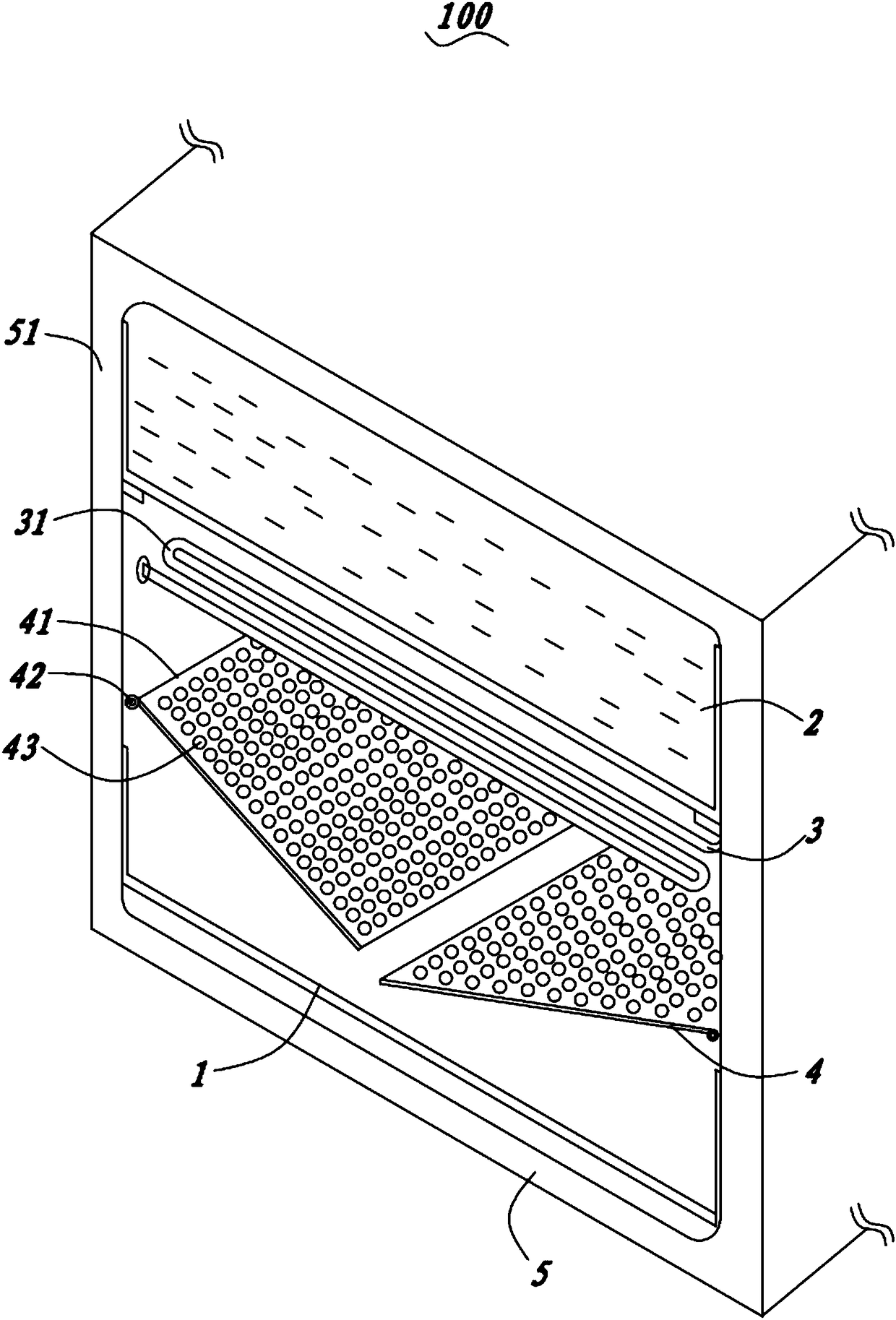

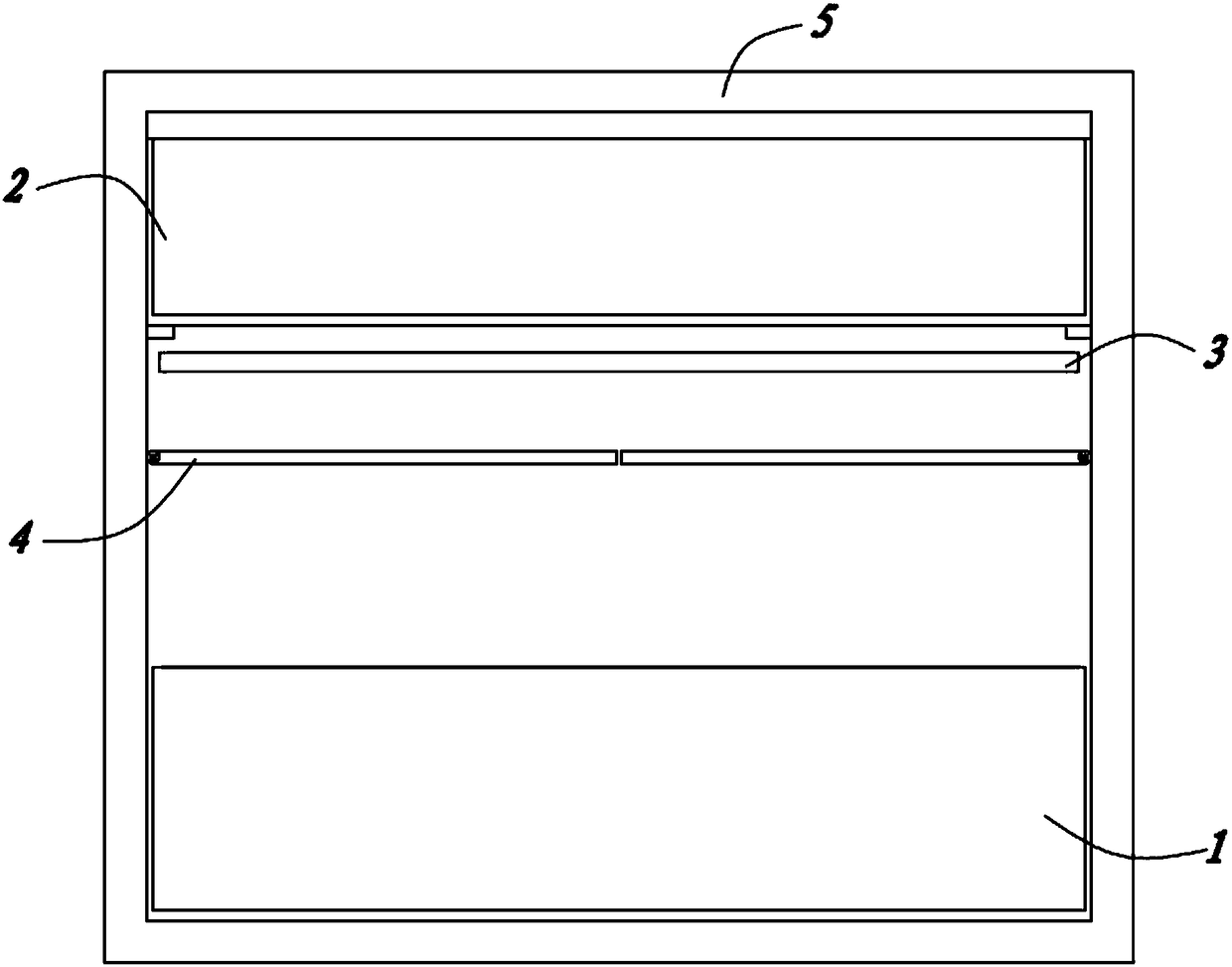

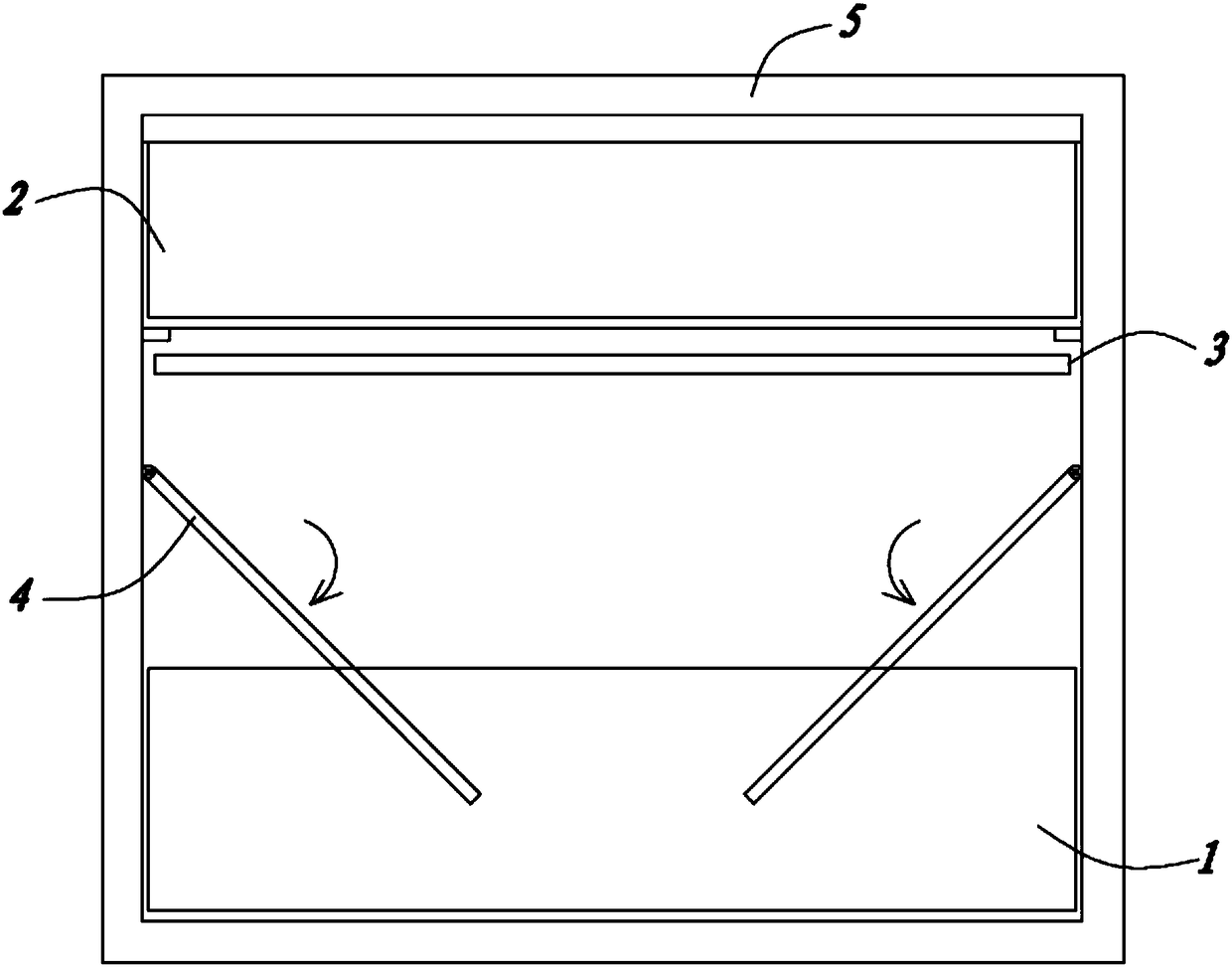

Ice glaze freshness retaining device, refrigerator and control method of refrigerator

