An atomizing spray cooling method for producing cooled meat

A technology of atomization spraying and cooling method, applied in chemical instruments and methods, preservation of meat/fish by freezing/cooling, preservation of meat/fish with chemicals, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

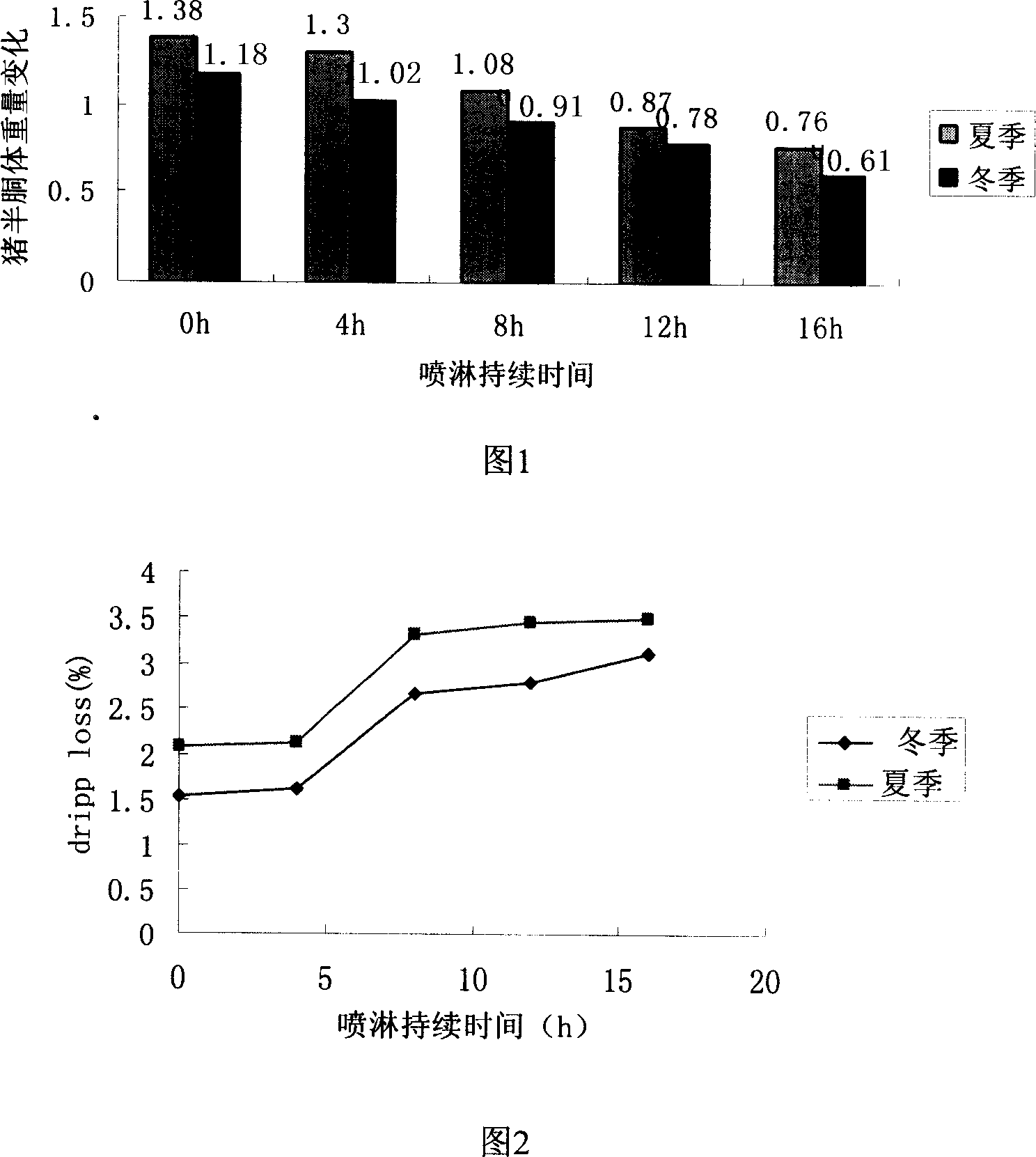

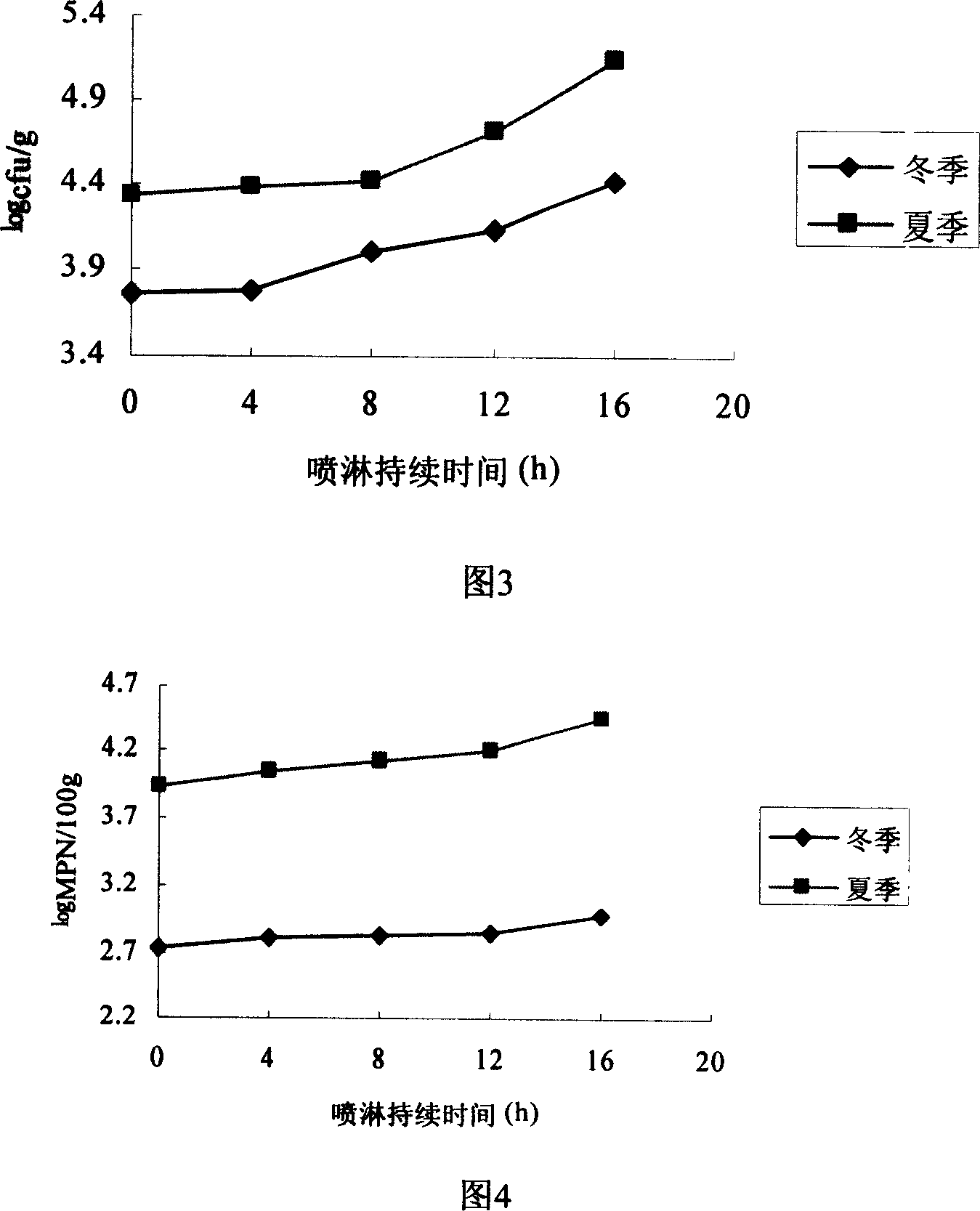

[0017] Materials: 25 freshly slaughtered pig half carcasses, each half carcass weighs about 40Kg;

[0018] Method: After the samples enter the warehouse, perform intermittent spraying, use a small sprayer (30Kg) to spray the half-carcass, spray water at 0-5°C, spray once every 30min-50min, each time about 40-60s, The spray pressure is 0.25MP, and the flow rate is 11.2L / h.

[0019] The carcasses of different treatment groups are distributed in the four corners and the center of the cooling room. The temperature in the cooling room is 0-4°C, and the air velocity is 2.5m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com