Low-drying-loss quick freezing device and quick freezing method

A quick-freezing device and drying consumption technology, which is applied to household refrigeration devices, coolers, lighting and heating equipment, etc., can solve the problems of difficult progress, long freezing time, and high drying consumption of food, so as to reduce the burden and improve food quality , the effect of reducing dry consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

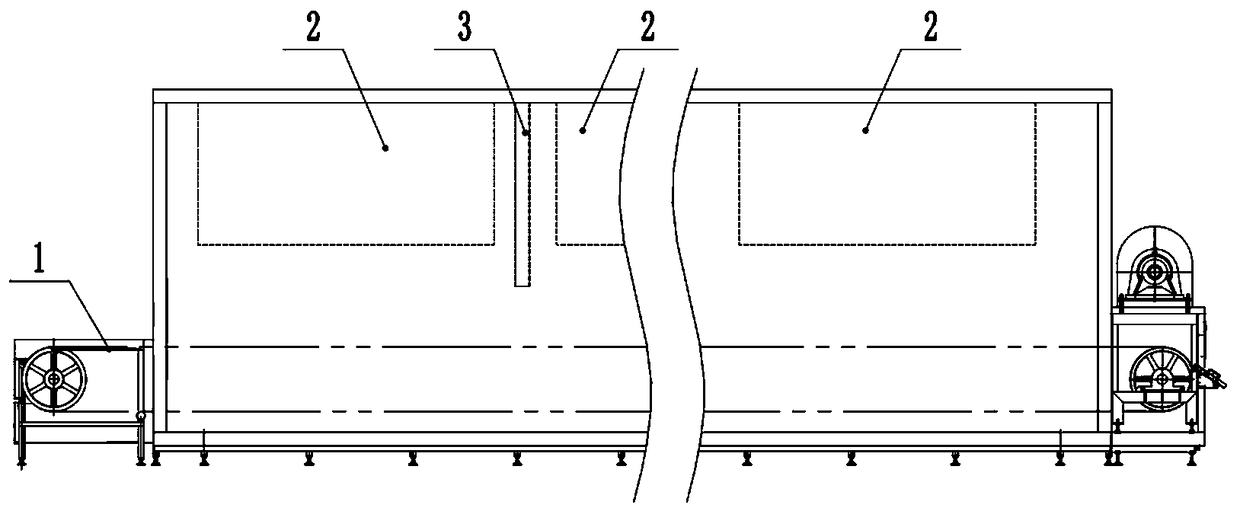

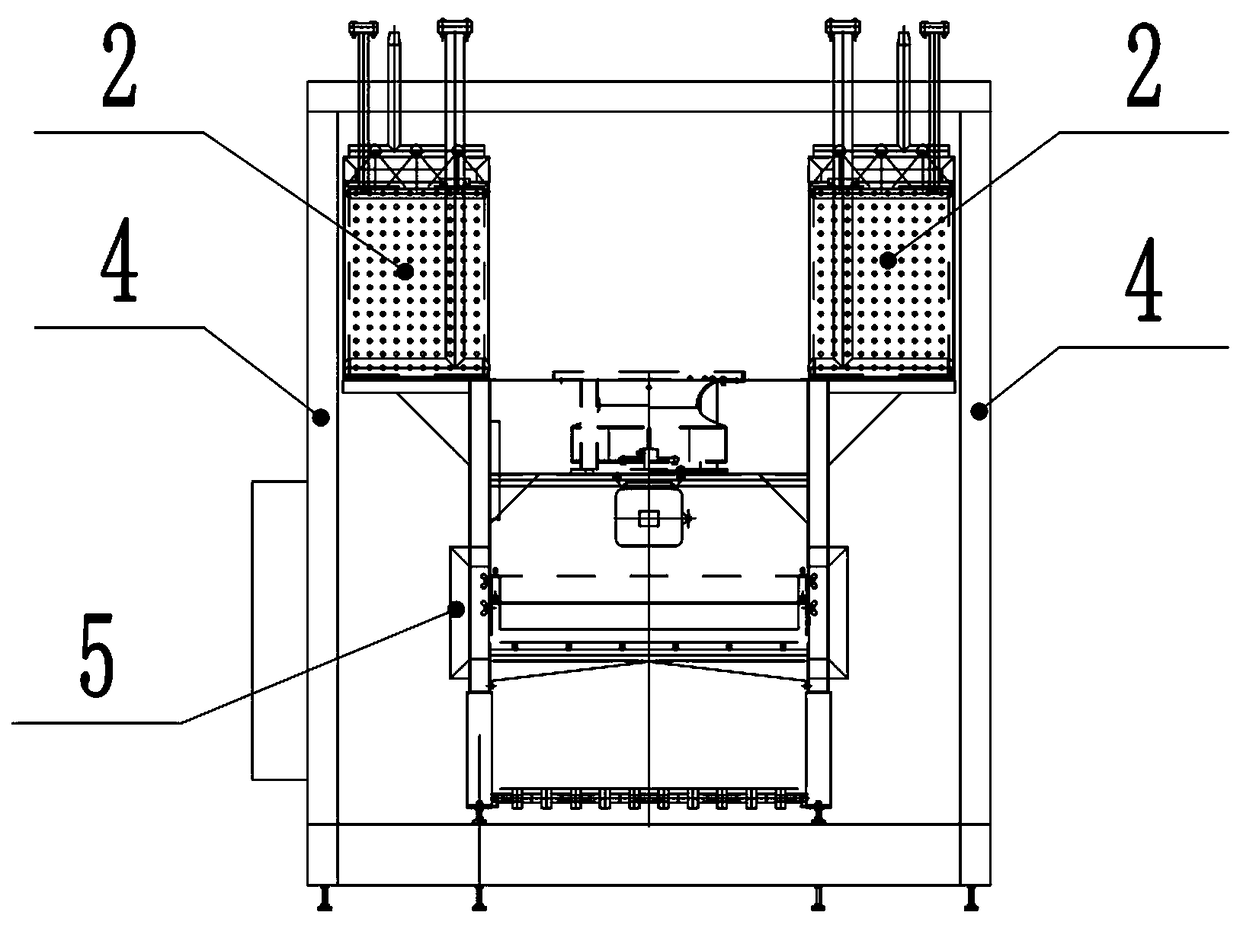

[0020] Such as figure 1 and 2 , a quick-freezing device with low drying consumption, including a rack. A thermal insulation device 4 is installed on the frame to encircle the freezing passage. The thermal insulation device 4 refers to a kind of enclosure structure that isolates the environment of the freezing area from the environment of the food processing room. Generally, polyurethane foam sandwich panels are used to effectively prevent the freezing area from freezing. Cooling loss in the freezing zone.

[0021] The device also includes a conveying device 1 for conveying the items to be frozen along the freezing channel. The conveying device 1 is preferably a transmission belt, and may also be other mechanical devices. up, wait.

[0022] Several air coolers 2 are arranged and installed on the top of the frame along the conveying direction, and eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com