ActiveCN108253720AGuaranteed tasteAvoid churnLighting and heating apparatusFood preservationWater storageAdditive ingredient

The invention provides an ice glaze freshness retaining device, a refrigerator and a control method of the refrigerator. The ice glaze freshness retaining device comprises a shelf assembly, a water storage box, a spraying assembly which is located above the shelf assembly and connected with the water storage box and a movable assembly which is arranged between the shelf assembly and the spraying assembly. The movable assembly has a first state at which the movable assembly can store the articles and a second state at which the articles stored on the movable assembly fall down. In addition, a storage chamber of the refrigerator is internally provided with the ice glaze freshness retaining device, food to be stored is subjected to two times of spraying, so that ice glaze formed on the surface of the food to be stored can be more complete and uniform, the refrigeration drying loss is reduced, great loss of nutritional ingredients is avoided, and the taste of stored food is improved.

Owner:HAIER SMART HOME CO LTD

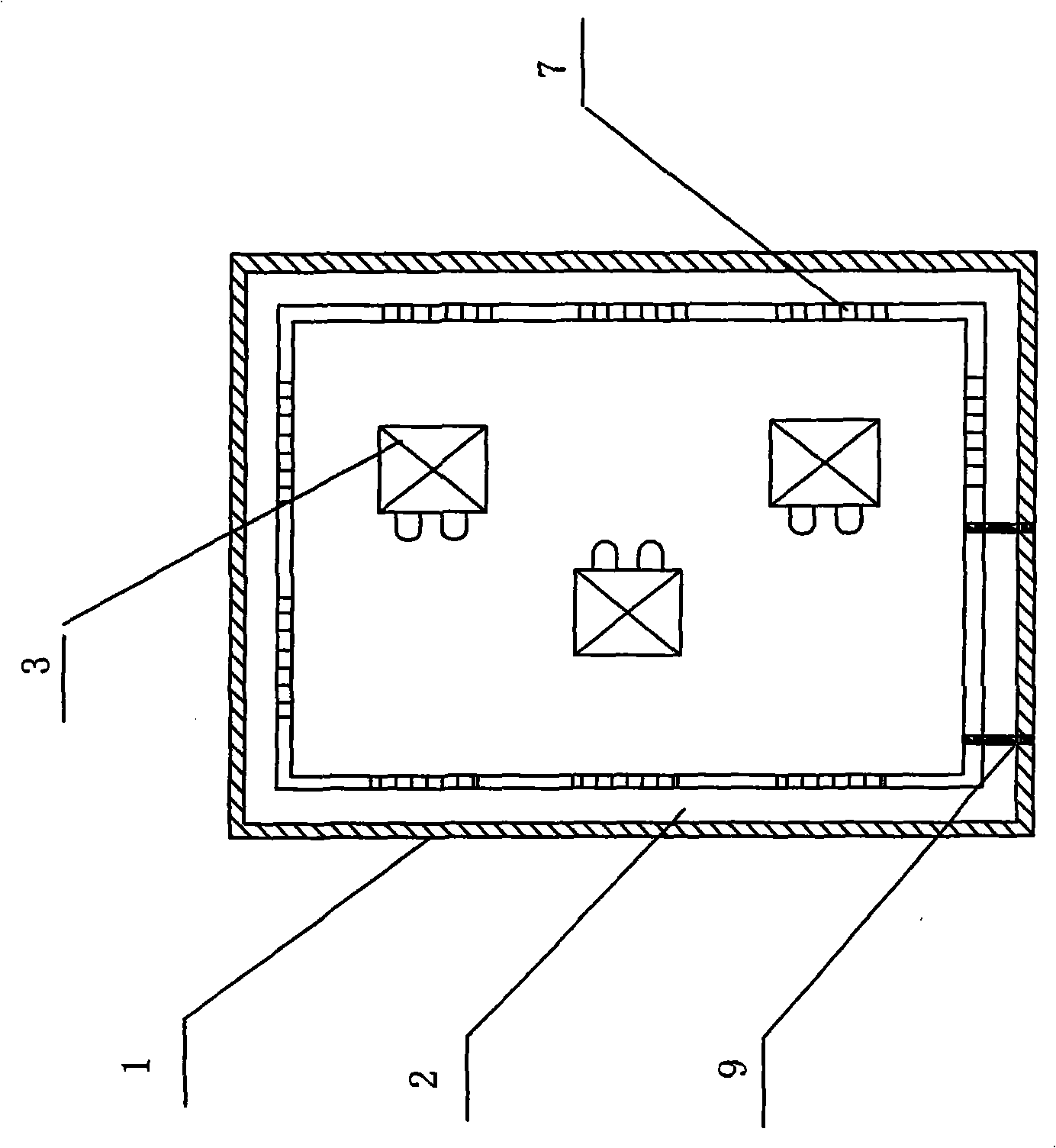

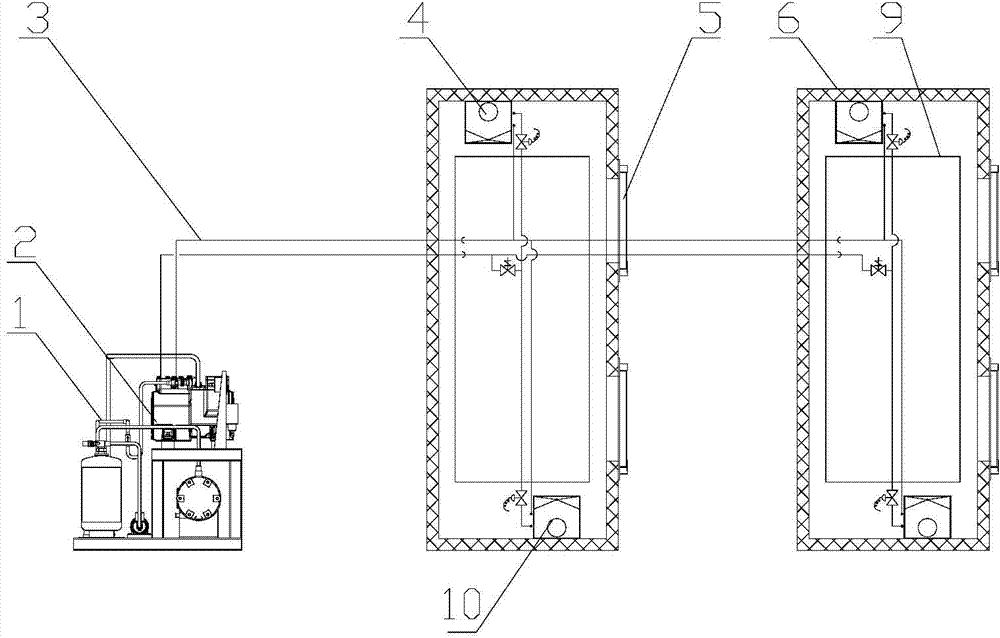

Ship ice-temperature cold storage

ActiveCN104748483AReduce dry consumptionImprove qualityLighting and heating apparatusStationary refrigeration devicesRefrigeration compressorEngineering

The invention discloses a ship ice-temperature cold storage which comprises a plurality of cold storages and a refrigerating system. Each cold storage comprises an inner coaming and an outer coaming, and an air interlayer is arranged between the inner coaming and the outer coaming. The refrigerating system comprises a refrigerating compressor and a cooling unit, the refrigerating compressor is arranged outside the cold storage, the cooling unit is arranged inside the cold storage and comprises at least one group of air feeders, the air feeders are arranged in the air interlayer at the top of the cold storage, air inlets of the air feeders are communicated with the air interlayer, side plates are arranged between the inner coaming and the outer coaming at the top of the cold storage and enclose a static pressure box, vent holes are formed in the top and the bottom of the inner coaming, and air outlets of the air feeders are positioned in the static pressure box. The ship ice-temperature cold storage is simple in structure, capable of storing various foods, long in preservation cycle, fine in preservation effect and suitable for occasions such as ships requiring long preservation cycle.

