Cover plate structure, touch panel structure and protective panel structure of display device

A display device and touch panel technology, which is applied in the field of cover structure and protective panel structure, can solve problems such as poor bonding, easy generation of air bubbles, filling gaps, etc., and achieve the effect of reducing thickness and facilitating thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

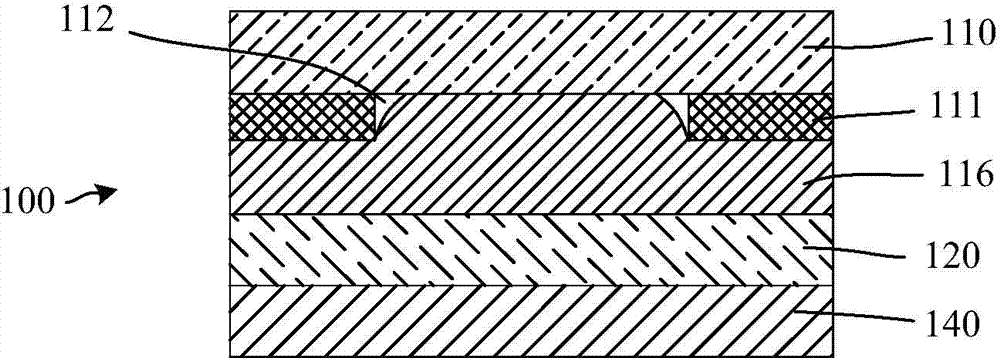

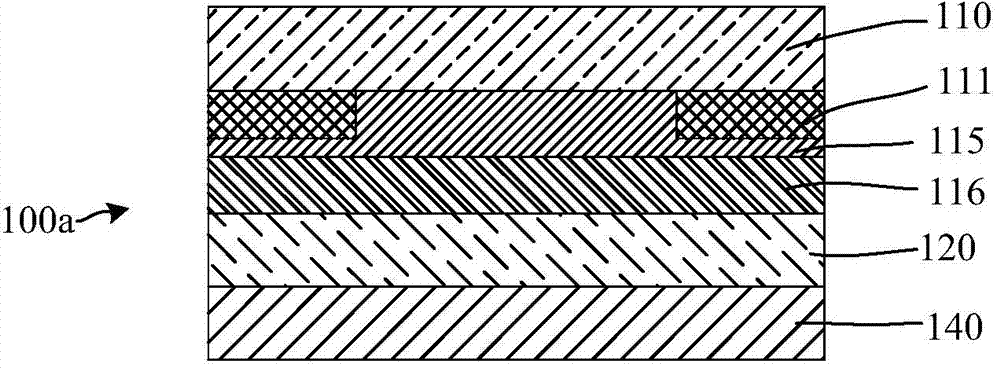

[0041] Such as figure 2 Shown is a touch panel structure 100a of a mobile phone, which includes: a first substrate 110 , a second substrate 120 and an optical adhesive 116 . Wherein, the surrounding area of the first substrate 110 is printed with an ink layer 111 for forming a display area and a non-display area, and in the display area, that is, the recessed area surrounded by the ink layer on the first substrate 110 is filled with a leveling material layer 115 , used to fill the recessed area, the second substrate 120 is bonded to the display module (LCM) 140 of the mobile phone by using optical glue.

[0042] In this embodiment, the first substrate 110 adopts a glass substrate structure, and the second substrate 120 is a touch driving layer of a mobile phone. The touch driving layer may be a single-layer sensing layer structure or a double-layer sensing layer structure. The mobile phone touch panel with this structure can reduce the thickness of the optical adhesive fro...

Embodiment 2

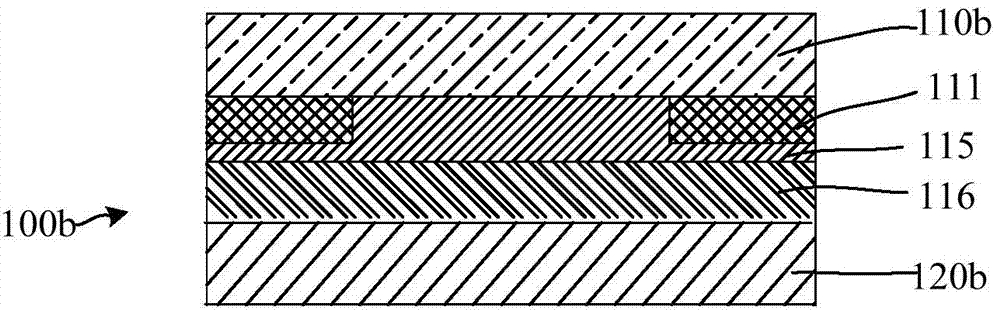

[0044] Such as image 3 Shown is another touch panel structure 100b of a mobile phone, which includes: a glass substrate 110b (first substrate), a driver module layer 120b (second substrate) and optical glue 116 . Wherein, the surrounding area of the glass substrate 110b is printed with an ink layer 111, which is used to form a display area and a non-display area. In the display area, that is, the recessed area surrounded by the ink layer on the glass substrate 110b is filled with a leveling material layer 115. To fill the recessed area, the glass substrate 110b is bonded to the driver module layer 120b of the mobile phone by using optical glue.

[0045] In this embodiment, the module driving layer 120b is the combination of the touch driving layer and the display module layer of the mobile phone, that is, the touch sensing layer is directly arranged on the display module, and the ink layer 111 is printed on the glass substrate 110b After being combined with the leveling ma...

Embodiment 3

[0047] Such as Figure 4 Shown is another mobile phone touch panel structure 100c. The difference from Embodiment 1 is that the first substrate shown is a high-hardness PET substrate 110c, which plays an explosion-proof and decorative role on the surface of the mobile phone. The second substrate is a glass substrate 120c, and a capacitive sensing layer (not shown in the figure) is provided on the second substrate, namely the glass substrate 120c, to achieve touch sensing. Below the glass substrate 120c is a display module 140 (LCM) of the mobile phone . Printing or coating the ink layer 111 on the PET substrate is more advantageous than coating the ink layer 111 on the glass substrate. Because of the high hardness and material properties of the glass substrate, generally only black or white ink can be formed on the glass substrate. layer, and the processing cost is expensive, and it is also difficult to process 3D or rich colors. In this embodiment, by coating or printing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com