Laminar-flow centrifugal separator

A technology of centrifugal separator and separation structure, which can be used in centrifuges, centrifuges with rotating drums, etc., and can solve the problem that the separation of components is not very efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

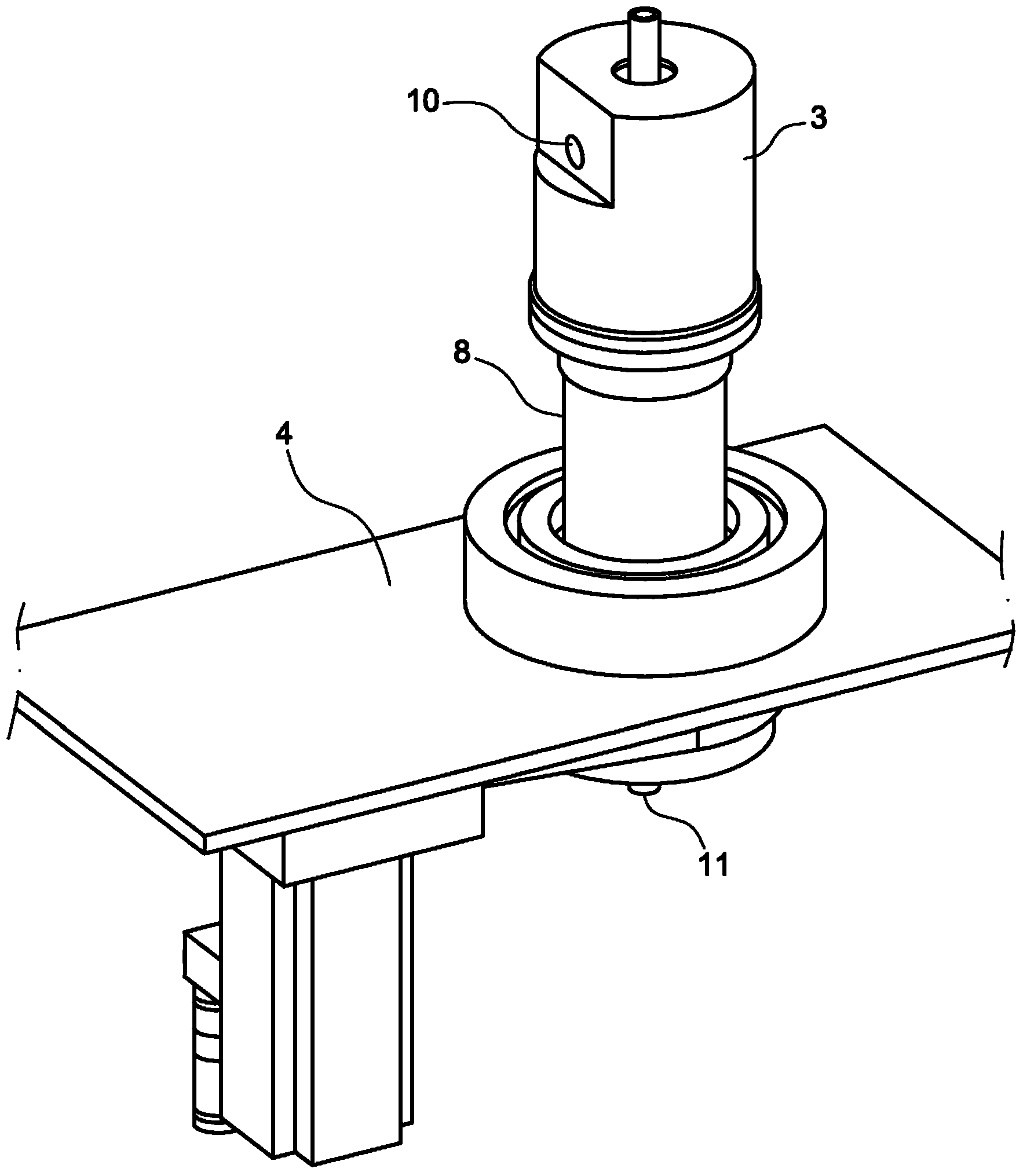

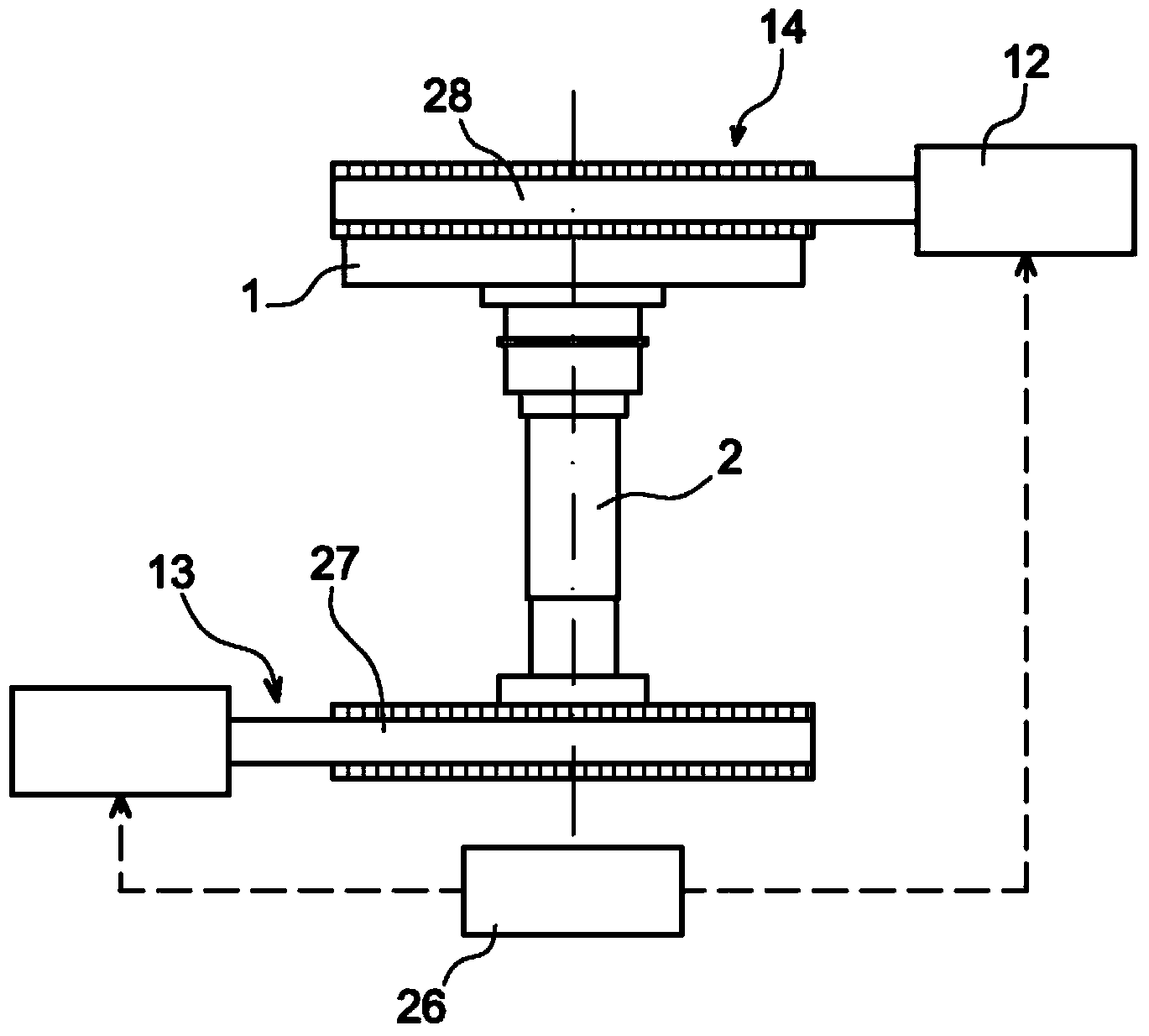

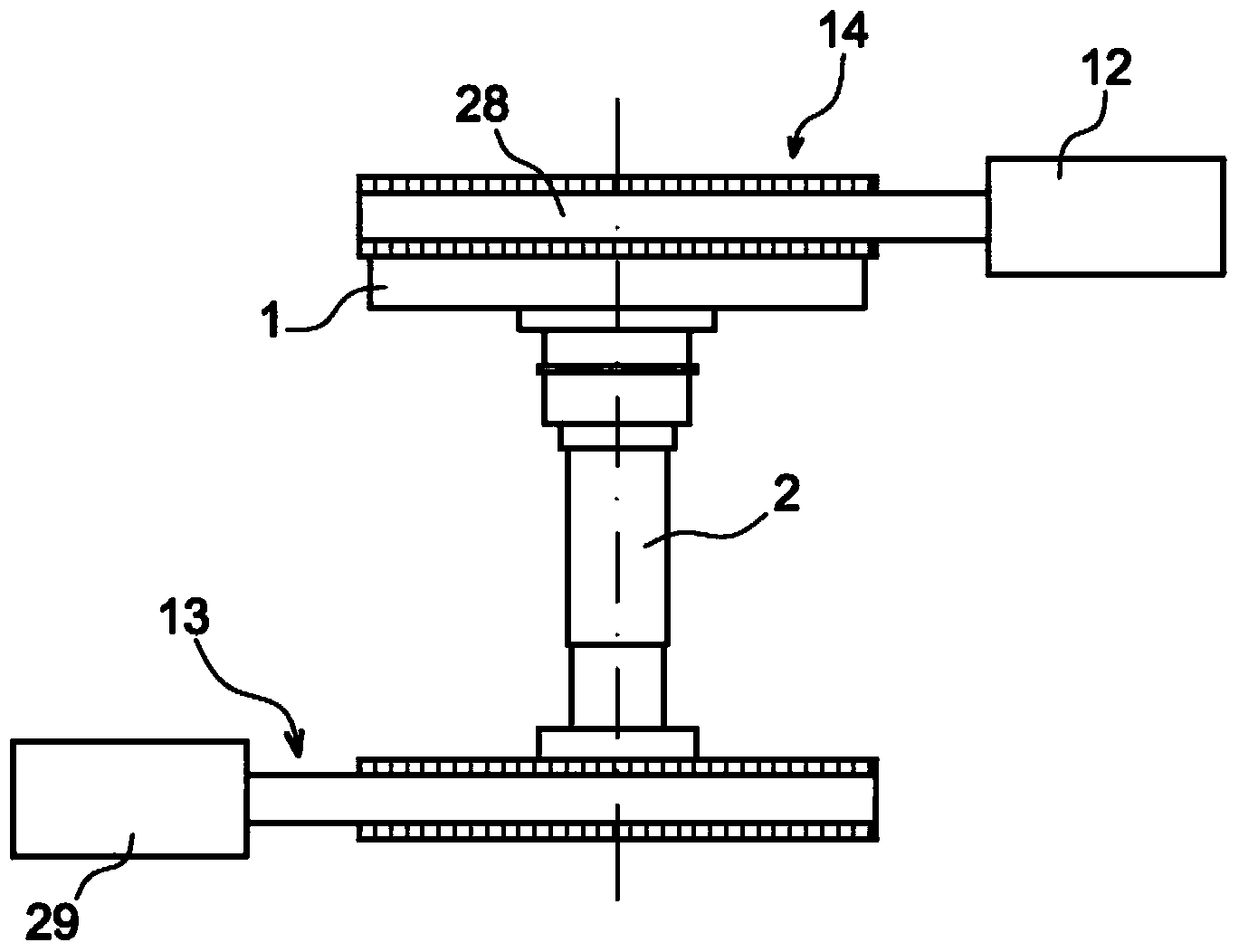

[0019] The separator comprises a rotating drum 1 constituted by a cylindrical body forming a side wall 8 and a central shaft 2 . The central shaft 2 and the rotating drum 1 are maintained between the upper stationary head 3 and the lower frame 4 with a constant distance maintained between the upper stationary head 3 and the lower frame 4 . The mixture is introduced via a duct 5 contained in the central shaft 2, in this case from the top and from the stationary head 3 and reaches the rotating drum 1 via an opening 6 which may be located at the bottom of the duct 5 or along the duct 5 height distribution. The central shaft 2 supports a conical structure made up of separate sectors 7 which, in contrast to the flower shape, overlap the entire height of the barrel to the liquid recovery manifold 20 or part of said height and rotate towards The side walls 8 of the drum 1 are inclined downwards. The segments 7 are angularly offset from one segment to the other such that their gap 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com