Owner:李建臣 +2

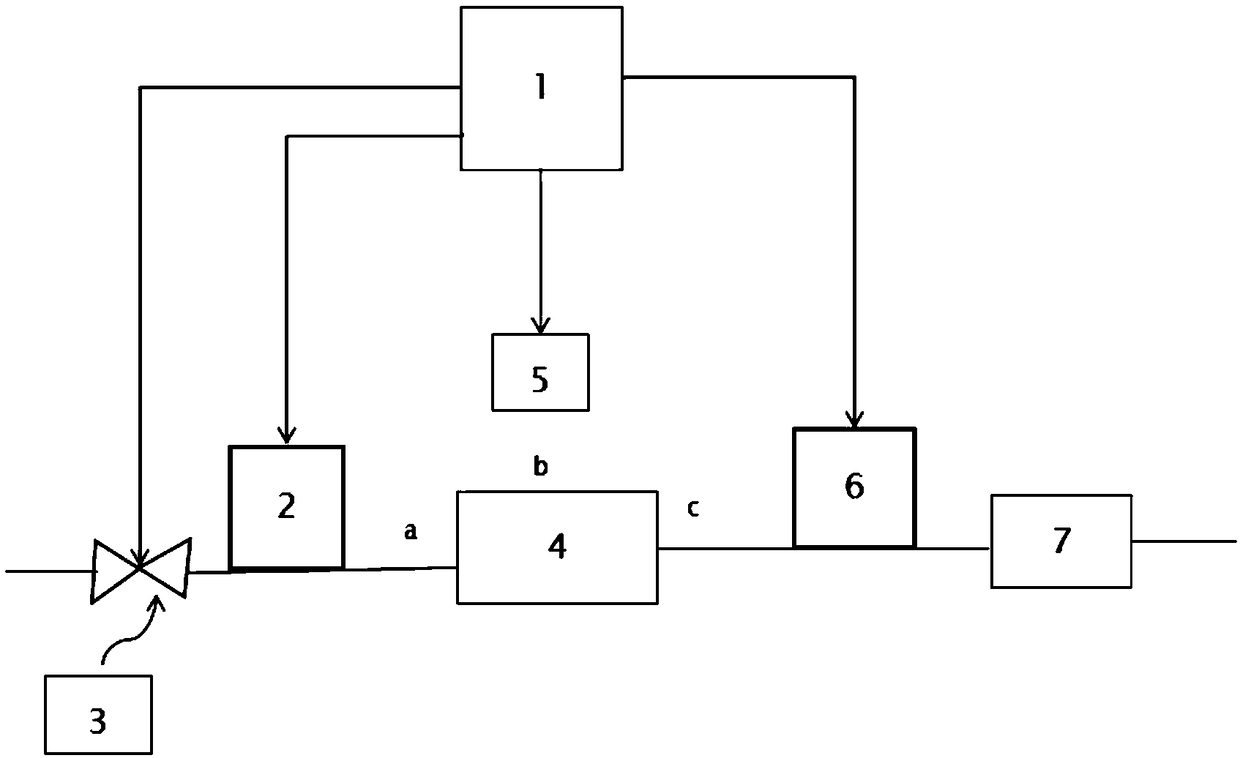

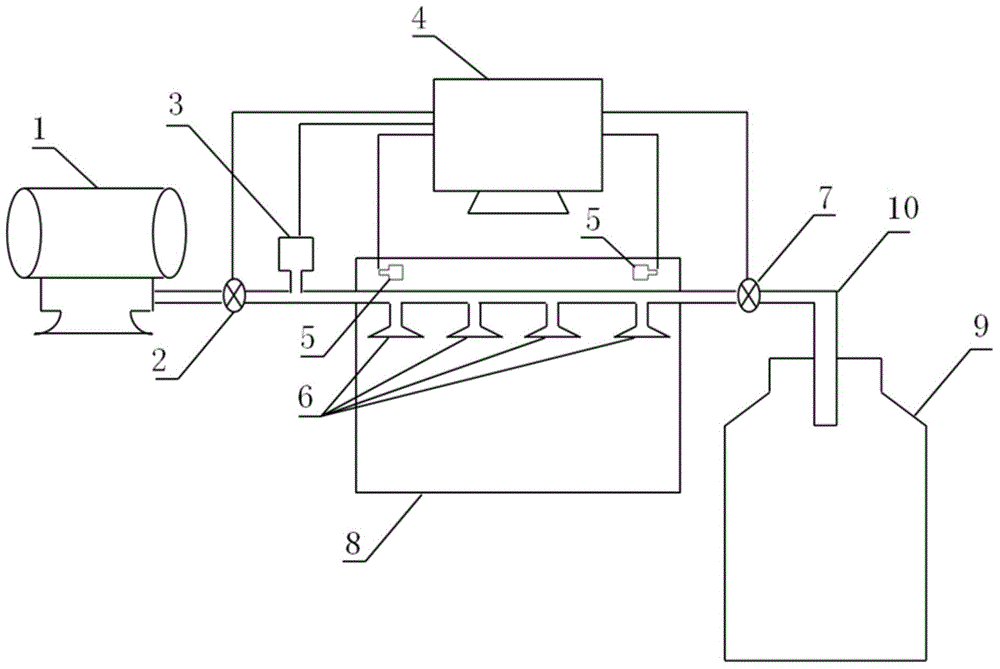

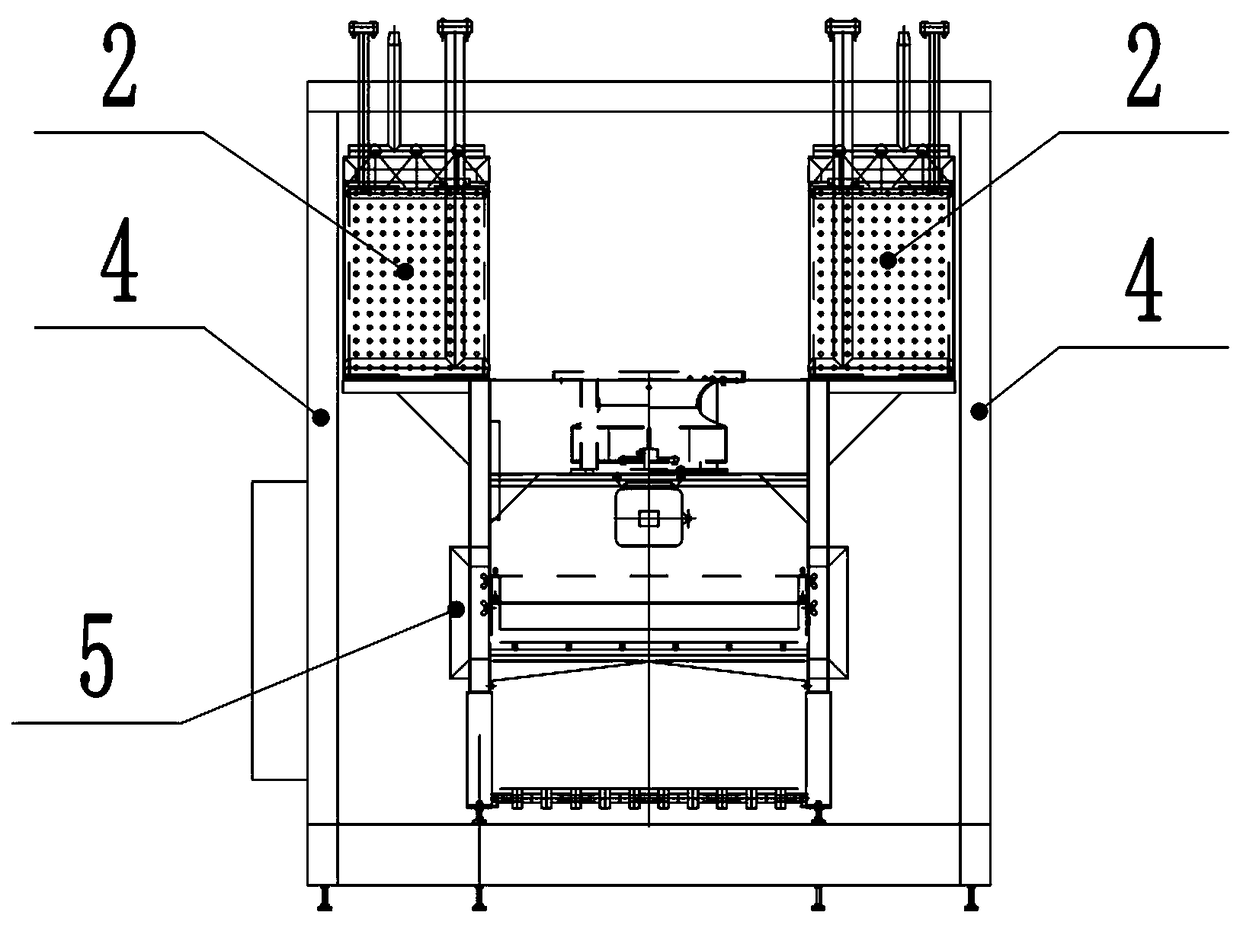

Experimental type liquid nitrogen quick freezing simple device

InactiveCN104785311AControl freeze rateQuick freezing effect is goodHeating or cooling apparatusQuick FreezeTwo temperature

The invention relates to an experimental type liquid nitrogen quick freezing simple device, which comprises: an air pump; a sealed quick freezing chamber, which is internally provided with two temperature sensors, wherein one temperature sensor is disposed at one quick freezing chamber end close to the air pump, and the other temperature sensor is arranged at one quick freezing chamber end close to a liquid nitrogen storage tank, with a first control valve being disposed between the air pump and the quick freezing chamber, and a wind speed measurement instrument being disposed between the first control valve and the quick freezing chamber; the liquid nitrogen storage tank, which is arranged at one end of the quick freezing chamber, with a second control valve disposed between the liquid nitrogen storage tank and the quick freezing chamber; a heat-insulated pipe, which has one end communicated with the air pump and the other end passing through the quick freezing chamber and communicated with the liquid nitrogen storage tank, and is located below the temperature sensors; at least 4 liquid nitrogen outlet pipes, which are disposed in the quick freezing chamber and are respectively communicated with the heat-insulated pipe, and have outlets facing down; and a controller. The liquid nitrogen quick freezing device provided by the invention has the advantages of simple structure and excellent quick freezing effect.

Owner:HANSHAN NORMAL UNIV

Quick-freezing device for bulk food

InactiveCN105466108AImprove cooling efficiencyReduce dry consumptionLighting and heating apparatusStationary refrigeration devicesSpray nozzleCotton cloth

