Refractory castable

A technology of refractory castables and refractory materials, applied in the field of refractory castables, can solve problems such as insufficient green body strength, difficult setting time to meet site construction conditions, and restrictions on large-scale use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The second aspect of the present invention provides the method for preparing the refractory castable, comprising: mixing various raw materials to obtain the refractory castable.

[0034] The third aspect of the present invention provides the use of the refractory castable in the field of tapping channel refractory preparation.

[0035] The fourth aspect of the present invention provides a tapping trough refractory material prepared from the refractory castable.

[0036] The fifth aspect of the present invention provides a method for preparing the tapping trough refractory material, comprising: mixing the refractory castable with an appropriate amount of water, and hardening and forming. Those skilled in the art can choose a suitable method to prepare the tapping trough refractory material through the refractory castable. Generally speaking, the refractory castable can be mixed with an appropriate amount of water to form a slurry, poured, and hardened. After forming, th...

Embodiment 1

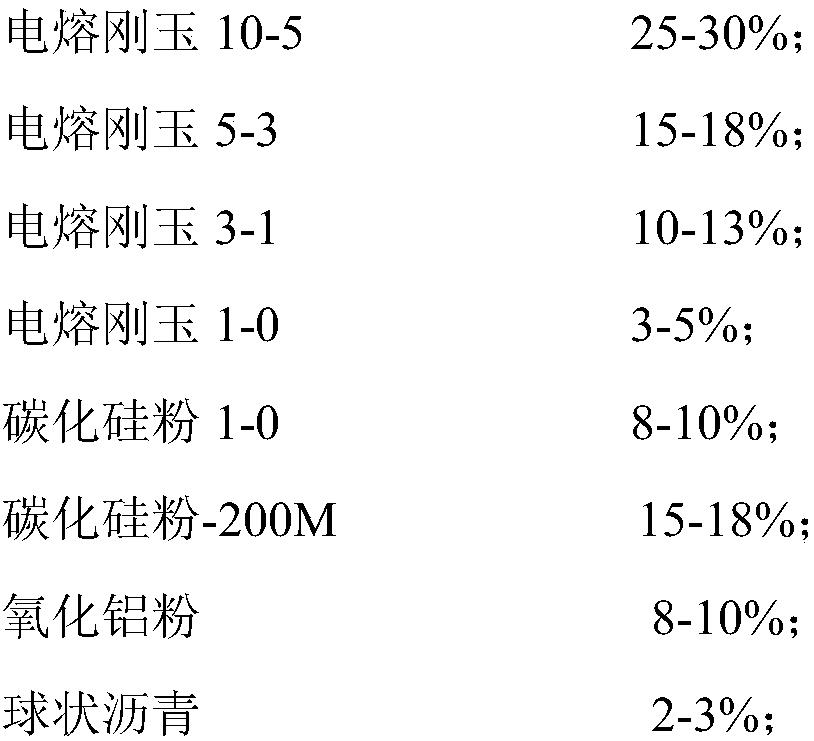

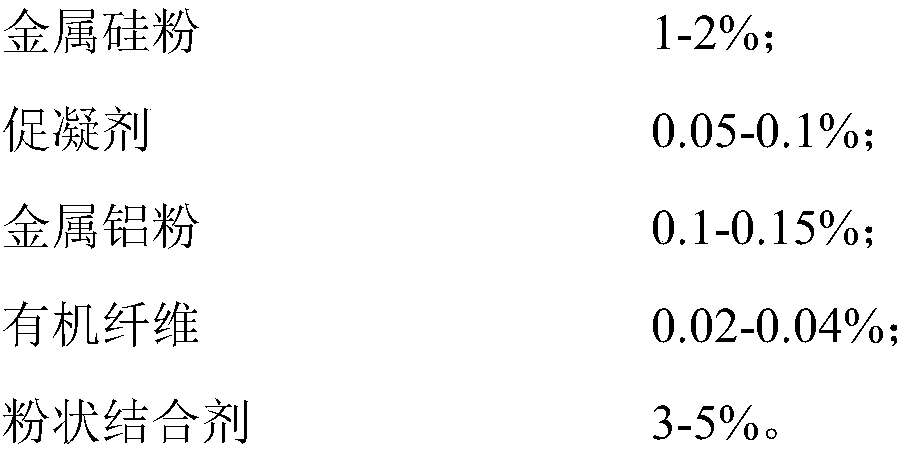

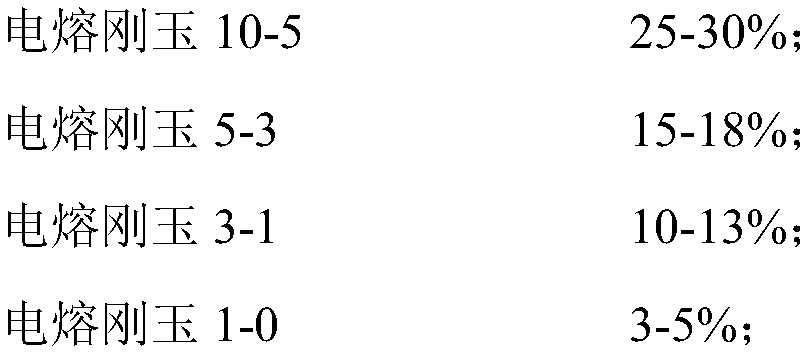

[0045] The formula of each example of the refractory castable used in the embodiment is specifically shown in table 1:

[0046] Table 1

[0047]

[0048] Mix each raw material with water according to the formula, stir evenly, see Table 2 for the specific mixing ratio, wherein, the amount of water added (%)=(the quality of added water ÷ the sum of the raw materials in Table 1)*100%.

[0049] The preparation method of the iron channel refractory material is as follows:

[0050] 1) After mixing the raw materials except for the fused corundum according to the ratio of the raw materials, put them into the kneader and knead them fully, and the kneading time is about 3 minutes;

[0051] 2) Put the regenerated corundum aggregate into the kneader and fully knead it, then package it for storage, and the kneading time is about 3 minutes;

[0052] 3) Then add an appropriate amount of water and stir for another 3 minutes, then vibrate and form, the sample size is 40*40*160mm.

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com