Single-unit foodstuff quick freezing machine

A single freezer and food technology, applied in the direction of coolers, lighting and heating equipment, cooling fluid circulation devices, etc., can solve the problem of affecting the output and quality of food freezing processing, normal cooling, affecting normal production progress, small adjustable range of wind speed, etc. Problems, achieve the effect of reducing temperature difference, improving efficiency, and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, it will be further described in detail below with reference to the accompanying drawings and embodiments.

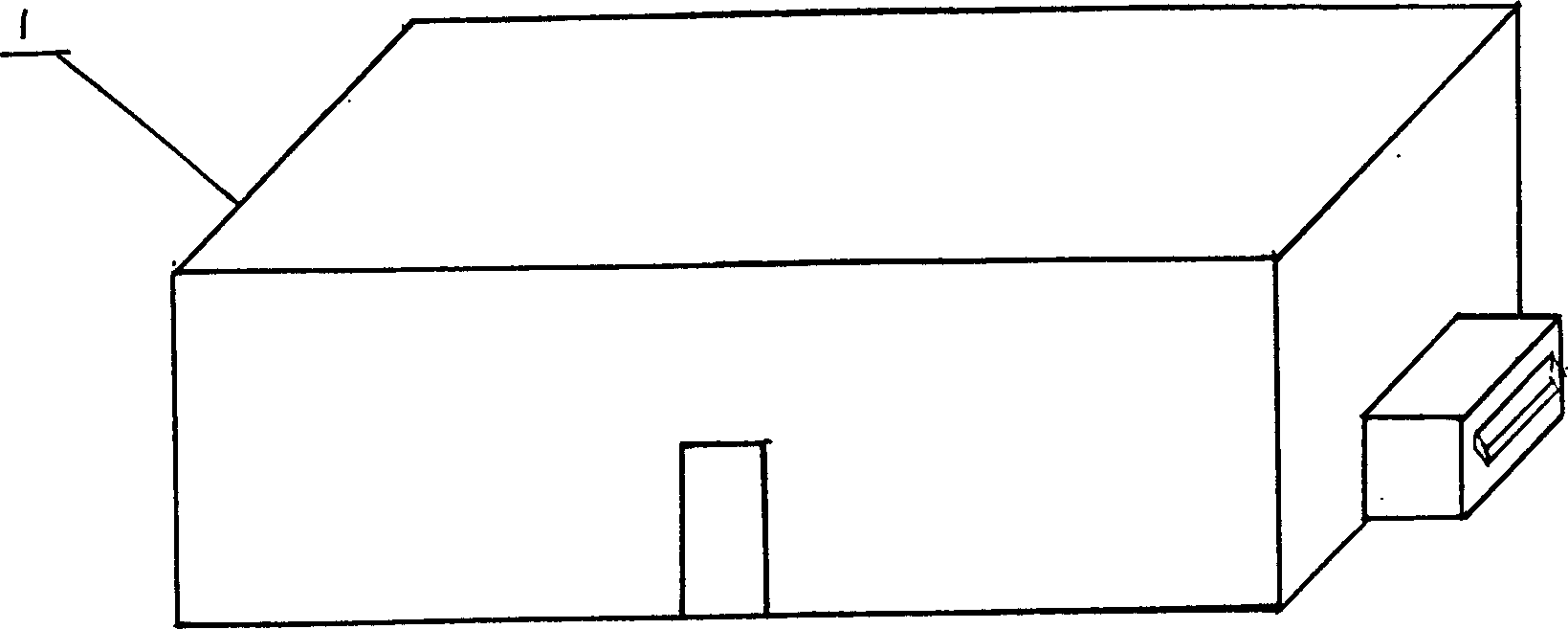

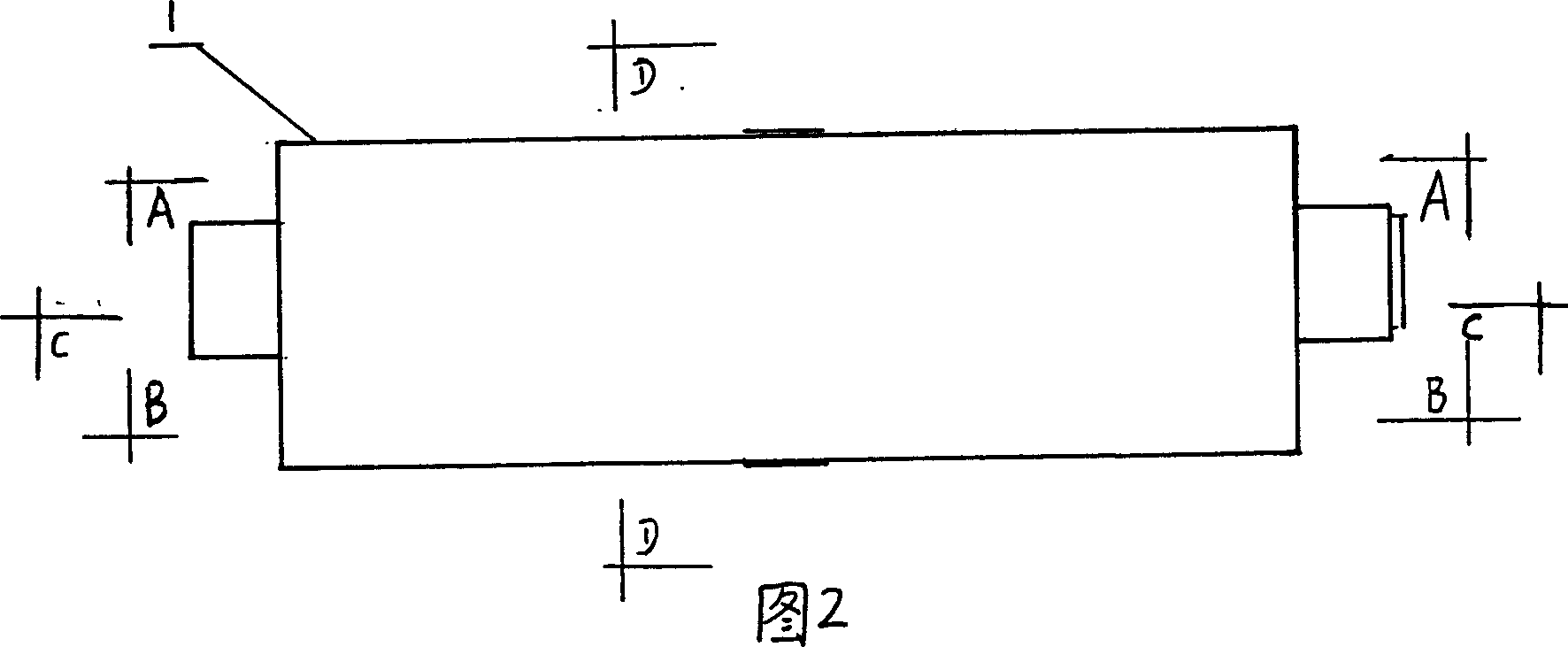

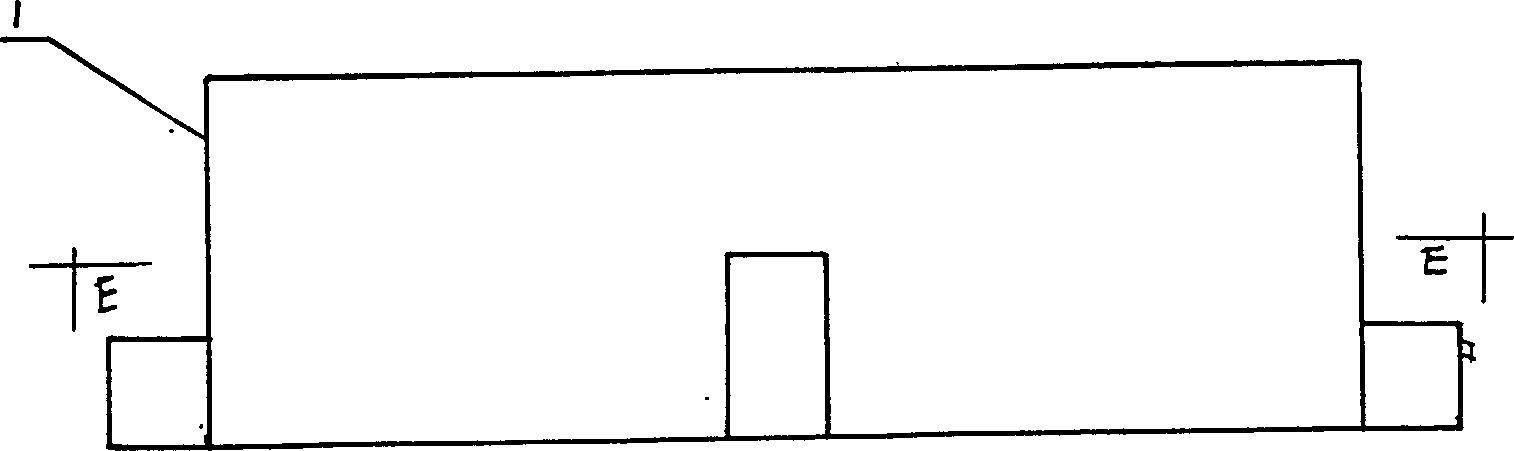

[0018] Refer to Figure 1-Figure 9 It can be seen that the new type food single freezer of the present invention is mainly composed of a shell 1 and an evaporator located in the shell, a circulating fan installed in the air supply chamber and the air supply chamber, the return air chamber, the air supply duct, and the transportation of food. The evaporator is composed of several independent evaporator units 2, among which there is a spare evaporator unit. Each evaporator unit 2 is provided with a peripheral guard plate on the periphery, and a water receiving tray 3 is installed underneath. Each evaporator unit is equipped with an air inlet 4 and an air outlet 5, and is equipped with a switchable air door 6 respectively. A circulating fan 8 is installed in the air supply chamber 7; the air supply duct 9 of the single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com