The invention belongs to the field of quick-freezing devices, and particularly discloses a quick-freezing device for bulk food. The quick-freezing device comprises a machine frame, a cooling tunnel, a conveyor belt, a storage frame and a spray nozzle. The cooling tunnel is fixed to the machine frame and provided with a gas return pipe connected with the two ends of the cooling tunnel. The conveyor belt is fixed to the lower portion in the cooling tunnel. The cooling tunnel is internally provided with at least two air coolers and at least two axial flow fans. All the air coolers and all the axial flow fans are distributed on the upper portion in the cooling tunnel at intervals. The conveyor belt comprises a feeding end and a discharging end. The storage frame comprises side walls, a bottom plate, cotton cloth layers and a conical frame cap matched with the storage frame. The cotton cloth layers are fixed to the outer portions of the side walls. The side walls are fixed to the bottom plate. The conical cap is arranged on the storage frame. The spray nozzle is located above the feeding end and fixed to the machine frame. The invention aims at providing the quick-freezing device which is high in cooling efficiency and small in food drying loss and used for bulk food.

Owner:CHONGQING XUPENG ECOLOGICAL AGRI DEV CO LTD

Frozen dough, making method of frozen dough and bread

InactiveCN108835159AReduce generationReduce crackingPre-baking dough treatmentDough freeze-dryingBiotechnologyAntifreeze Peptides

The invention discloses frozen dough, a making method of the frozen dough and bread. The making method of the frozen dough comprises the steps that (1) bread powder, white granulated sugar, salt, yeast, water, rhopilema esculentum antifreeze peptides, gum, saccharose monopalmitate, transglutaminase and xylanase are evenly mixed to obtain the dough; (2) secondary stirring and standing are conducted; (3) the dough after standing in the second step is cut into dough with the designated size and shape, and shaping is conducted until the designated shape is formed; (4) whole egg liquid, lecithin, short daisy chain powder and salad oil are mixed, evenly stirred and cooled, spraying is conducted, and a layer of thin film is formed on the surface of the dough; (5) the dough in the fourth step is frozen to obtain the frozen dough. According to the frozen dough, novel ocean-type antifreeze peptides, namely rhopilema esculentum antifreeze peptides are adopted, the generation quantity of ice crystals in the dough can be lowered, moisture migration is reduced, and the activity of the yeast in the frozen dough can be protected.

Owner:WUHAN POLYTECHNIC UNIVERSITY

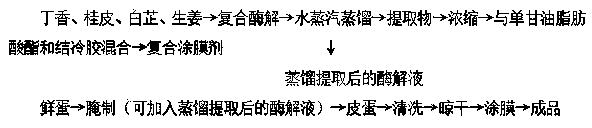

Plant-derived coating preserved eggs and preparation method thereof

ActiveCN104382083AShorten marinating timeShorten curing cycleEggs preservation by coatingFood preparationBiotechnologyGellan gum

The invention relates to plant-derived coating preserved eggs and a preparation method thereof. The method comprises the following steps: performing composite enzymatic hydrolysis on clove, cassia bark, dahurian angelica root and ginger in a ratio of 2:1:1:3.5, and performing distillation, extraction and concentration on the treated materials to obtain an extract and a residual extracting solution; preparing the extract, fatty acid monoglyceride and gellan gum into a compound coating agent; and adding the residual extract into preserved egg pickling liquid. Through adoption of the method, the preservation effect of the preserved eggs can be enhanced greatly. Meanwhile, the pickling time of the preserved eggs is shortened; the color and cluster and jelly strength of the preserved eggs are enhanced; and the product quality is improved.

Owner:RUICHANG YIXIANG AGRI PROD

Liquid nitrogen spray type fresh winter cordyceps sinensis quick-freezing method

ActiveCN109744457ASolve the problem of freshness dropSuitable for long-term preservationFood preservationQuick FreezePreservative

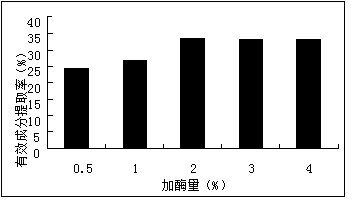

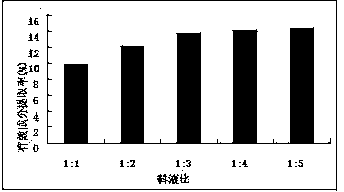

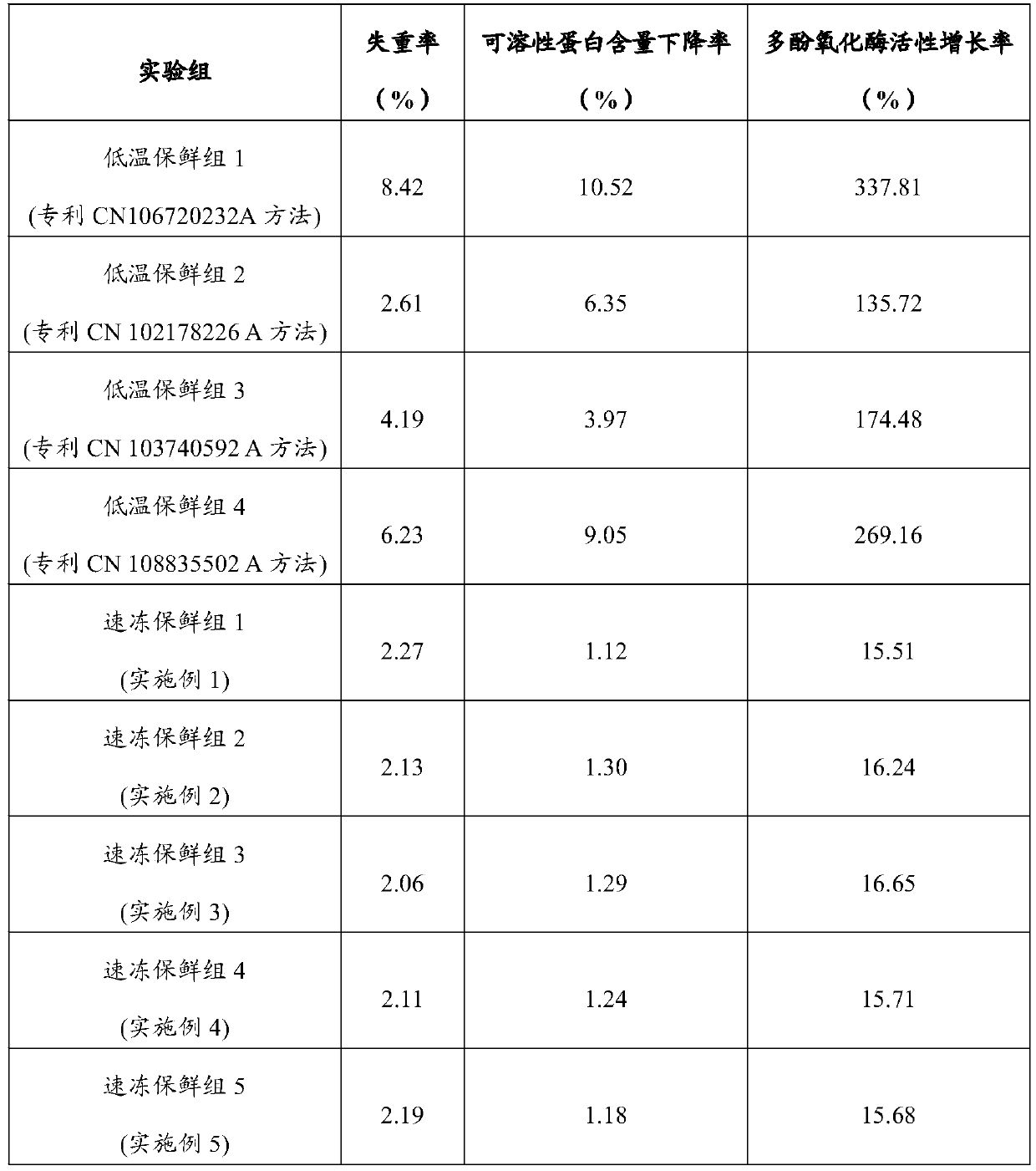

The invention relates to a liquid nitrogen spray type fresh winter cordyceps sinensis quick-freezing method, and belongs to the technical field of freshness preservation of cordyceps sinensis. The method comprises the following steps of 1) washing cordyceps sinensis with water; 2) ultrasonically washing washed cordyceps sinensis; 3) soaking cordyceps sinensis in a cryoprotectant; 4) placing cordyceps sinensis soaked in step 3 in a liquid nitrogen spray quick-freezing device for multi-stage quick freezing; 5) spraying a preservative onto quick-frozen cordyceps sinensis; 6) conducting modified atmosphere packaging on cordyceps sinensis onto which the preservative is sprayed; 7) refrigerating cordyceps sinensis after modified atmosphere packaging. By means of the method, the problem that thefreshness of cordyceps sinensis in the freshness preservation process is reduced can be solved, the weight loss rate is low, the soluble protein content is high, and the polyphenol oxidase activity islow.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Fresh keeping method of garden lettuce based on storage in air-conditioned cold store

InactiveCN108633992AReduce dry consumptionLower water activityFood ingredient for microbe protectionFruits/vegetable preservation by freezing/coolingPhacusCold store

The invention relates to a fresh keeping method of garden lettuce based on storage in an air-conditioned cold store. The fresh keeping method is characterized by sequentially comprising the followingsteps of preparing an air-conditioned cold store and hollow baskets, cleaning the air-conditioned cold store and performing disinfection, setting the temperature of the air-conditioned cold store, performing low-temperature precooling and selecting on picked garden lettuce, loading selected garden lettuce in the hollow baskets, sleeving the hollow baskets loaded with the garden lettuce with perforated fresh keeping bags, putting the hollow baskets which are loaded with the garden lettuce and sleeved with the fresh keeping bags in the air-conditioned cold store at intervals in a laying manner,sterilizing the garden lettuce in the air-conditioned cold store with ozone, storing the garden lettuce in two stages of the first 10 days and days after the first 10 days, maintaining the humidity inthe air-conditioned cold store to be 80-95% with a humidifier in the air-conditioned cold store and the like. Through the fresh keeping method, the fresh keeping time of the garden lettuce can be prolonged, the long-time fresh keeping requirements of the garden lettuce in places of ocean vessels can be met, unsafe factors are eliminated, and the fresh keeping method can be accepted by people. Thefresh keeping method is suitable for storage and fresh keeping of the garden lettuce in the ocean vessels.

Owner:WUXI HAIHE EQUIP TECH CO LTD

Low-drying-loss quick freezing device and quick freezing method

InactiveCN108800718AImprove qualityReduce the burden onLighting and heating apparatusStationary refrigeration devicesCold airQuick Freeze

The invention discloses a low-drying-loss quick freezing device and a quick freezing method. The device is provided with a freezing channel and further comprises a conveying device for conveying to-be-frozen objects along the freezing channel. A rack is further provided with air coolers and an air supply device. The air coolers blow cold air to the to-be-frozen objects through the air supply device for freezing. The rack is further provided with a vertical partition plate, and the partition plate divides the freezing channel into a first freezing section and a second freezing section, and windfields of the two sections are isolated. The air supply speed of the first freezing section is smaller than that of the second freezing section. According to the low-drying-loss quick freezing deviceand the quick freezing method, the freezing process is divided into two stages including low-wind-speed freezing and high-wind-speed freezing, object surface freezing is achieved at the low-wind-speed stage, and accordingly, water is locked in the objects; and in the high-wind-speed freezing stage, the whole objects are completely frozen, dry losses in the quick freezing process are reduced, thefood quality is improved, meanwhile, the quick freezing efficiency is improved, and the resource is saved.

Owner:YANTAI MOON

Method for preparing room temperature round ham using eugenol emulsion gel for preservation

InactiveCN107373402AControl releaseReduce dry consumptionFood ingredient as solubility improving agentMeat/fish preservation using chemicalsFlavorEmulsion

The invention discloses a method for preparing a room temperature round ham using eugenol emulsion gel for preservation, the eugenol-embedded emulsion gel is obtained by blending emulsion prepared from eugenol with gelatin, the eugenol-embedded emulsion gel is added into ingredients of the round ham to be filled, the eugenol-embedded emulsion gel is evenly dispersed in meat stuffing of the round ham by chopping, by sterilization after filling, harmful bacteria in the ham can be killed, hydrogel films can be formed on the surface and the interior of the round ham by the cooled eugenol emulsion gel, the hydrogel films can effectively reduce the dry loss of the round ham in the daily storage. The round ham has a granular taste by mincing pork and pig skin with a big-orifice baffle, by addition of minced chicken meat, the round ham is rich in taste and chewy, deep and natural in flavor and rosy and shiny in appearance, section meat blocks are really visible, and the product exceeds low temperature limit, and can be circulated and preserved at room temperature.

Owner:ANHUI XIAXING FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com